Book taking and placing management robot for library

A library and robot technology, applied in the field of robotics, can solve the problems of difficulty in finishing details, the degree of mechanical intelligence is not high, and the effect of intelligent processing is difficult, so as to achieve a reasonable storage method, a coherent processing process, and a scientific and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

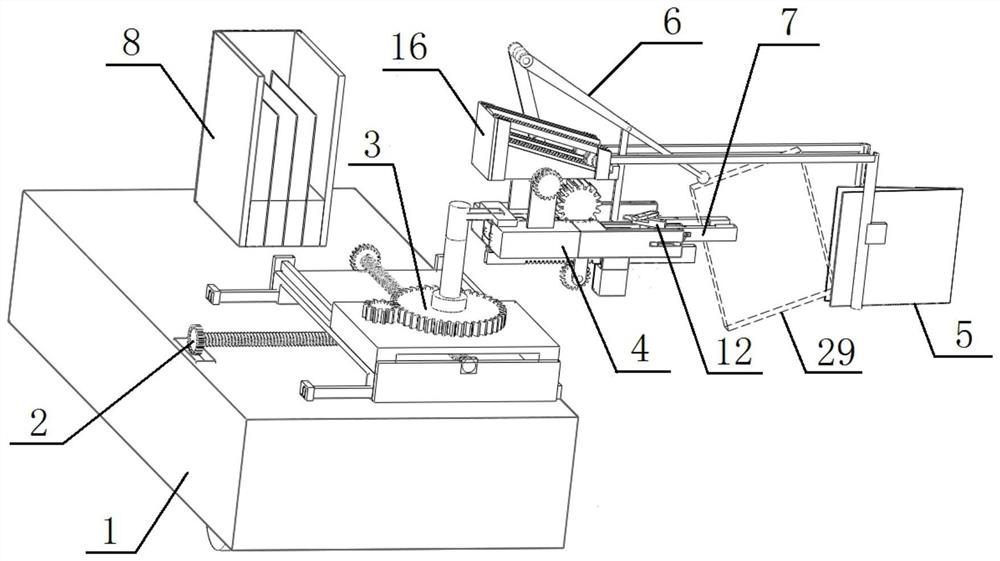

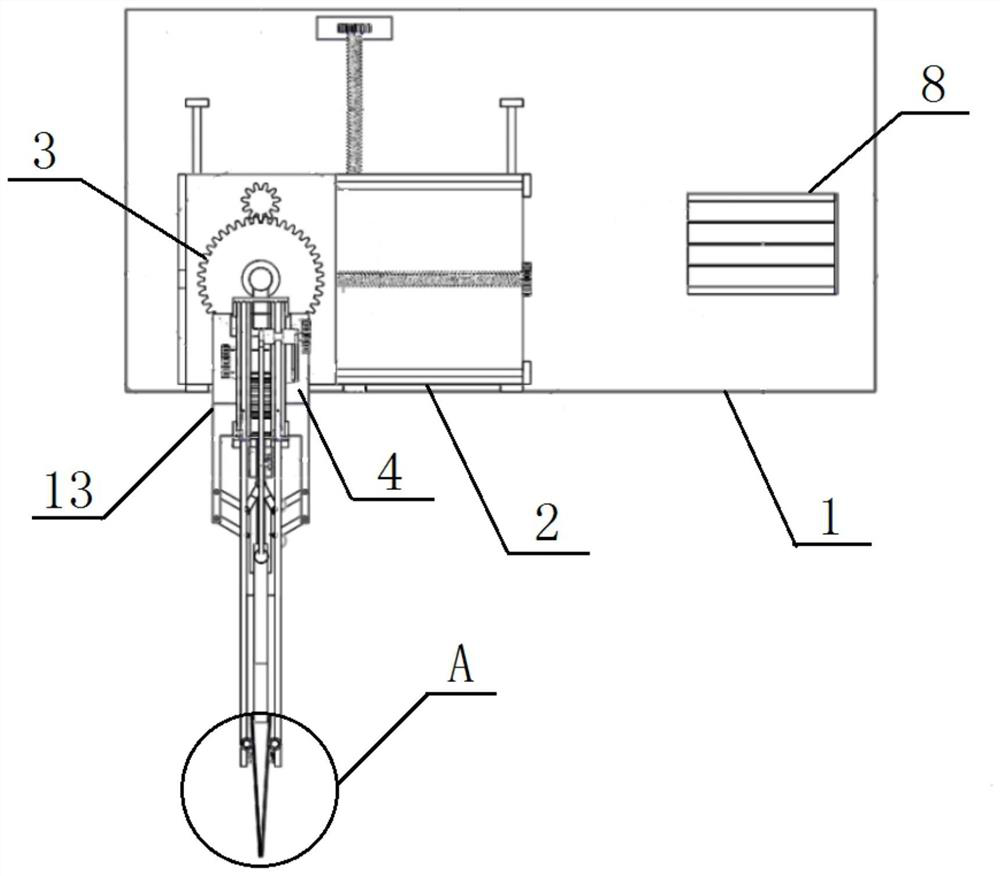

[0039] Specific implementation mode one: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, this specific embodiment adopts the following technical solutions: This embodiment includes a mobile base 1, a moving mechanism 2, a rotary mechanism 3, a pushing seat 4, a guide assembly 5, a book guide assembly 6, a clamping assembly 7 and a book storage frame 8;

[0040] The mobile base 1 is arranged horizontally, the mobile mechanism 2 and the book storage frame 8 are all arranged on the top surface of the mobile base 1, the rotary mechanism 3 is arranged on the mobile mechanism 2, and the rotary mechanism 3 is provided with a push seat body 4, and the push seat The body 4 is respectively provided with a guide assembly 6 and a clamp assembly 7;

[0041] The clamping assembly 7 includes two sets of clamping pieces 7-1, the two sets of clamping pieces 7-1 are respectively hinged on the push seat ...

specific Embodiment approach 2

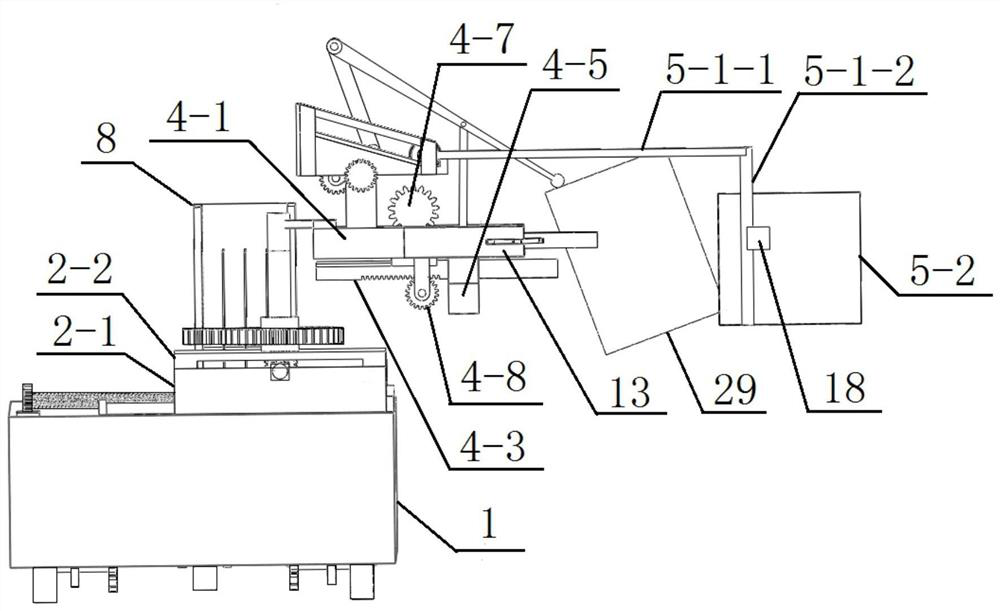

[0046] Embodiment 2: This embodiment is a further limitation of Embodiment 1. The push base 4 includes a fixed frame 4-1, an upper movable rack 4-2, a lower movable rack 4-3, and a block 4-5. , connecting bar 4-6, upper gear 4-7 and lower gear 4-8, the transverse section of the fixed frame body 4-1 is a 匚 font, and the open end of the fixed frame body 4-1 is set toward the clamping assembly 7, and the upper movement The rack 4-2 is arranged in the fixed frame body 4-1, the upper movable rack 4-2 slides and fits with the fixed frame body 4-1, and the upper movable rack 4-2 meshes with an upper gear 4-7, Driven by the upper gear 4-7, the movable rack 4-2 stretches out or retracts in the fixed frame 4-1, and the lower movable rack 4-3 is arranged under the fixed frame 4-1. The movable rack 4-3 is slidably matched with the bottom of the fixed frame 4-1, and a lower gear 4-8 is arranged below the fixed frame 4-1, and the lower gear 4-8 meshes with the lower movable rack 4-3. The l...

specific Embodiment approach 3

[0047] Specific Embodiment 3: This embodiment is a further limitation of Embodiment 1 or 2. The clamping assembly 7 is connected to the connecting bar 4-6 through the connecting rod assembly 12. The connecting rod assembly 12 includes two first rod bodies 12-1 1. Two second rod bodies 12-2, the first rod body 12-1 and the clamping piece 7-1 are arranged in one-to-one correspondence, and one end of the two first rod bodies 12-1 is hinged on the connecting bar 4 through the first rotating shaft 12-3 -6, the other end of each first rod body 12-1 is hinged on the top surface of the rear end of the corresponding clamping piece 7-1; the second rod body 12-2 corresponds to the clamping piece 7-1 one-to-one Set, one end of the two second rod bodies 12-2 is hinged at the bottom of the connecting bar 4-6 through the second rotating shaft, and the other end of each second rod body 12-2 is hinged at the rear end of its corresponding clamping piece 7-1 top surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com