Automatic rubber sheet stacking device

A technology of lamination device and raw film, which is used in transportation and packaging, conveyor objects, stacking of objects, etc., can solve the problems of error-prone, insufficient film pulling height, low efficiency, etc., and achieve smooth and precise movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

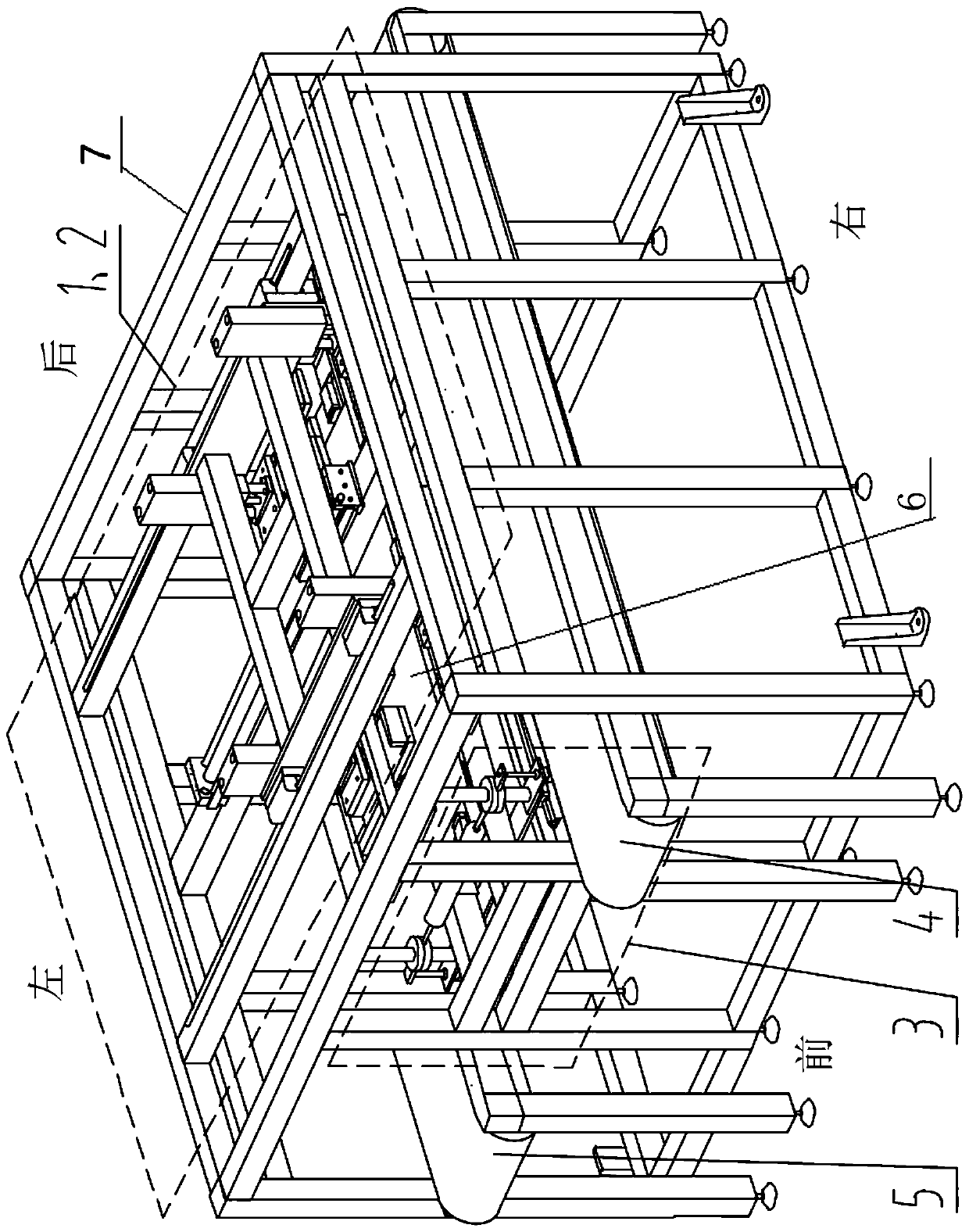

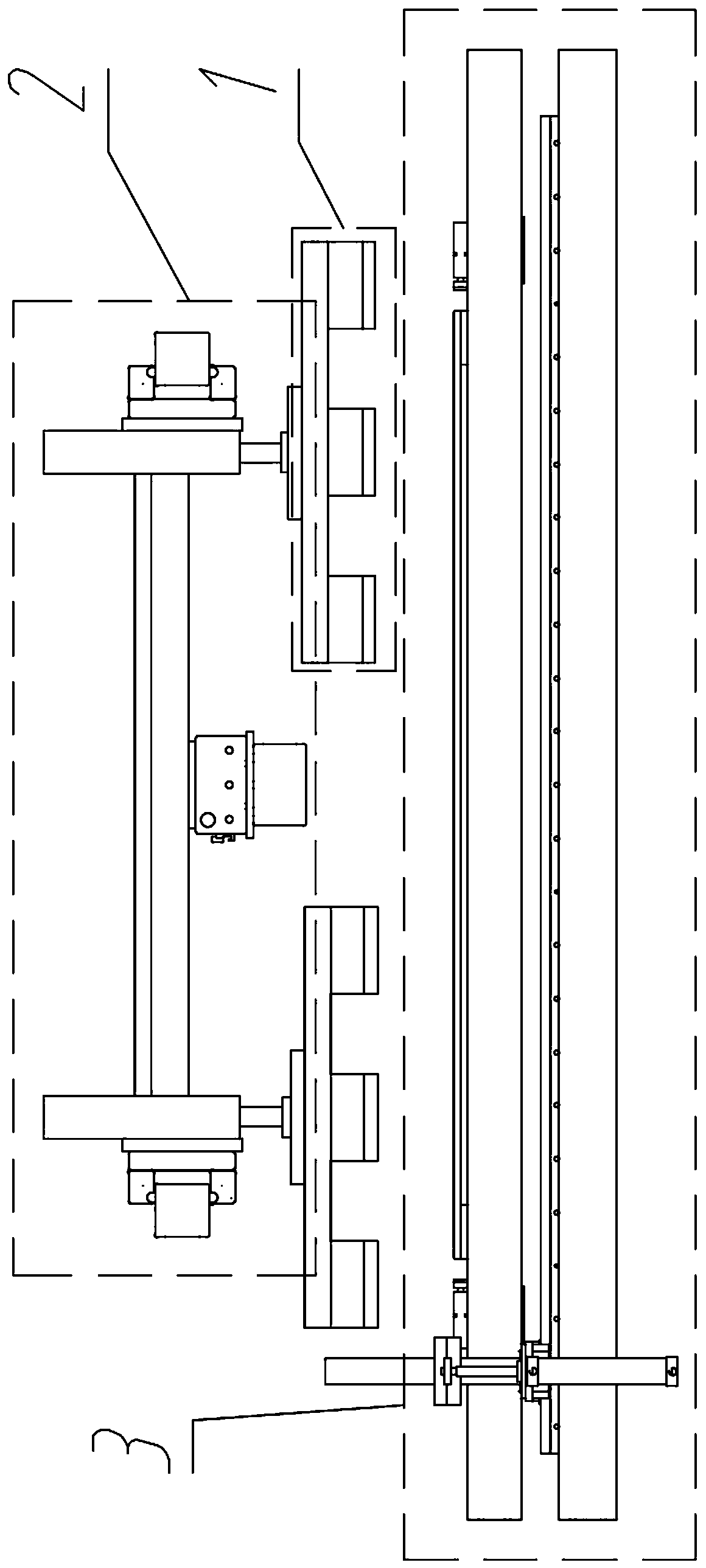

[0089] refer to Figure 1-4 , an automatic lamination device for raw film, comprising a support frame 7, a lamination workbench 6, a workbench installation frame 6-1, a conductive black film conveyor belt 4 and an insulating white film conveyor belt 5, and also includes a support frame 7 The pick-up assembly 1, the transfer assembly 3 and the rolling assembly 3; the insulating white film conveyor belt 5 and the conductive black film conveyor belt 4 are symmetrically arranged on the left and right sides of the stacking workbench 6, respectively conveying the insulating white film 5-1 and the conductive black film conveyor belt. Black film 4-1. In this embodiment, the dimensions of the insulating white film 5-1 and the conductive black film 4-1 are: length 1500mm, width 400mm, and thickness 0.2mm.

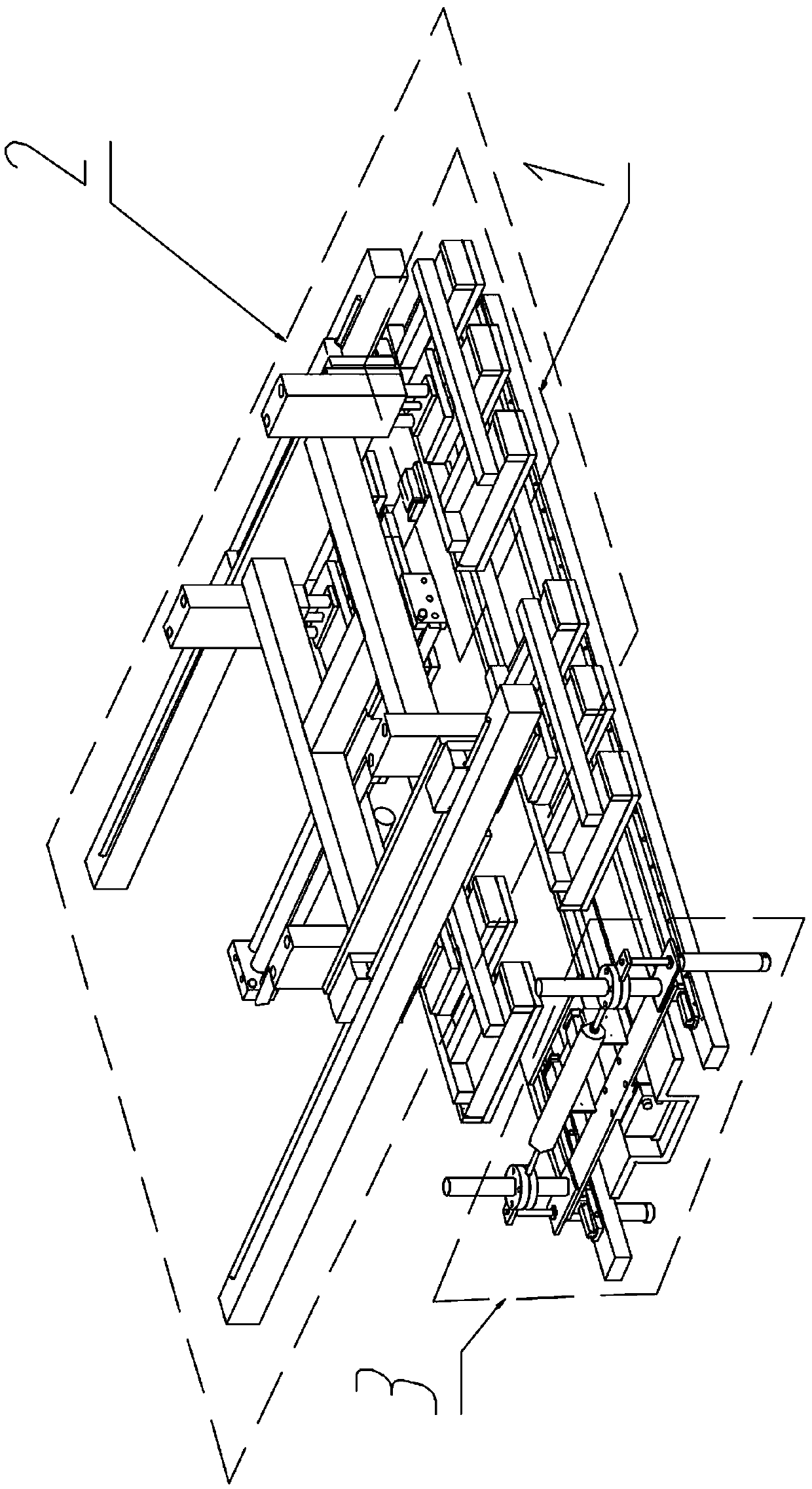

[0090] refer to Figure 5 , the pick-up assembly 1 is composed of 4 groups of pick-up assemblies 1 that work independently; each pick-up assembly 1 that works independently is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com