Metal chip safe cleaning device

A technology for cleaning devices and metal fragments, applied in the field of tools, can solve problems such as easy cuts to workers, and achieve the effect of ensuring that they are not scratched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

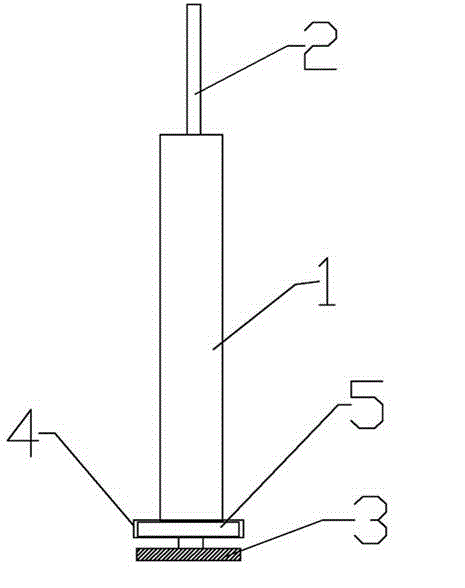

[0009] Such as figure 1 As shown, the metal fragment safety cleaning device includes a housing 1, a connecting rod 2, an annular groove 4, a magnetic ring 5, and a baffle 3. The annular groove 4 is fixed at one end of the housing 1, and the connecting rod 2 It is arranged in the housing 1 and is coaxially connected with the housing 1. The length of the connecting rod 2 is greater than the length of the housing 1, and a baffle 3 is fixed at one end of the connecting rod 2; the magnetic ring 5 is arranged in the annular groove 4 .

[0010] When working, lift the connecting rod 2 upwards to make the baffle 3 close to the annular groove 4 so that the metal fragments can be attracted to the surface of the baffle 3, and push the connecting rod 2 downwards to keep the metal fragments away from what the magnetic ring 5 can attract. Range, metal fragments can be moved to the recycling place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com