Patents

Literature

103 results about "Metallic debris" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum chip dryers

InactiveUS20140041252A1High emissivityDrying solid materials with heatDrying gas arrangementsEmissivityCombustor

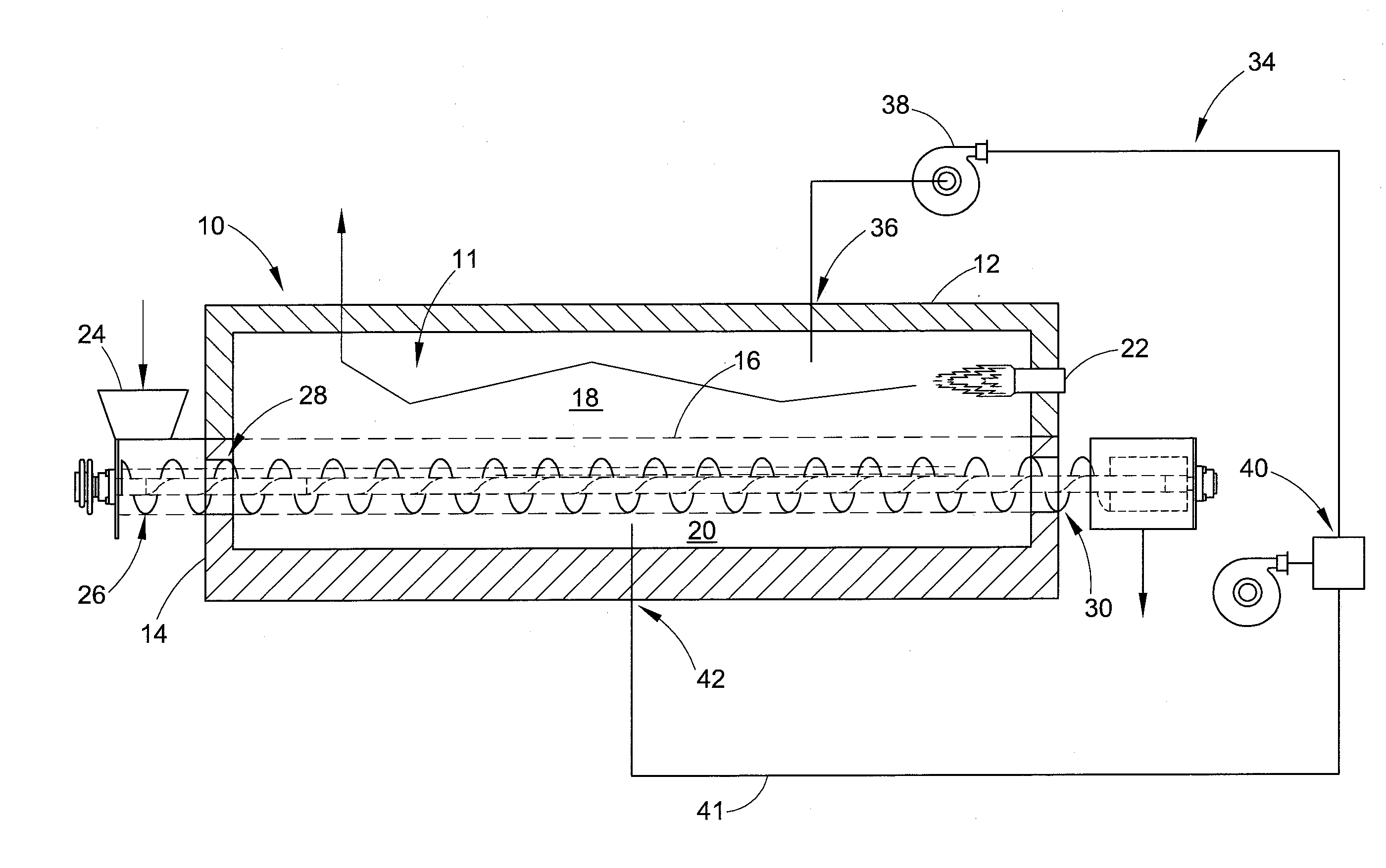

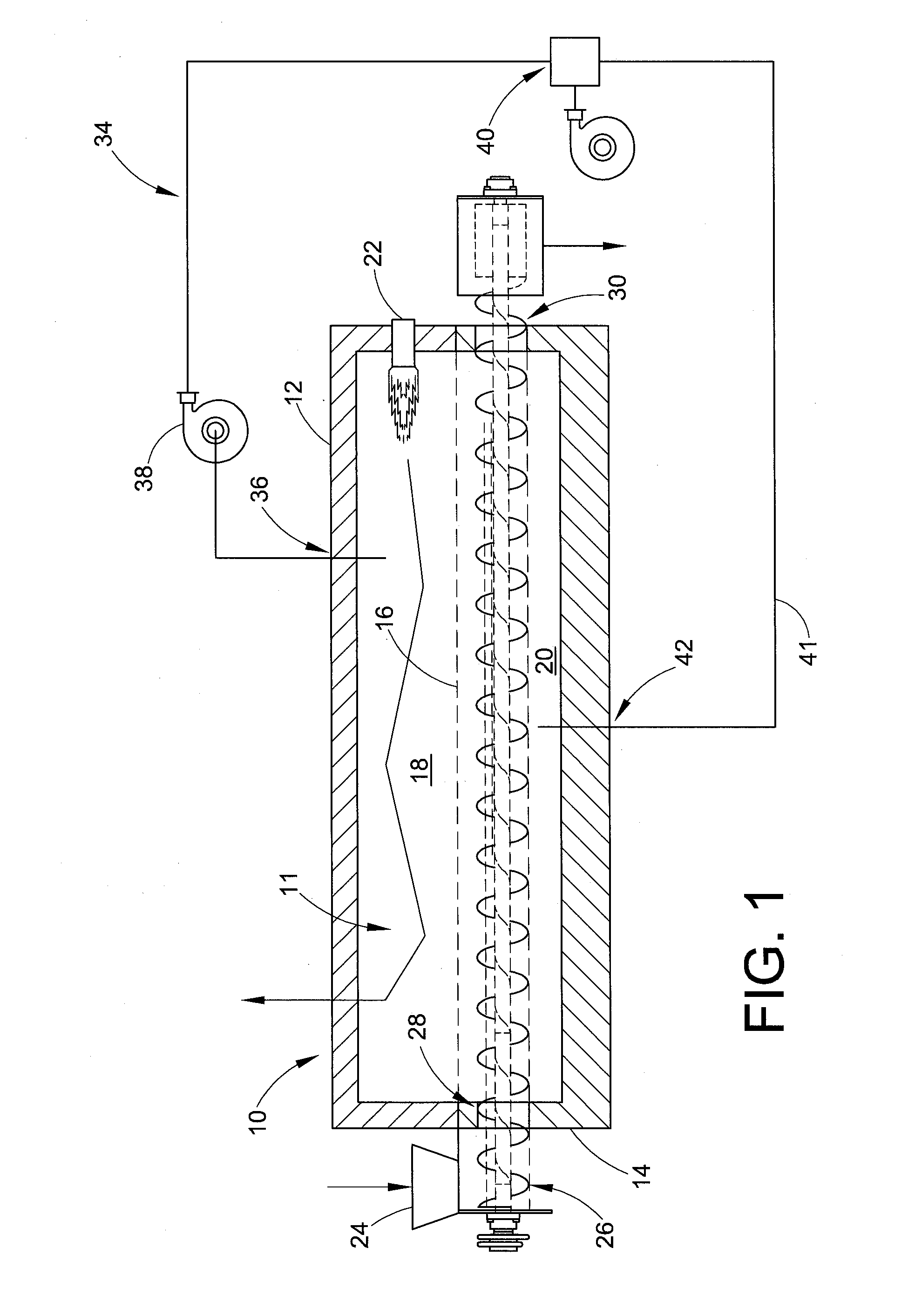

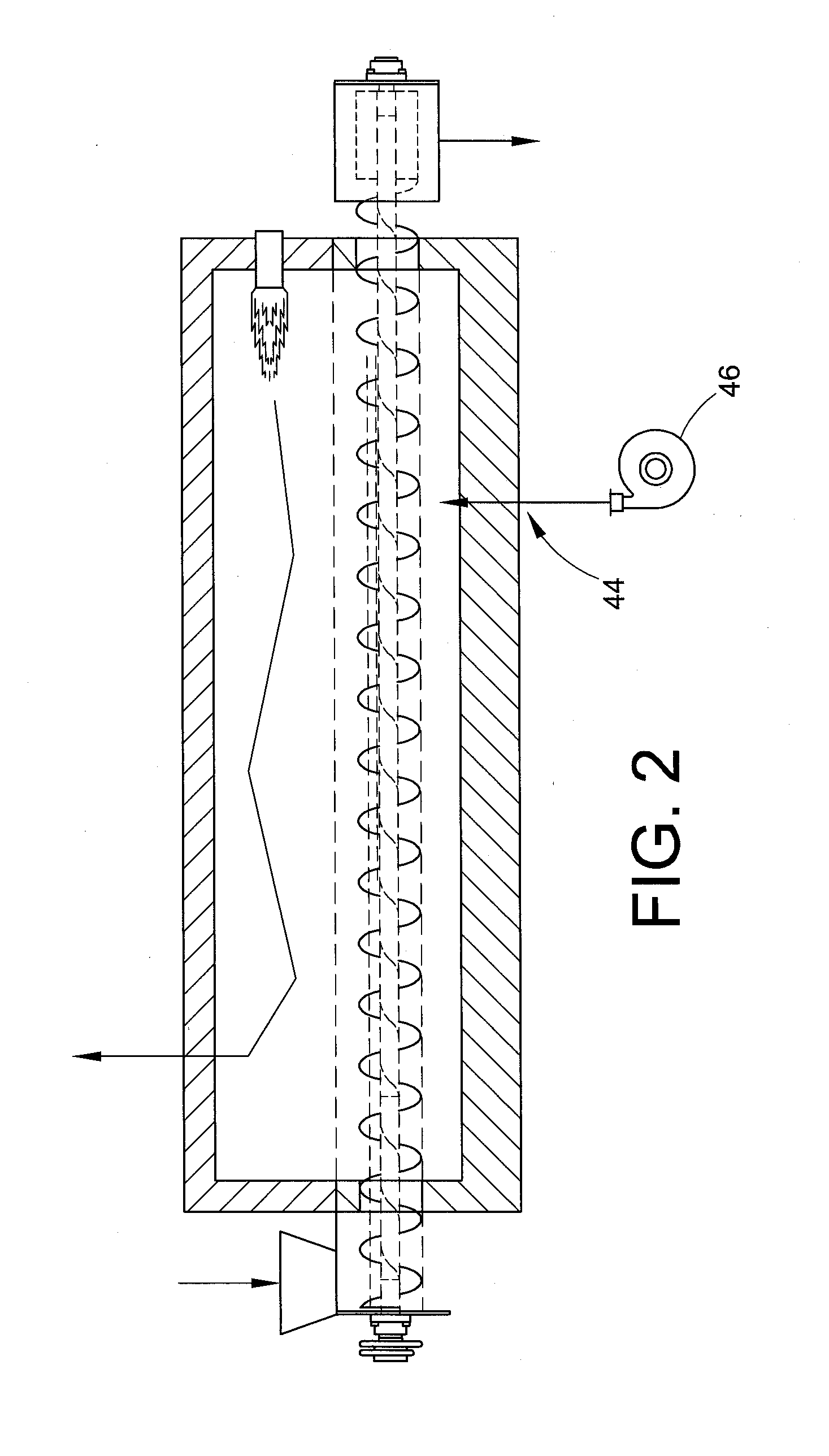

In accordance with one aspect of an exemplary embodiment, a dryer for removing hydrocarbons and / or moisture from metal chips is provided. The dryer has a chamber including a top portion and a base portion. The top portion is comprised of a material having a higher emissivity than the material forming the base portion. A burner is provided which introduces heated gas into the top portion. A device for transporting the metal chips is provided in the base portion. The device receives the metal chips at an inlet and transporting the metal chips to an outlet.

Owner:PYROTECK INC

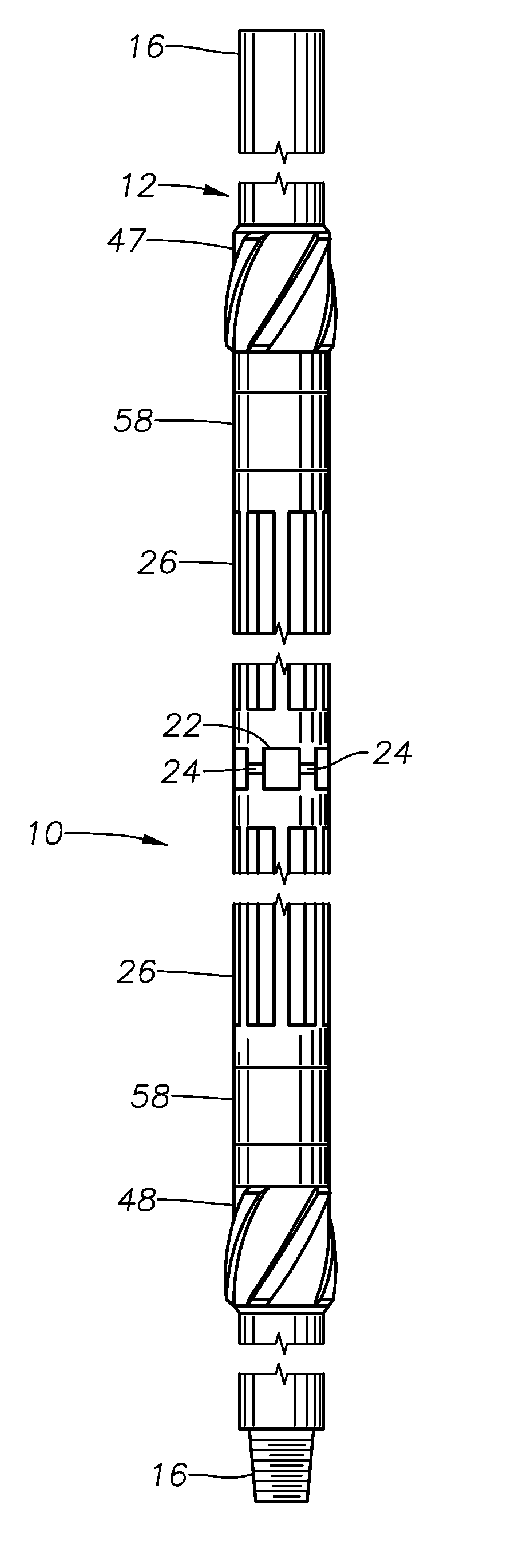

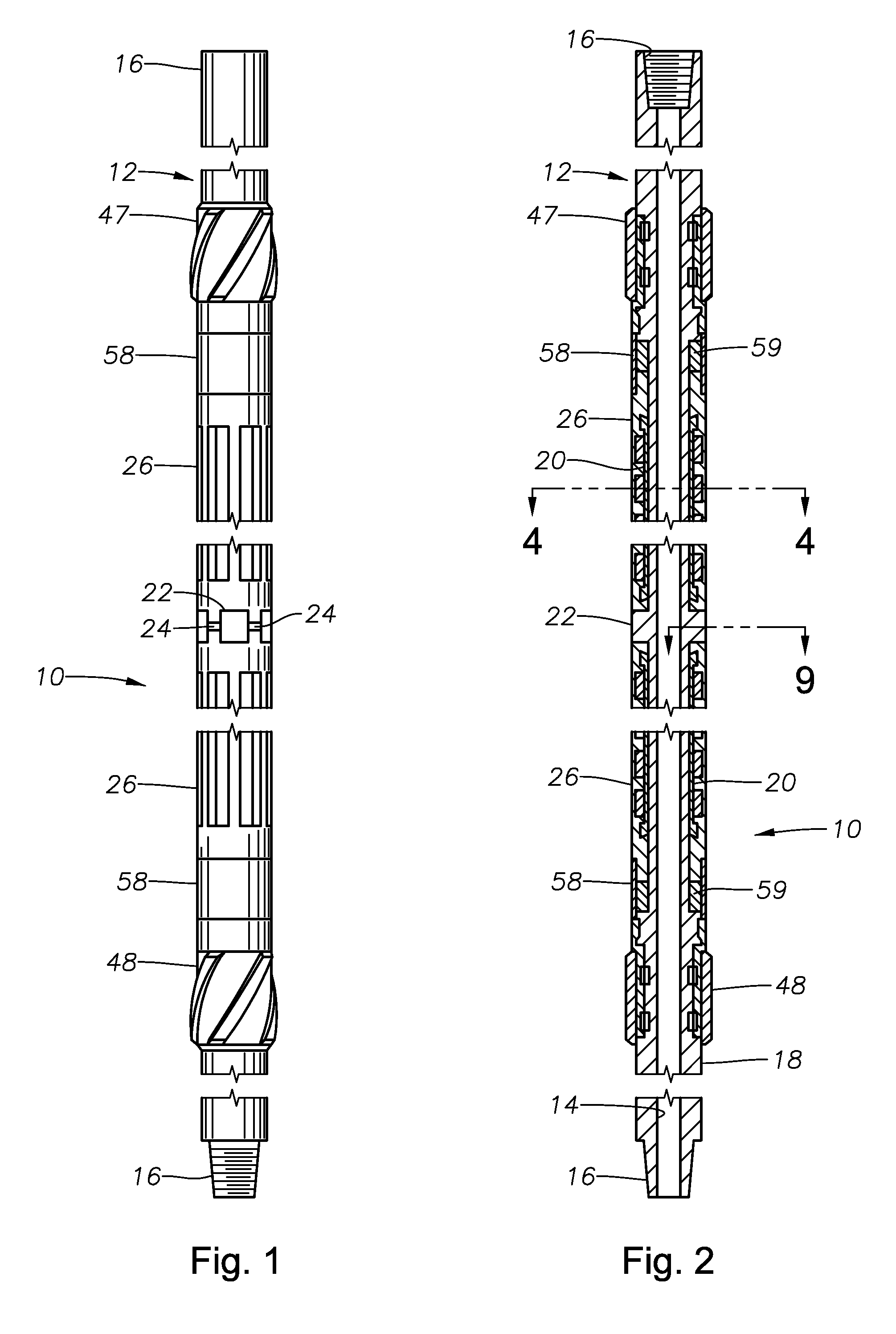

Magnet arrangement and method for use on a downhole tool

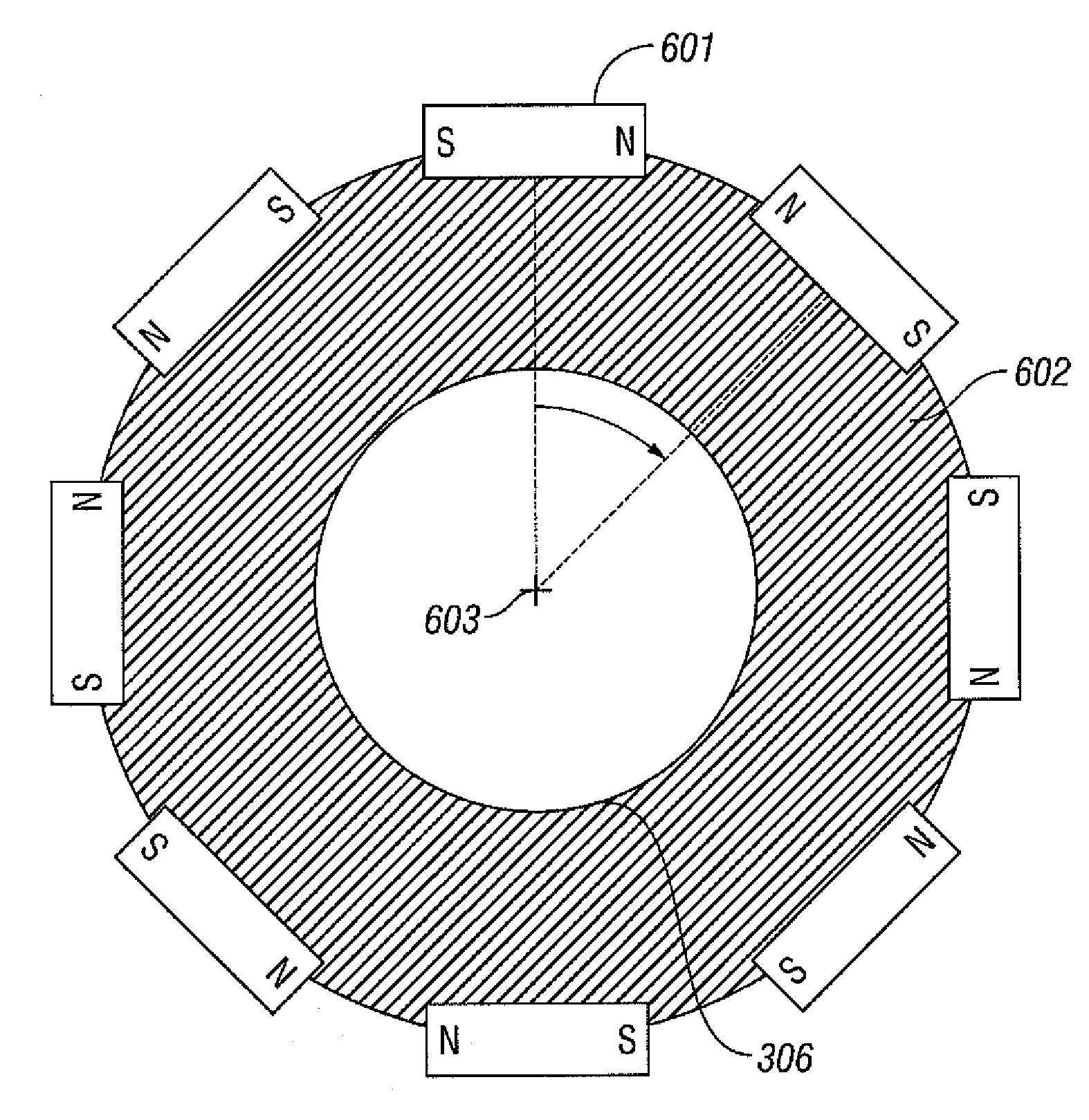

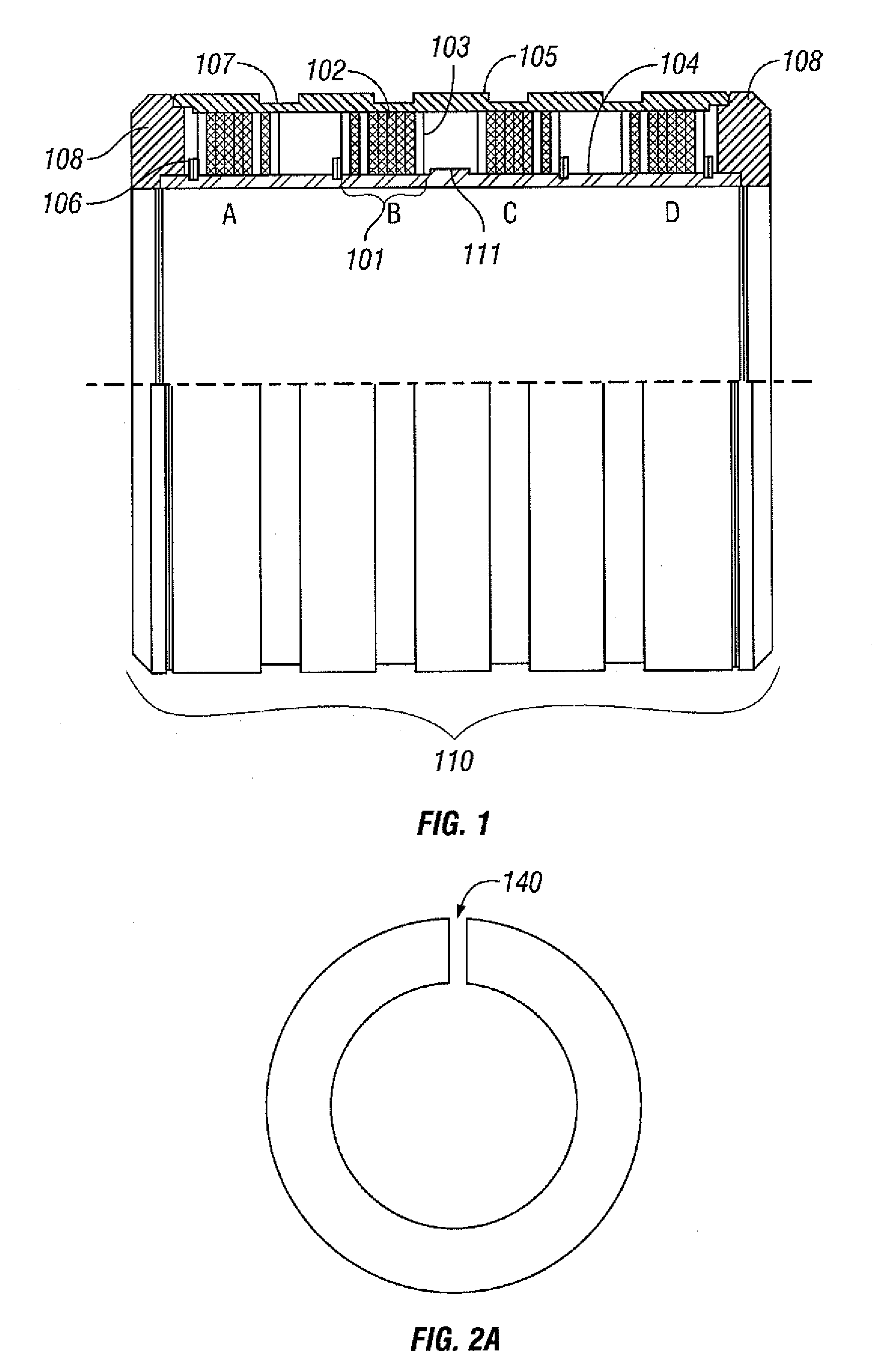

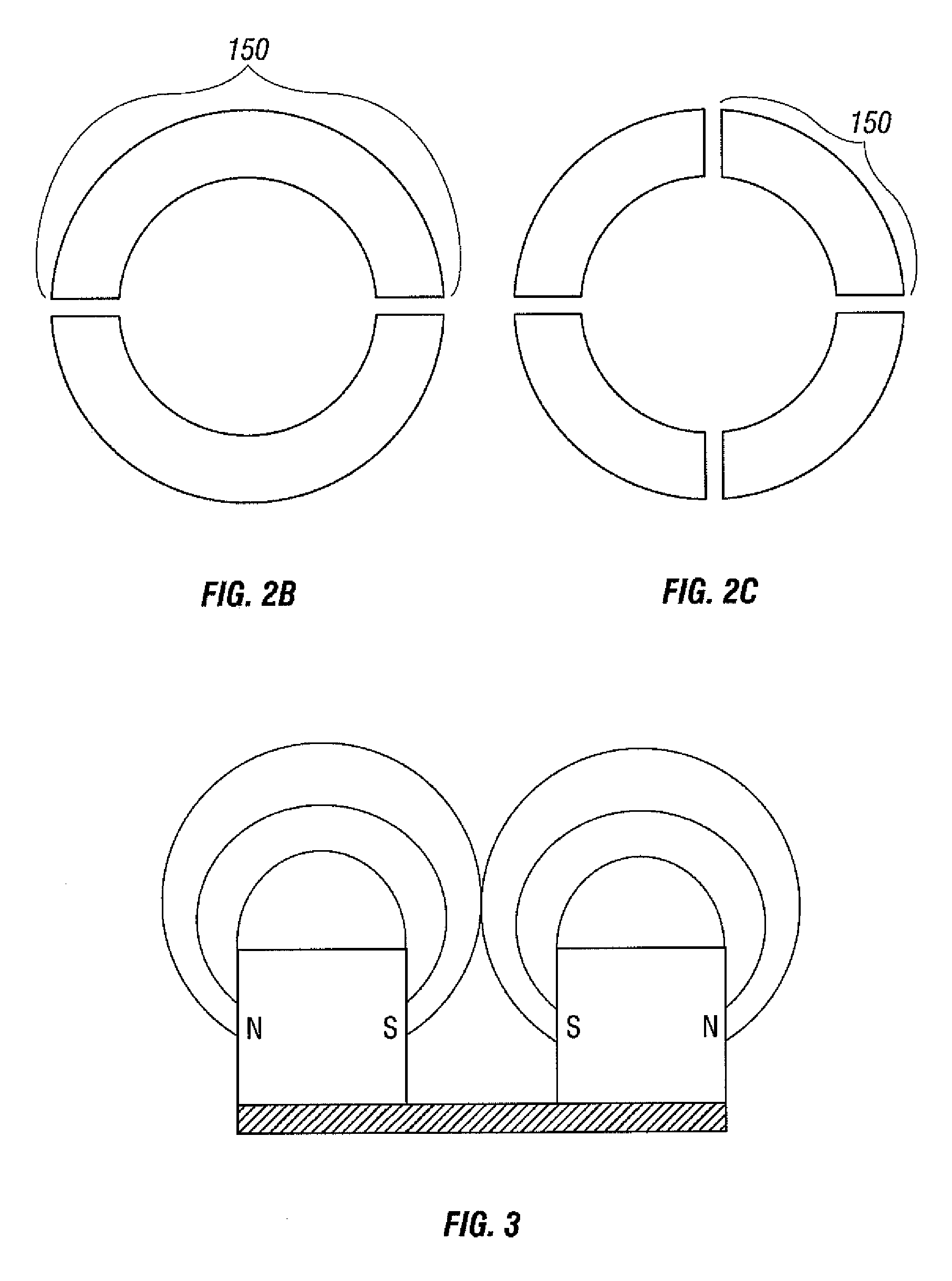

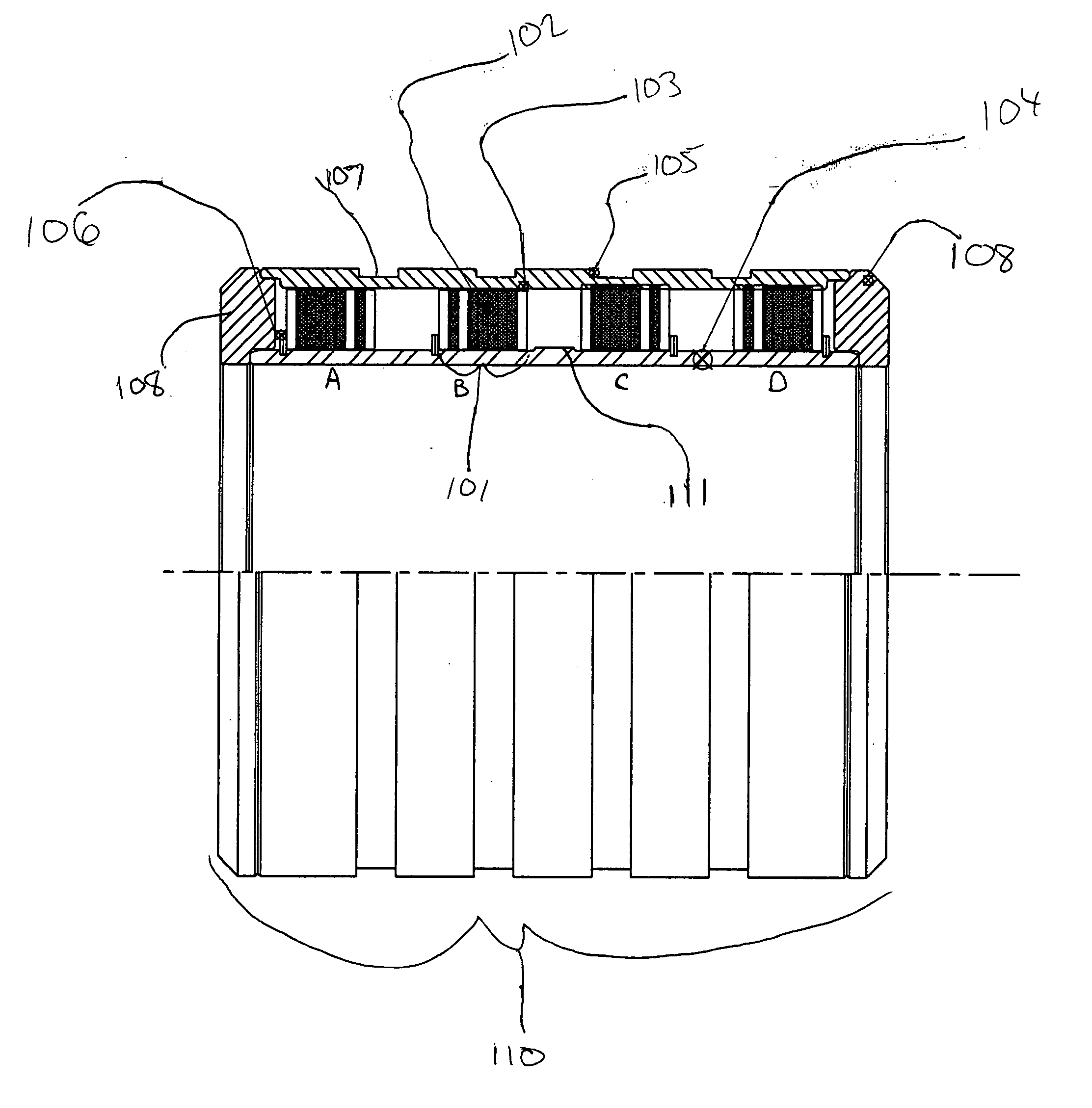

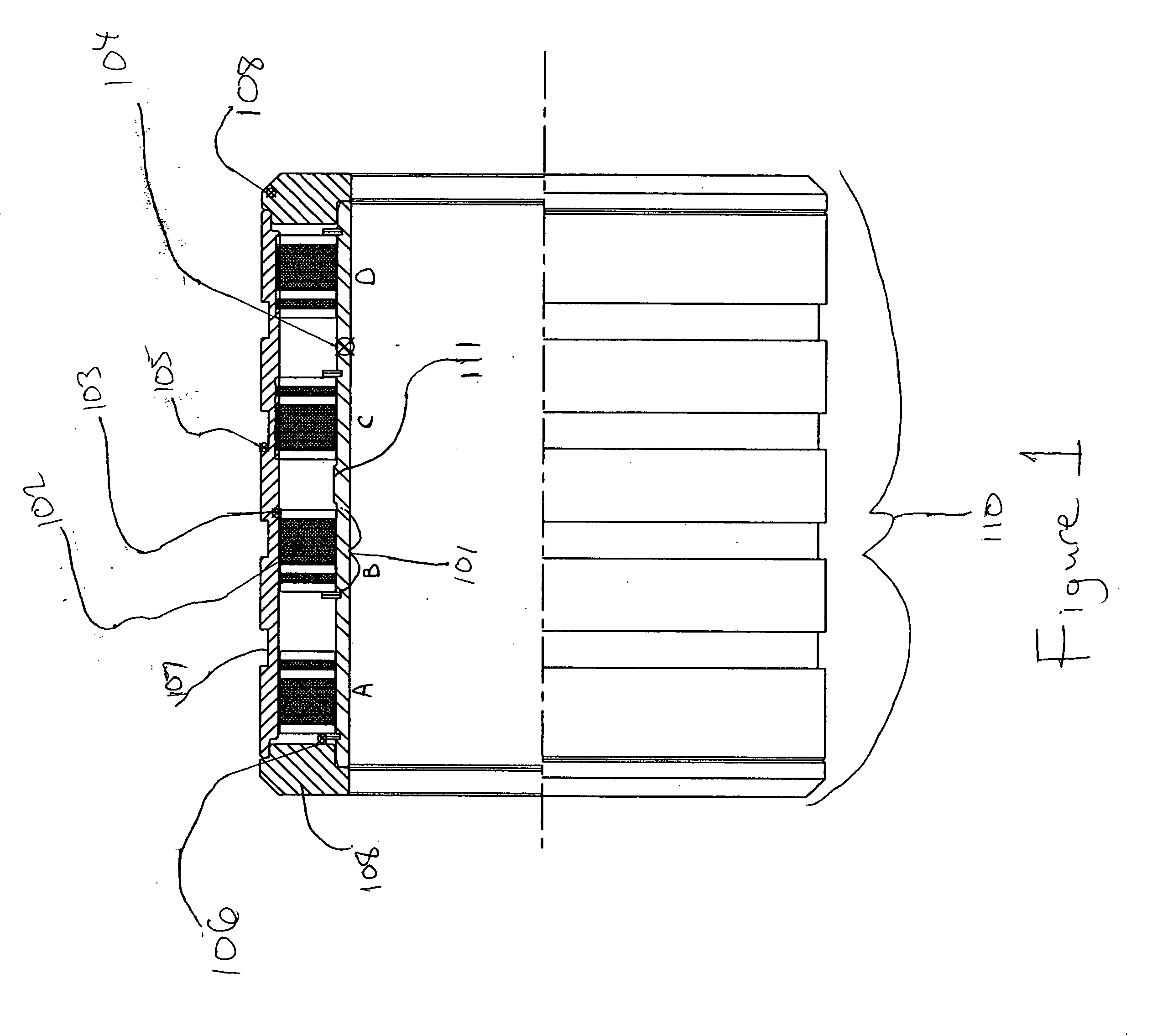

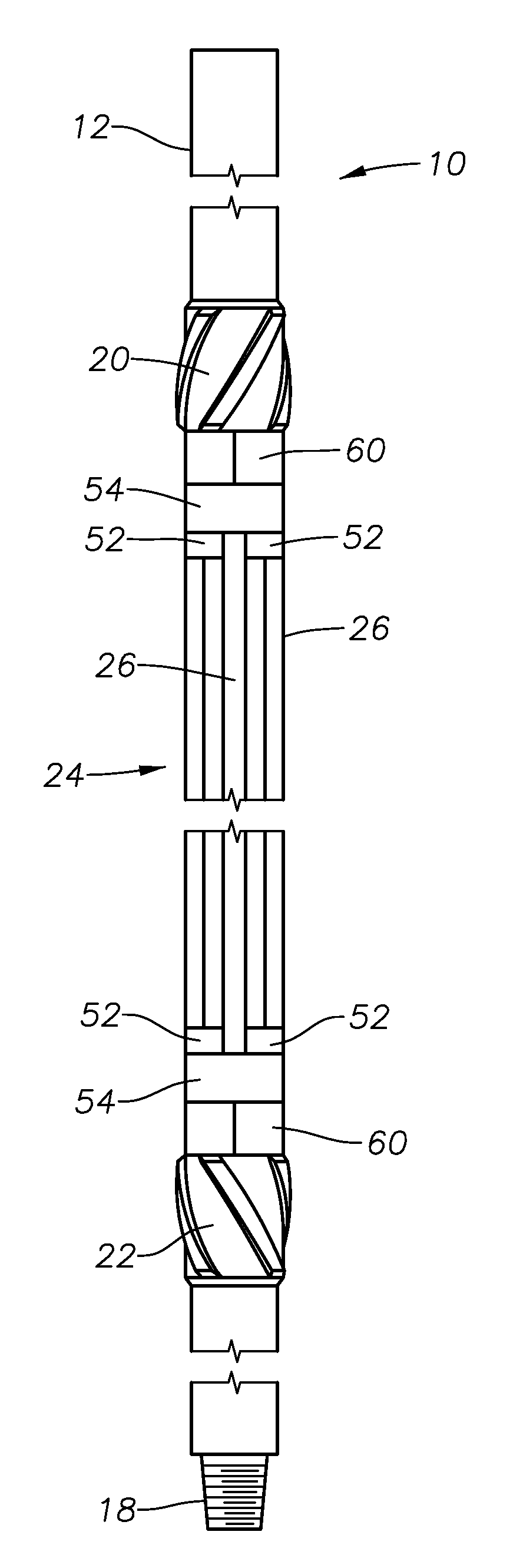

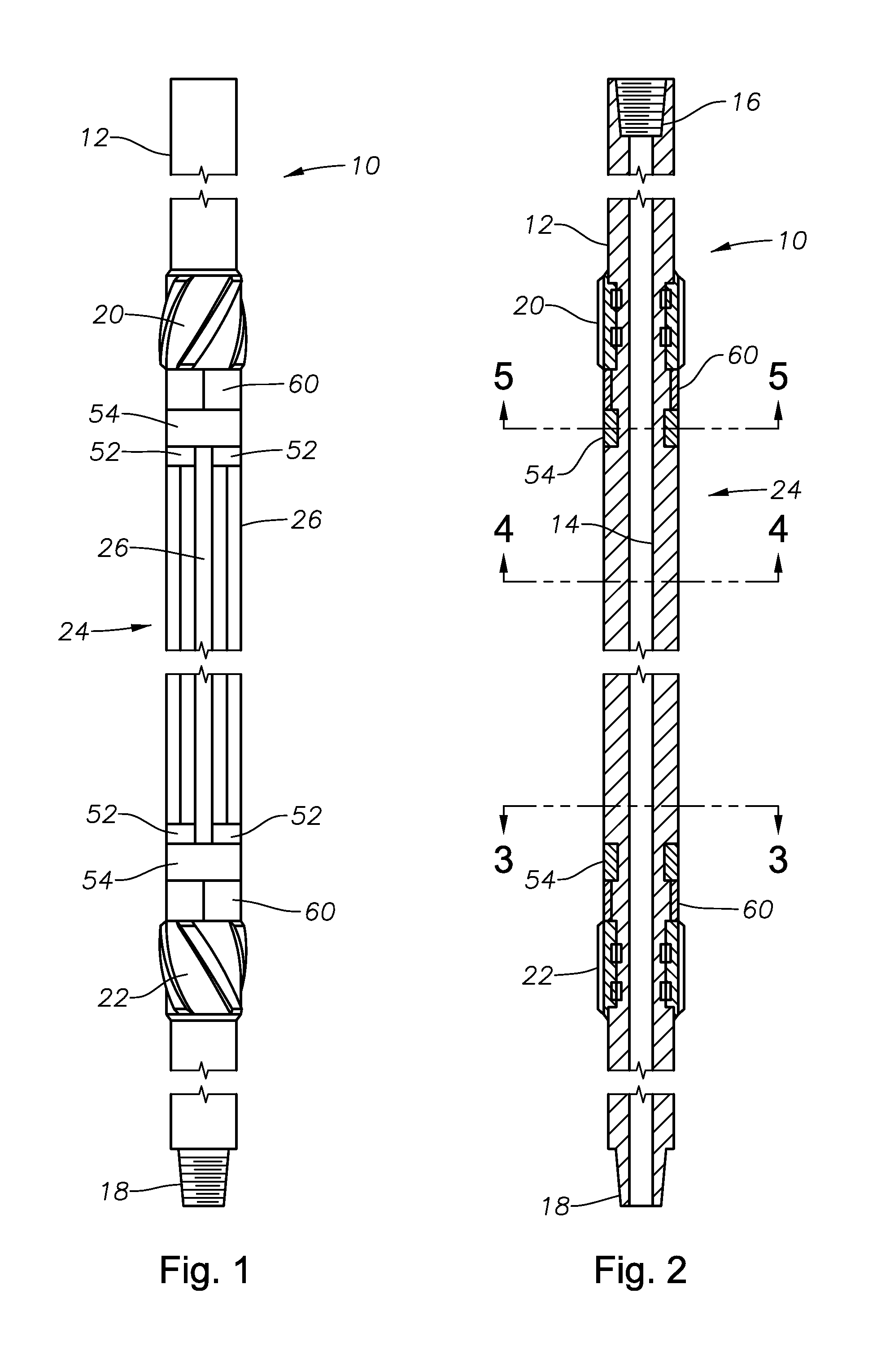

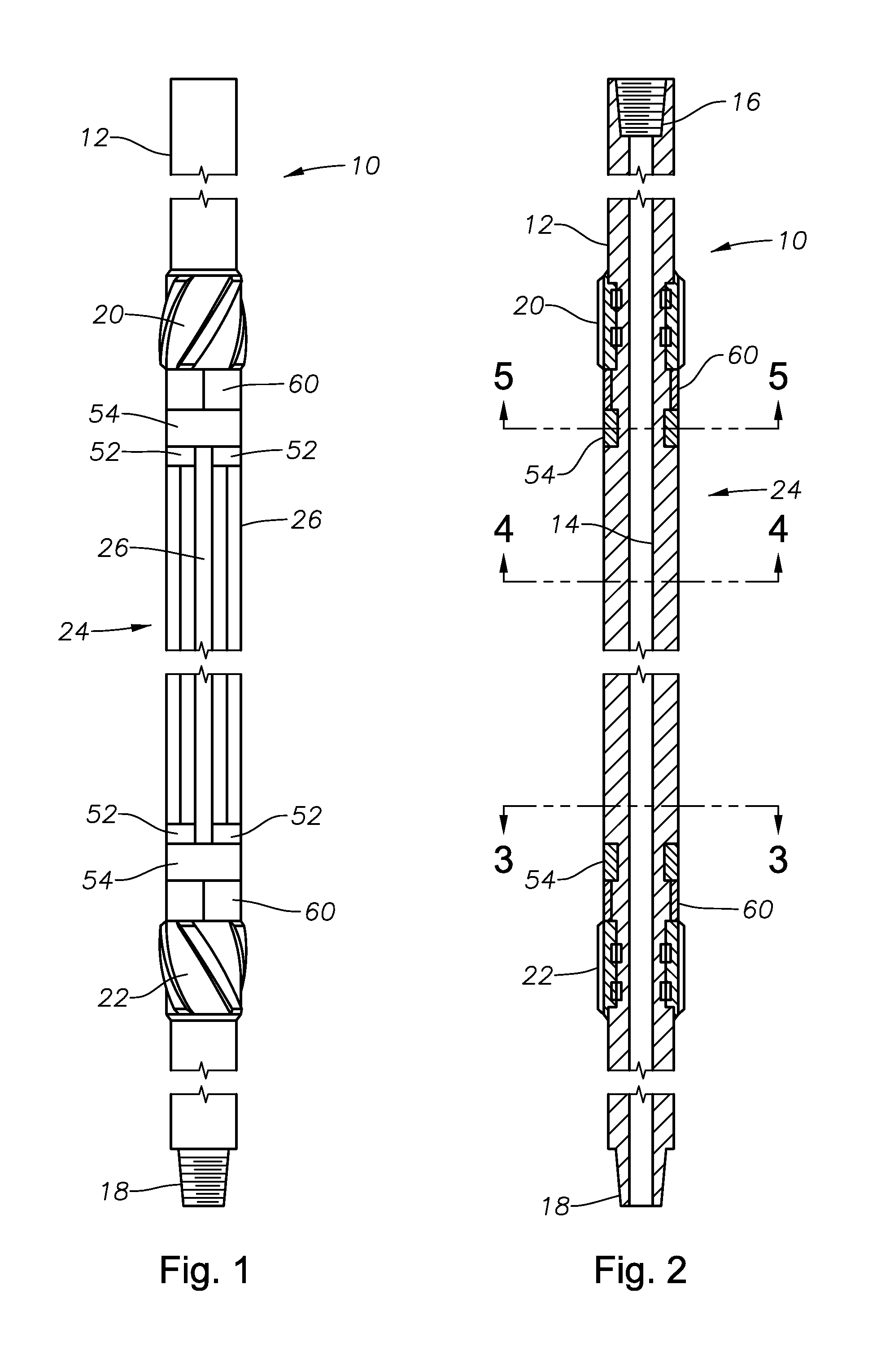

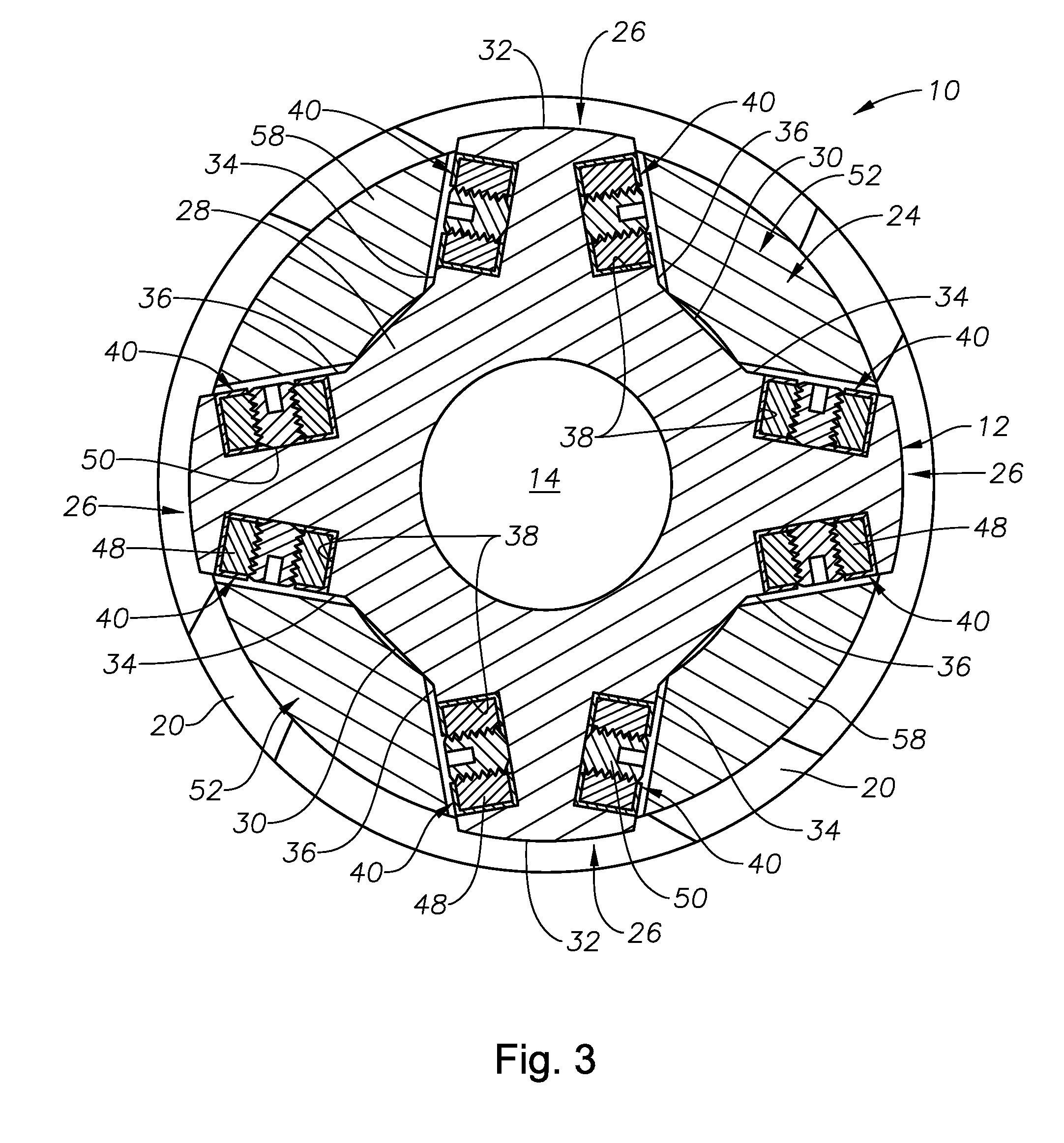

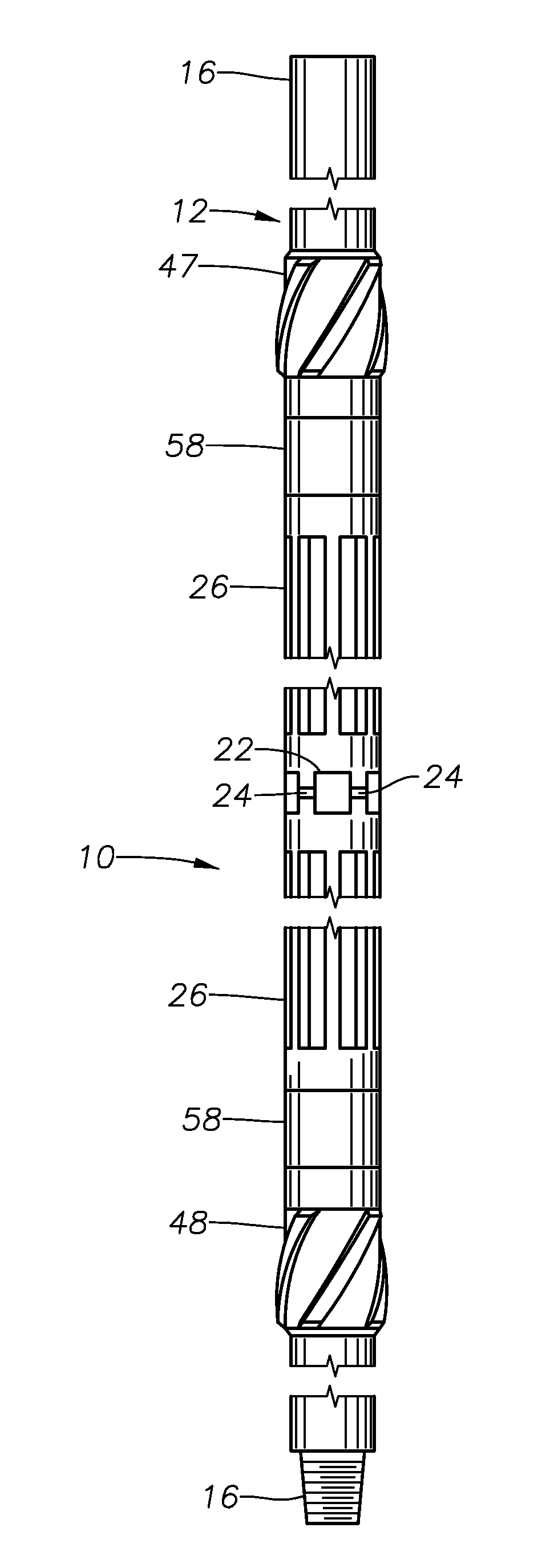

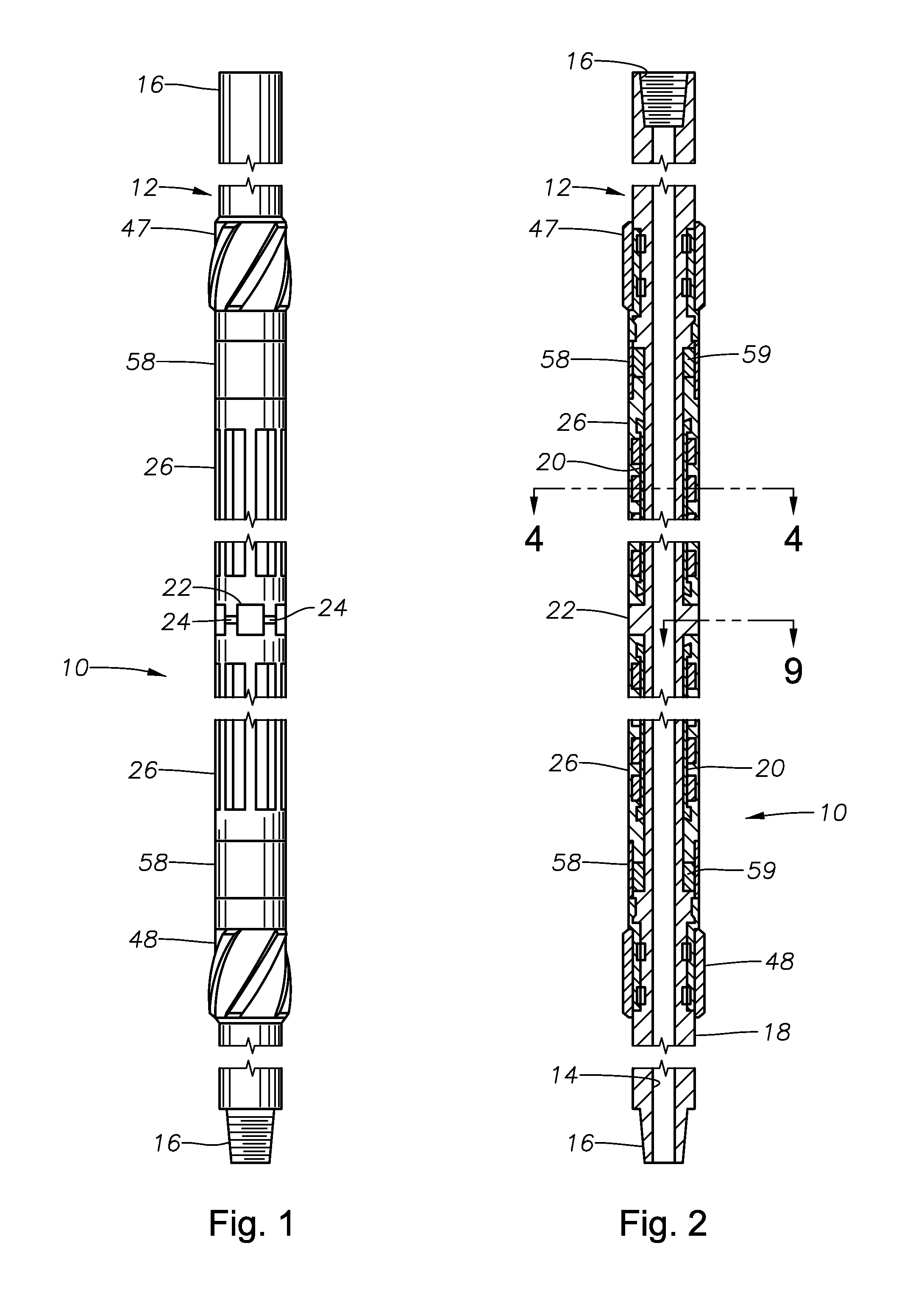

The present invention relates to a downhole tool for removing metallic debris from a well bore. The downhole tool includes a plurality of magnets disposed on the tool body. The plurality of magnets are arranged in a bucking arrangement such that repulsing forces are generated between neighboring pairs of the plurality of magnets. The bucking arrangement results in an expanded reach of the magnetic fields of the magnets to enhance the removal of metallic debris.

Owner:MI

Magnet arrangement for use on a downhole tool

The present invention relates to a downhole tool for removing metallic debris from a well bore. The downhole tool includes a plurality of magnets disposed on the tool body. The plurality of magnets are arranged in a bucking arrangement such that repulsing forces are generated between neighboring pairs of the plurality of magnets. The bucking arrangement results in an expanded reach of the magnetic fields of the magnets to enhance the removal of metallic debris.

Owner:MI

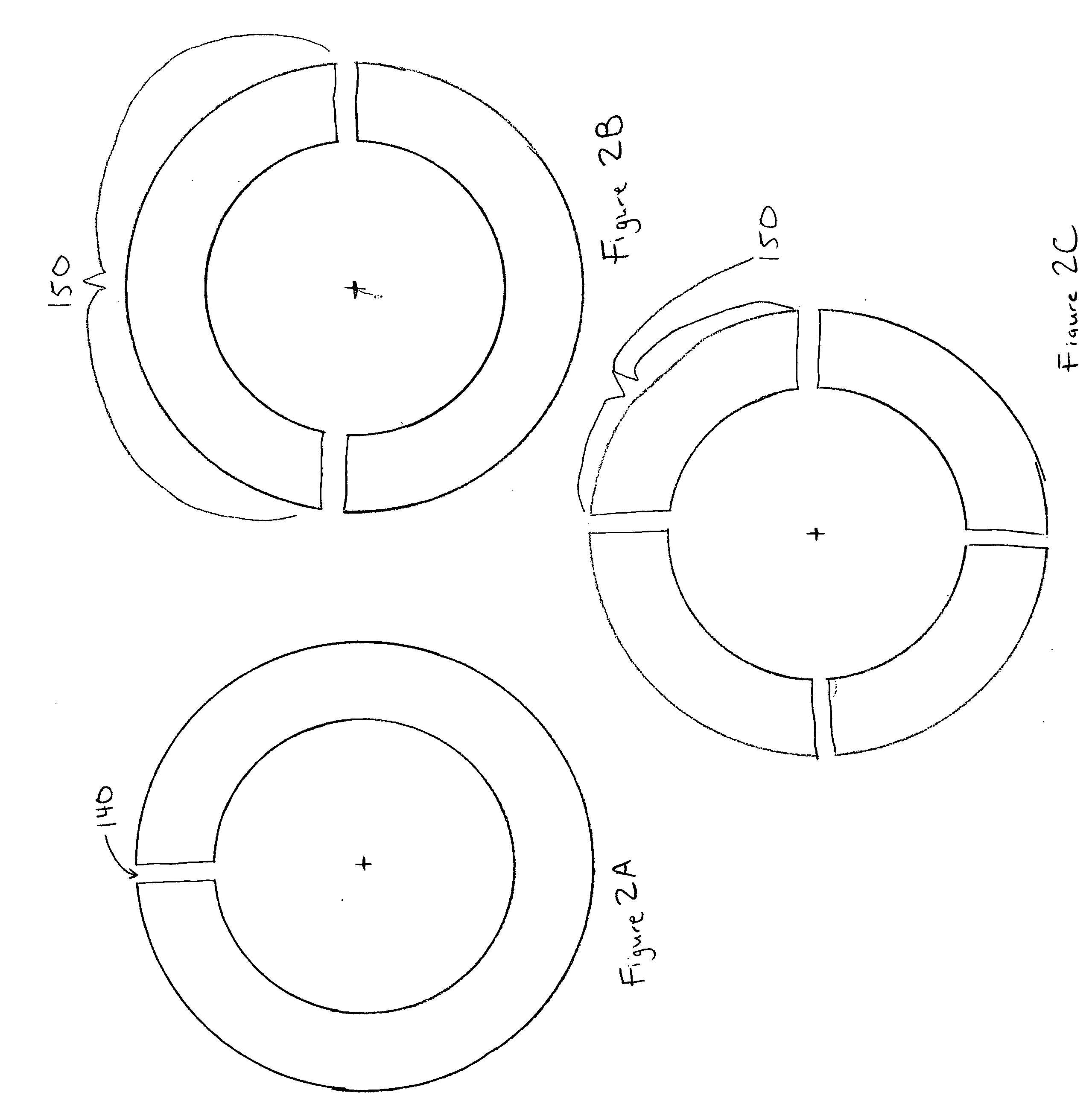

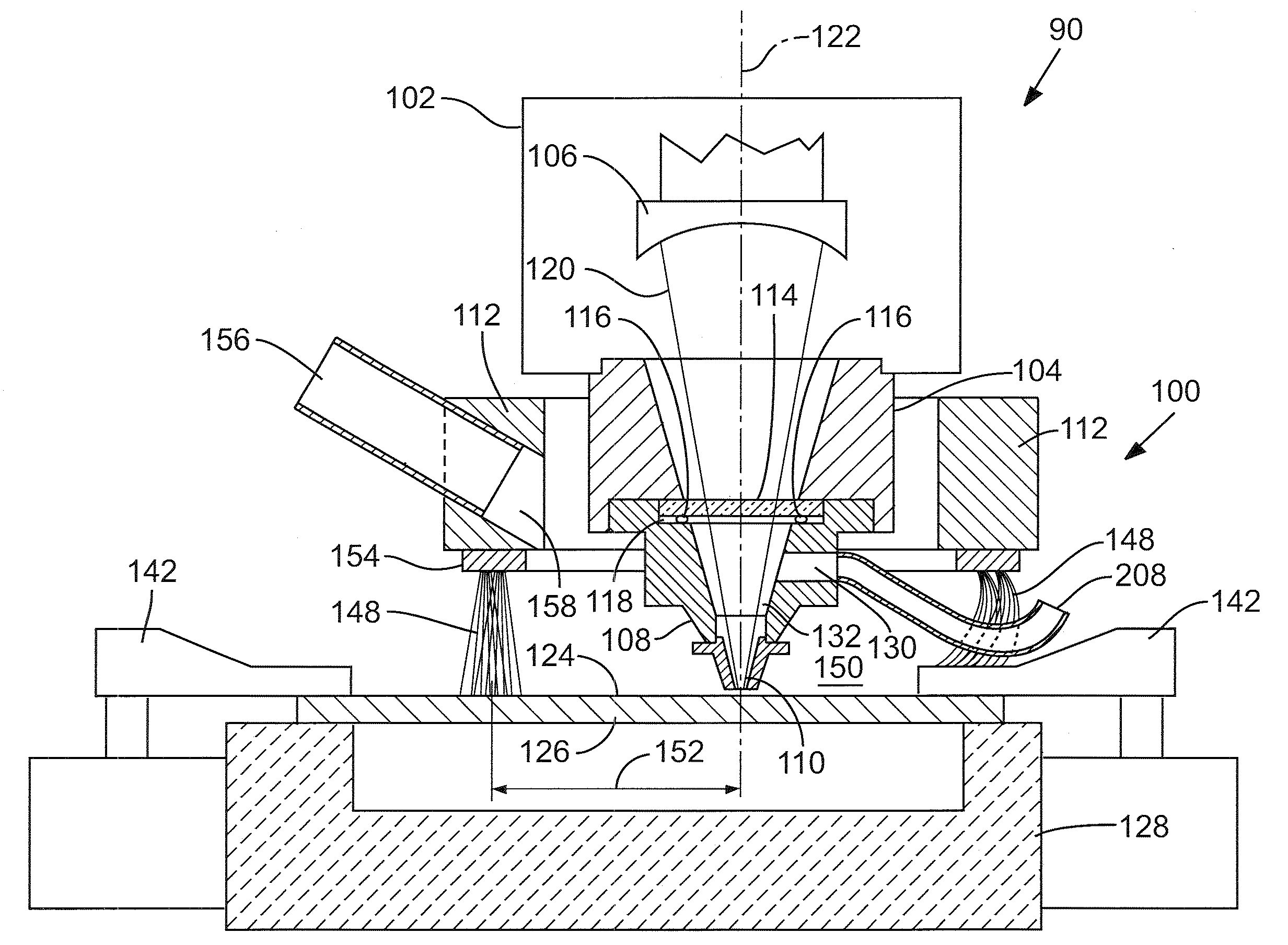

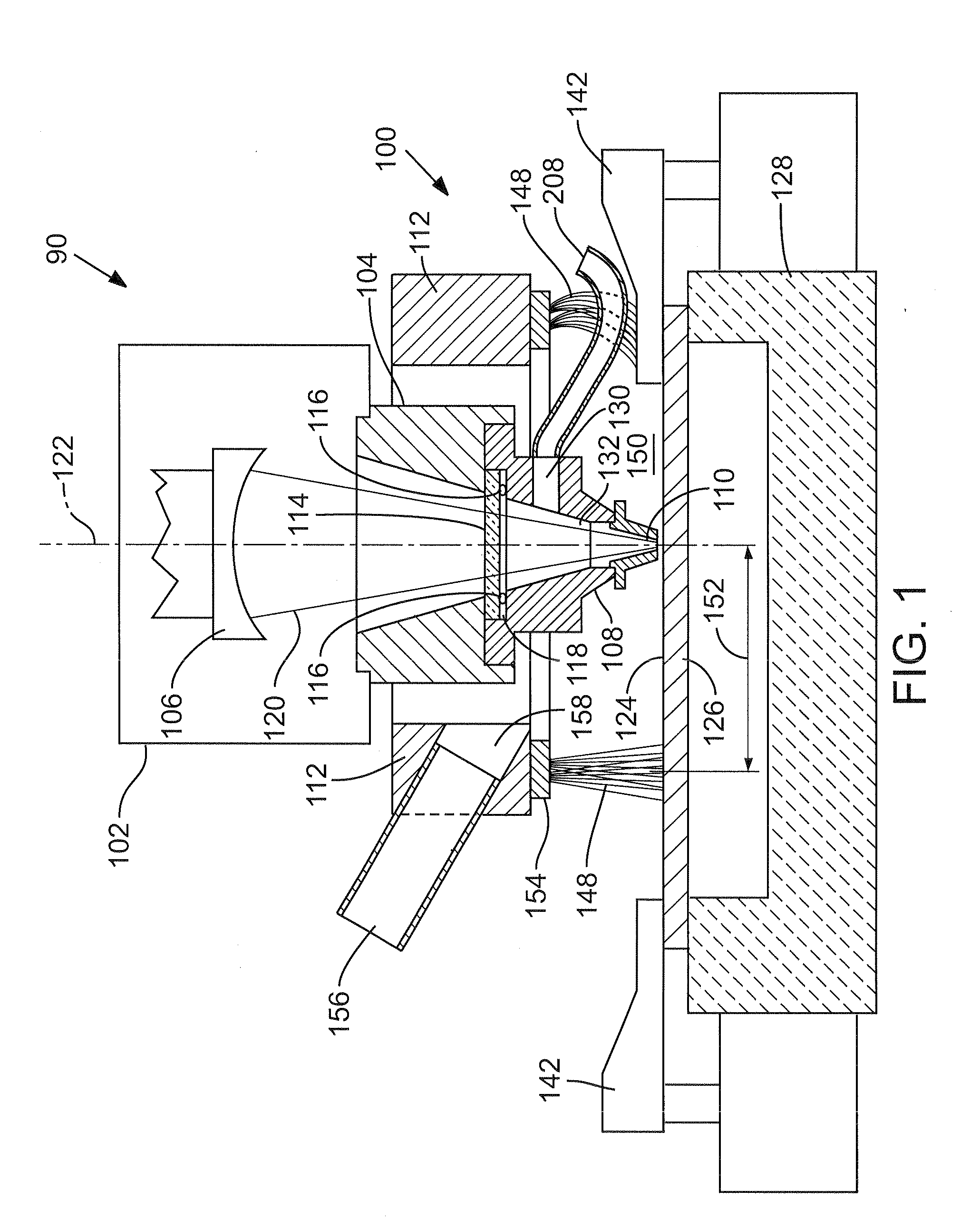

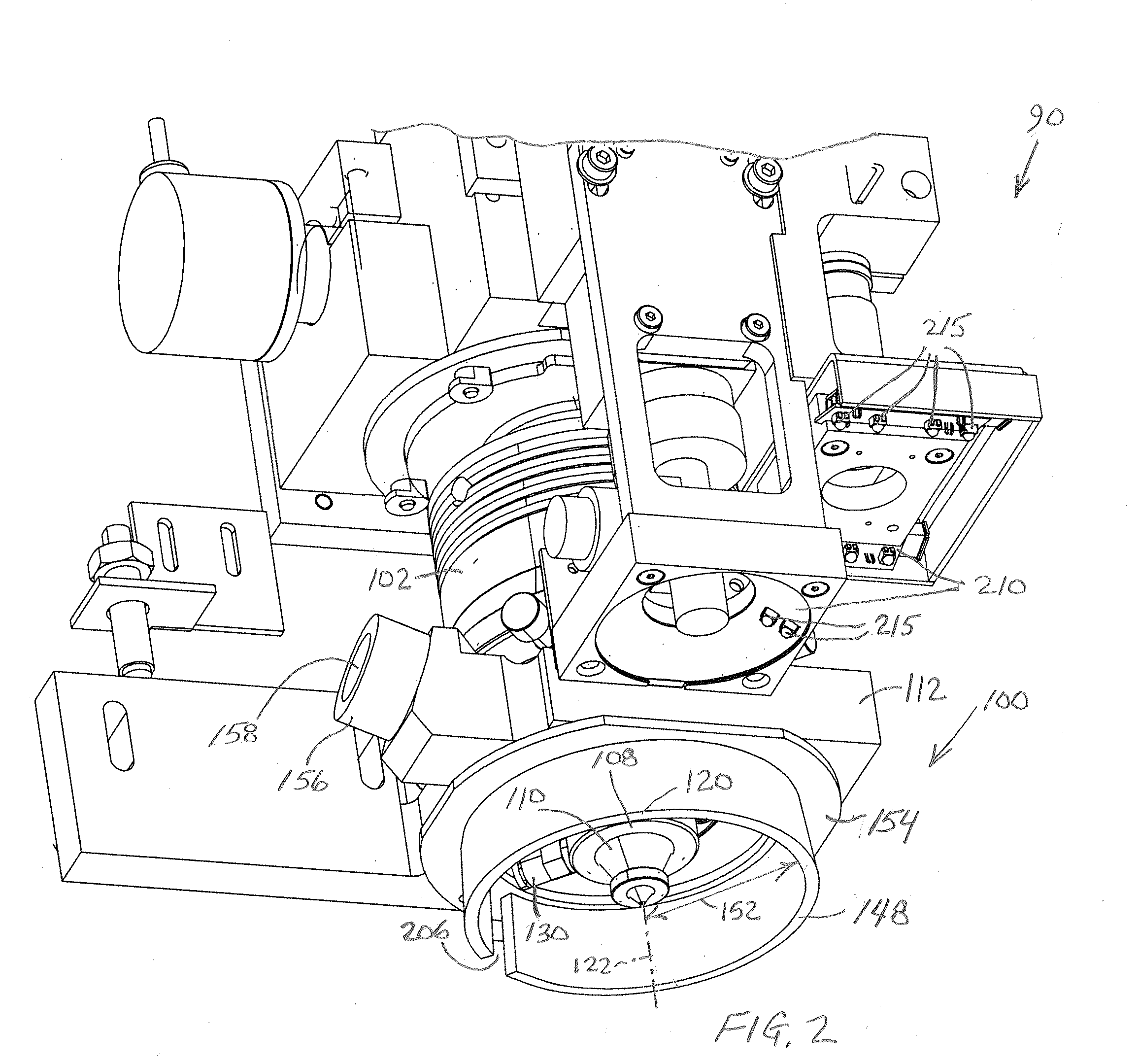

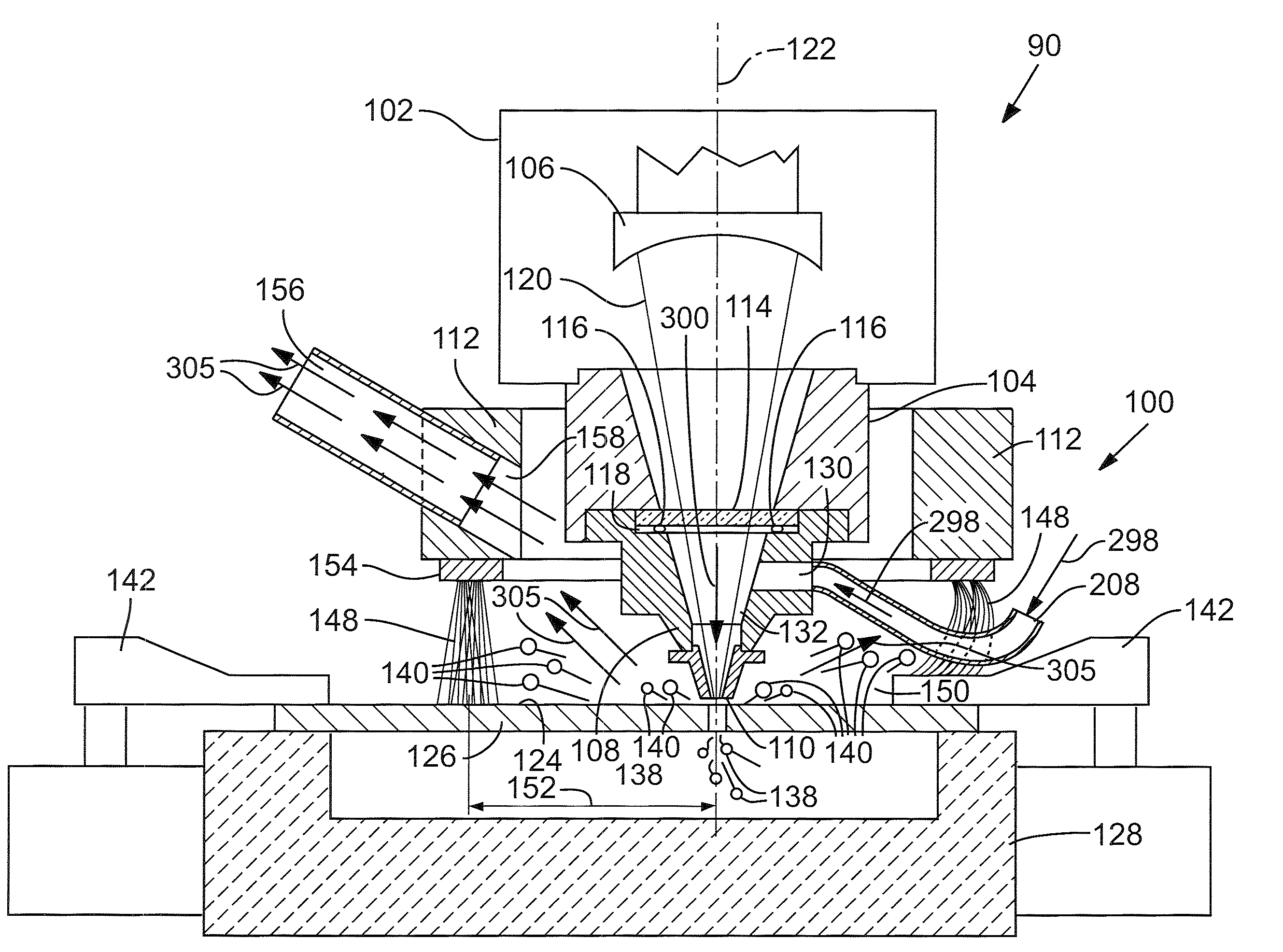

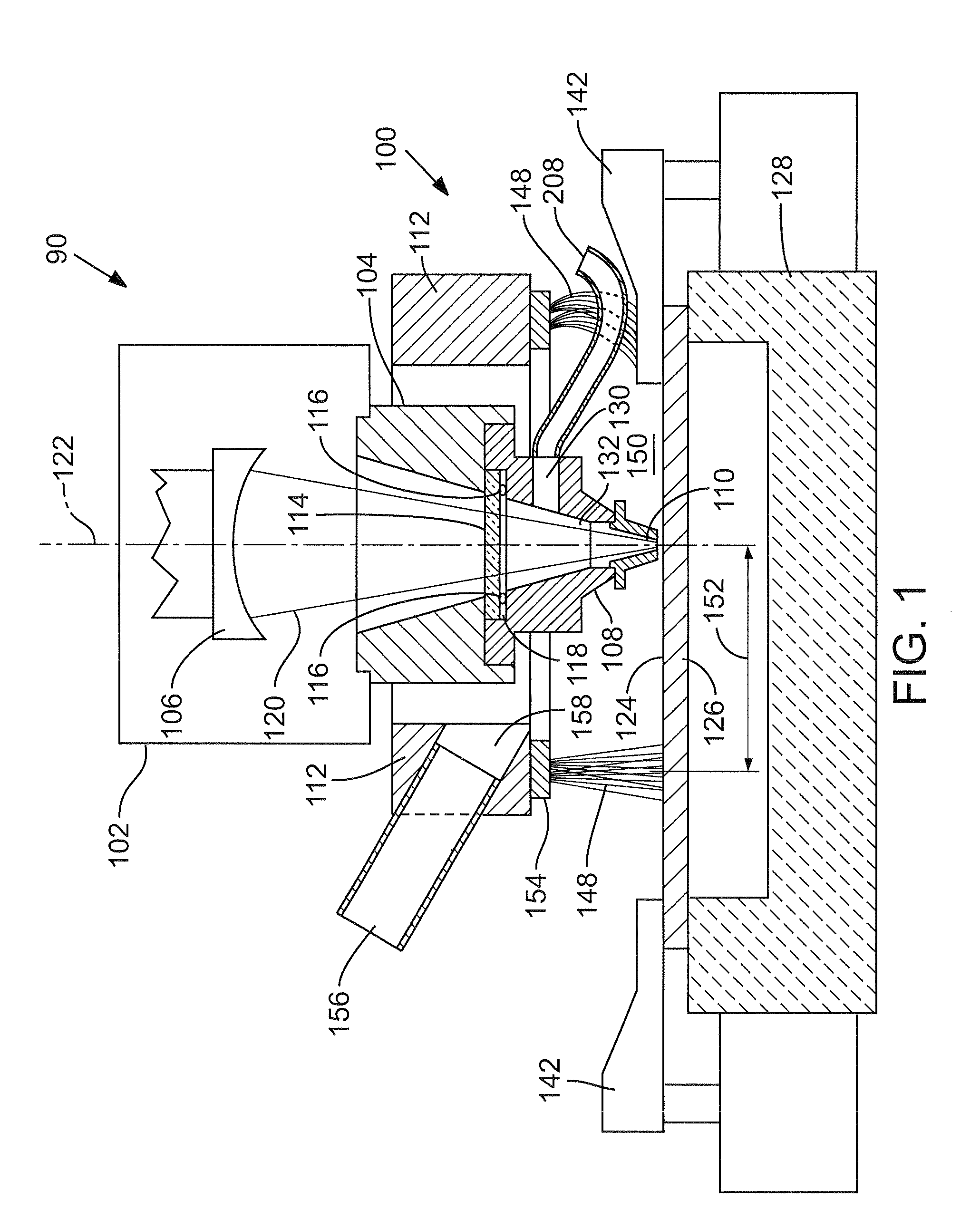

Debris capture and removal for laser micromachining

A method of capturing and removing metallic debris created on a target side of a target metal specimen undergoing laser micromachining entails providing a barrier that encompasses the immediate volume surrounding a laser cutting head output nozzle to contain the ejected debris and extracting the debris through a vacuum outlet. A preferred system implementing this approach to debris management includes a barrier in the form of a flexible fiber brush configured in the shape of a ring and positioned to trap ejected debris within a localized area surrounding a target area where the laser beam is incident on the target metal specimen. The ring brush is made of material that is robust to molten metals. An inert gas directed at a high flow rate along the target surface of the metal specimen carries ejected surface debris trapped in the ring brush toward a vacuum outlet.

Owner:ELECTRO SCI IND INC

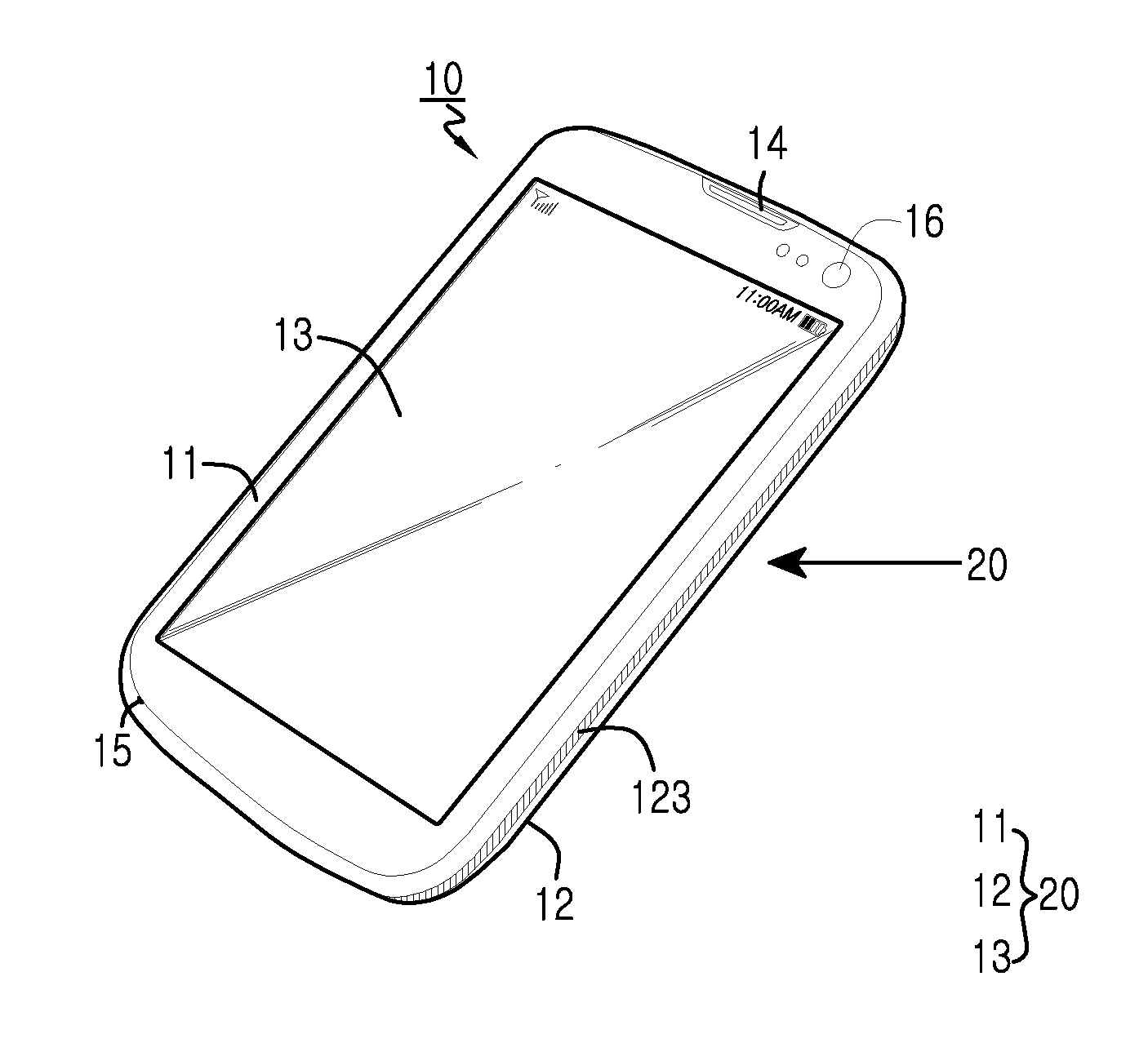

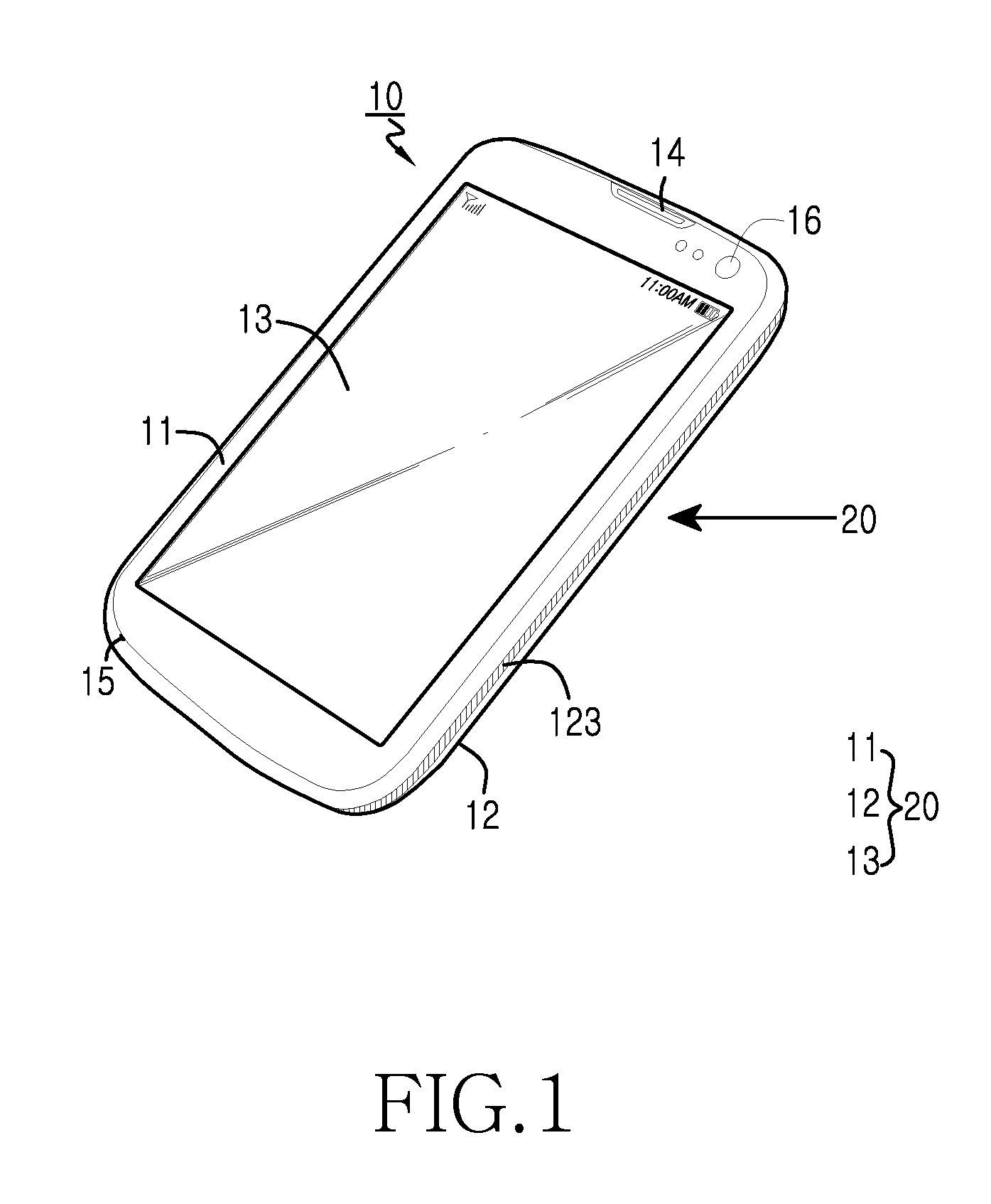

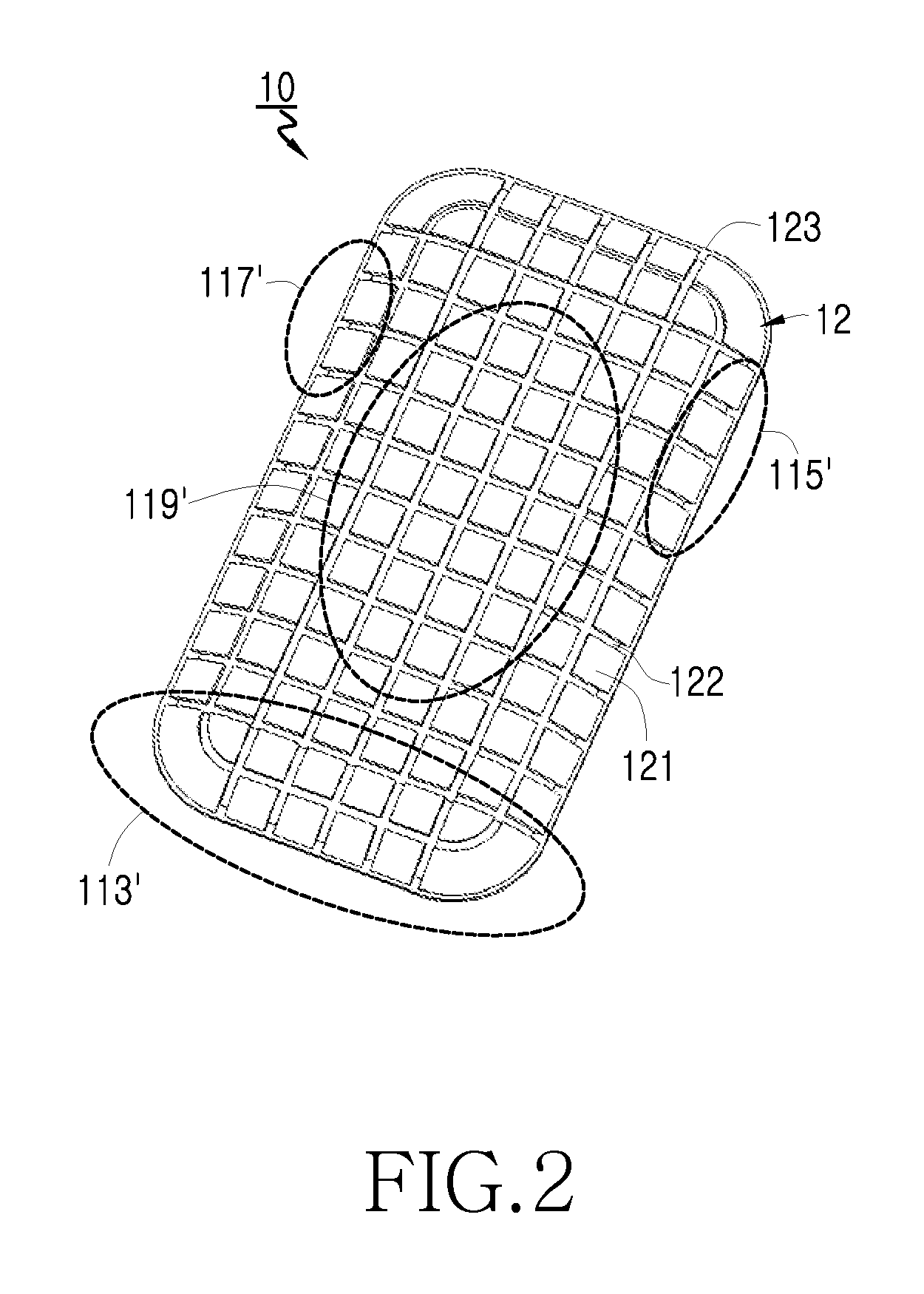

Antenna apparatus for portable terminal

ActiveUS20130234910A1Space minimizationImprove textureSimultaneous aerial operationsAntenna supports/mountingsEngineeringAntenna element

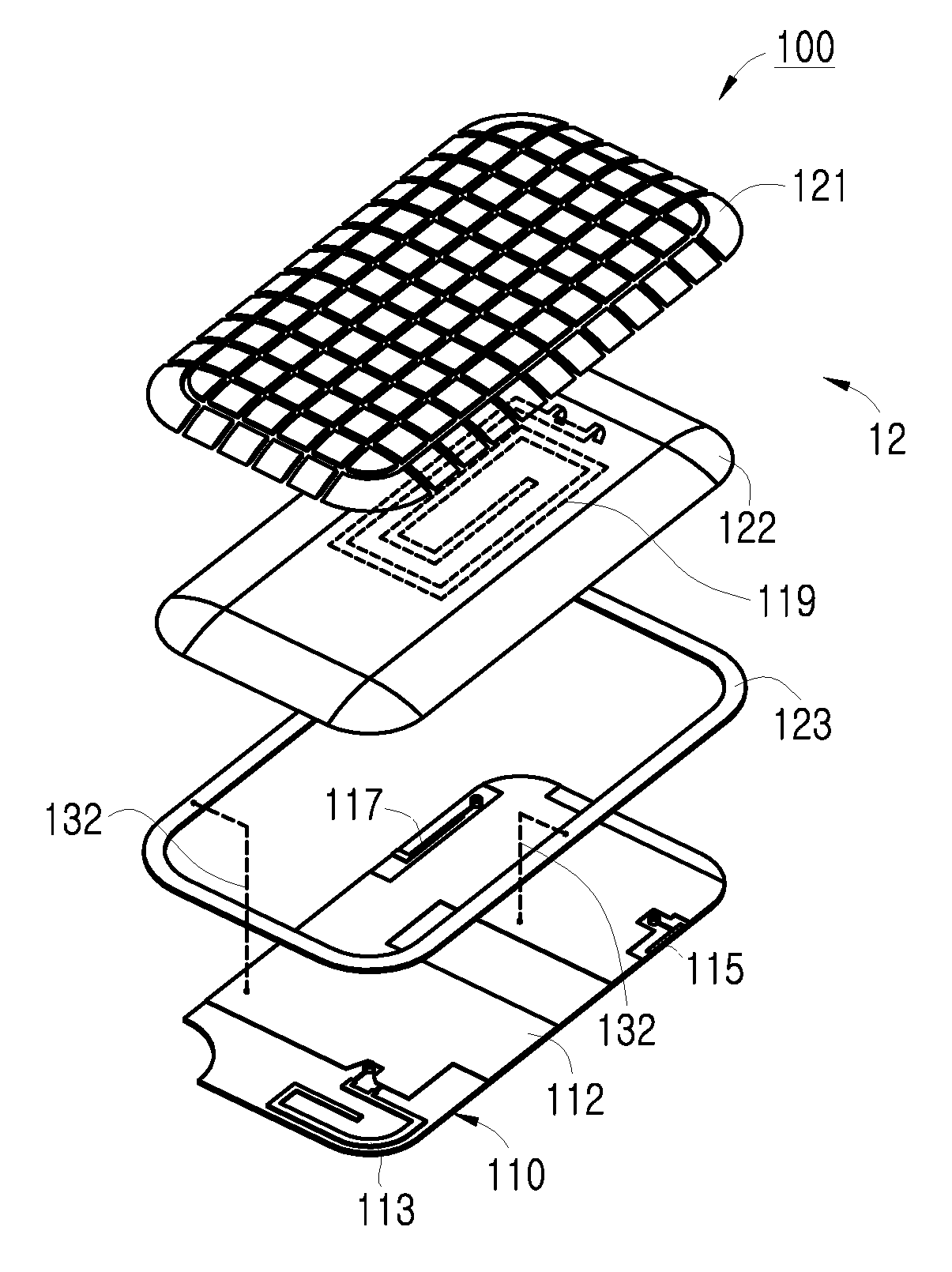

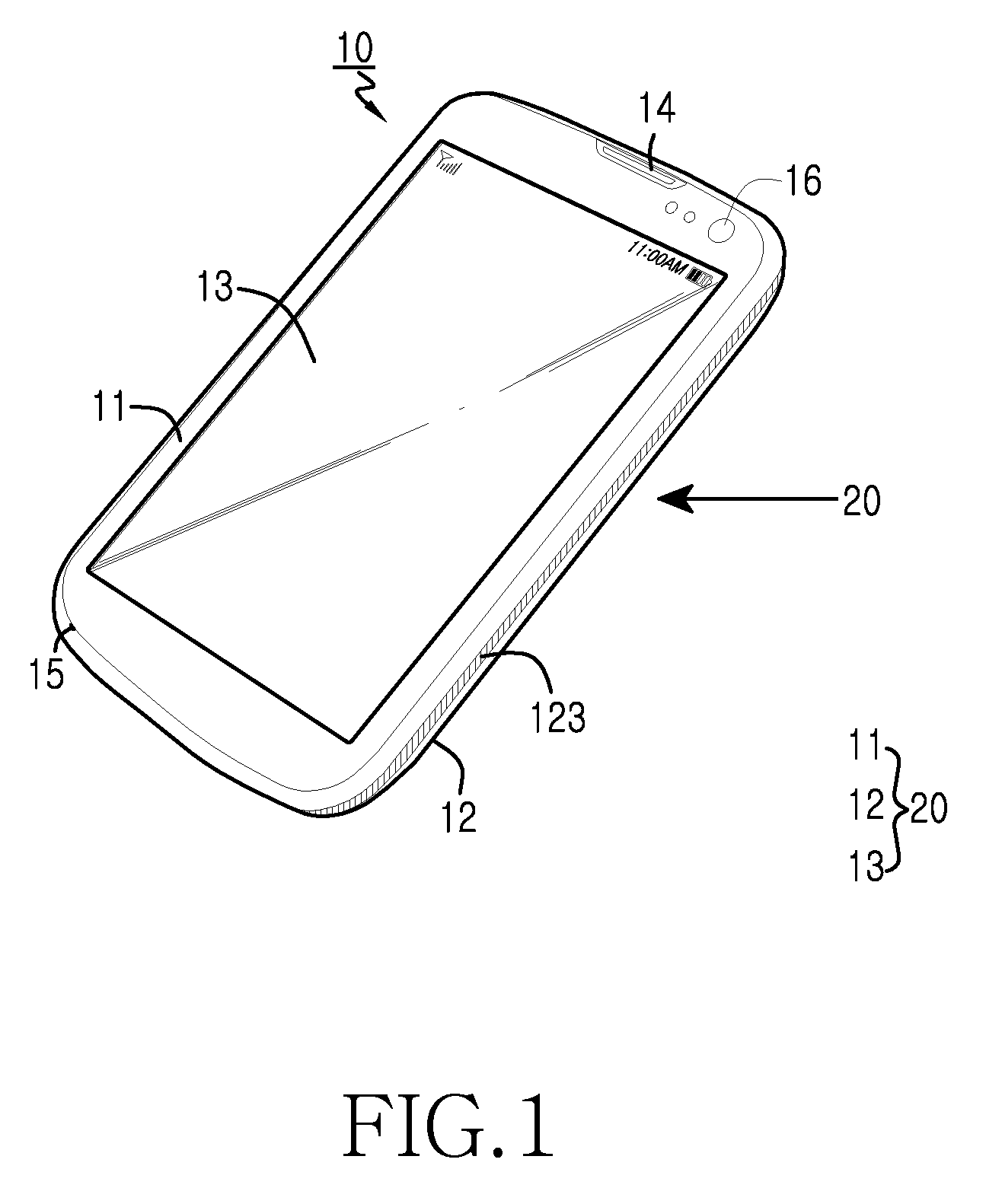

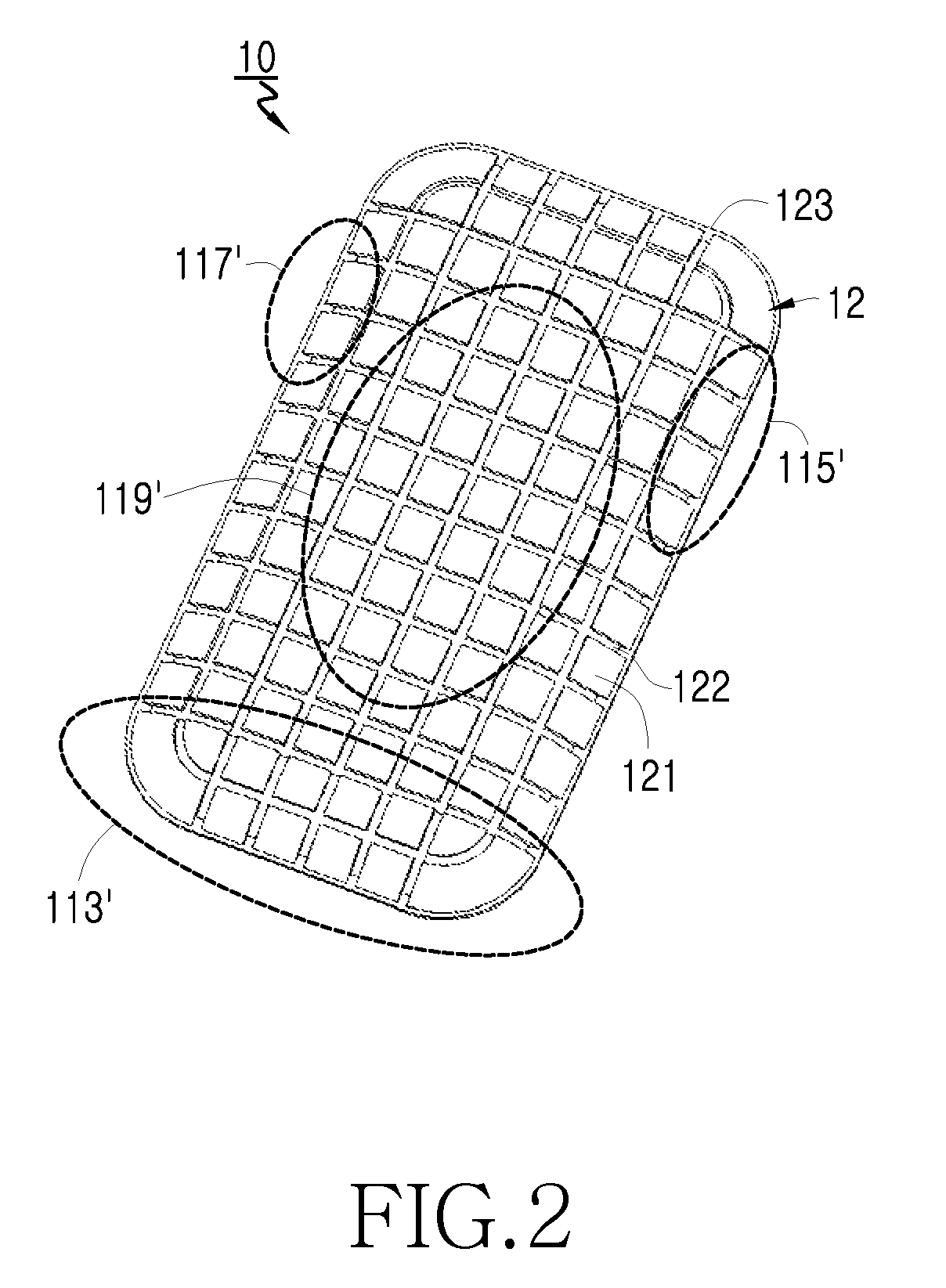

An antenna apparatus for a portable terminal is provided. The portable terminal includes a printed circuit board (PCB) having a ground surface and RF components to process a wireless signal received through at least one antenna element. A housing forms an external appearance of the portable terminal, and has a non-conductive member with a plurality of metal fragments attached thereto. At least one of the metal fragments is electrically connected to the ground surface. The metal fragments may enhance the texture and durability of the housing. Preferably, the shapes, sizes and distances separating the metal fragments are designed to minimally impact, or improve, the antenna performance provided by the at least one antenna element.

Owner:SAMSUNG ELECTRONICS CO LTD

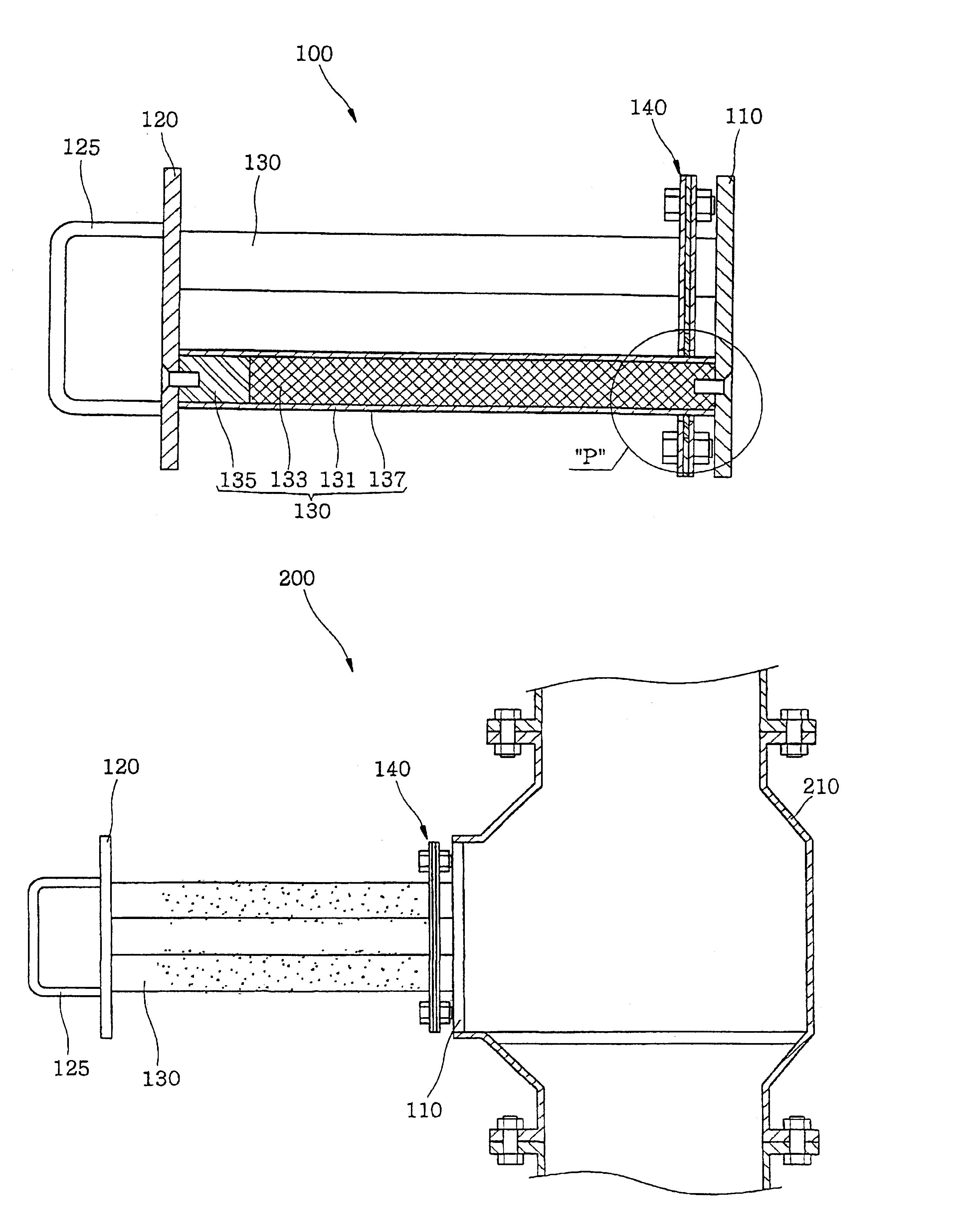

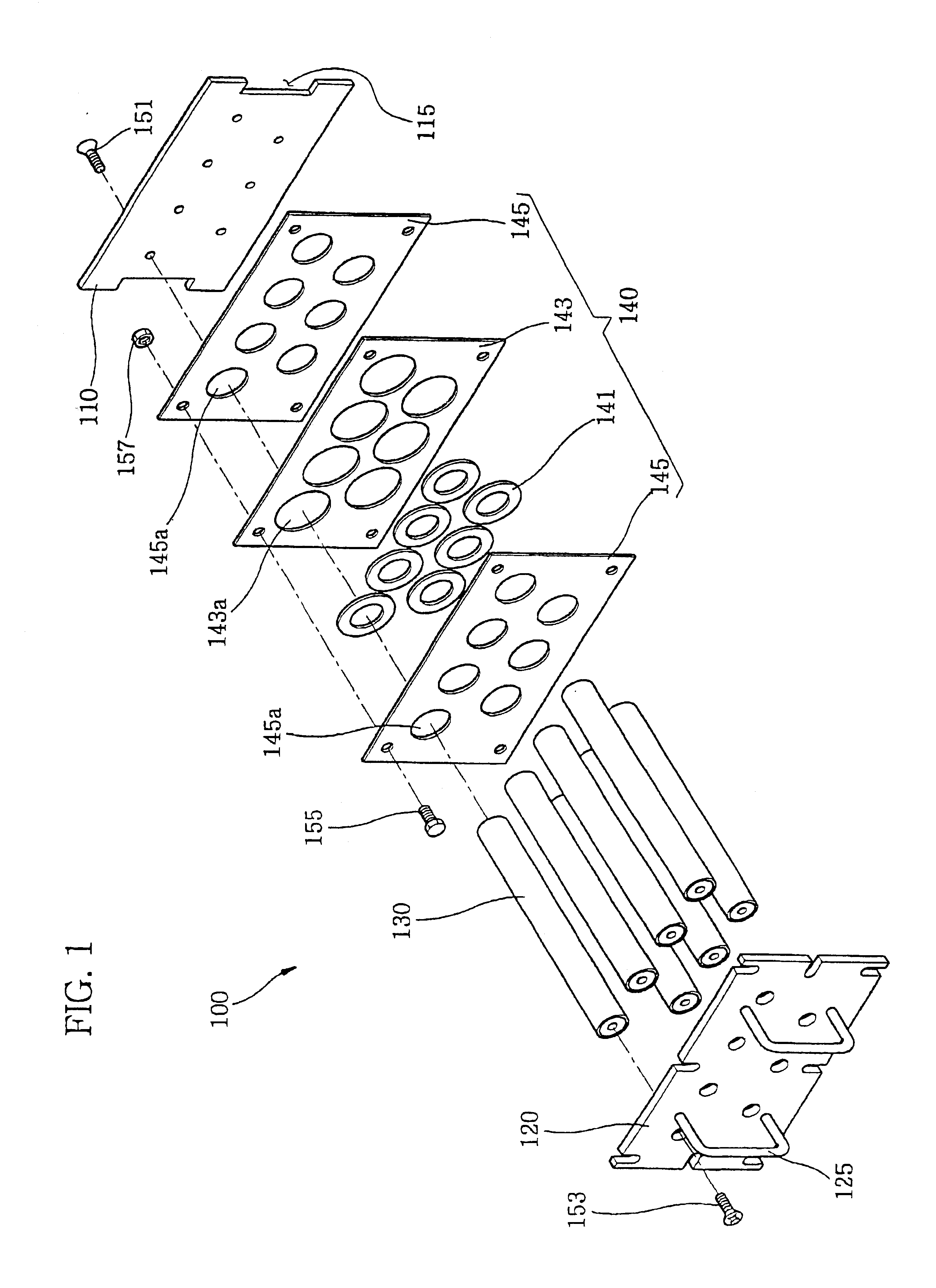

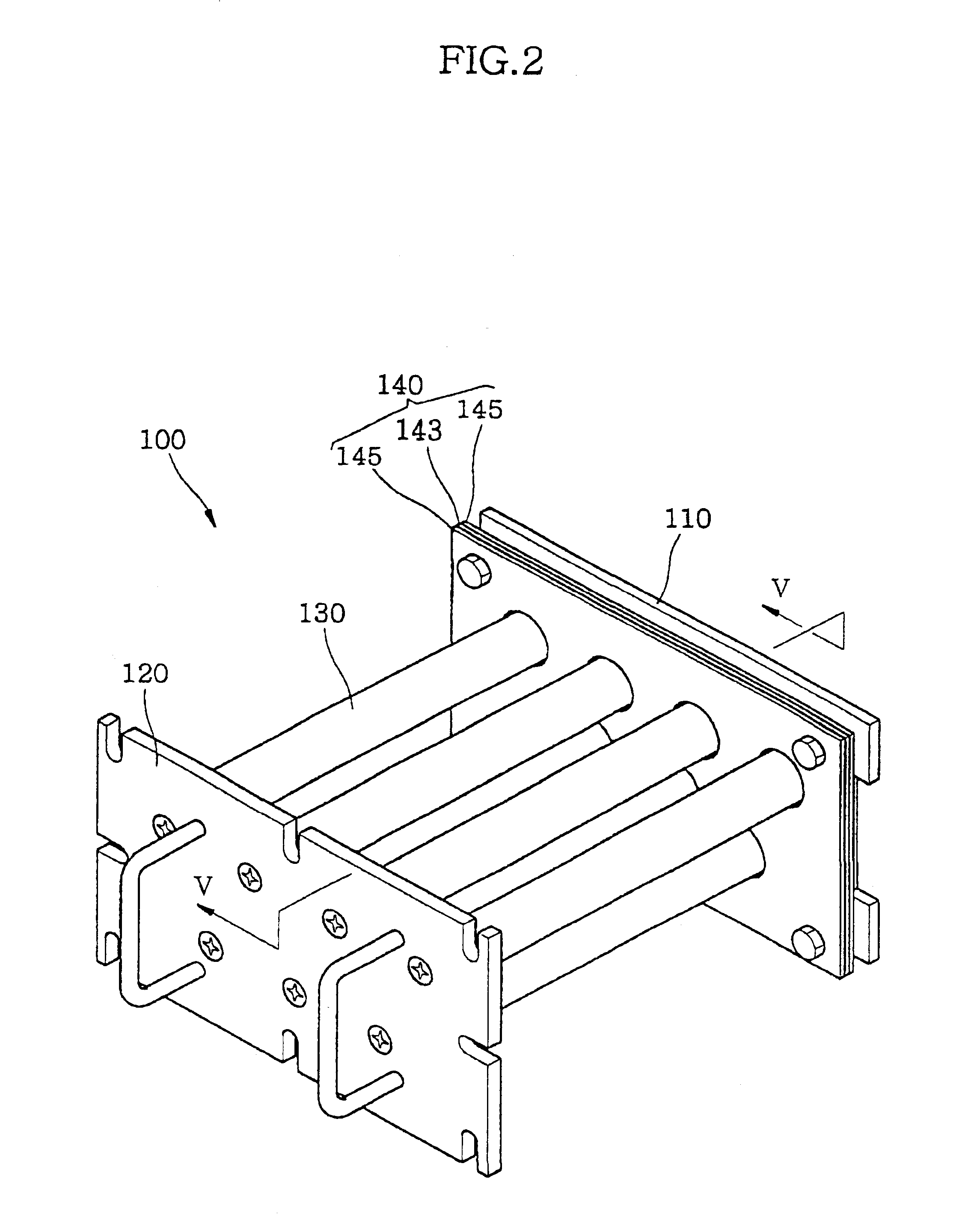

Removal unit for metal alien material removal apparatus

InactiveUS6902066B2Easily and conveniently removeWater/sewage treatment by magnetic/electric fieldsFiltration separationForeign matterMaterial removal

Disclosed is a removal unit for removing metallic alien materials, which is adapted to remove metallic alien materials such as metal fragments contained in powder or liquid raw materials. The removal unit includes an outer plate, an inner plate spaced apart from the outer plate, and magnet members coupled between the inner and outer plates. Each magnet member includes a cylindrical stainless steel rod, a magnet received in the stainless steel rod to extend from one end of the stainless steel rod to at least an intermediate portion of the stainless steel rod, a non-magnetic piece received in the other end of the stainless steel rod and coupled to the outer plate, and a fluorine resin coating formed over an outer peripheral surface of the stainless steel rod. A removal member is arranged to be slidable in a longitudinal direction along the magnet members while being in contact with the outer peripheral surfaces of the magnet members.

Owner:YANG BYEONG GON

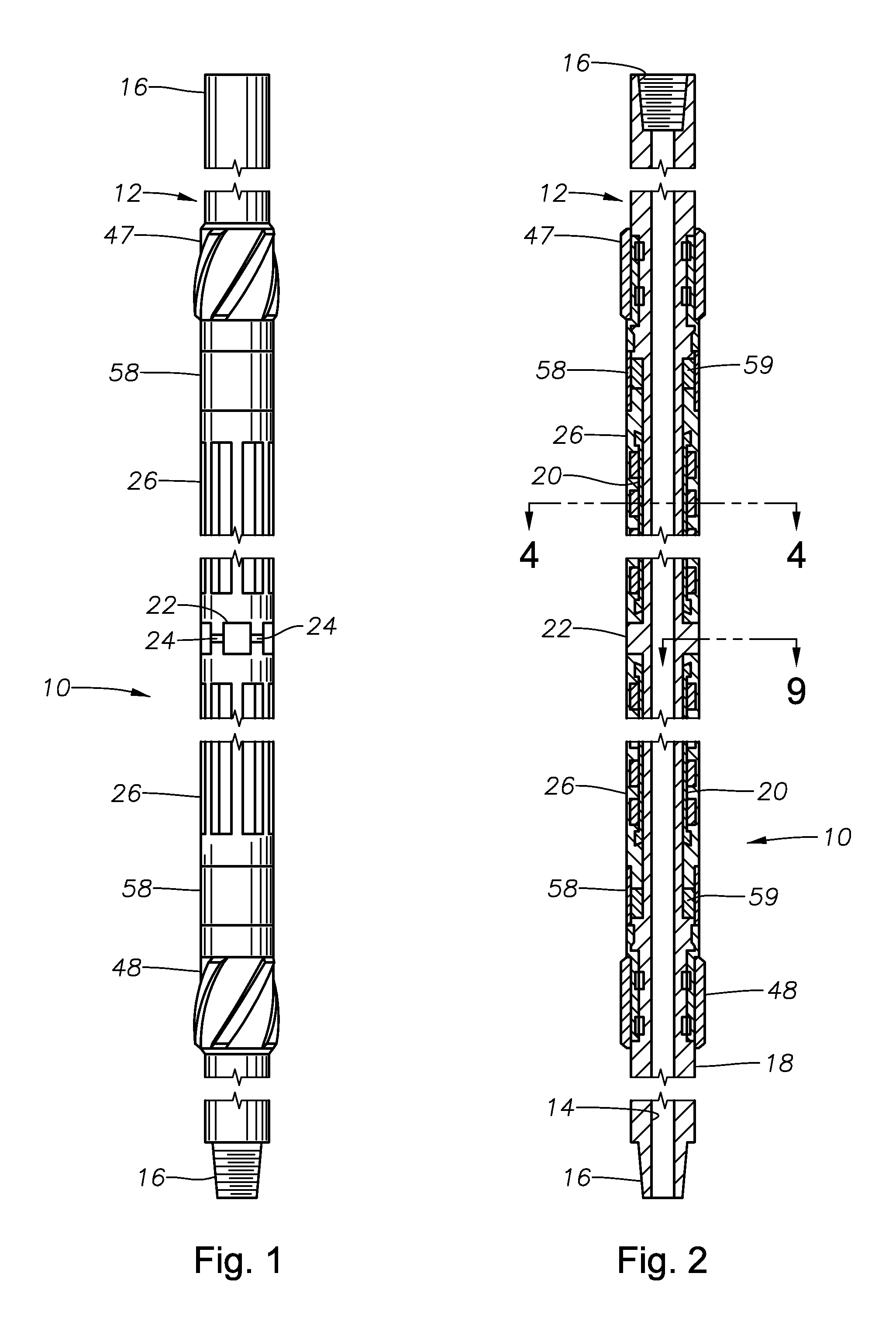

Downhole Magnetic Retrieval Devices with Fixed Magnetic Arrays

A magnetic retrieval tool used for collecting metallic debris and material from within a wellbore or other surrounding downhole tubular. The tool includes a tool mandrel with one or more pockets formed in its outer radial surface. A removable insert resides within each pocket. Each of the inserts retains a plurality of individual magnets in a fixed array or matrix surrounding the mandrel.

Owner:BAKER HUGHES INC

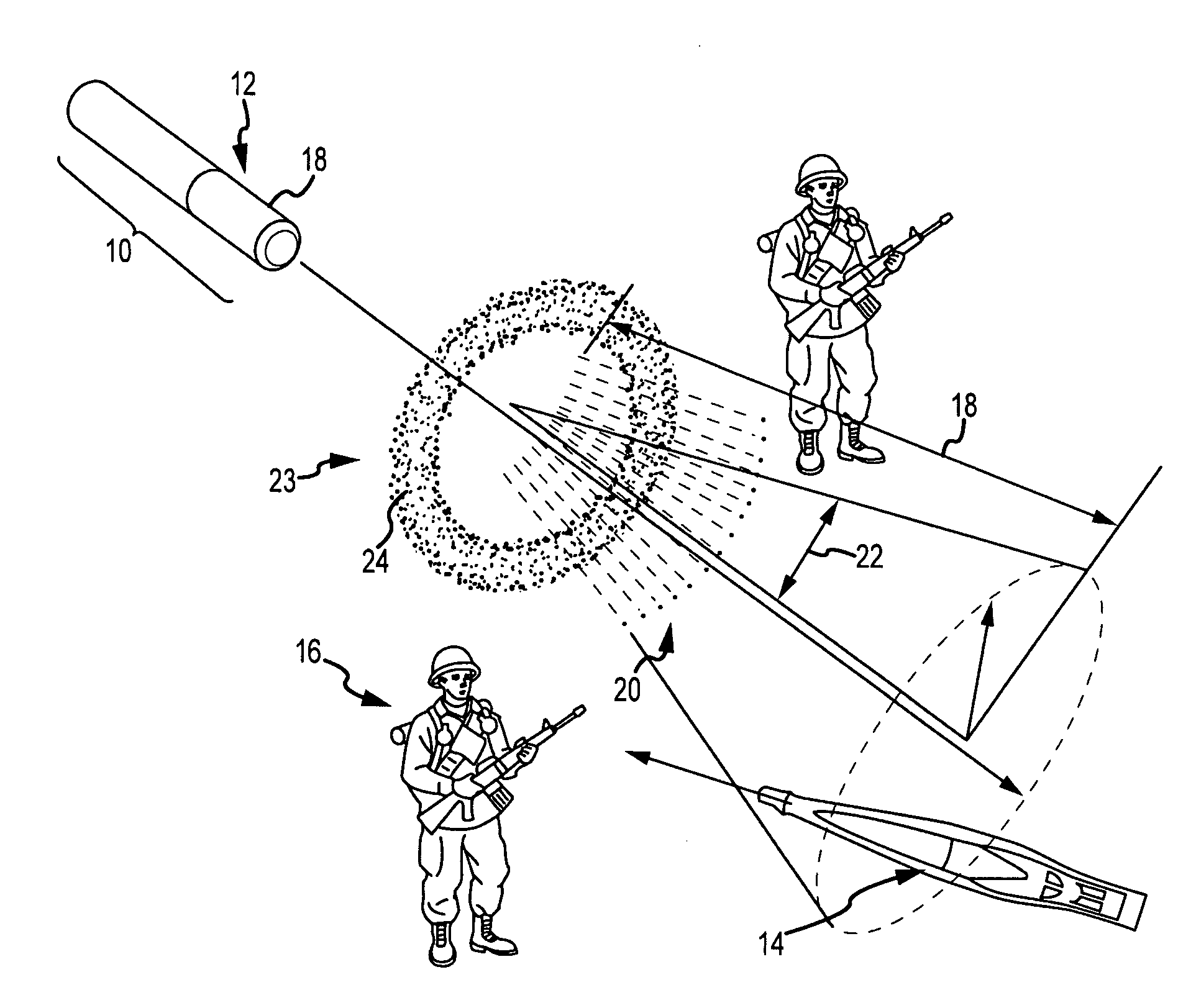

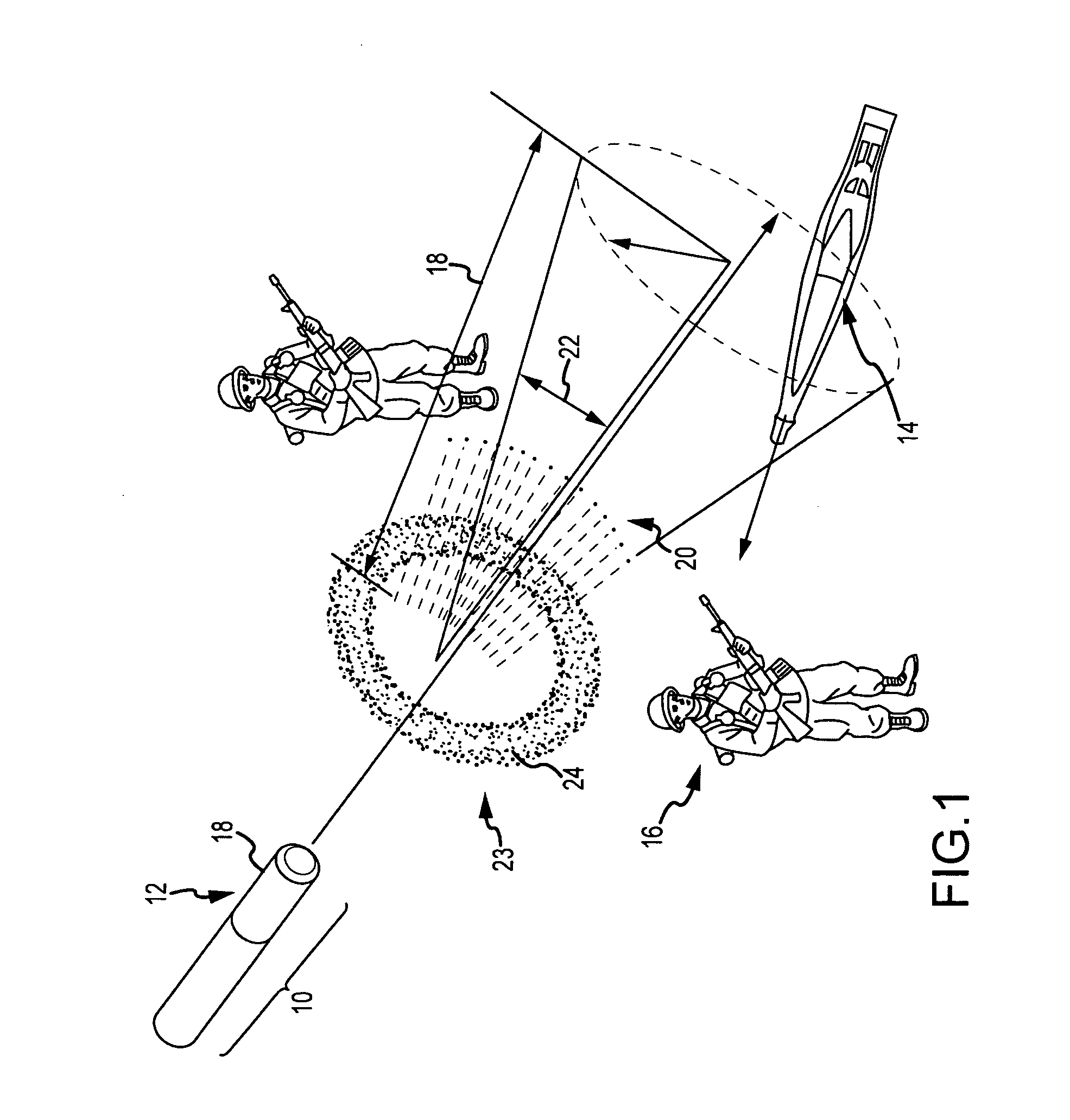

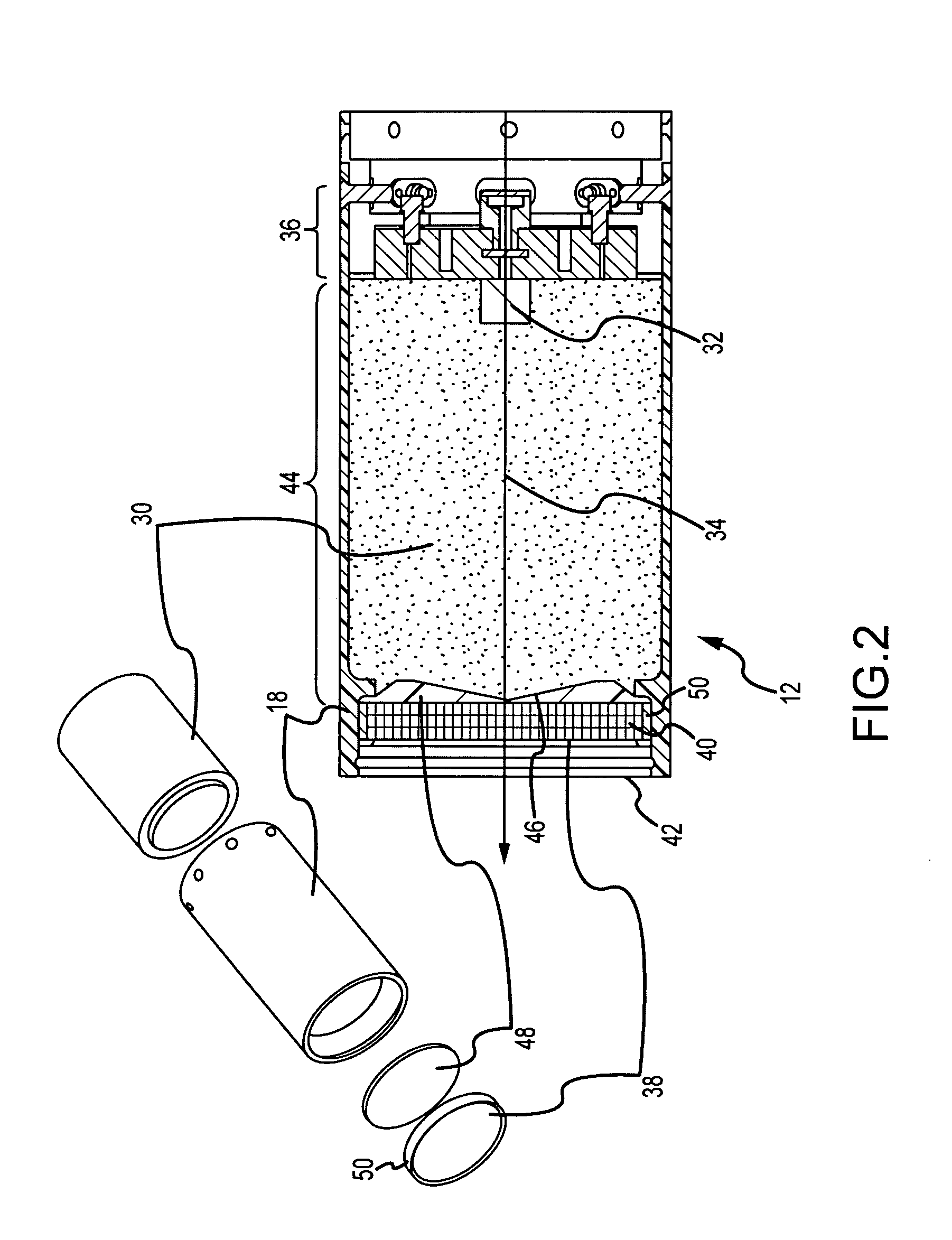

High-lethality low collateral damage fragmentation warhead

ActiveUS20110146523A1High-lethality low collateral damageReduced collateral damageAmmunition projectilesProjectilesWavefrontDetonation

The present invention provides a high-lethality low collateral damage fragmentation warhead. The case is formed of a material that is pulverized upon detonation of the explosive. As a result, the lethality radius of the pulverized case fragments is no greater than that of the gas blast, thus reducing potential collateral damage. Warhead lethality is improved by placing a pattern shaper between the fragment assembly and the explosive. The explosive and pattern shaper have a conformal non-planar interface that shapes the pressure wavefront as it propagates there through to expel metal fragments from the fragmentation assembly with a desired pattern density over a prescribed solid angle.

Owner:RAYTHEON CO

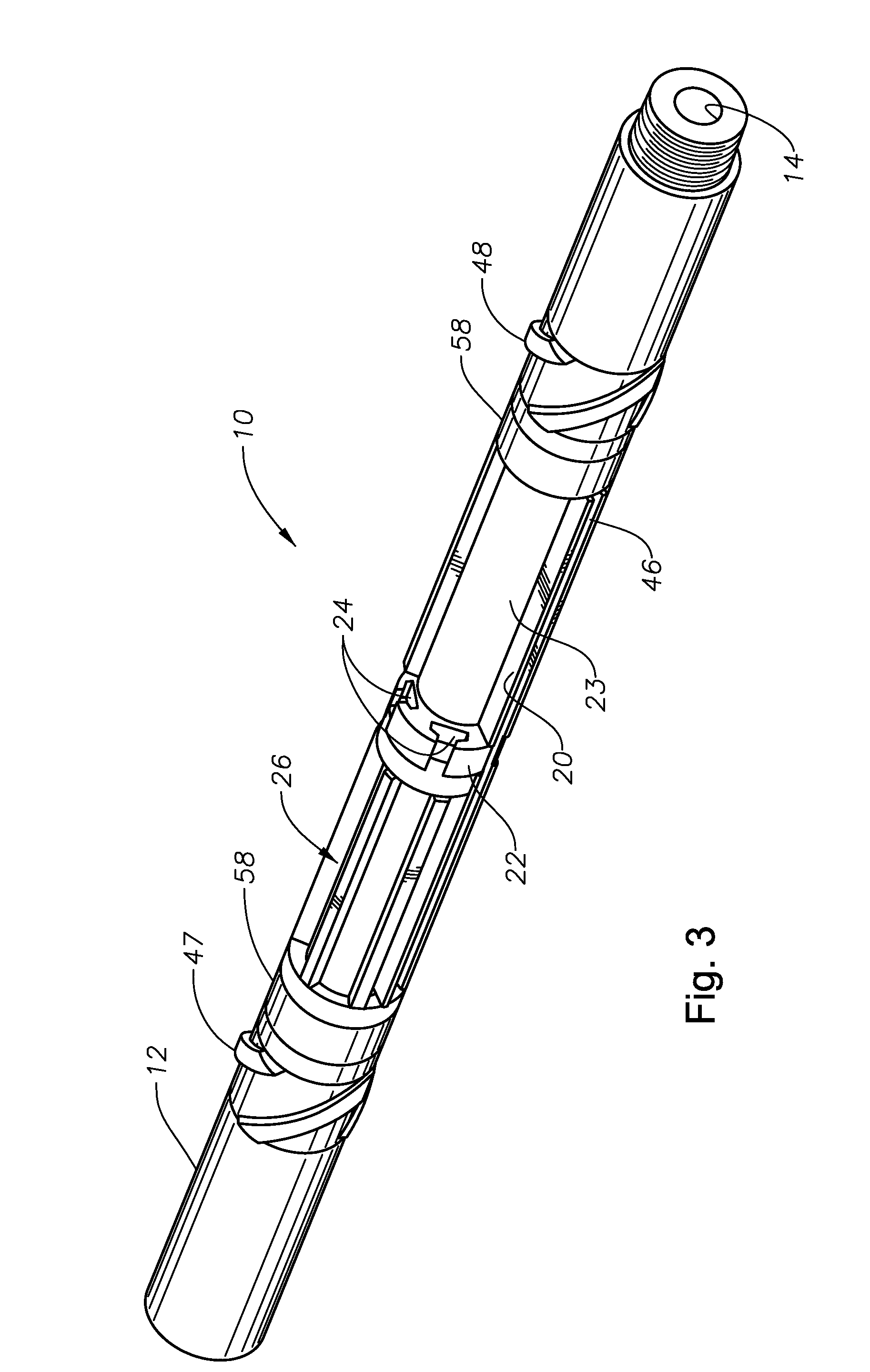

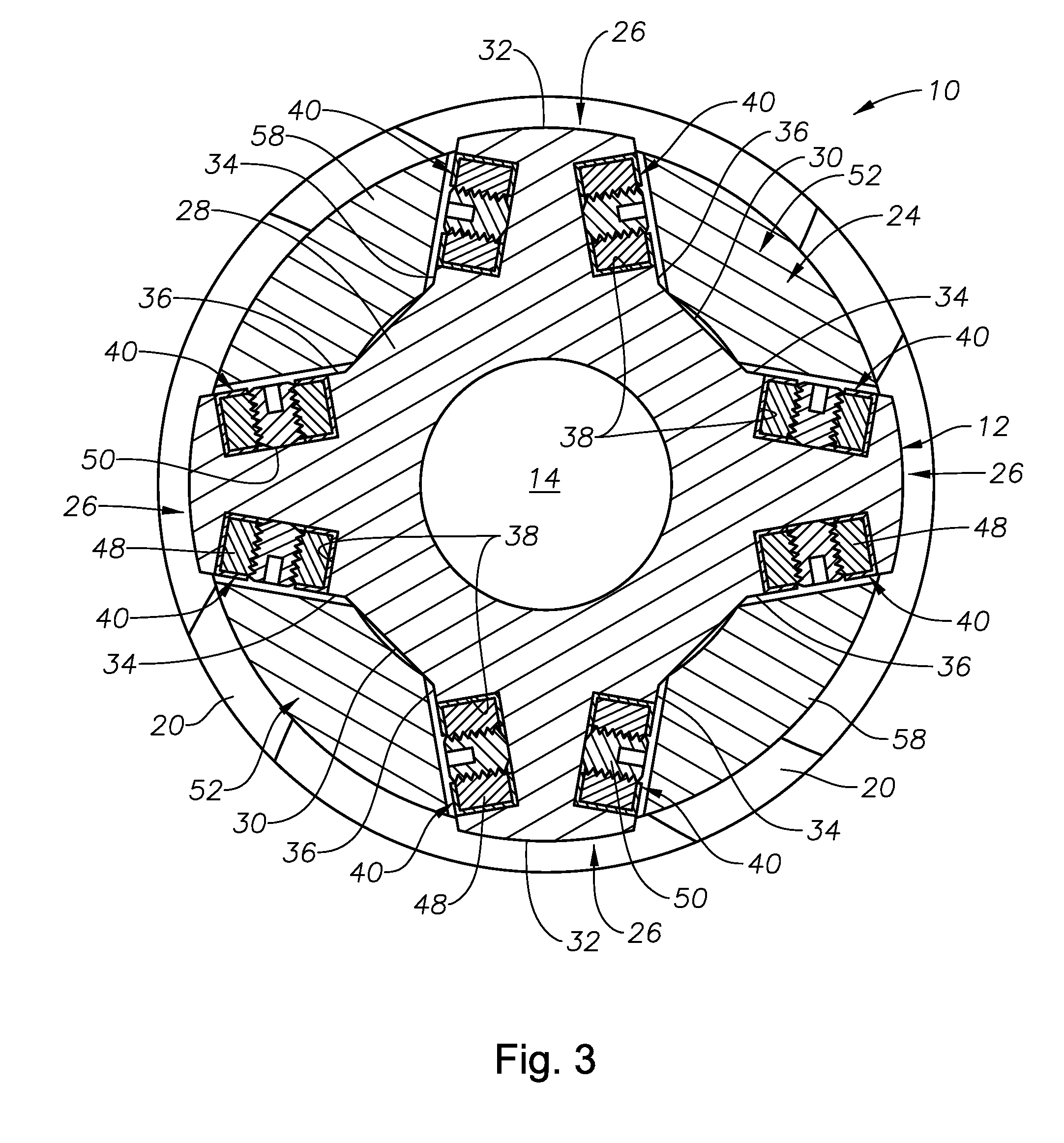

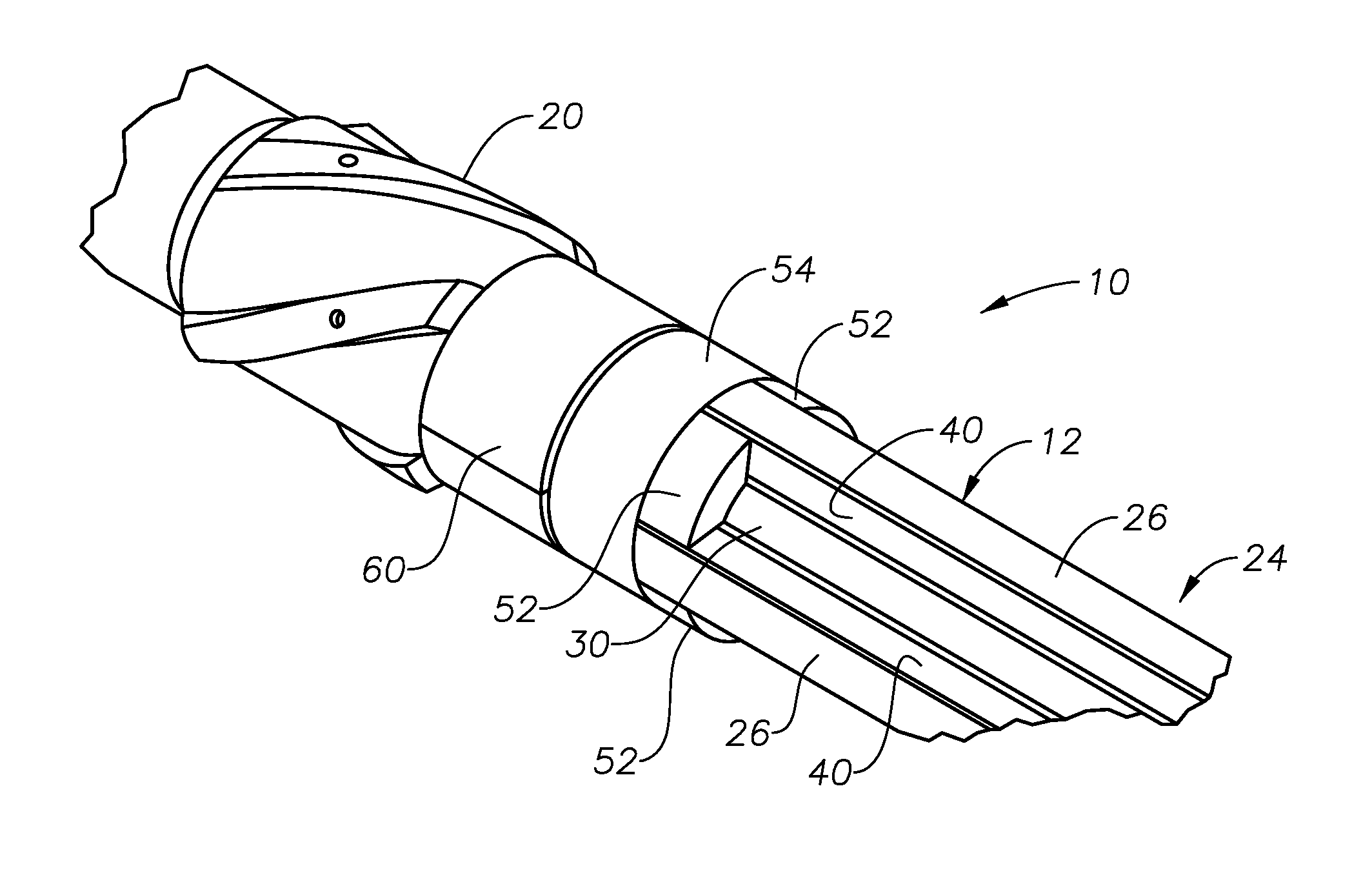

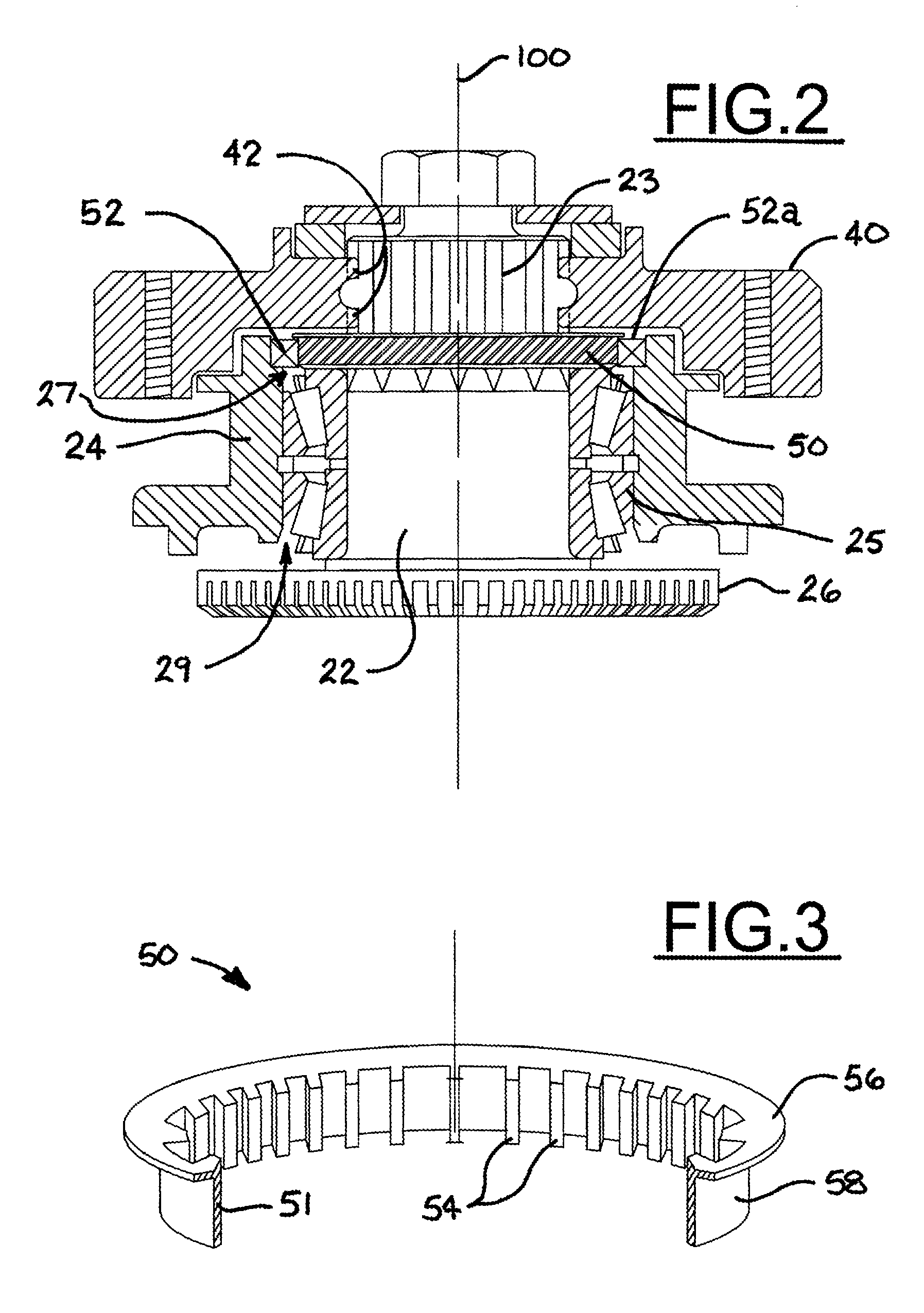

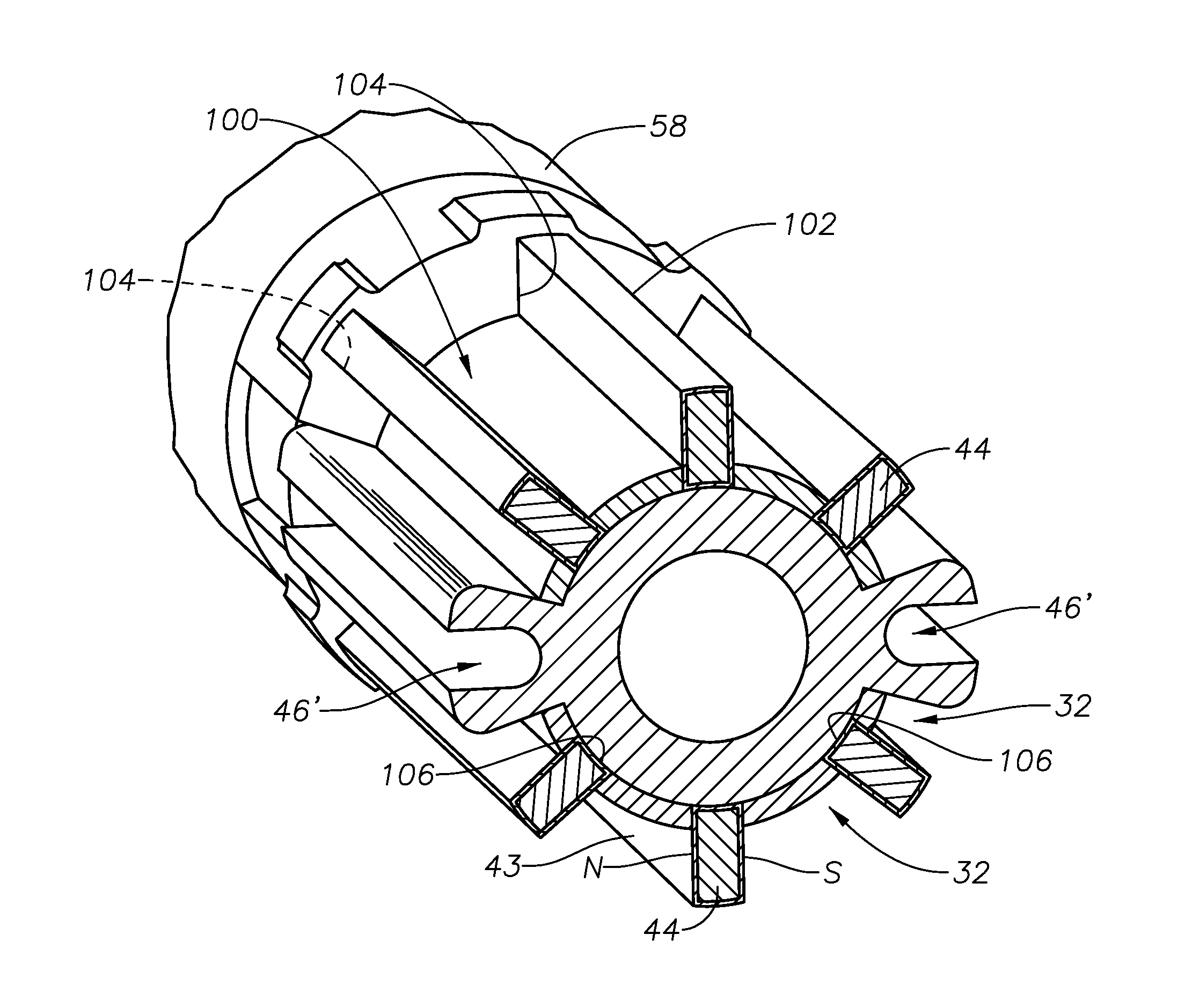

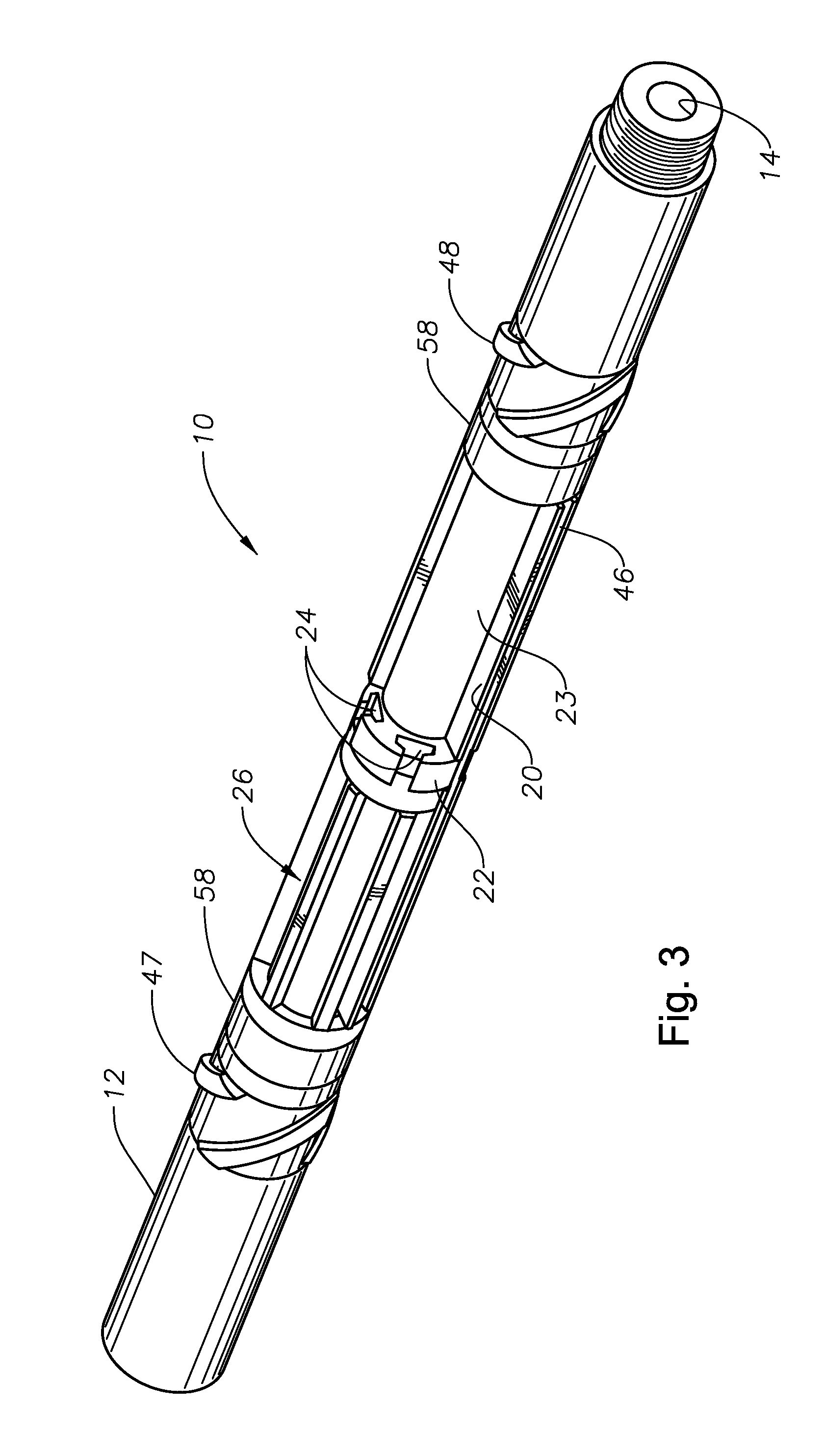

Magnetic Retrieval Apparatus and Method for Retaining Magnets on a Downhole Magnetic Retrieval Apparatus

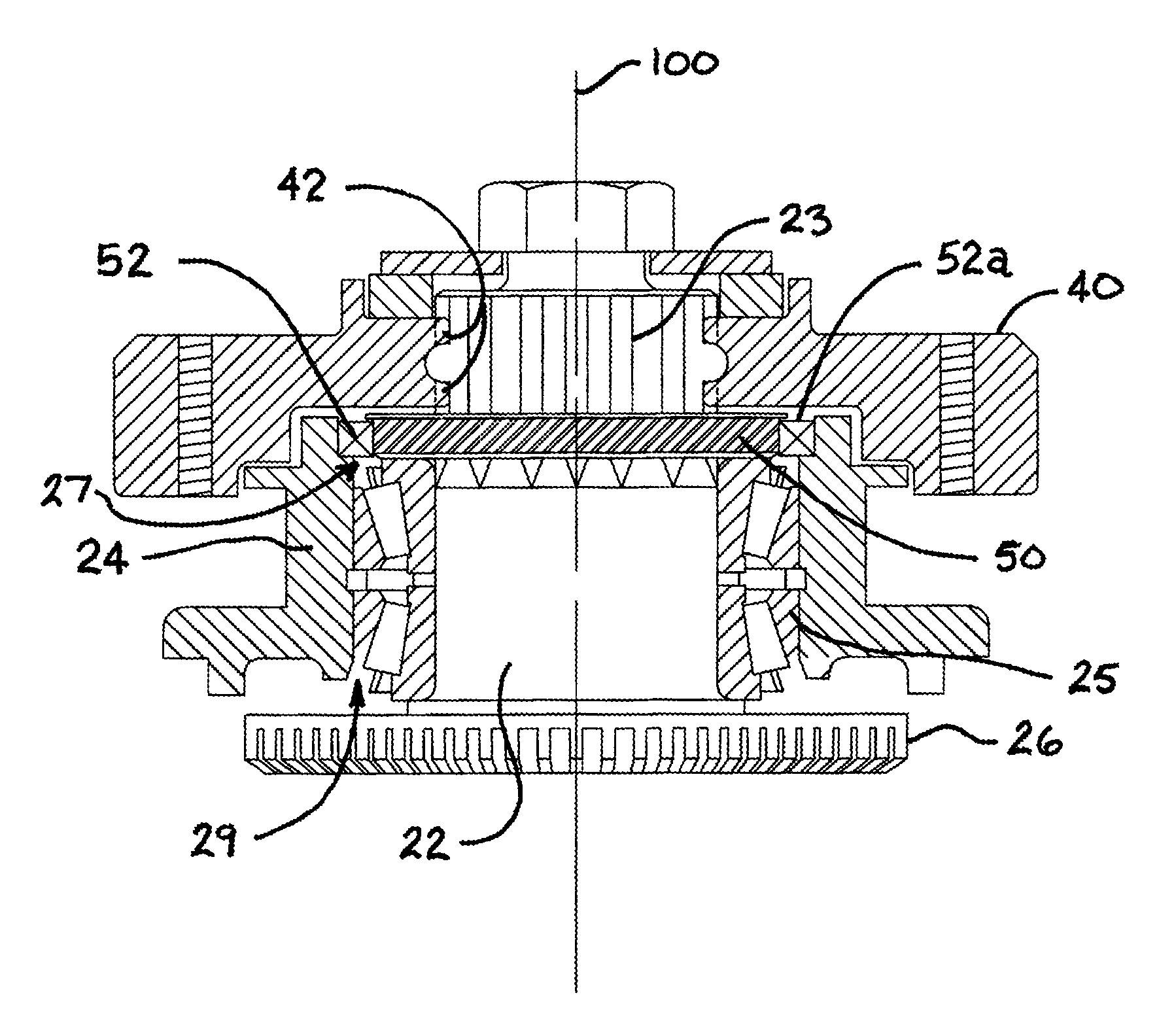

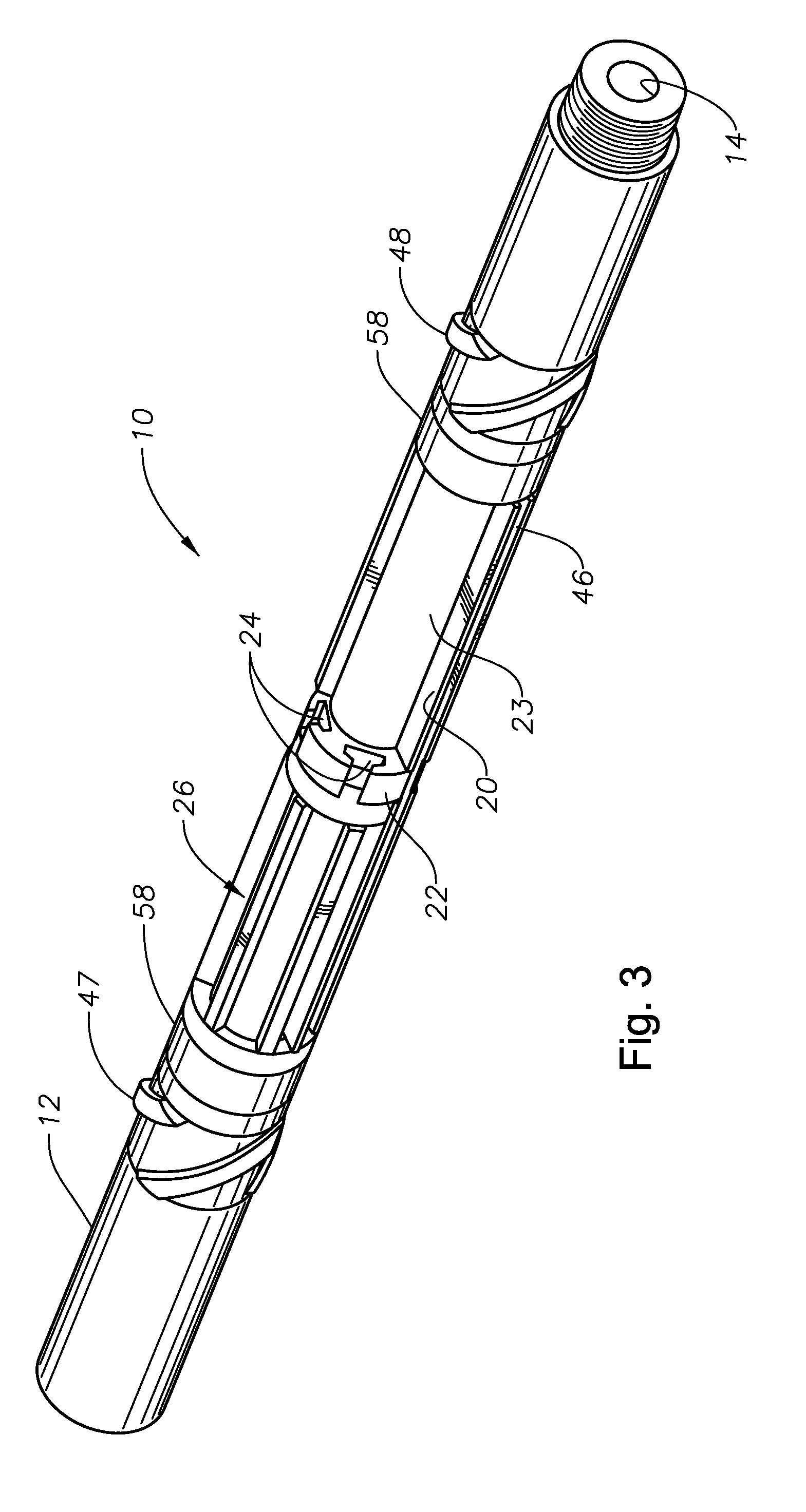

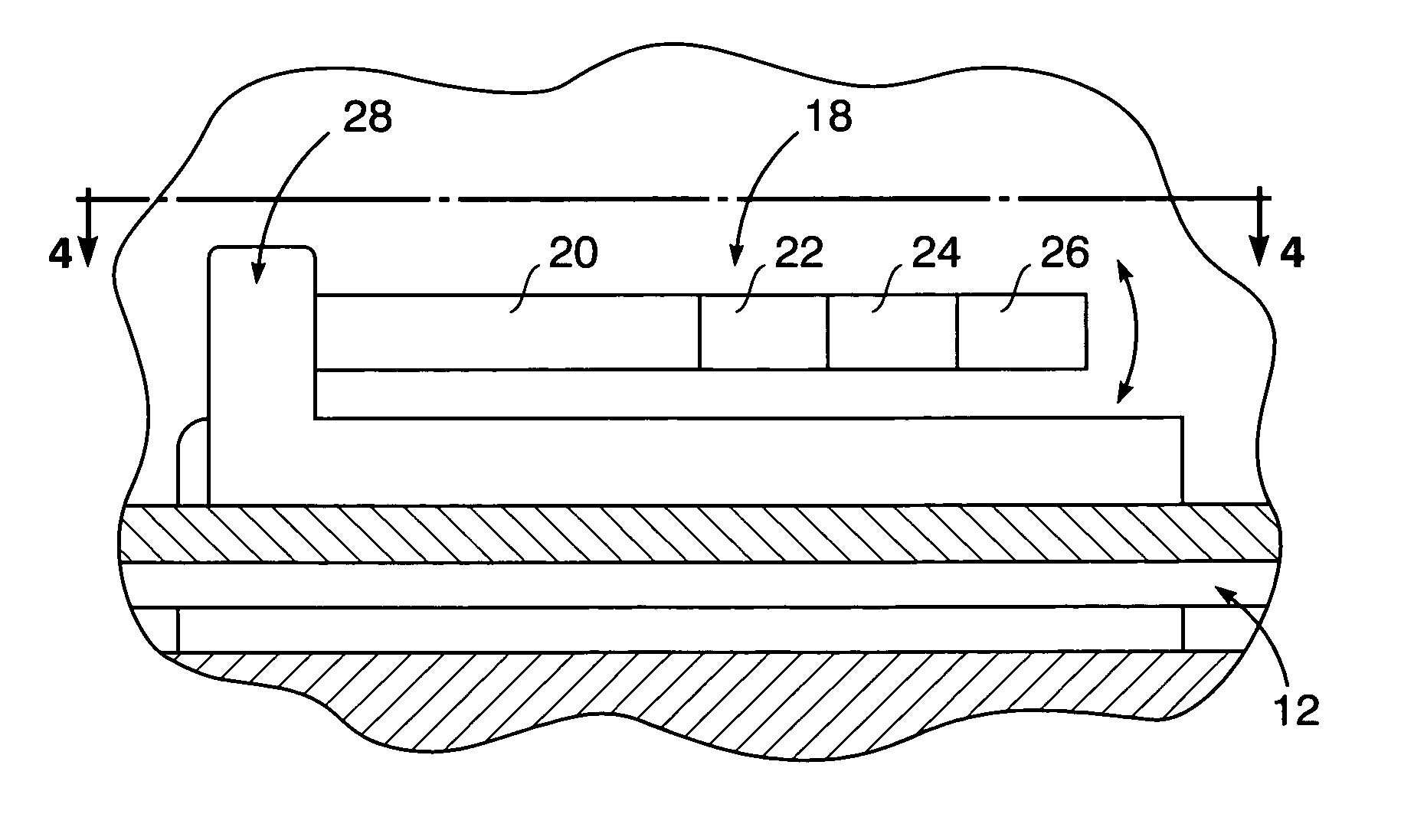

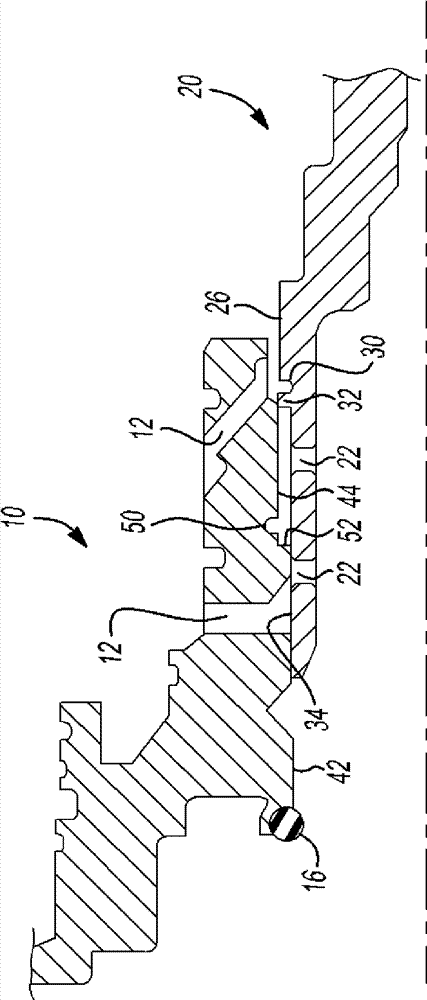

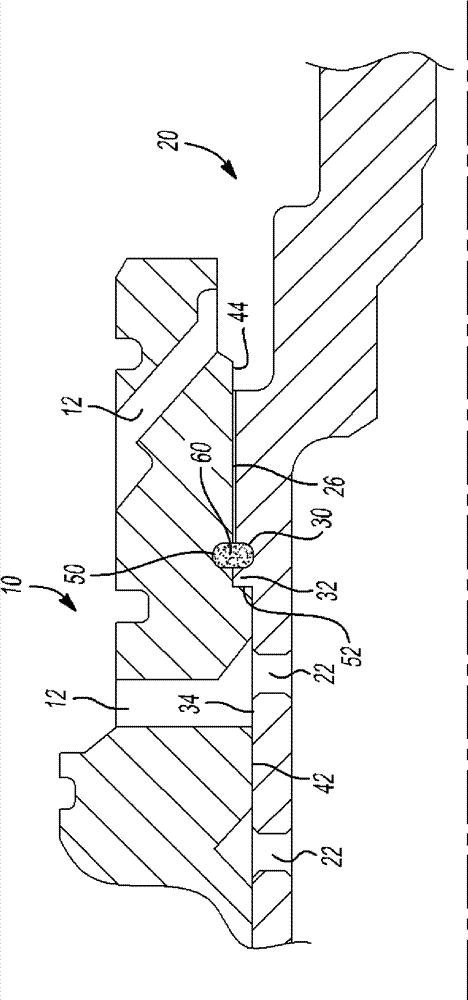

Magnetic retrieval tools for use in a wellbore or other tubular member to remove metallic debris. A magnetic retrieval tool includes a tool body having a central shaft with a plurality of ribs that project radially outwardly therefrom. The ribs present lateral sides that have recesses formed therein. Magnet bars are retained within the recesses by wedge members and retaining rings. The magnet bars include a hollow protective housing that encloses a plurality of magnets. Retaining plugs are used to secure the magnets within the housing.

Owner:BAKER HUGHES INC

Magnetic retrieval apparatus and method for retaining magnets on a downhole magnetic retrieval apparatus

Magnetic retrieval tools for use in a wellbore or other tubular member to remove metallic debris. A magnetic retrieval tool includes a tool body having a central shaft with a plurality of ribs that project radially outwardly therefrom. The ribs present lateral sides that have recesses formed therein. Magnet bars are retained within the recesses by wedge members and retaining rings. The magnet bars include a hollow protective housing that encloses a plurality of magnets. Retaining plugs are used to secure the magnets within the housing.

Owner:BAKER HUGHES INC

Seal hub for protection of seal and bearing from metal fragments due to shearing of a shock device

ActiveUS7988380B2Avoid enteringEasily incorporated into drivelineMowersCouplings with disconnecting safety membersDrive shaftEngineering

Owner:BLUE LEAF I P INC

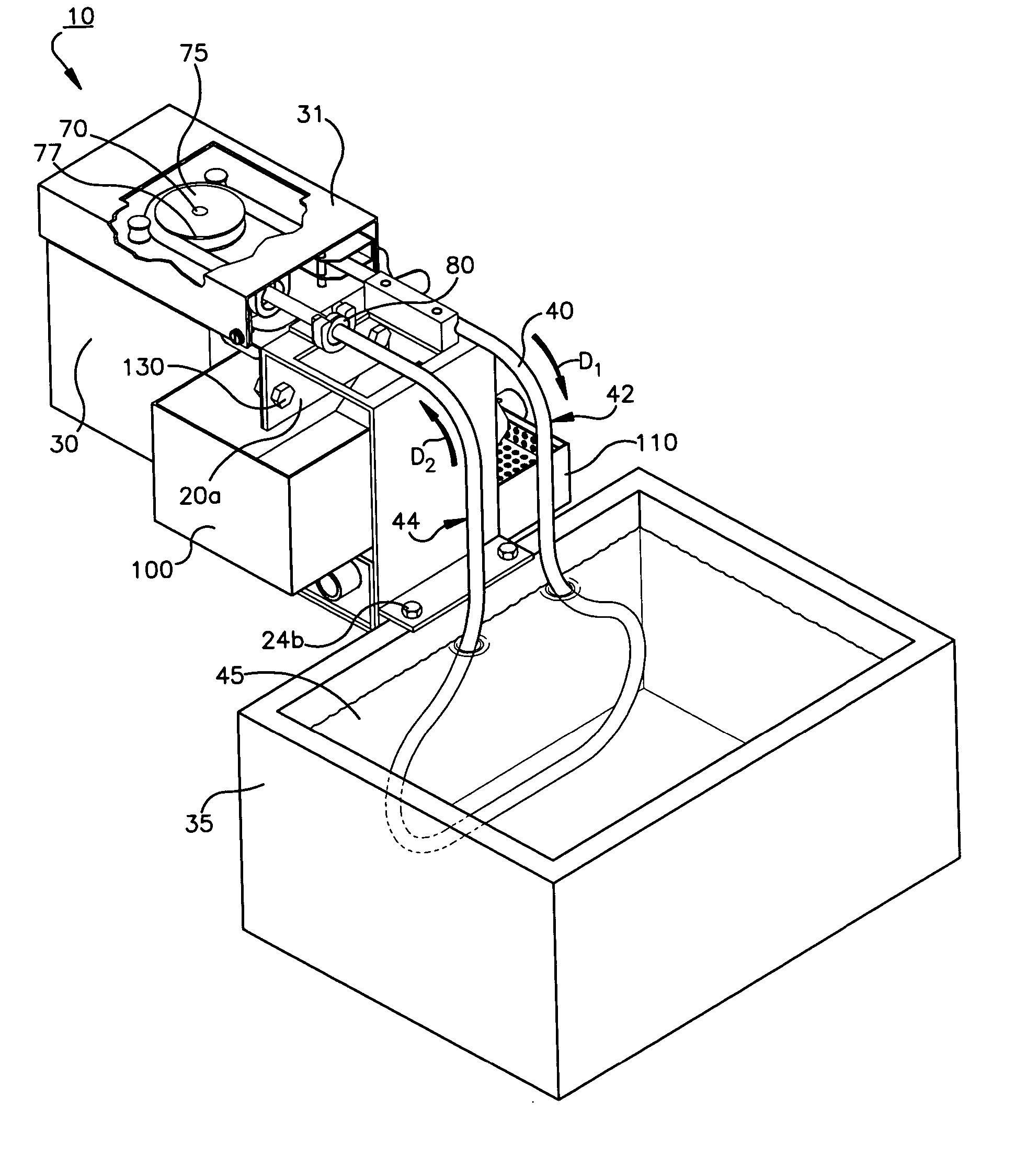

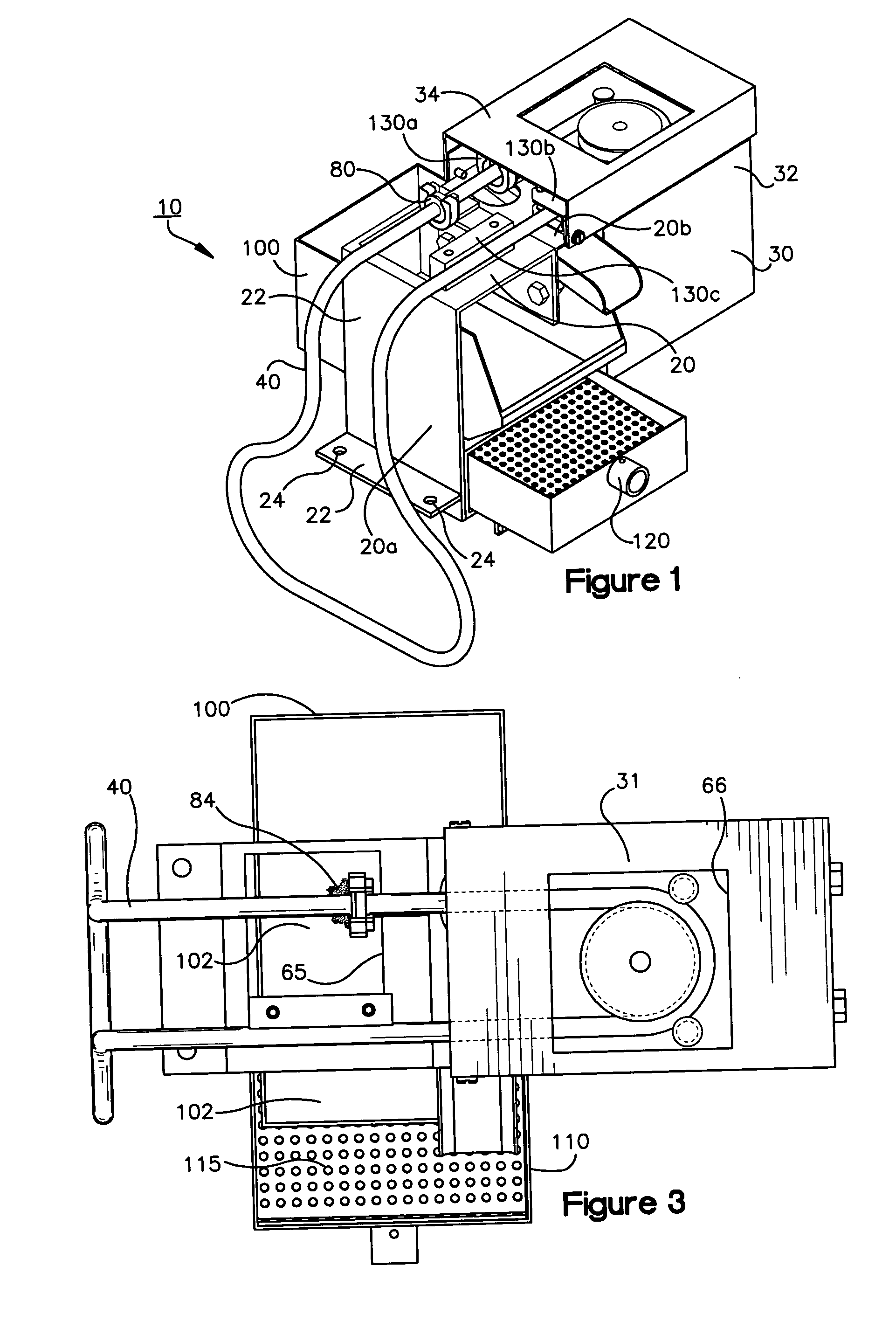

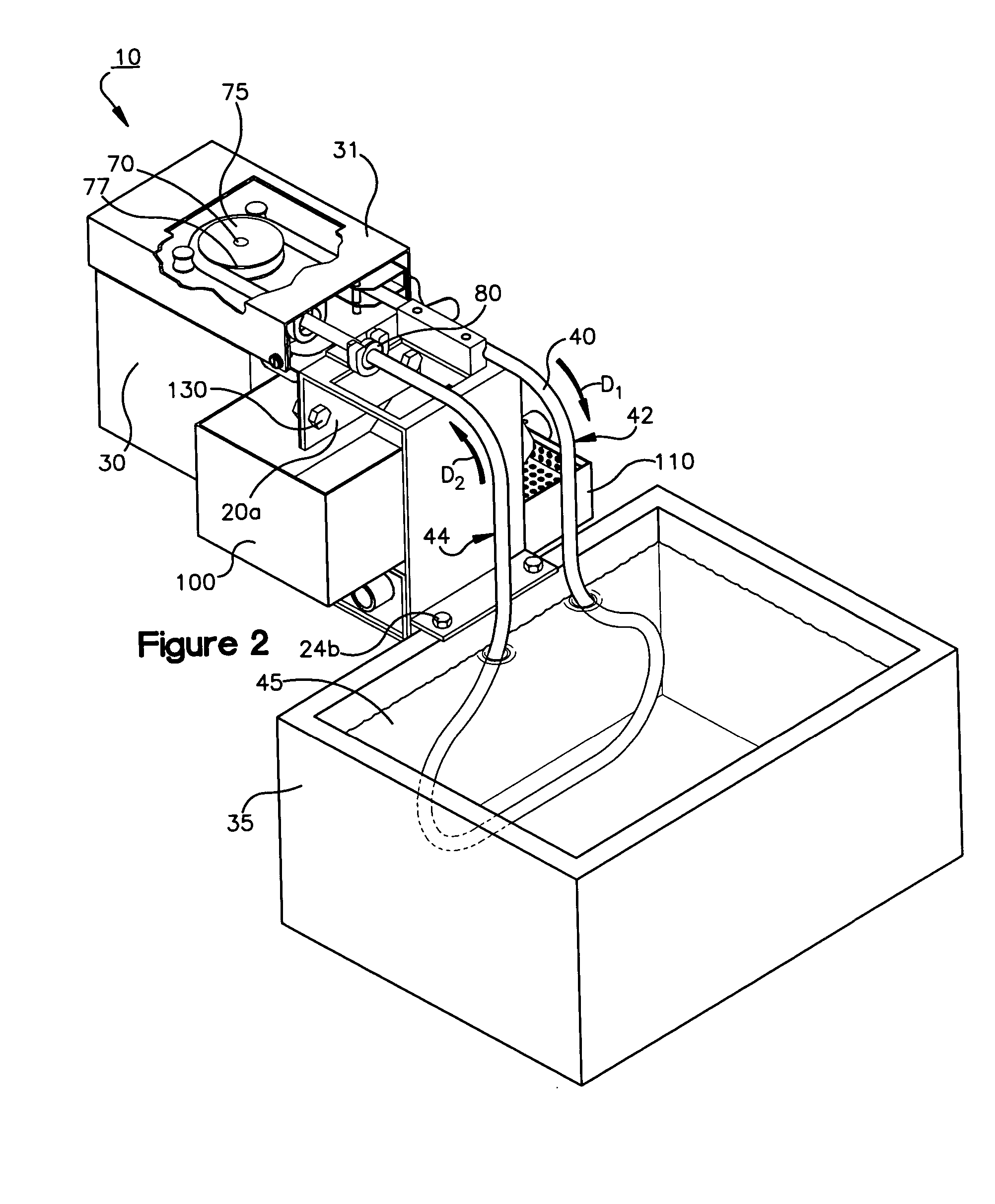

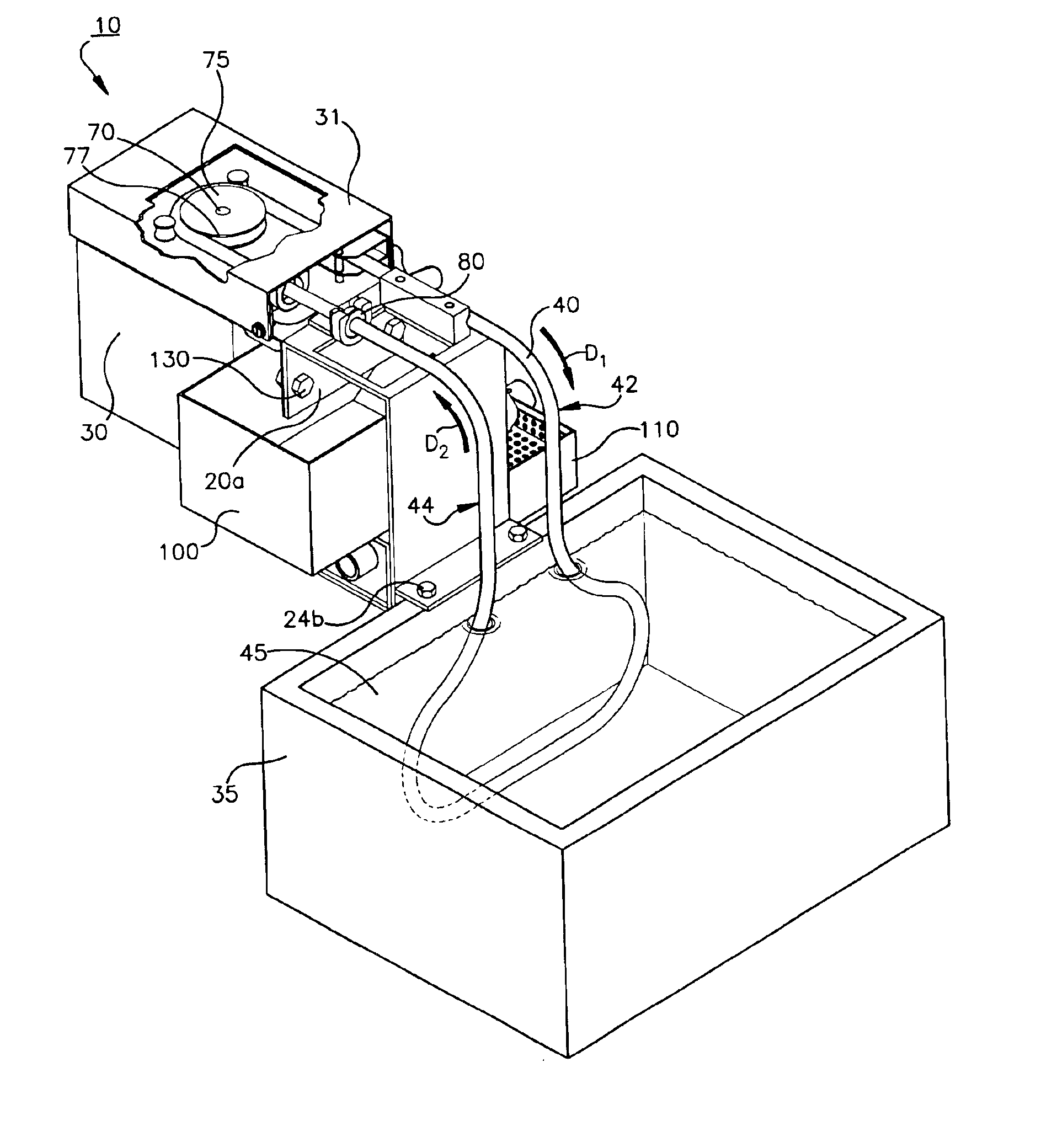

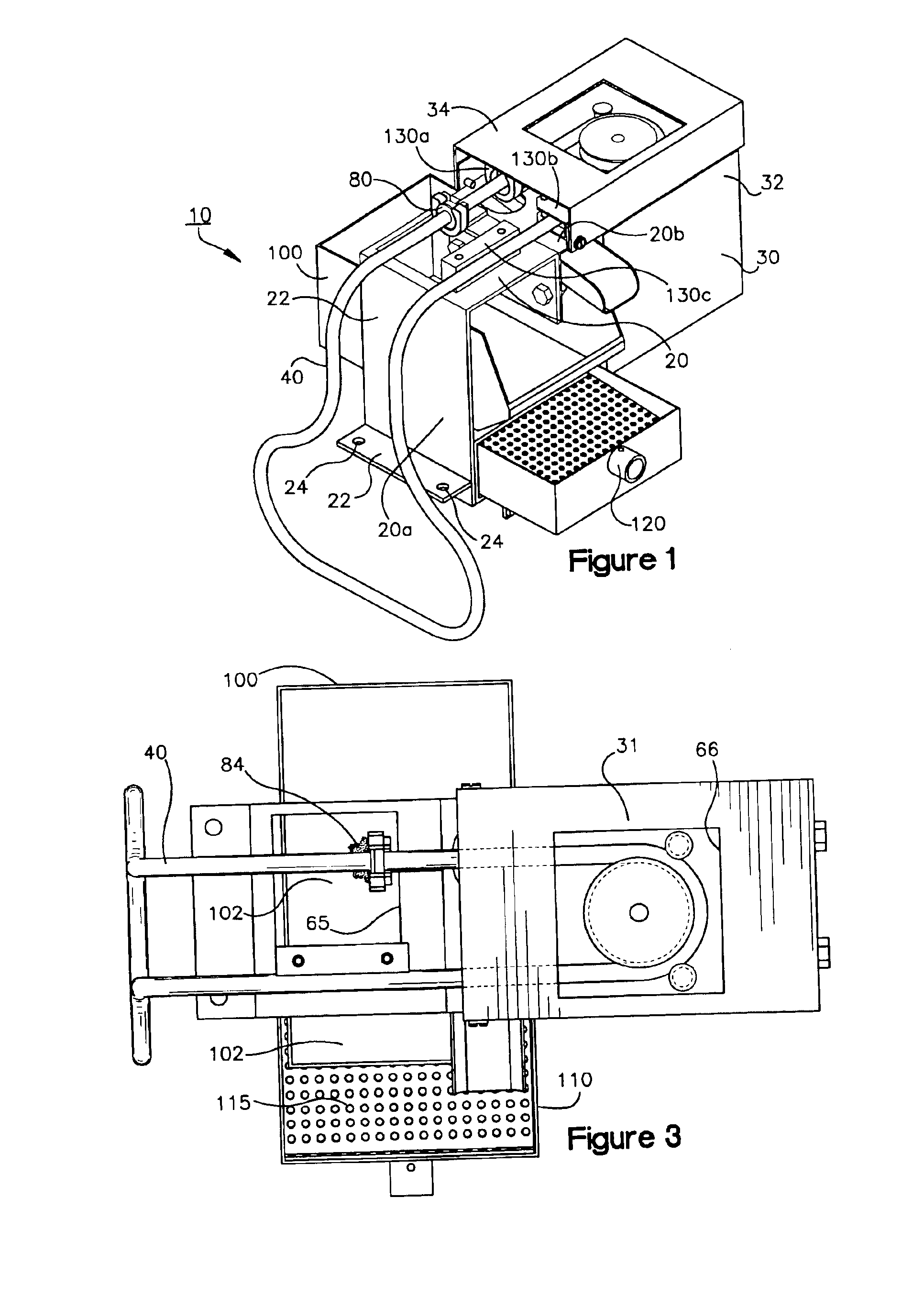

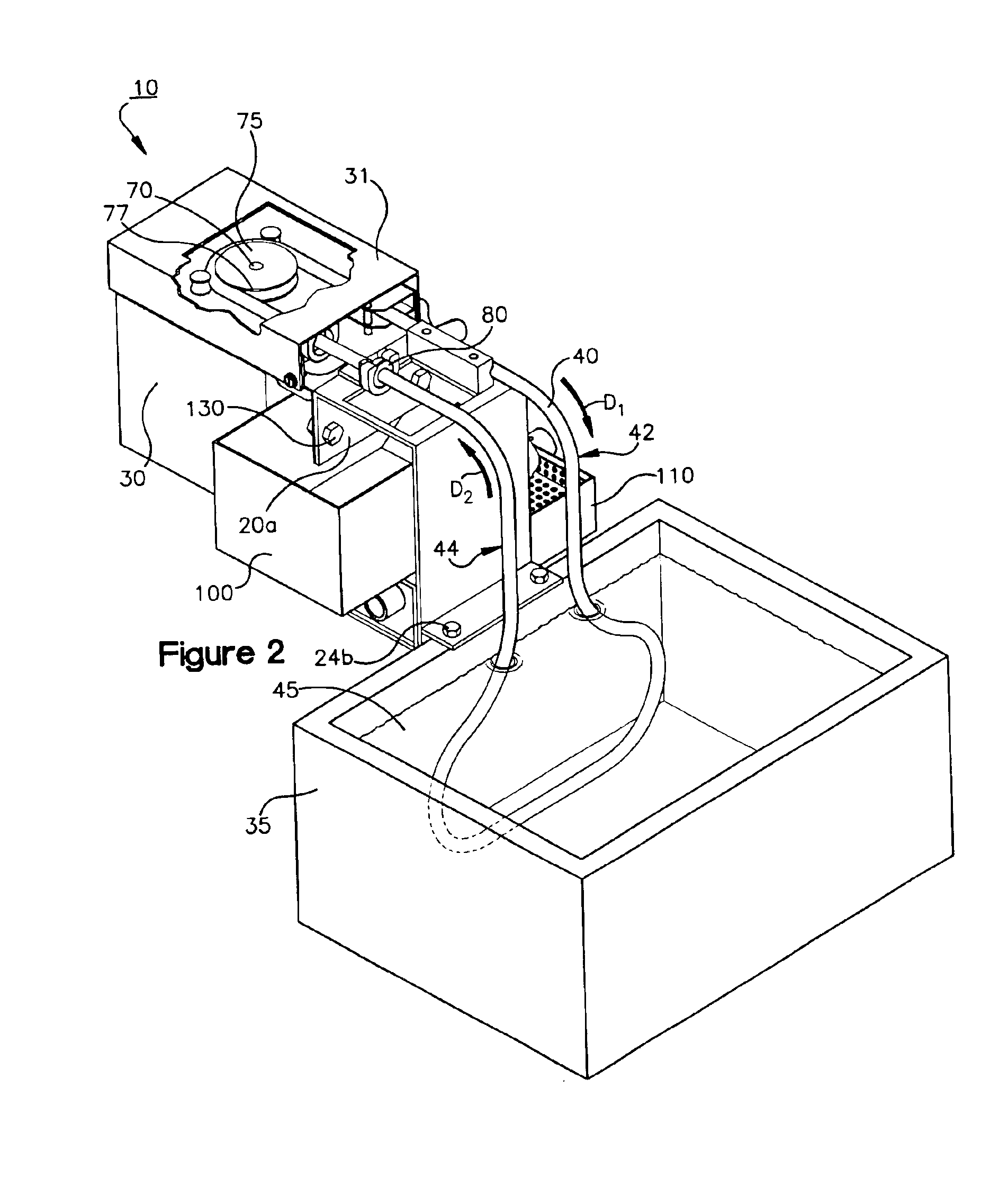

Oil and chip skimmer

InactiveUS20050045542A1Improve performanceFatty/oily/floating substances removal devicesWater cleaningEngineeringMachine tool

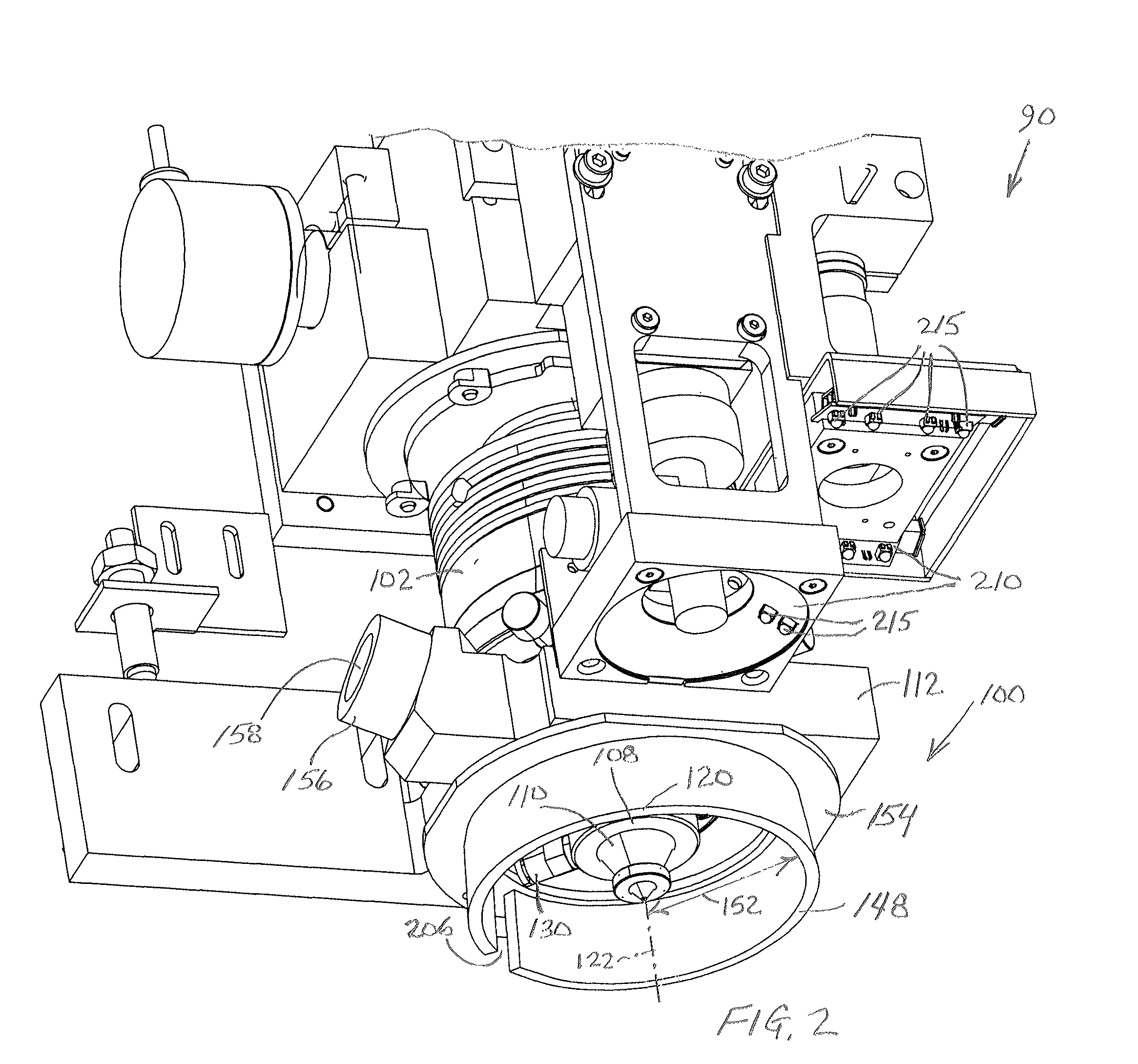

A skimmer for removing oil and paramagnetic chips from a contaminated body of machine tool coolant. The skimmer includes a frame and an endless tube partially trained within the frame that defines a travel path. The path of the tube includes a first section within the body of coolant and a second section out of the body of coolant. The skimmer further includes a magnet disposed within the tube, a drive system mounted to the frame and operatively coupled to the tube to power travel of the tube, and a wiper connected to the frame at a position along the travel path. The wiper is advantageously positioned adjacent to the tube such that the wiper removes oil and metal chips carried by the tube. A receptacle is included that delineates a collection space positioned below the wiper to receive oil and metal chips.

Owner:ABANAKI CORP

Magnetic metal extractor from drilling fluid

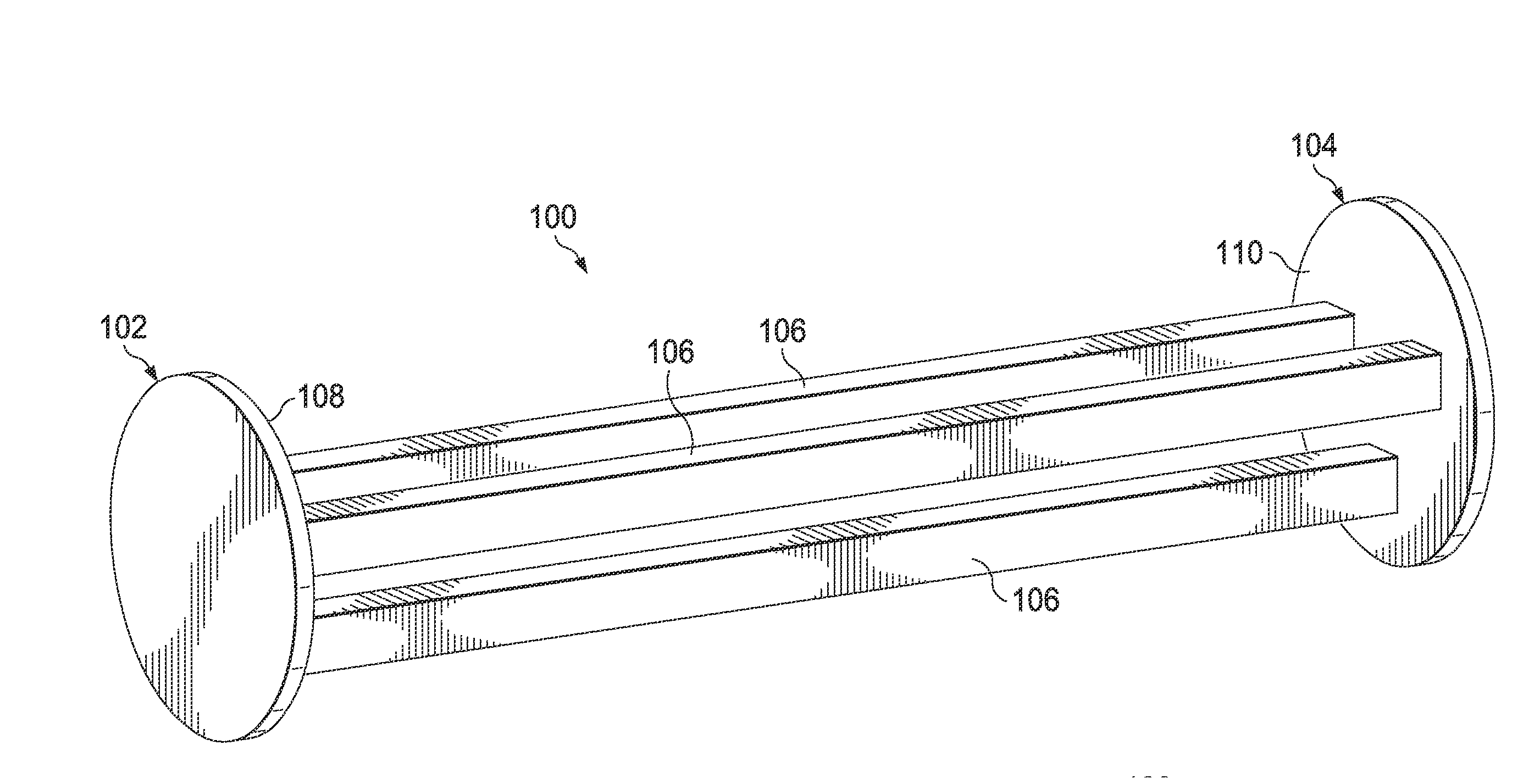

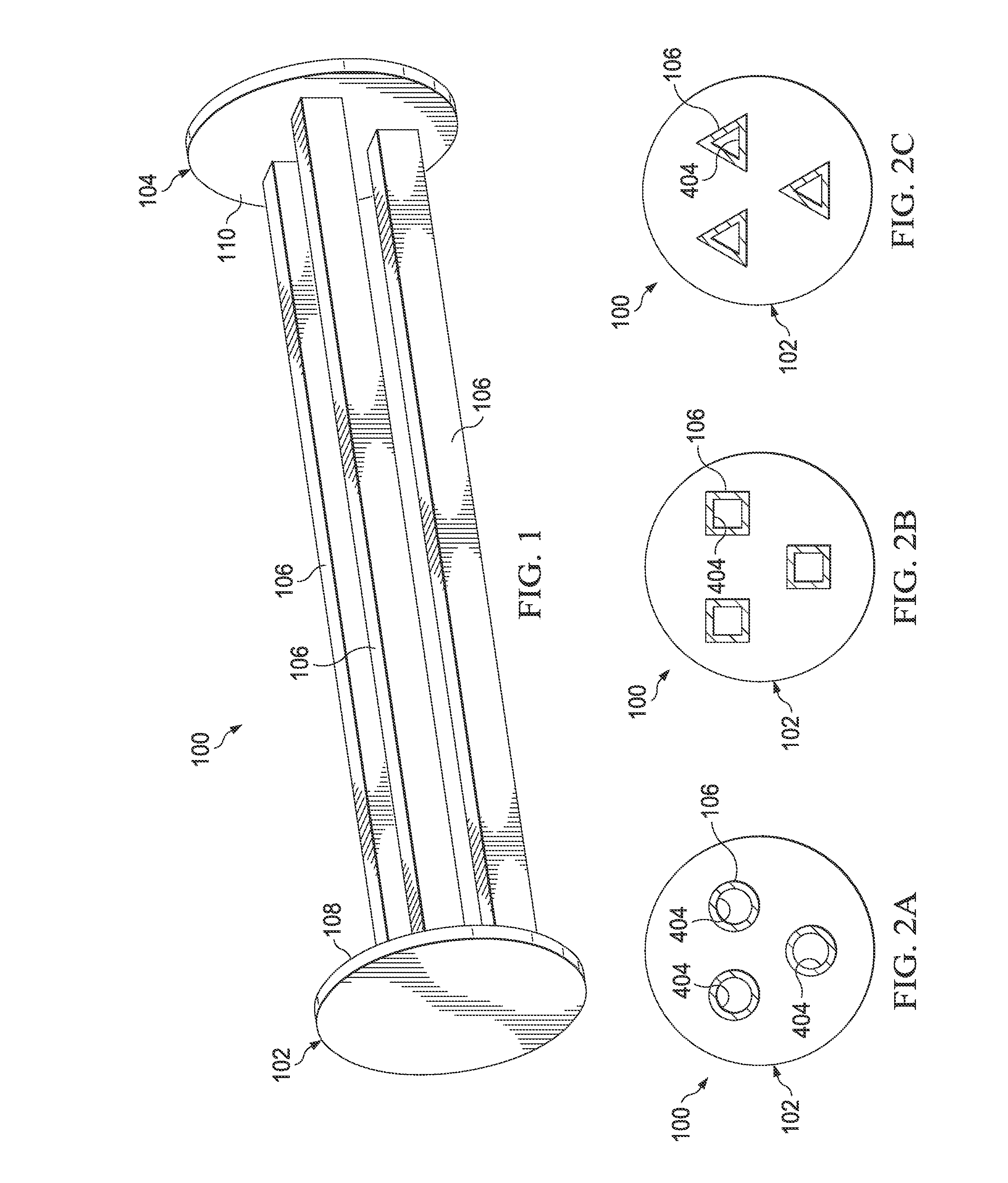

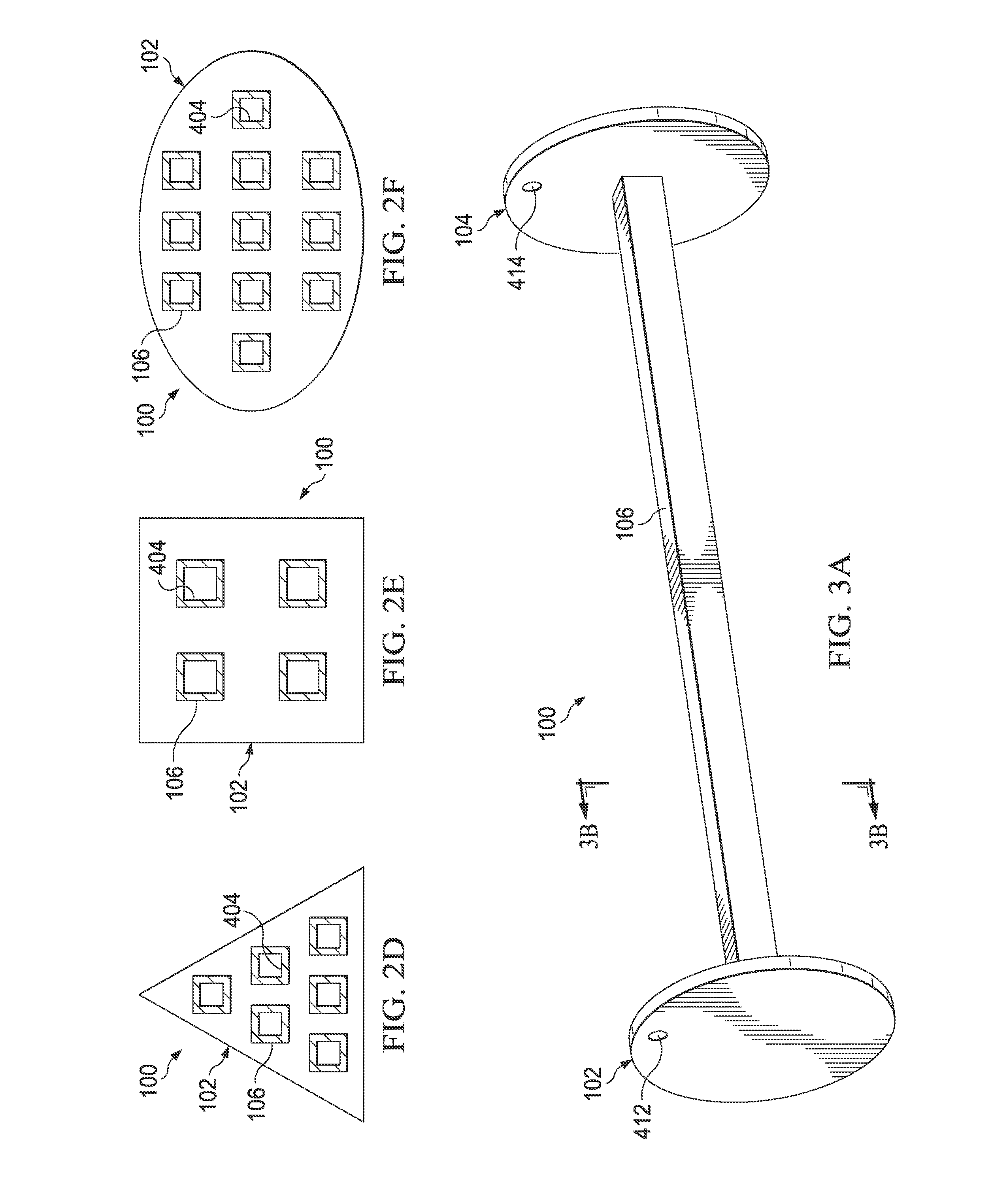

An exemplary apparatus for removing metallic debris from a drilling fluid is provided that includes a first end member, a second end member, and one or more elongated members extending between the first end member and the second end member. The elongated members may each include at least one magnet. Drilling fluid may flow past the elongated members, which may be located in a drilling fluid cleansing machine such as a shale shaker, so that metallic debris in the drilling fluid, if any exist, are attracted by the magnets in the elongated members. Some of the metallic debris may adhere to an exterior surface of the elongated members so that the metallic debris are removed from the drilling fluid. The metallic debris can then be removed from the exterior surface of the elongated members.

Owner:FLO RITE FLUIDS

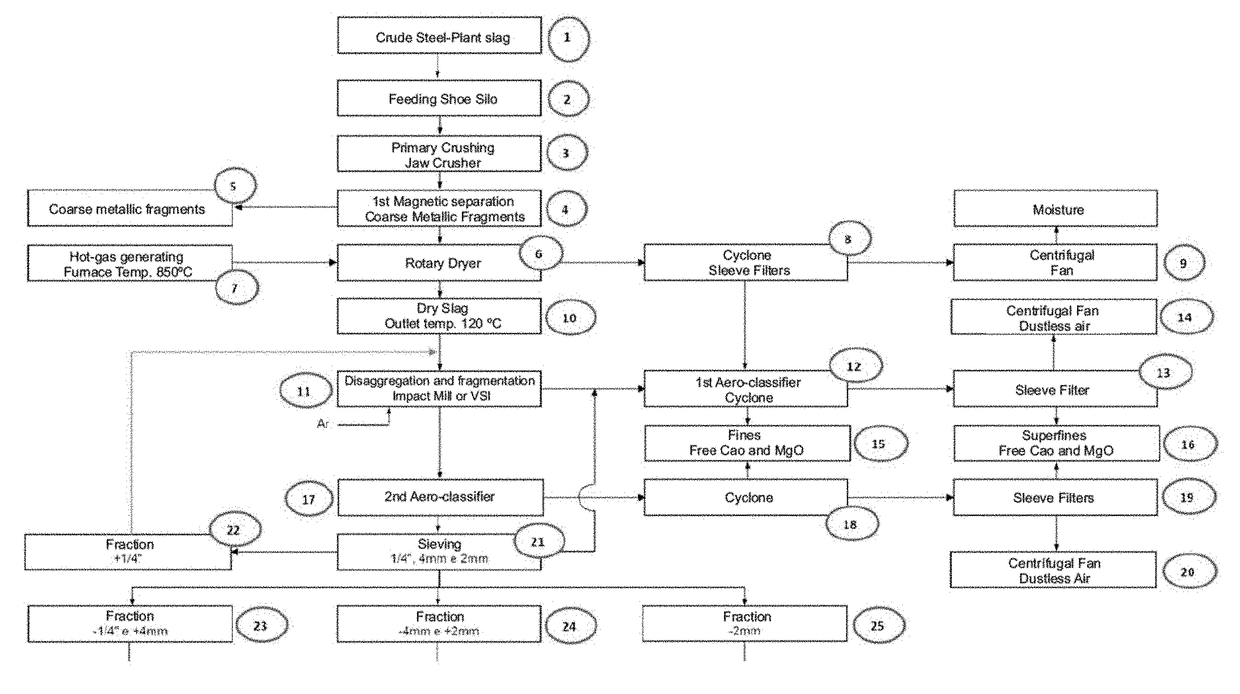

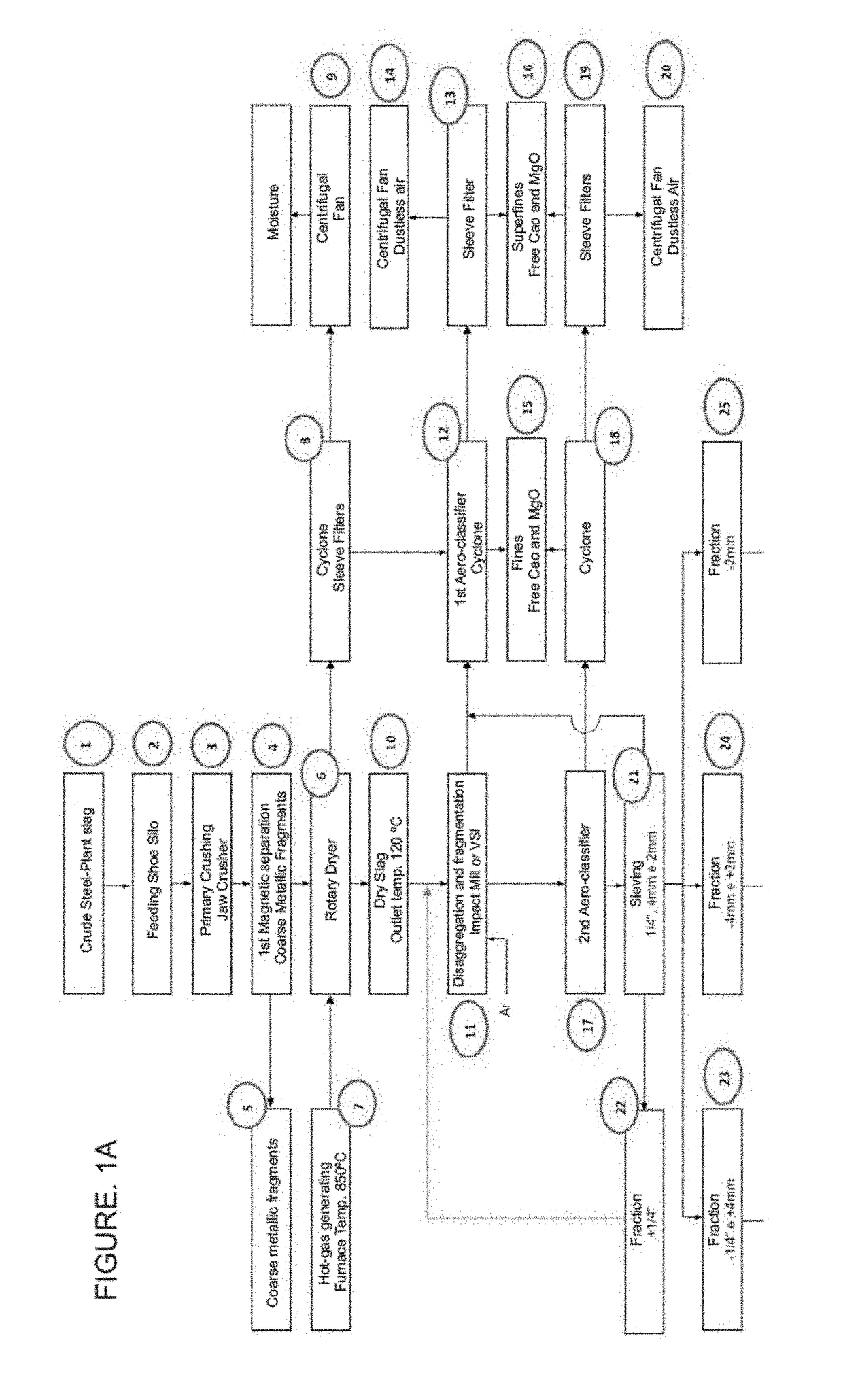

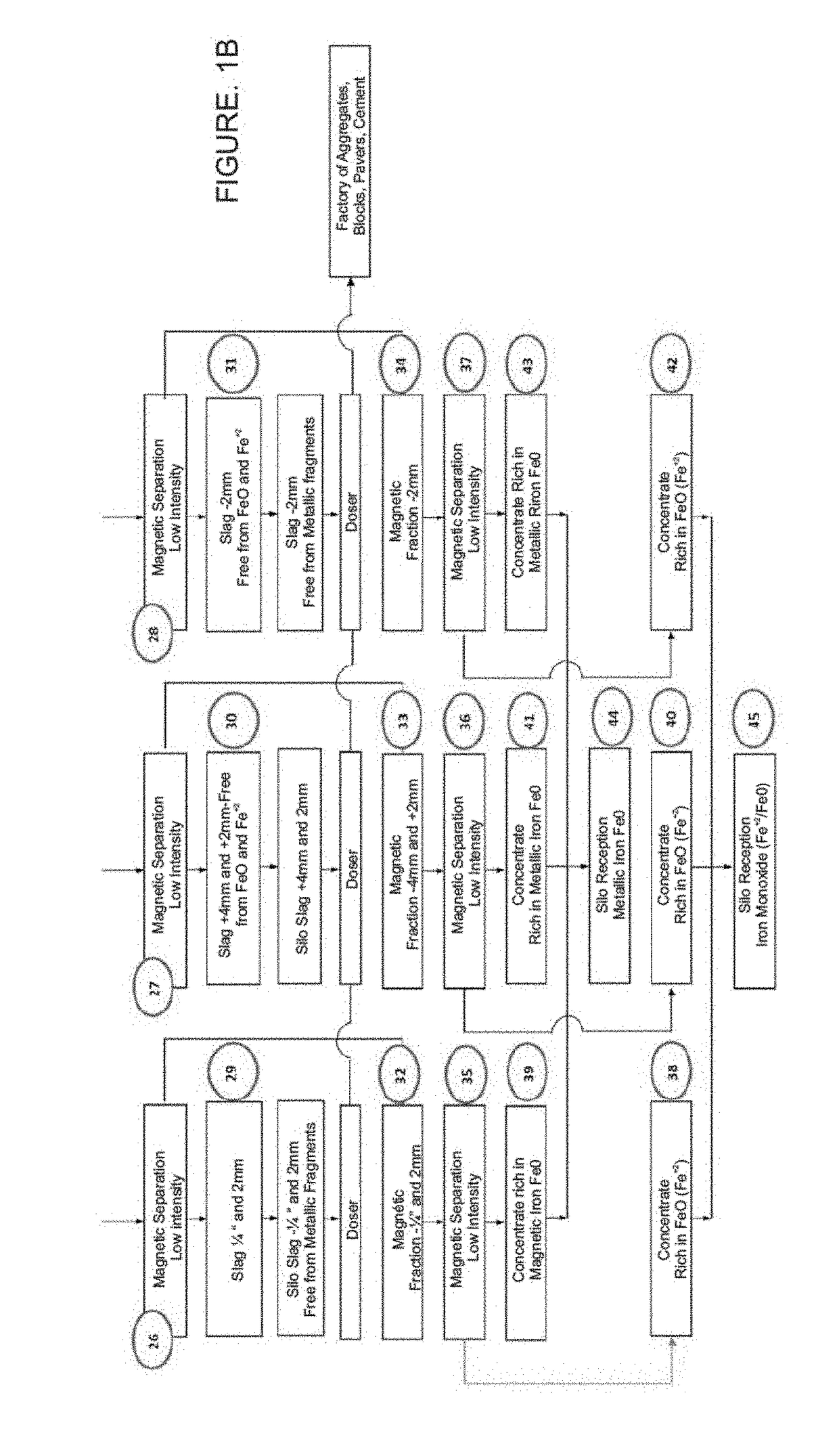

Process and system for eliminating the potential for ld and eaf steel slag expansion

The present invention relates to a process and to a system for eliminating the expandability of steel-plant slag, which comprises a primary crusher (3) to reduce the fragments according to their granulometry; a magnetic separator (4) to remove metallic fragments bigger than a determined granulometry (5); a rotary dryer (6) to dry slag free from bigger metallic fragments; an impact mill (11) to disaggregate and fragment slag particles that are bigger than a predetermined granulometry; a classifier (12) for aero-classification and drag of fine and superfine particles; a cooler (17) for cooling slag particles bigger than a predetermined granulometry by means of heat exchange and removal of the fine and superfine particles that were not collected by the impact mill (11); a vibrating sieve (21) provided with two or more decks (23, 24, and 25) with screens of predetermined sizes; low-intensity magnetic separators (26, 27 and 28), with generation of non-magnetic slag fractions free from metallic iron and from iron monoxide, and of magnetic fractions composed by metallic iron and iron monoxide; and low-intensity magnetic separators (35, 36 and 37) to reprocess the magnetic fractions with generation of concentrate with high metallic iron contents and a product with high concentration of iron monoxide.

Owner:ROLTH DO BRASIL IND COMML E SERVICOS LTDA

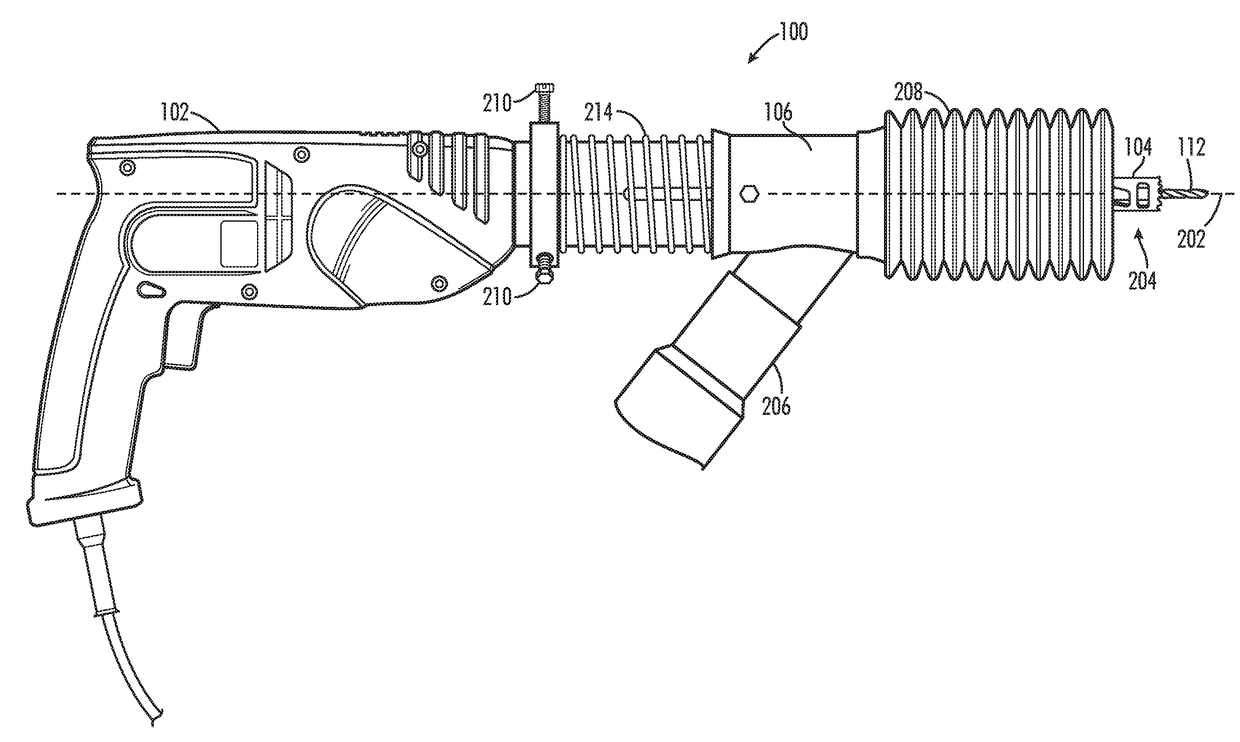

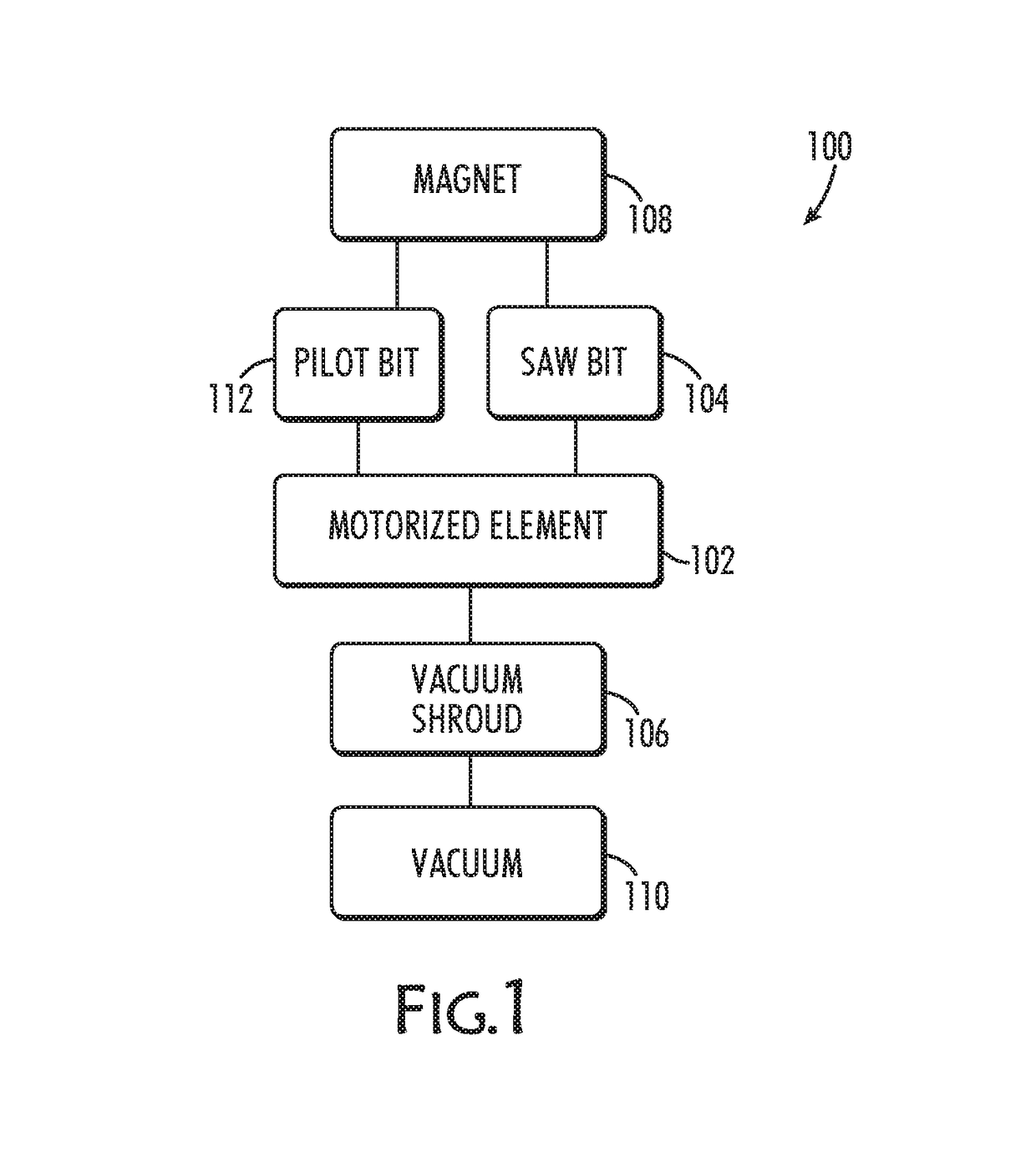

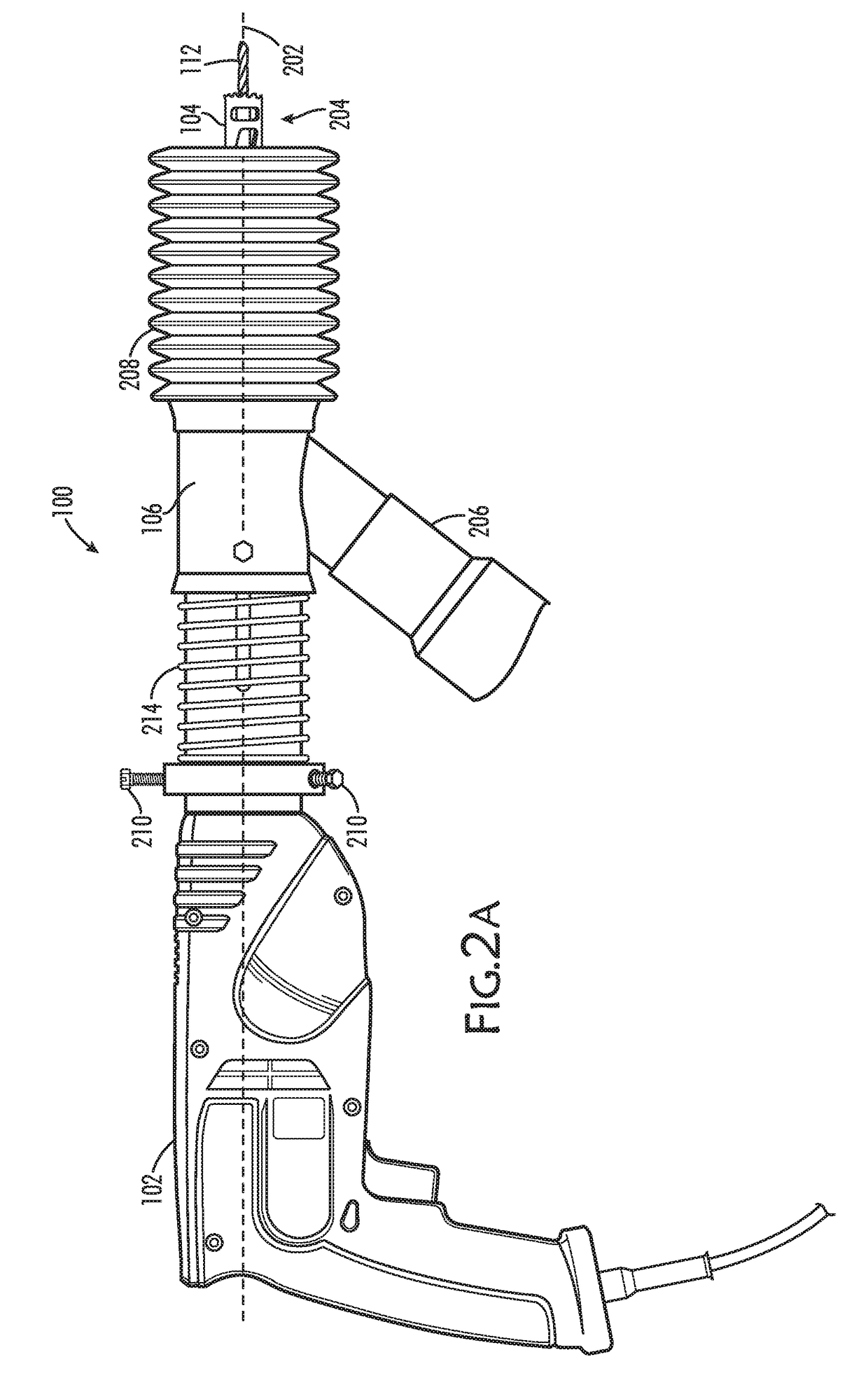

Drilling apparatus and methods of using same

InactiveUS20170368655A1Metal working apparatusPortable drilling machinesWell drillingClassical mechanics

A drilling apparatus comprising: at least one bit; a vacuum shroud, including a compressible boot, disposed around a longitudinal axis of the apparatus and configured to be in operative communication with a vacuum attachment port; and at least one magnetic element disposed near a distal end of the apparatus and configured to attract metallic debris resulting from drilling apparatus operation.

Owner:THE BOEING CO

Magnetic sweeper

A magnetic sweeper configured to collect magnetic metal debris, such as nails, screws, sheet metal fragments, staples, rivets and the like from a surface, and to permit easy removal of the collected debris from the sweeper is disclosed. The sweeper comprises a non-metallic body, a permanent magnet disposed within the body, a non-metallic cover hingably mounted to the underside of the body and an integrated latch configured to removably secure the cover to the body. The sweeper is configured to removably engage a handle for controlling the sweeper, and in another embodiment, an extendable, telescoping extender may be connected between the coupler and the handle to permit the sweeper to be used in a wide variety of locations. Preferably, the sweeper body is configured to swivel upon application of torque to the handle. In use, the sweeper is passed over metallic debris using the handle to guide the body. As the body passes over such debris, the magnet attracts the debris and holds it against the outer surface of the cover. When debris collection is complete, the cover is unlatched from the body, and swung outwardly from the body, thereby displacing the collected debris to a location outside of the magnetic field of the magnet and permitting the debris to fall away from the cover.

Owner:STEELWORKS HARDWARE L L C

Dual-Pole Magnetic Attraction Downhole Magnetic Retrieval Apparatus

A magnetic retrieval tool used for collecting metallic debris and material from within a wellbore or other surrounding downhole tubular. The tool includes a tool mandrel with a removable insert which contains one or more magnets. The insert is formed such that both the north and south magnetic poles of the one or more magnets are able to attract metallic debris.

Owner:BAKER HUGHES INC

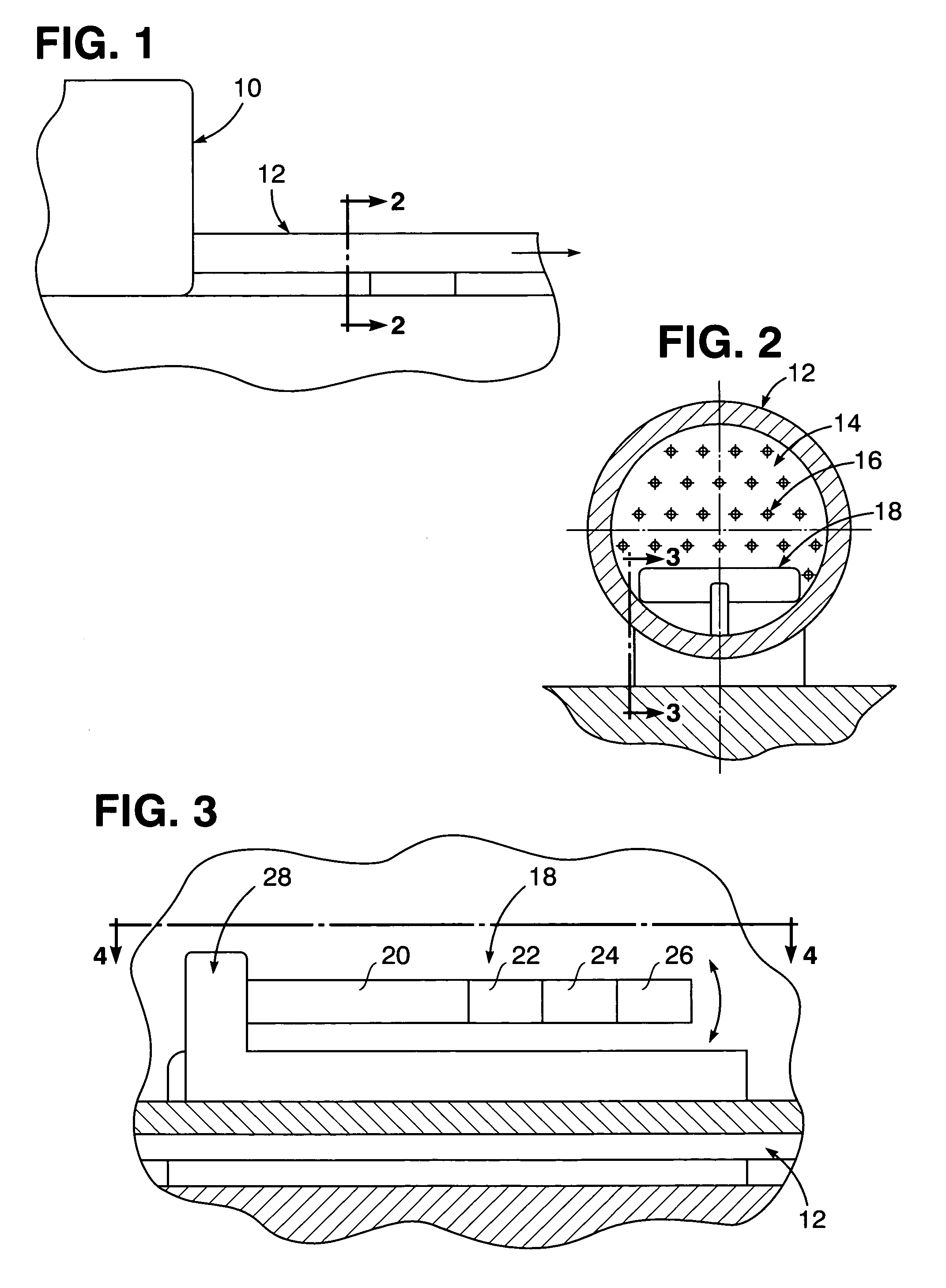

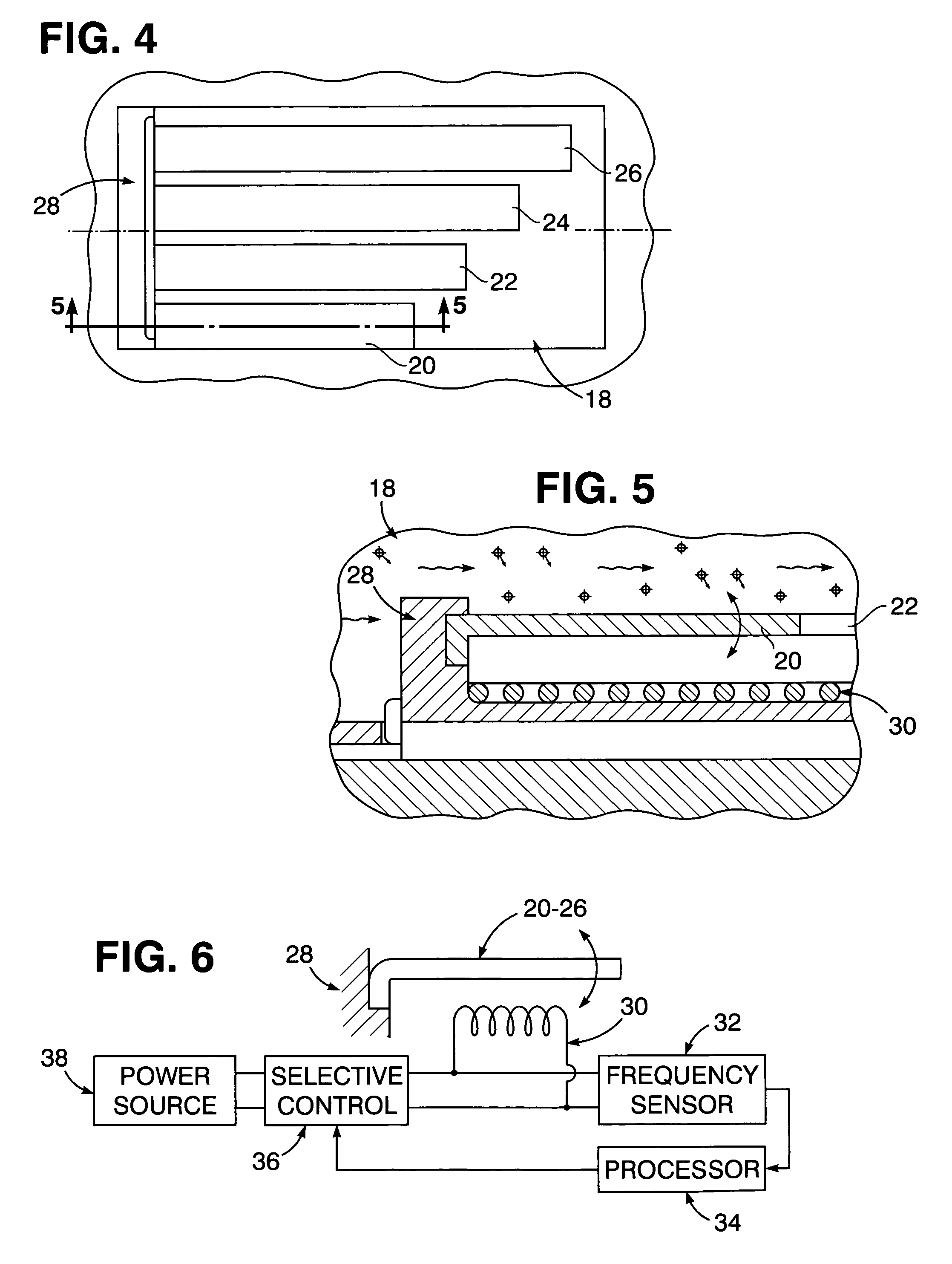

System for measurement of metallic debris in fluid

InactiveUS7068027B1Magnetic property measurementsMaterial magnetic variablesResonanceParticle physics

A debris sensor arrangement is positioned within an enclosed body of fluid for detecting the presence of metallic debris particles therein. Debris detection involves exposure of cantilever beams to the fluid when magnetized within an electromagnetic field to attract the metallic debris particles thereon and induce vibratory motion thereof at a resonant frequency varied by changes in the density of the debris particles magnetically held thereon. Measurement of the resonance frequency reflecting the density of the debris particles within the fluid being tested thereby monitors the corresponding wear of machinery reflected by the debris density.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Oil and chip skimmer

InactiveUS6887387B2Improve performanceWater cleaningFatty/oily/floating substances removal devicesEngineeringMachine tool

A skimmer for removing oil and paramagnetic chips from a contaminated body of machine tool coolant. The skimmer includes a frame and an endless tube partially trained within the frame that defines a travel path. The path of the tube includes a first section within the body of coolant and a second section out of the body of coolant. The skimmer further includes a magnet disposed within the tube, a drive system mounted to the frame and operatively coupled to the tube to power travel of the tube, and a wiper connected to the frame at a position along the travel path. The wiper is advantageously positioned adjacent to the tube such that the wiper removes oil and metal chips carried by the tube. A receptacle is includes that delineates a collection space positioned below the wiper to receive oil and metal chips.

Owner:ABANAKI CORP

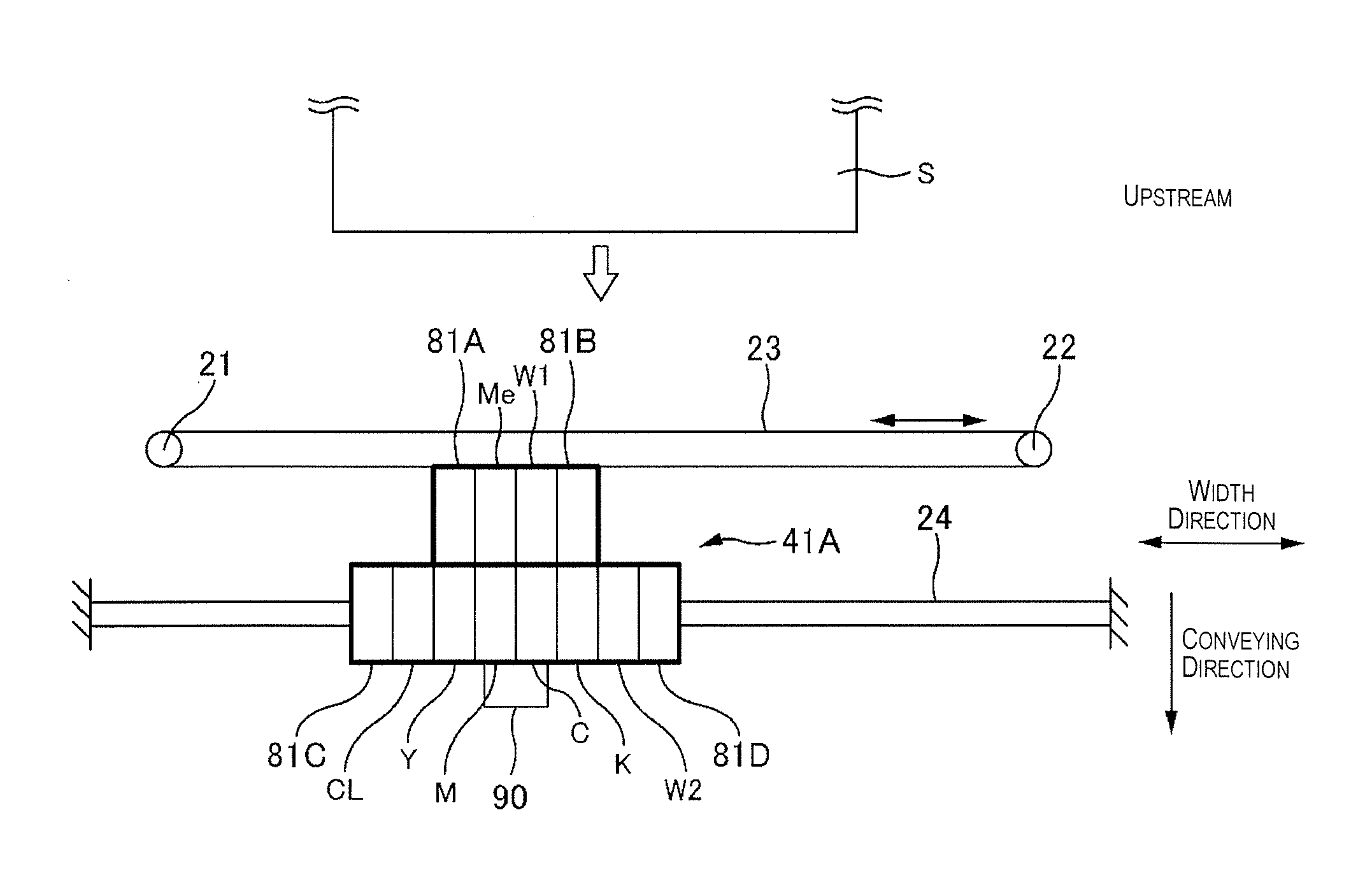

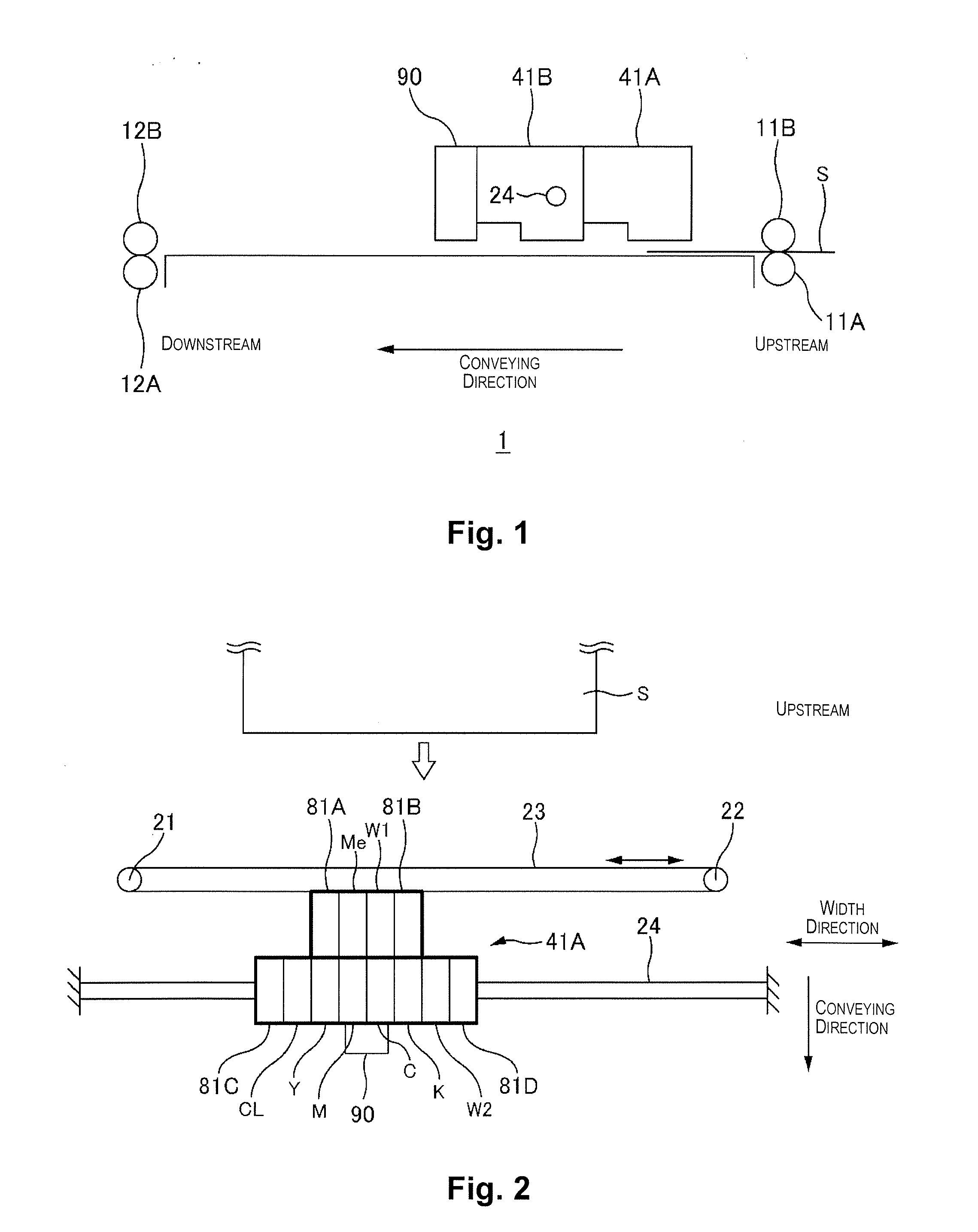

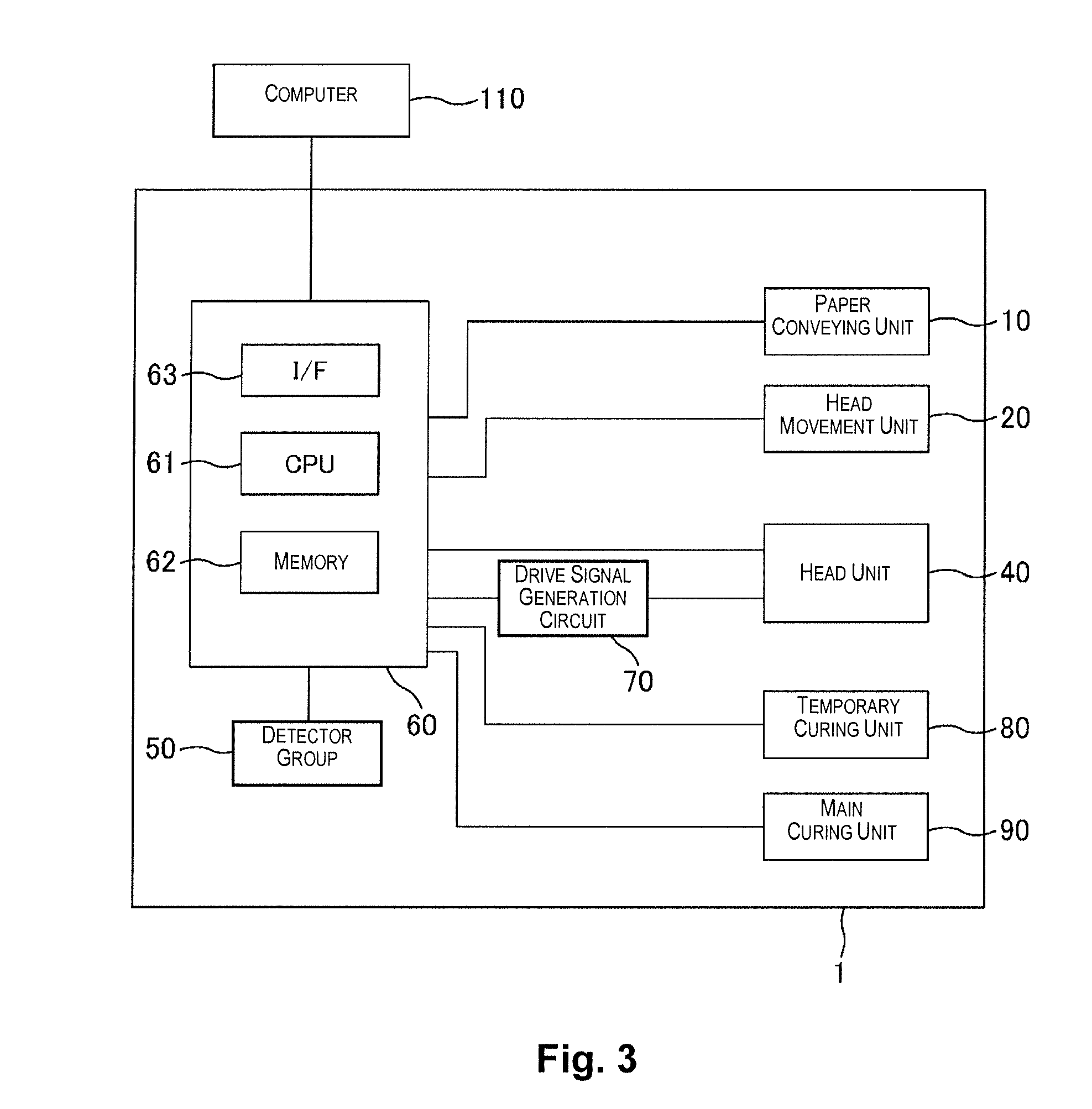

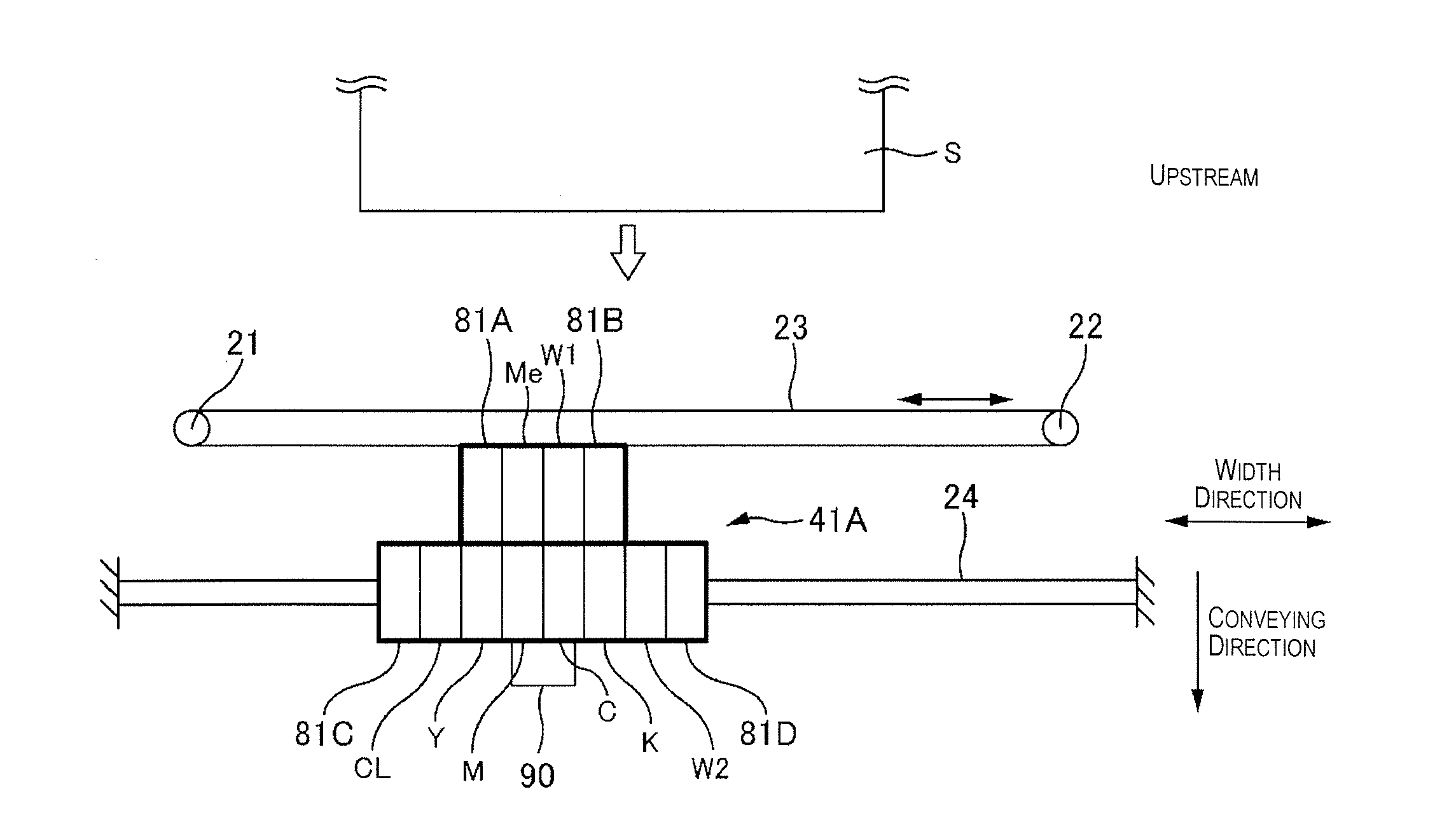

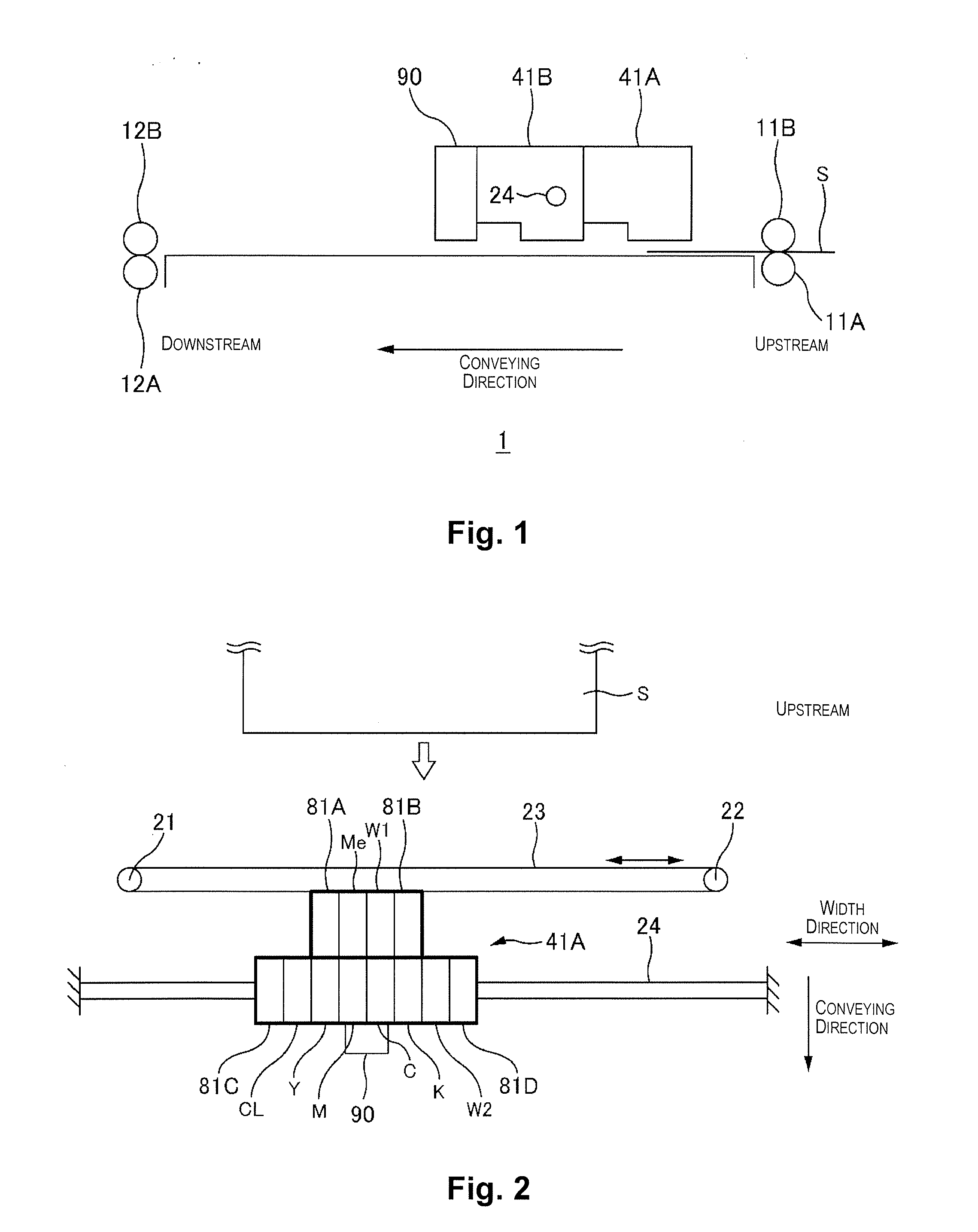

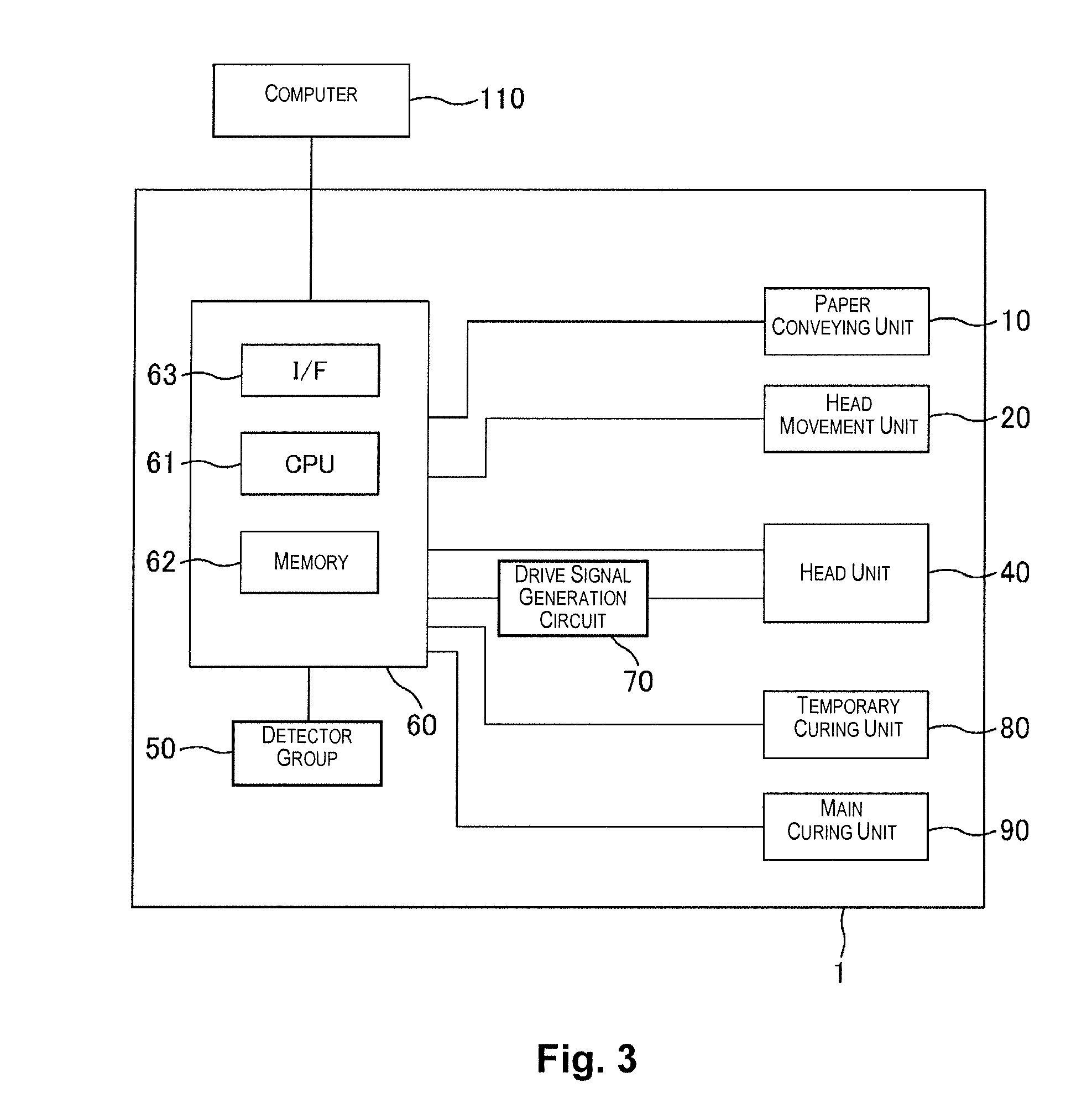

Printing device and printing method

A printing device includes a nozzle, a radiation unit and a control unit. The nozzle is configured to eject metallic ink including metal fragments onto a medium. The radiation unit is configured to irradiate the medium with light to temporarily cure the metallic ink. The control unit is configured to control irradiation of the light by the radiation unit so that a film thickness formed by the metallic ink is equal to or less than a length of a long side of the metal fragments when the metallic ink is temporarily cured on the medium.

Owner:SEIKO EPSON CORP

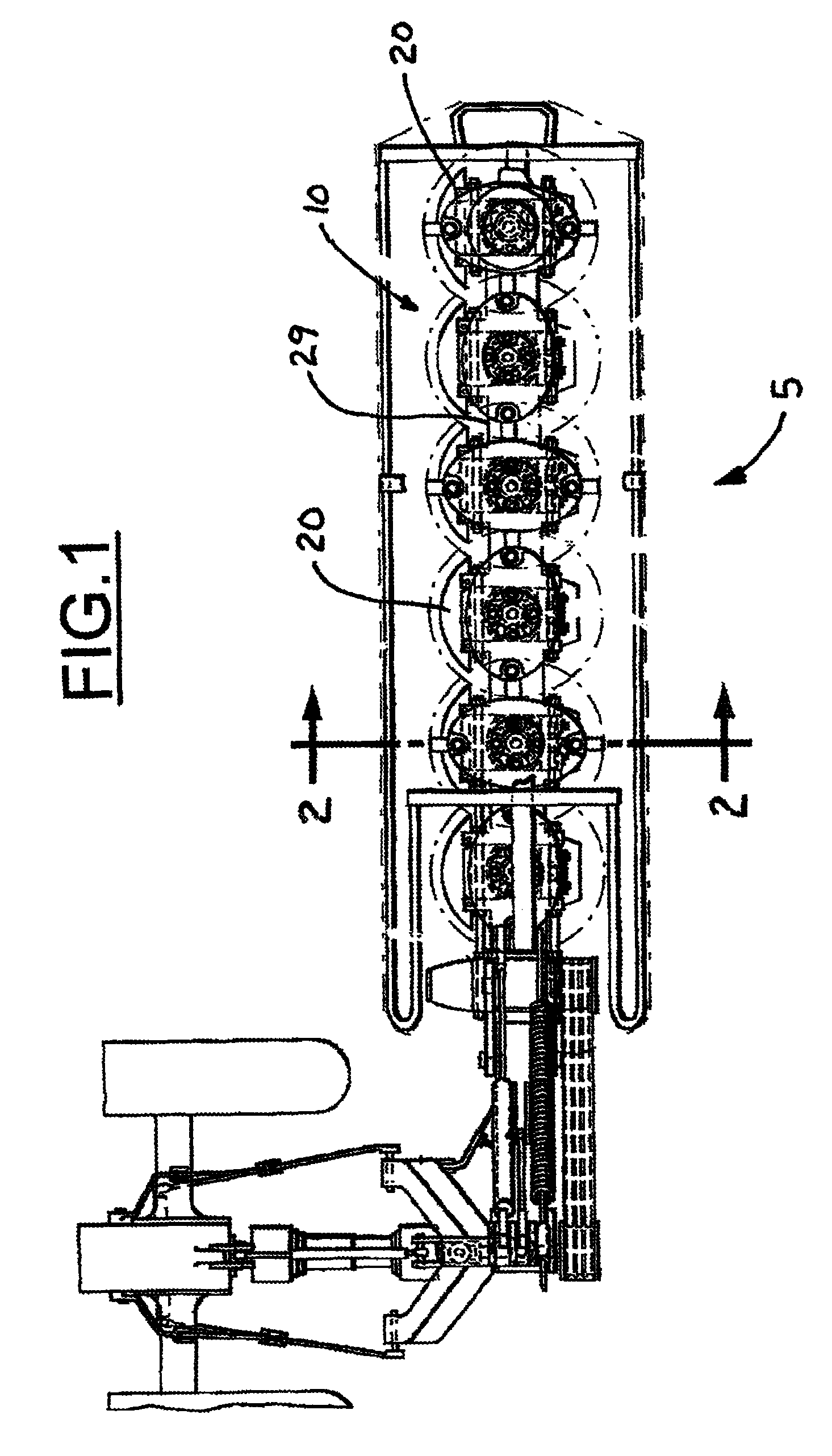

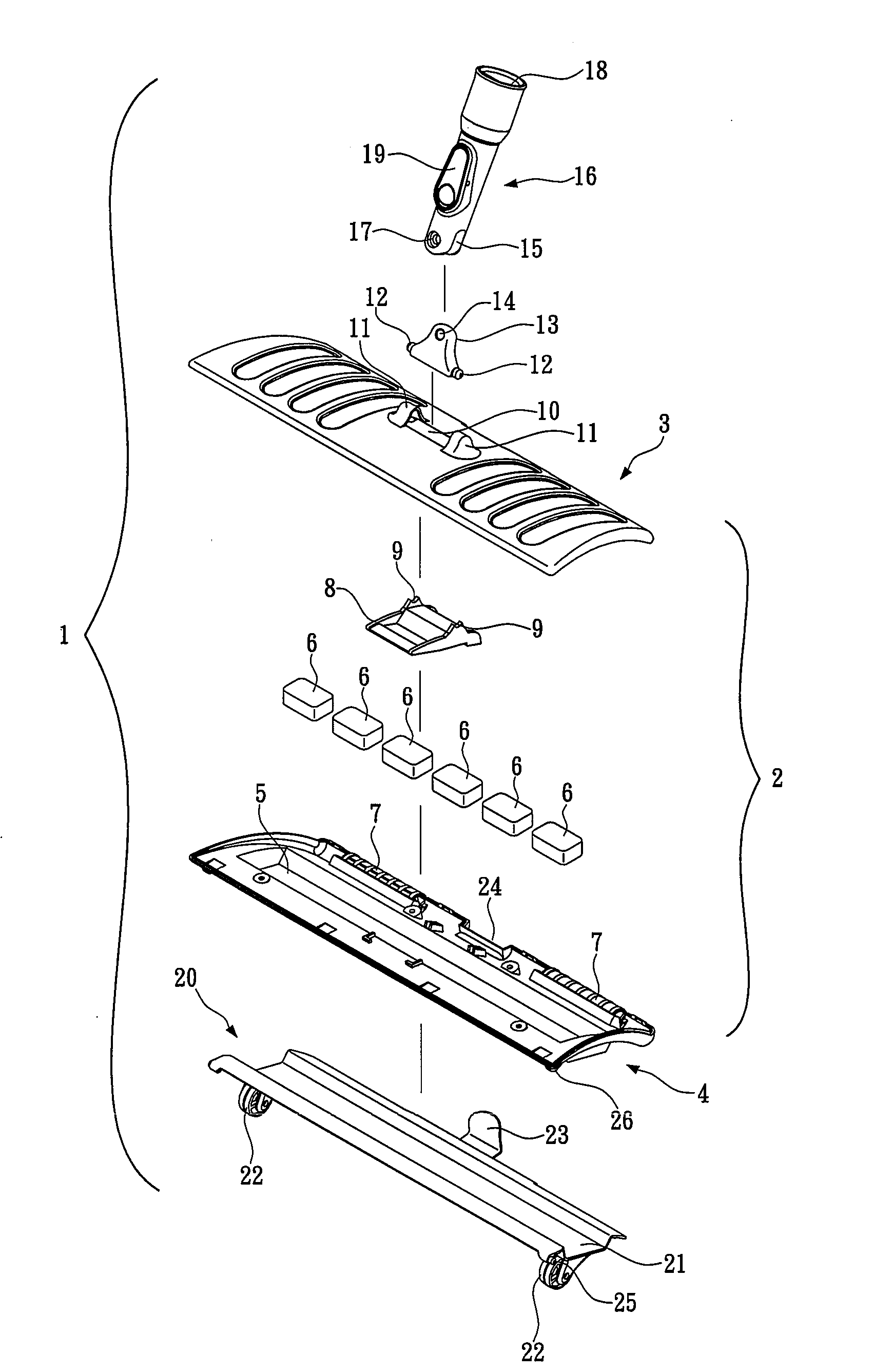

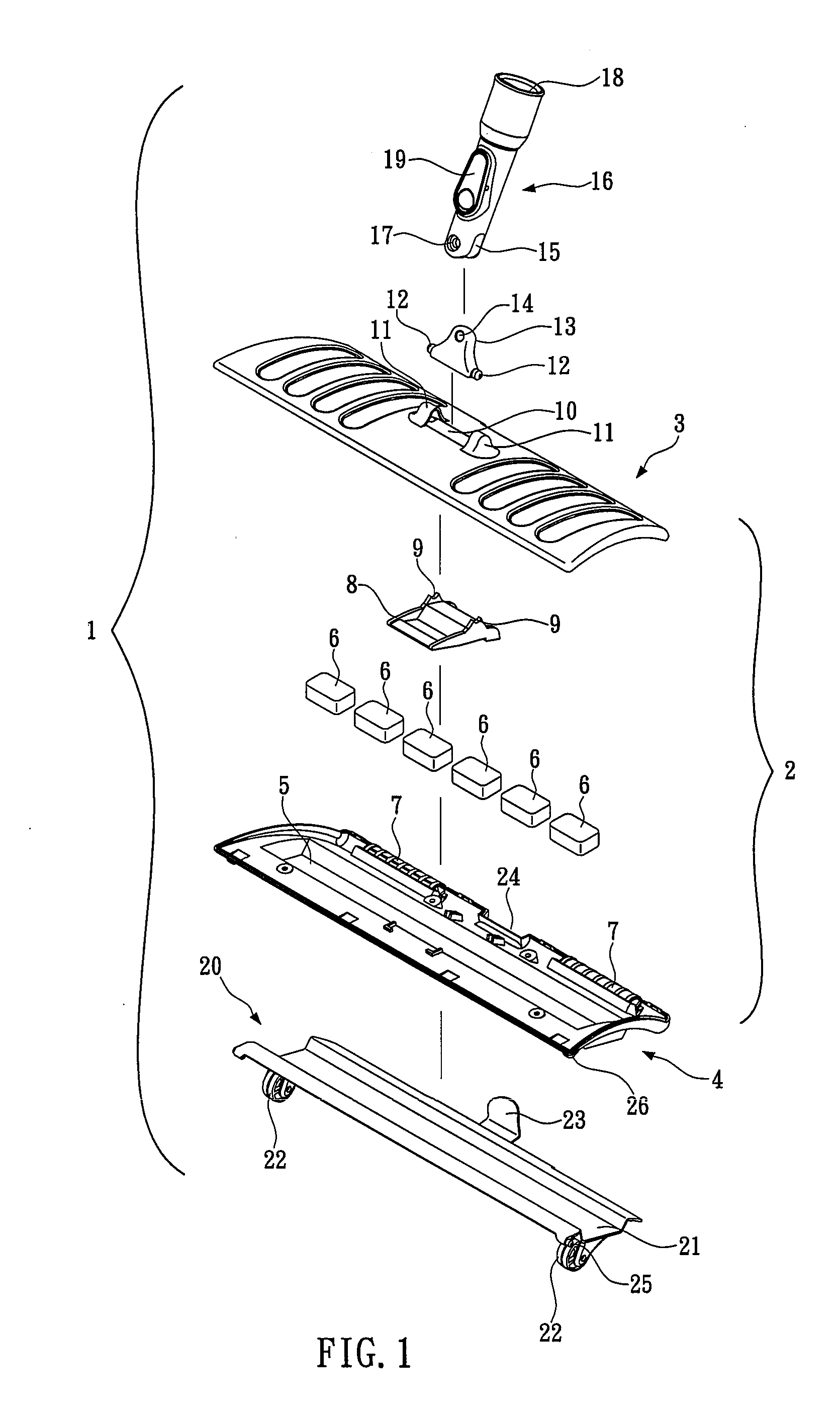

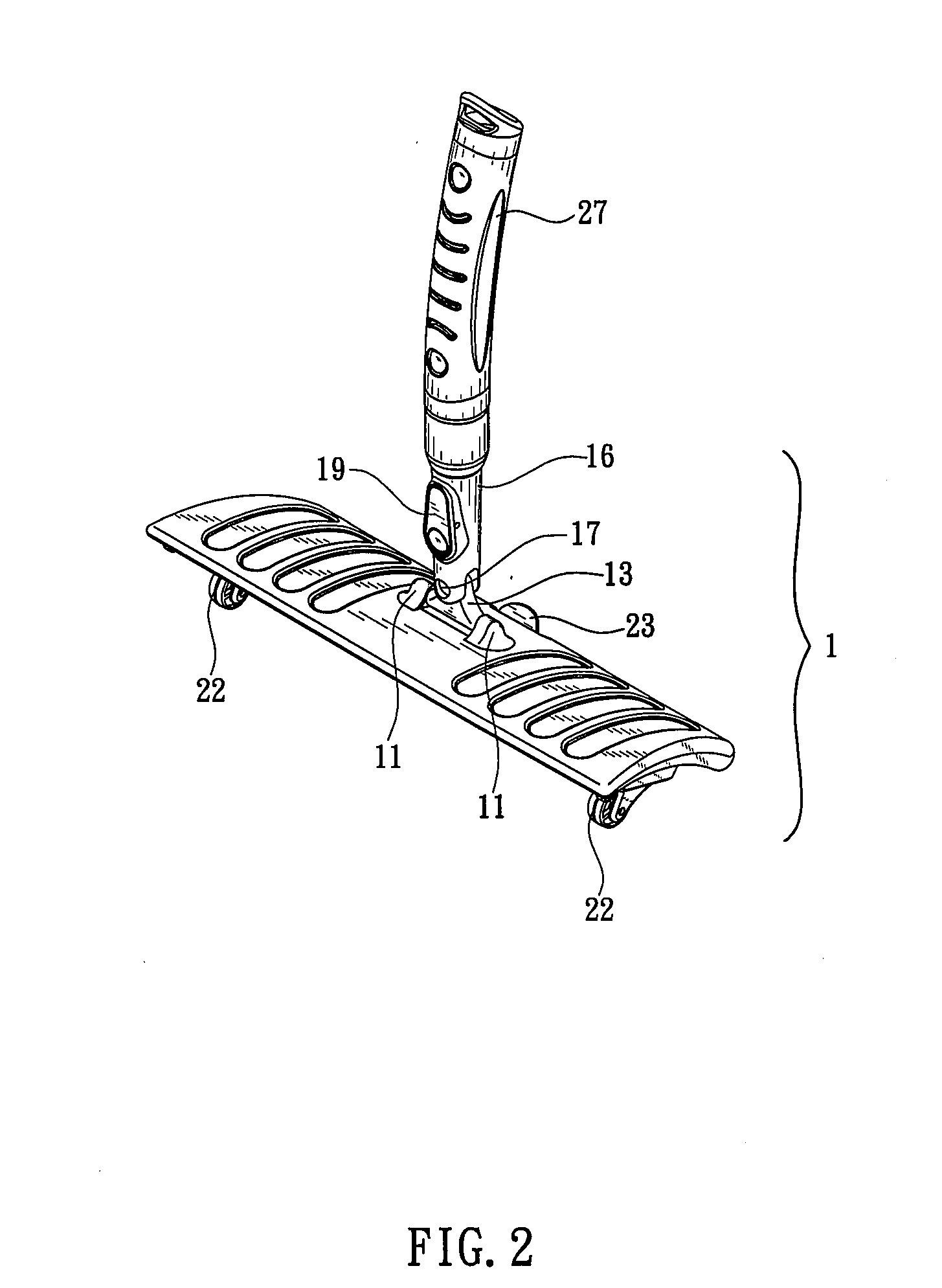

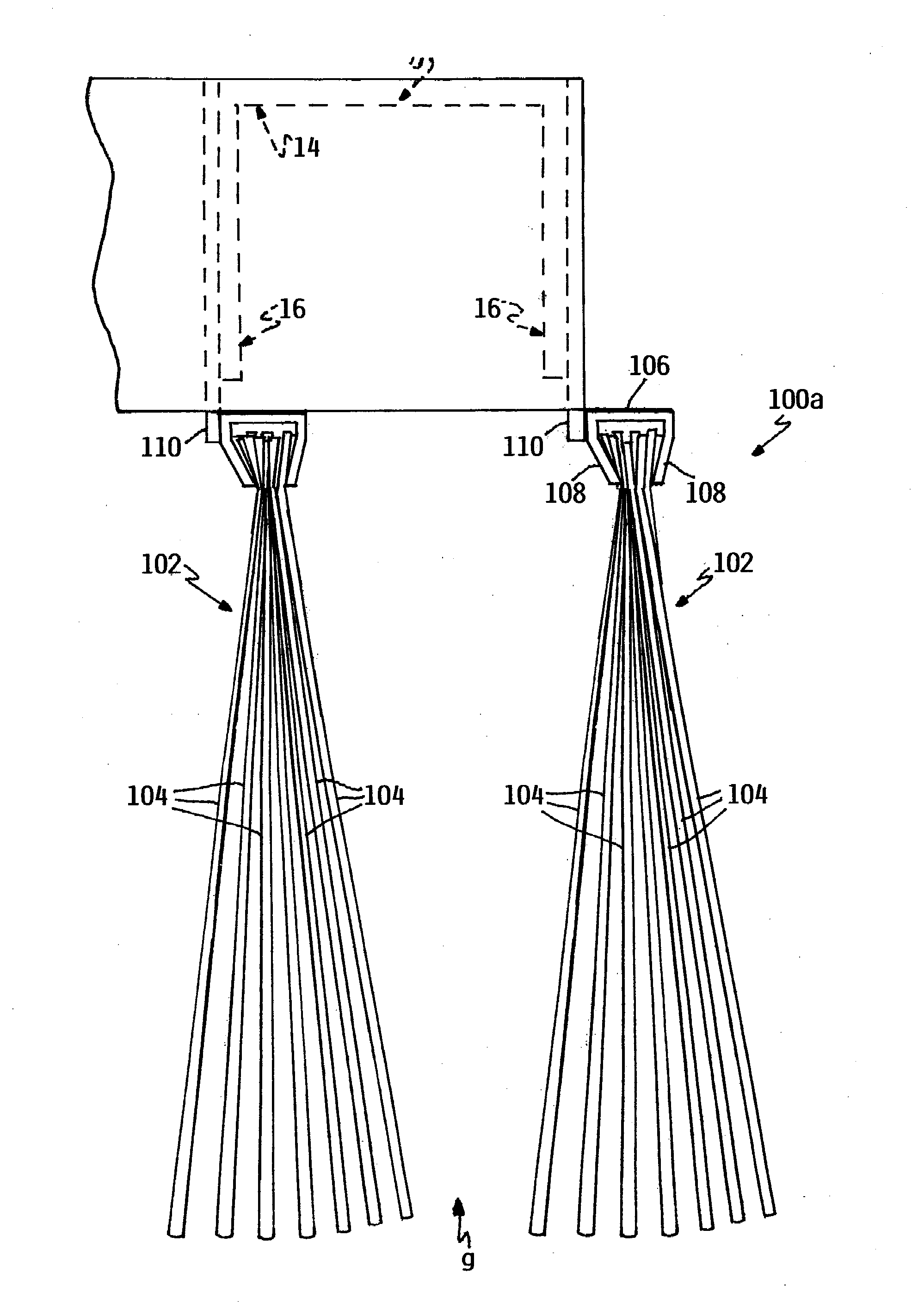

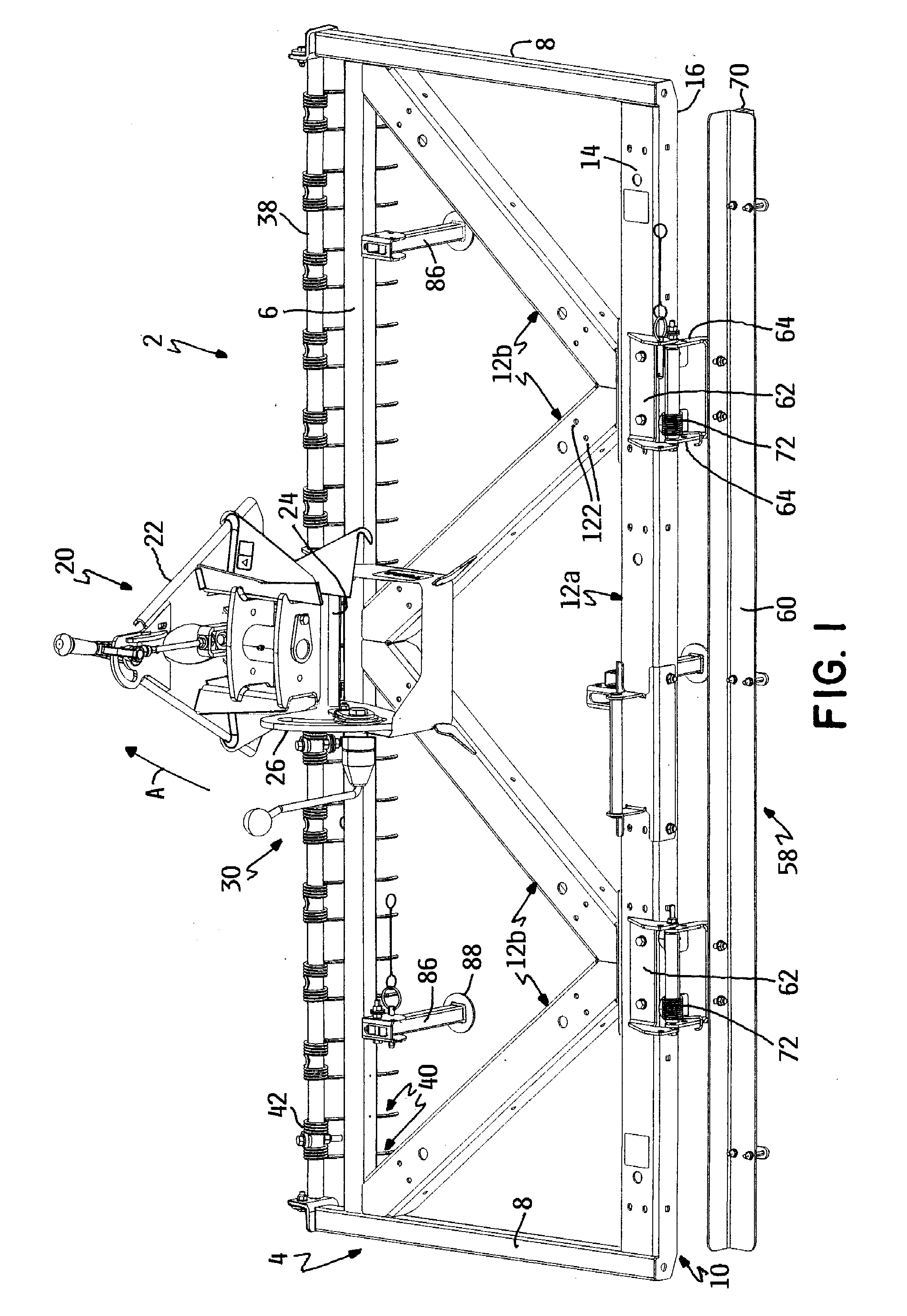

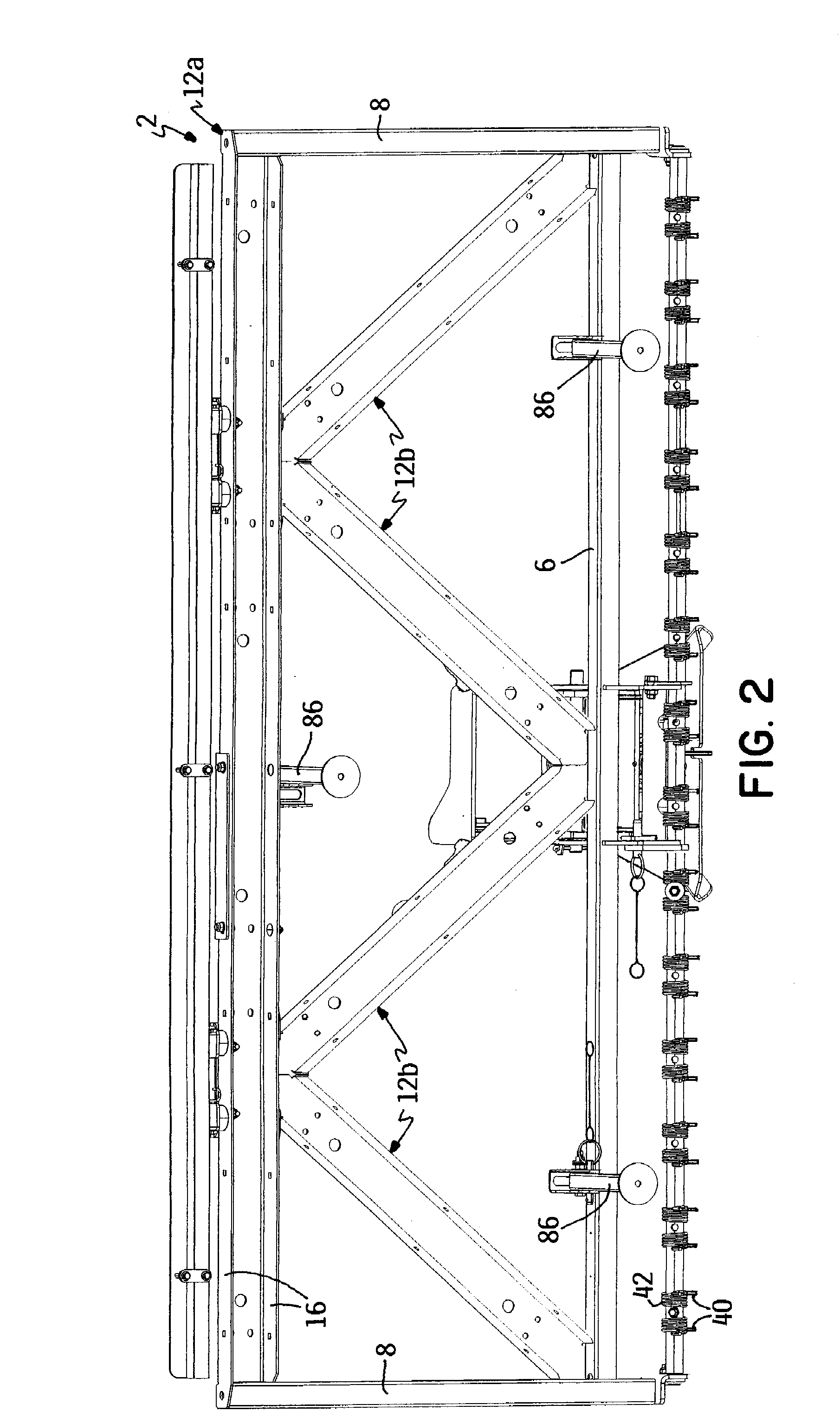

Turf groomer for natural and artificial turf surfaces

A groomer for turf surfaces includes a groomer frame that mounts a first style of grooming brush for use on an artificial turf surface and a second style of grooming brush for use on a natural turf surface. The first style of grooming brush comprises a brush formed by spaced brush walls with each brush wall having a substantially single row of brush bristles with no bristles being placed between the brush walls. The second style of grooming brush is that similar to a push broom where the brush bristles are packed across the width of the brush head. When configured for artificial turf surfaces, a front row of scarifying spring tines helps the trailing brushes to level out the infill material and the attitude of the groomer frame can be tilted tail down to put more downpressure on the infill material. A debris remover attached to the rear of the frame can pick up and hold metallic debris that is often found in the turf surface.

Owner:TORO CO THE

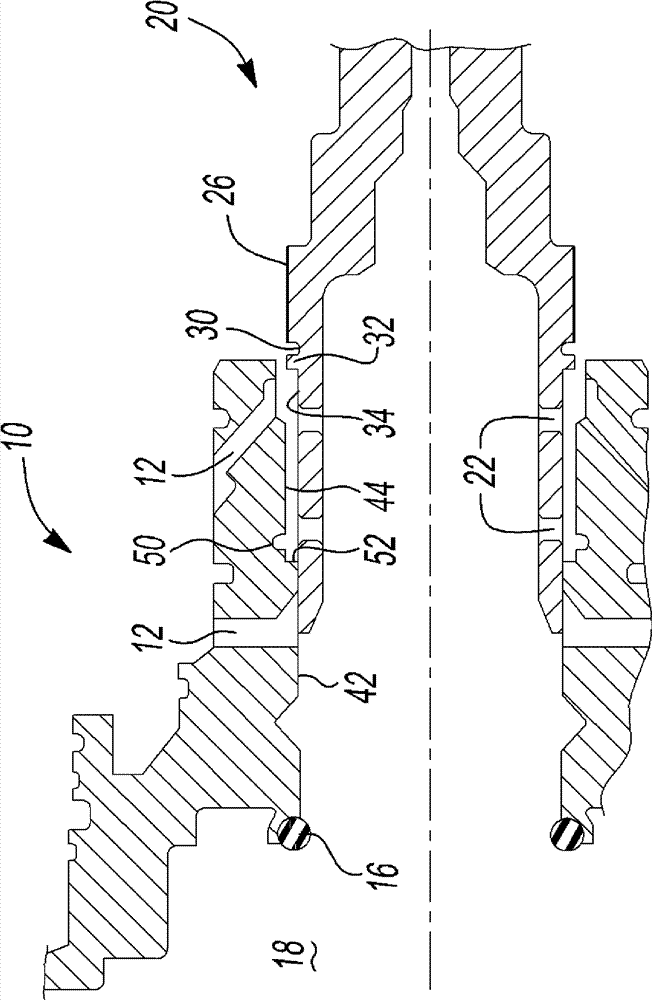

Serrated shaft debris collector

The invention relates to a serrated shaft debris collector. A chip or debris trap or collector are provided which retains metal chips, fragments and other debris generated when a serrated or splined, press fit connection is assembled between a shaft and another component such as a housing, gear, pulley or bearing. The chip collector includes a circumferential channel or groove disposed about the shaft adjacent the ring of serrations or male splines and an adjacent circumferential flange. An optional second channel or groove resides in the other component. As the shaft and the component are assembled, chips, fragments or other debris generated by the interference fit and axial sliding assembly of the components are collected in the channel or groove and retained there as the shaft fully seats within the other component.

Owner:GM GLOBAL TECH OPERATIONS LLC

Debris capture and removal for laser micromachining

A method of capturing and removing metallic debris created on a target side of a target metal specimen undergoing laser micromachining entails providing a barrier that encompasses the immediate volume surrounding a laser cutting head output nozzle to contain the ejected debris and extracting the debris through a vacuum outlet. A preferred system implementing this approach to debris management includes a barrier in the form of a flexible fiber brush configured in the shape of a ring and positioned to trap ejected debris within a localized area surrounding a target area where the laser beam is incident on the target metal specimen. The ring brush is made of material that is robust to molten metals. An inert gas directed at a high flow rate along the target surface of the metal specimen carries ejected surface debris trapped in the ring brush toward a vacuum outlet.

Owner:ELECTRO SCI IND INC

Antenna apparatus for portable terminal

ActiveUS9343804B2Space minimizationImprove textureSimultaneous aerial operationsAntenna supports/mountingsEngineeringAntenna element

An antenna apparatus for a portable terminal is provided. The portable terminal includes a printed circuit board (PCB) having a ground surface and RF components to process a wireless signal received through at least one antenna element. A housing forms an external appearance of the portable terminal, and has a non-conductive member with a plurality of metal fragments attached thereto. At least one of the metal fragments is electrically connected to the ground surface. The metal fragments may enhance the texture and durability of the housing. Preferably, the shapes, sizes and distances separating the metal fragments are designed to minimally impact, or improve, the antenna performance provided by the at least one antenna element.

Owner:SAMSUNG ELECTRONICS CO LTD

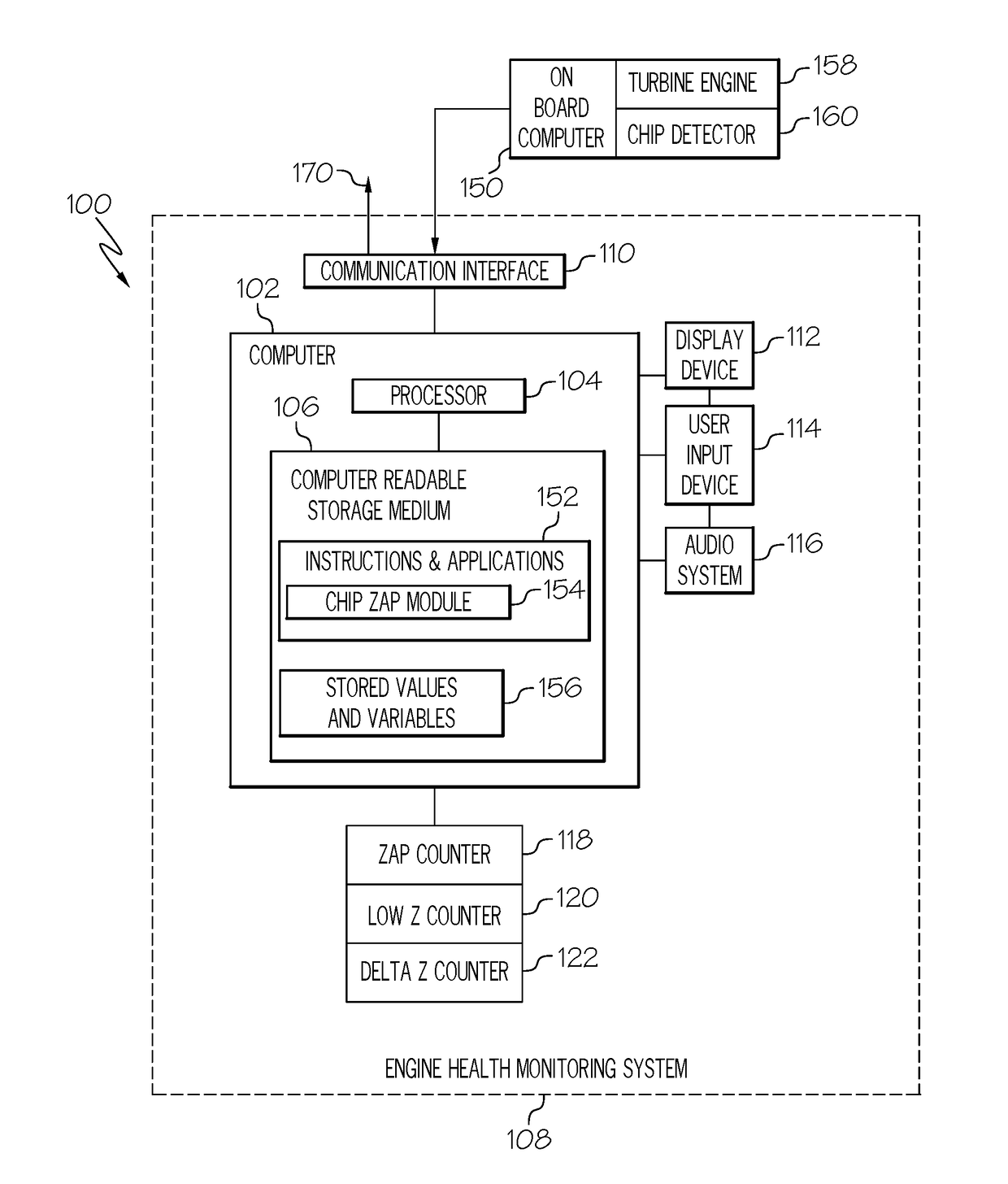

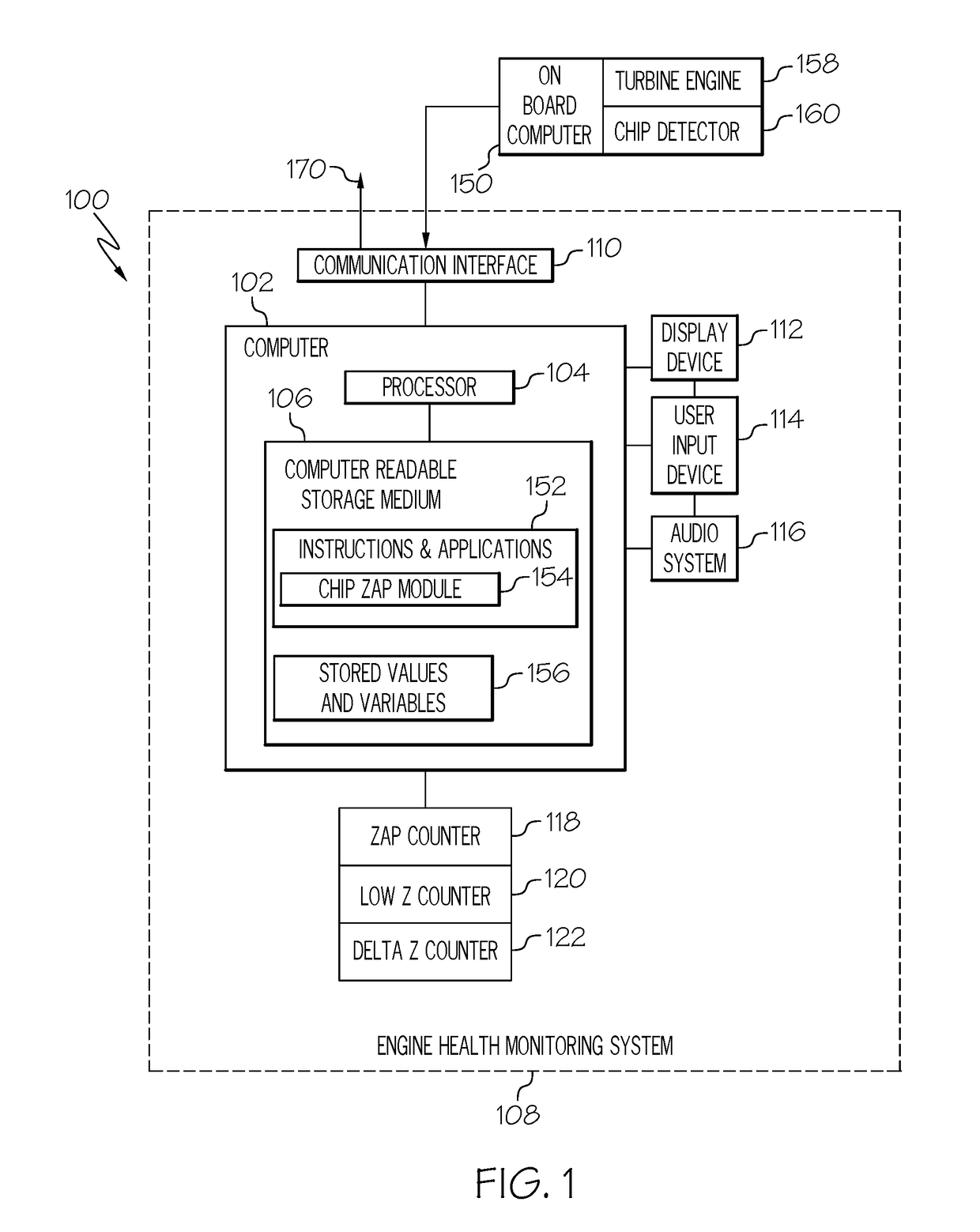

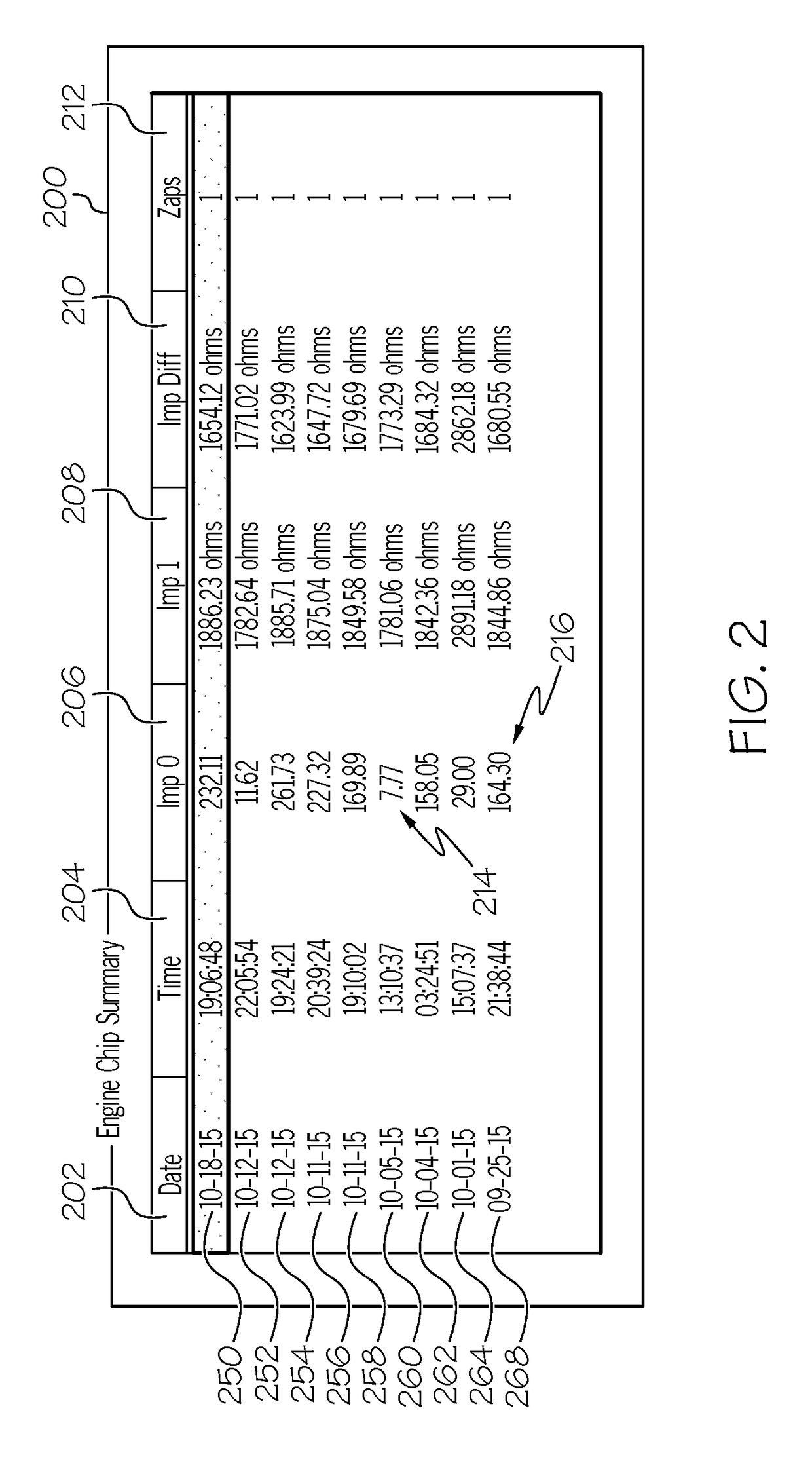

System and method for evaluating chip zap data

ActiveUS20180187622A1Reduction of false positiveImprove efficiencyElectrical controlInternal combustion piston enginesEngineeringEngine wear

A system and method for identifying engine wear based on engine oil debris is provided. The provided system and method utilize metallic debris data provided in summary reports. For each object of metallic debris, a zap count, an initial (pre-zap) impedance and an impedance change (post zap) are processed with configurable reference variables. Alerts (suggesting potential engine wear) are generated responsive to the impedance values of the objects of metallic debris and the reference variables.

Owner:HONEYWELL INT INC

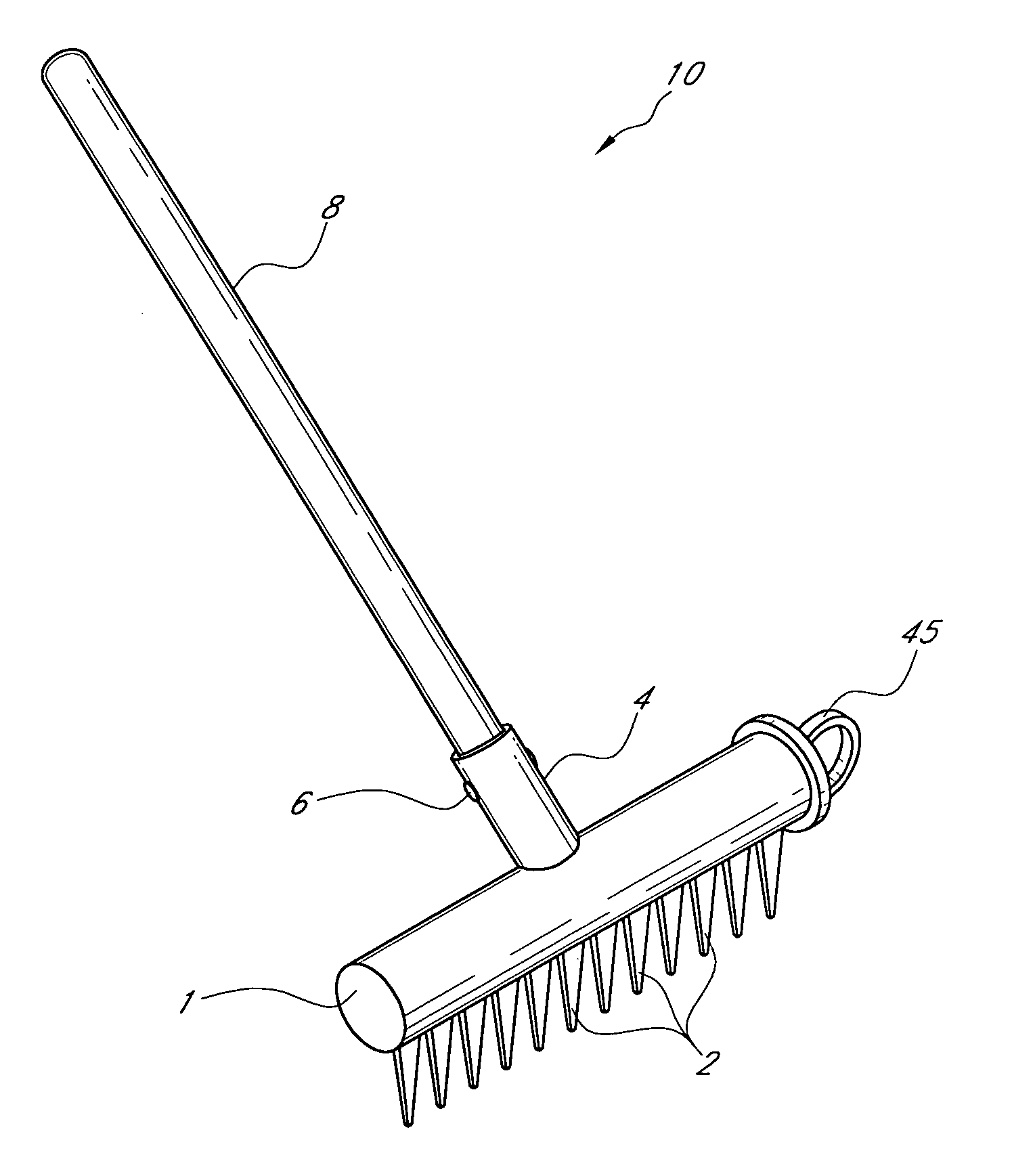

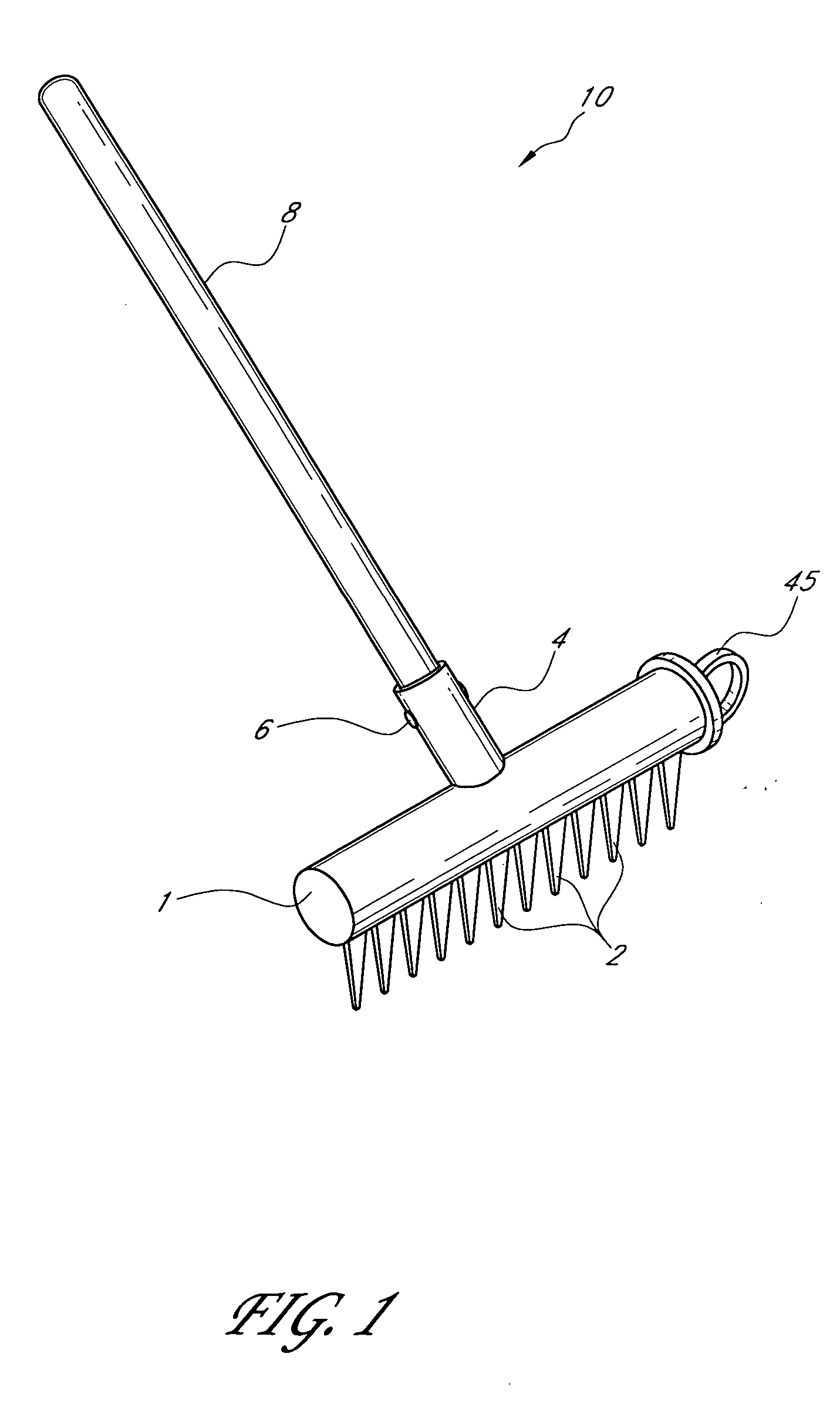

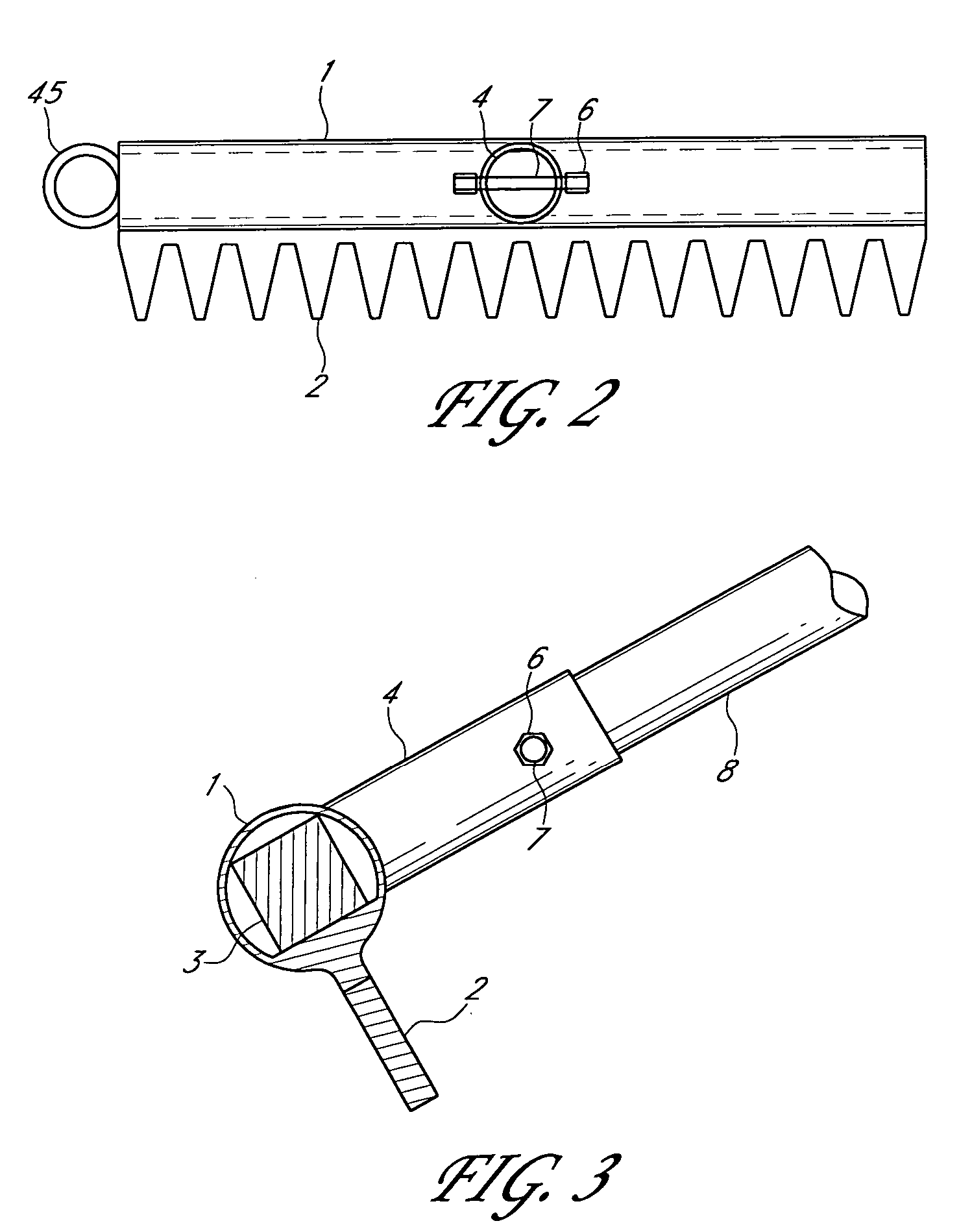

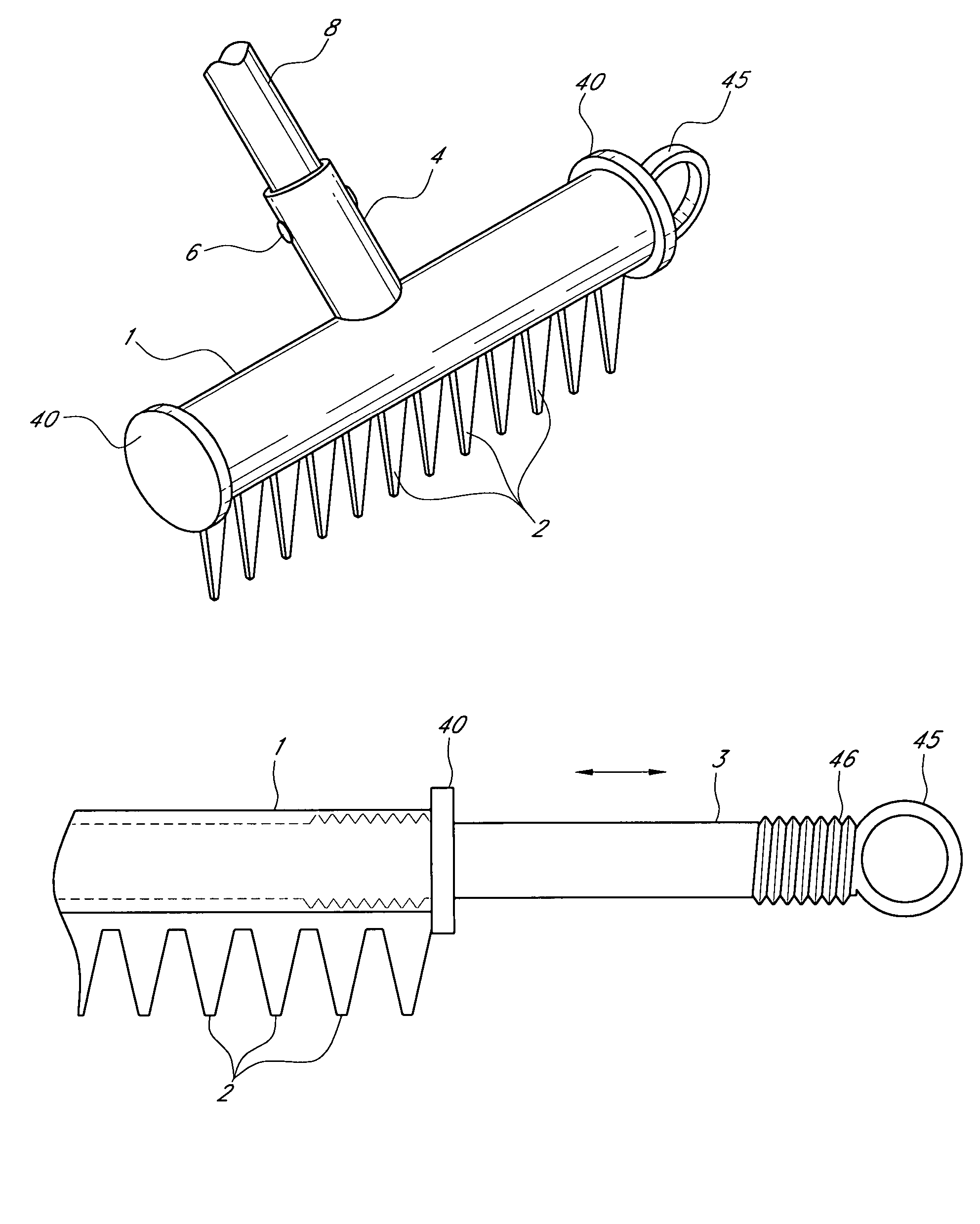

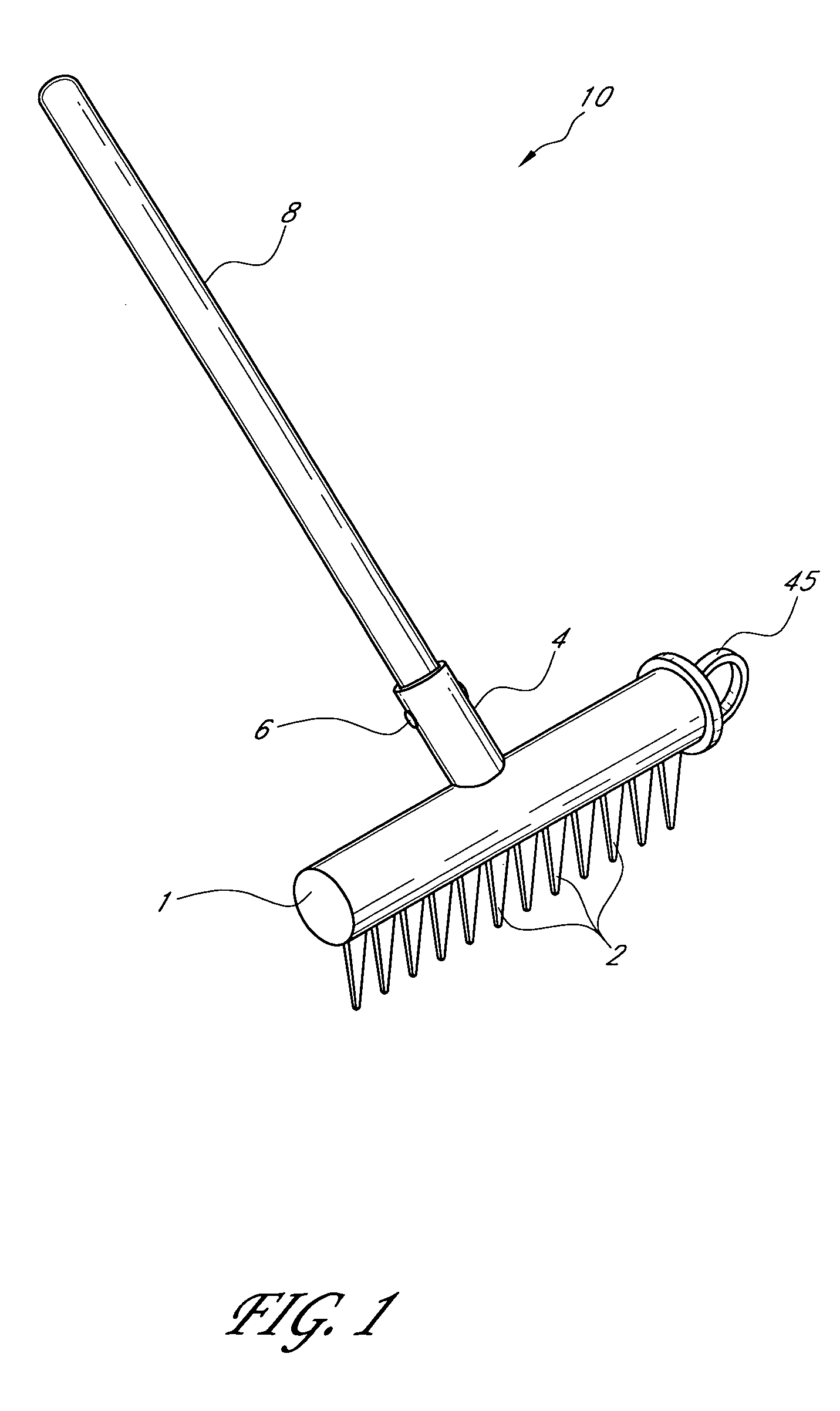

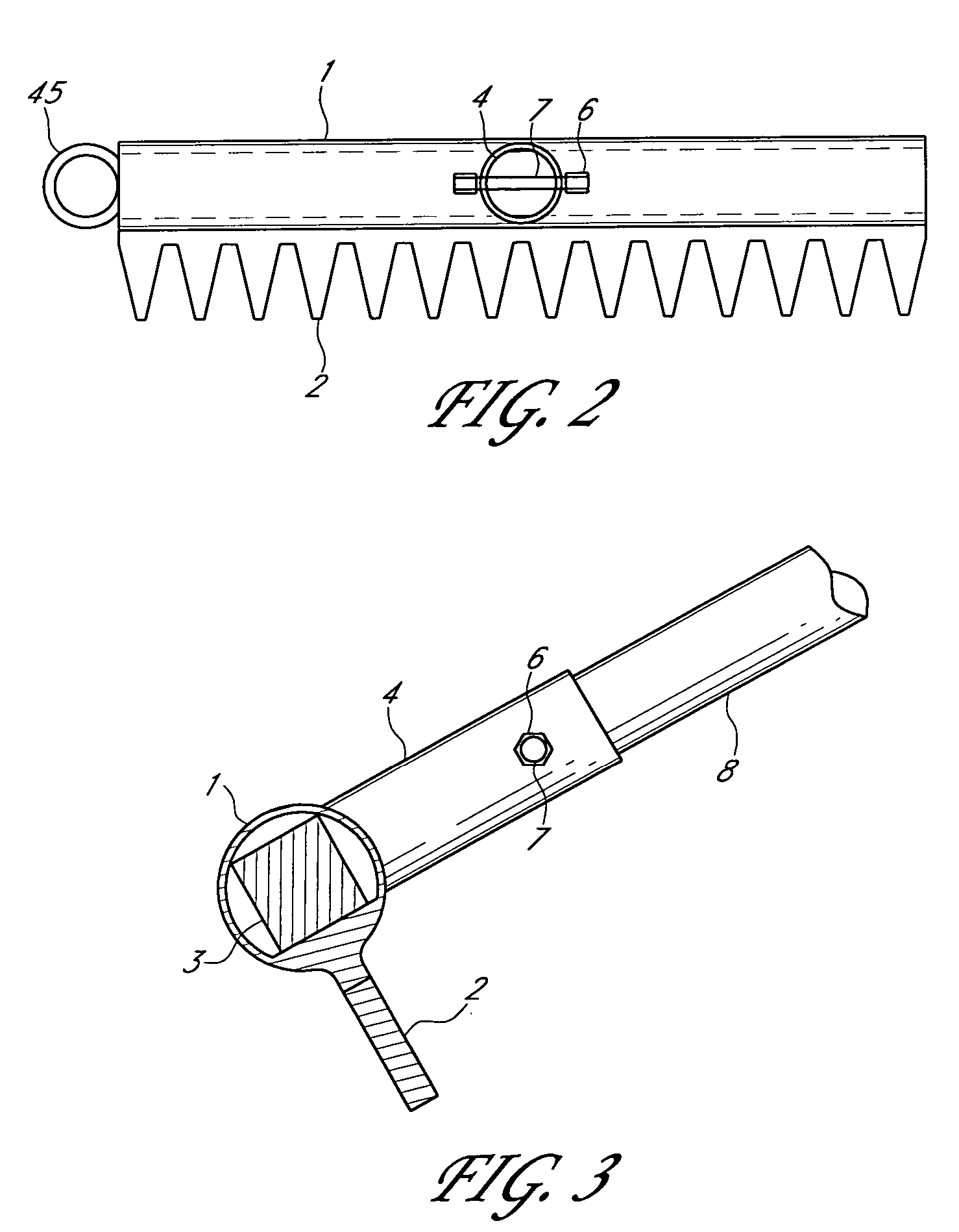

Magnetic rake with release mechanism

InactiveUS20060186025A1Eliminating magnetic attractionEliminate magnetic fieldSievingScreeningEngineeringJunk box

A magnetic raking device that agitates a ground surface and uses magnetic attraction for collecting ferro-metallic debris, such as nails and screws, at construction jobsites and other locations, includes a release mechanism that temporarily eliminates magnetic attraction of the debris to the rake, thus allowing collected debris to drop from the rake, such as into a trash or recycling container. One type of release mechanism physically removes one or more magnets from the rake body to eliminate magnetic attraction to the rake body. One type of release mechanism uses electromagnets in the rake body that attract ferro-metallic debris when current is allowed to run through the electromagnets, and that allows the debris to drop from the rake when the current is interrupted. The magnetic rake may be used in an inverted position to attract ferro-metallic debris without agitating, and may be used in a non-magnetic state as a conventional rake.

Owner:VERNON BRADLEY G +1

Retaining and isolating mechanisms for magnets in a magnetic cleaning tool

Owner:BAKER HUGHES INC

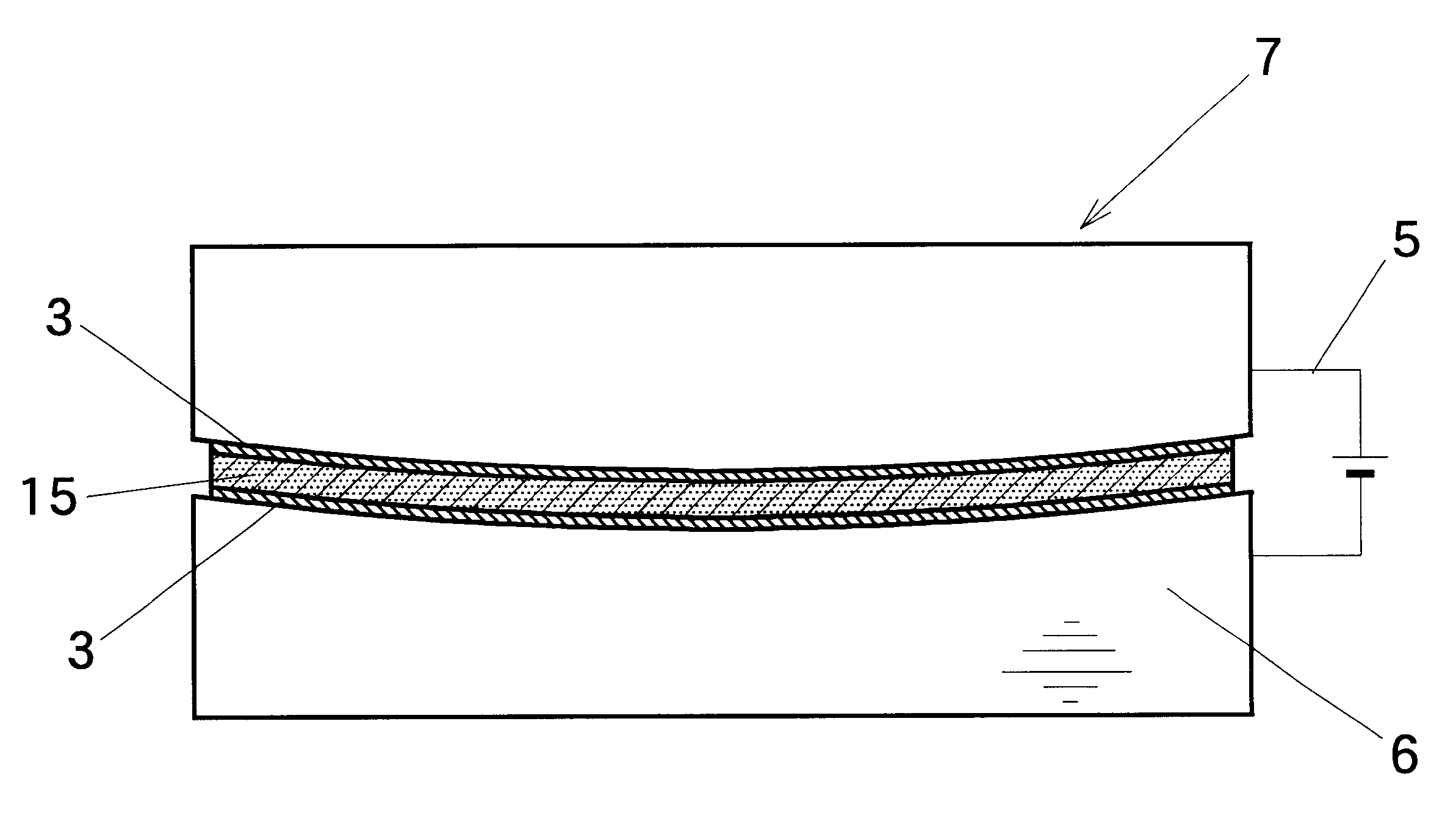

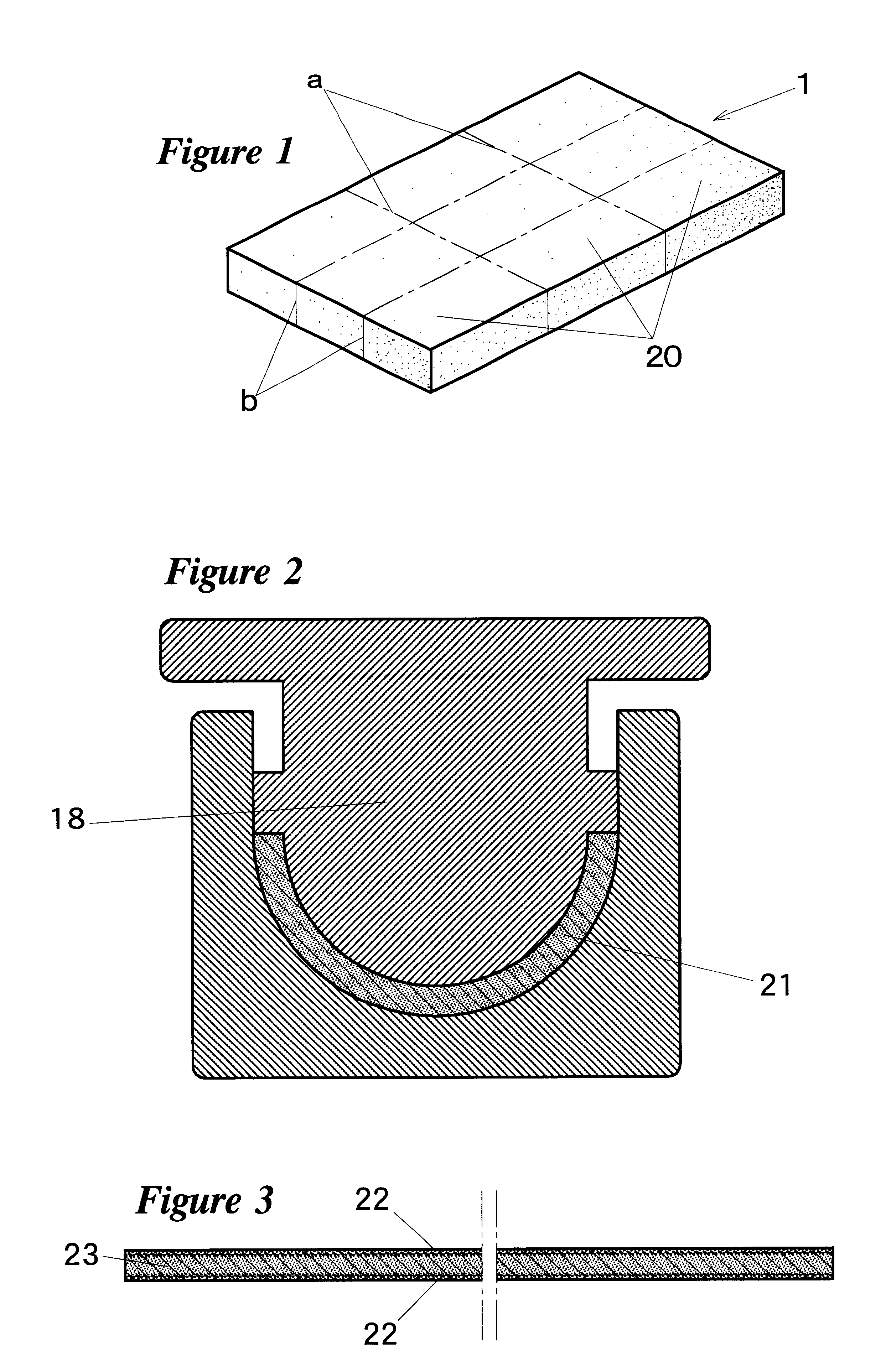

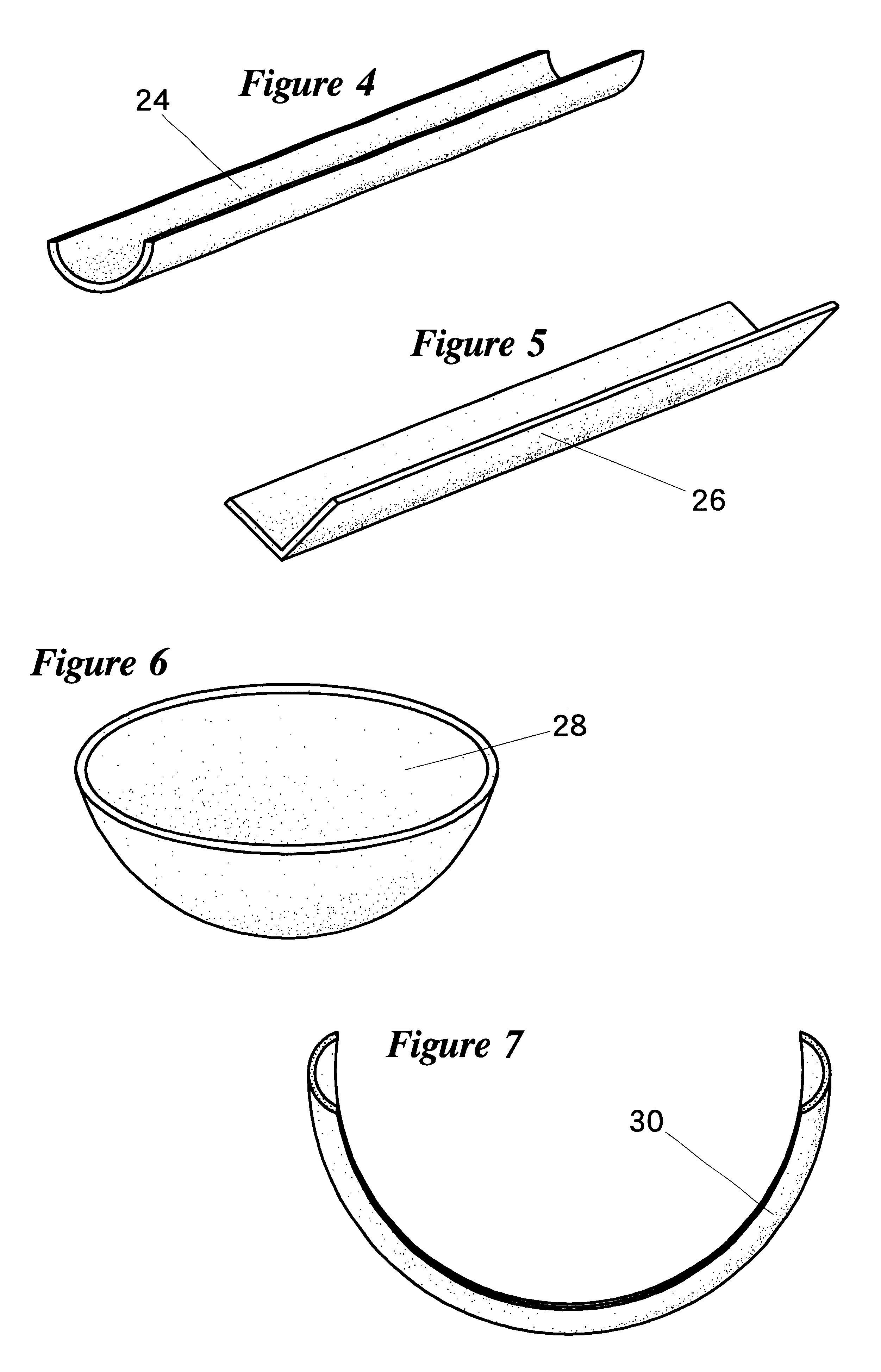

Porous structure body and method of forming it

InactiveUS6511758B1High strengthReduce weightVehicle componentsThin material handlingHigh pressureMaterials science

A porous structural material having a solid shape with a curved surface of which the dimensional accuracy is high and the uses are wide is produced. The porous structural material is made form metallic chips containing at least one kind of ingredients, and comprises a solid-shaped body having a smooth and curved surface, the solid-shaped body being reformed by compacting a plate-shaped intermediate product in the hot state, the product being a molding with heating under a pressure while being highly electrified.

Owner:SUITAYA

Magnetic rake with release mechanism

InactiveUS7331470B2Eliminate magnetic fieldEliminate the magnetic fieldSievingScreeningEngineeringNon magnetic

A magnetic raking device that agitates a ground surface and uses magnetic attraction for collecting ferro-metallic debris, such as nails and screws, at construction jobsites and other locations, includes a release mechanism that temporarily eliminates magnetic attraction of the debris to the rake, thus allowing collected debris to drop from the rake, such as into a trash or recycling container. One type of release mechanism physically removes one or more magnets from the rake body to eliminate magnetic attraction to the rake body. One type of release mechanism uses electromagnets in the rake body that attract ferro-metallic debris when current is allowed to run through the electromagnets, and that allows the debris to drop from the rake when the current is interrupted. The magnetic rake may be used in an inverted position to attract ferro-metallic debris without agitating, and may be used in a non-magnetic state as a conventional rake.

Owner:VERNON BRADLEY G +1

Printing device and printing method

A printing device includes a nozzle, a radiation unit and a control unit. The nozzle is configured to eject metallic ink including metal fragments onto a medium. The radiation unit is configured to irradiate the medium with light to temporarily cure the metallic ink. The control unit is configured to control irradiation of the light by the radiation unit so that a film thickness formed by the metallic ink is equal to or less than a length of a long side of the metal fragments when the metallic ink is temporarily cured on the medium.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com