Magnetic metal extractor from drilling fluid

a magnetic metal and extractor technology, applied in the direction of magnetic separation, manufacturing tools, and borehole/well accessories, etc., can solve the problems of small metal debris, equipment through which the drilling fluid is recirculated, and can be damaged or quickly worn,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

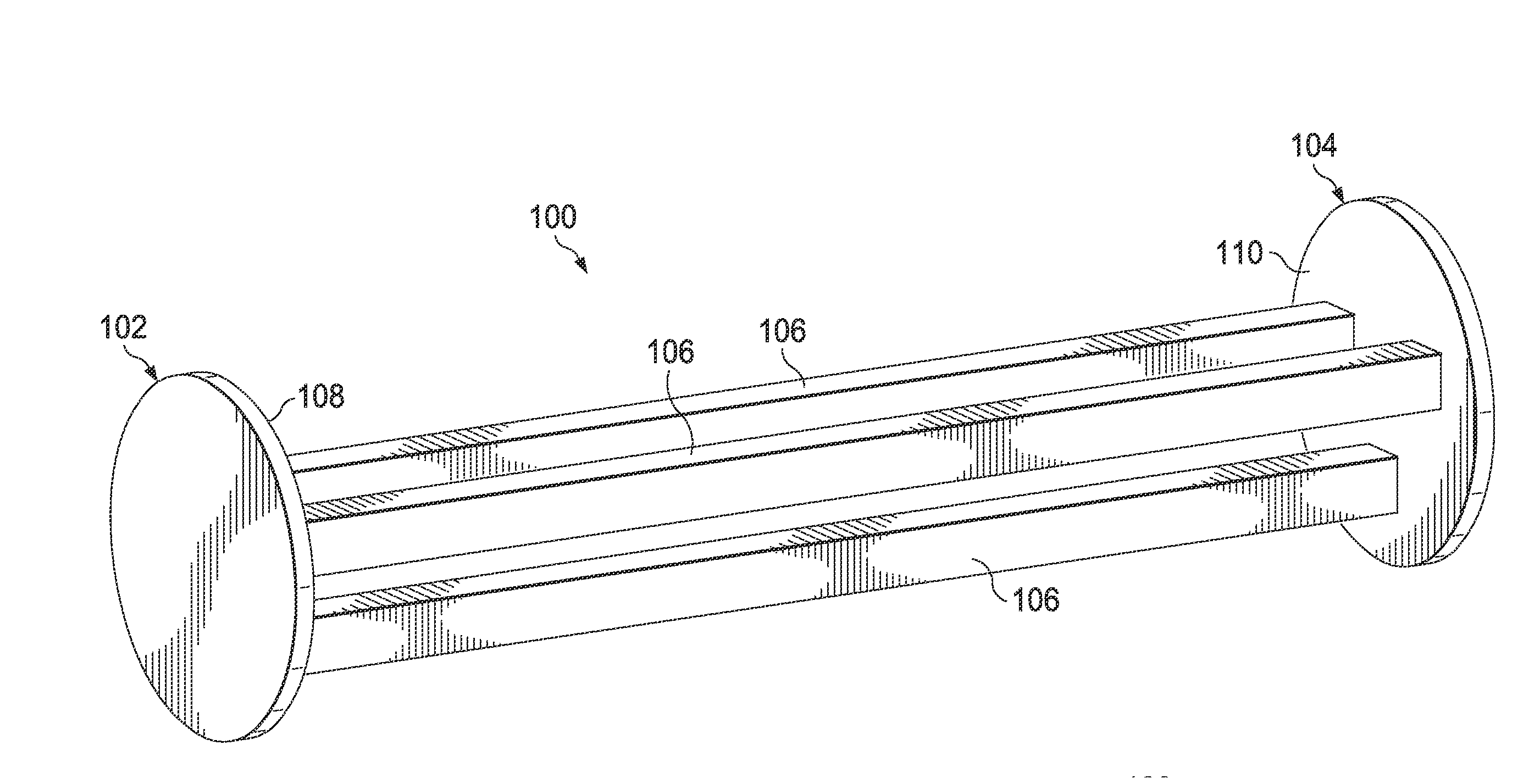

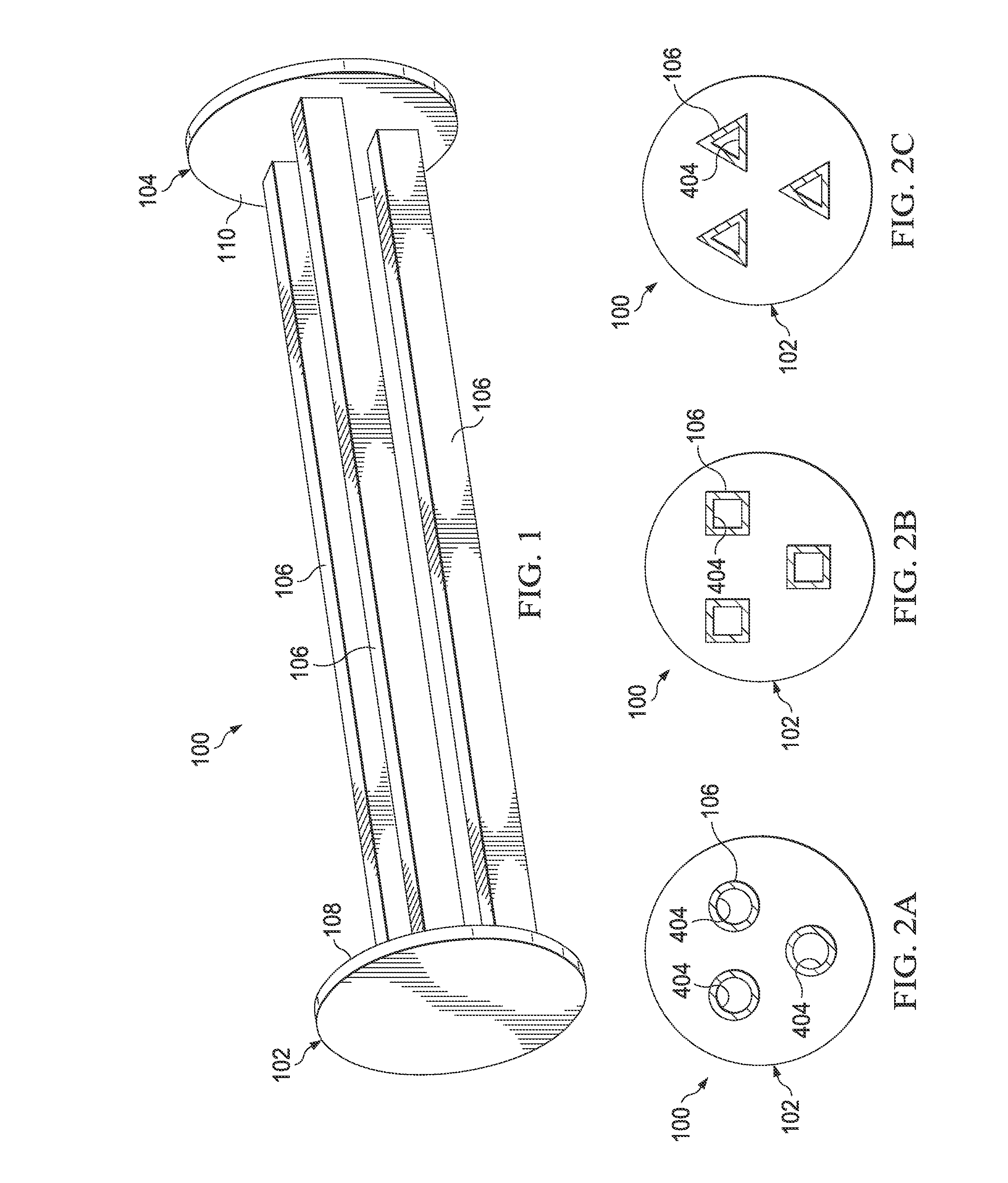

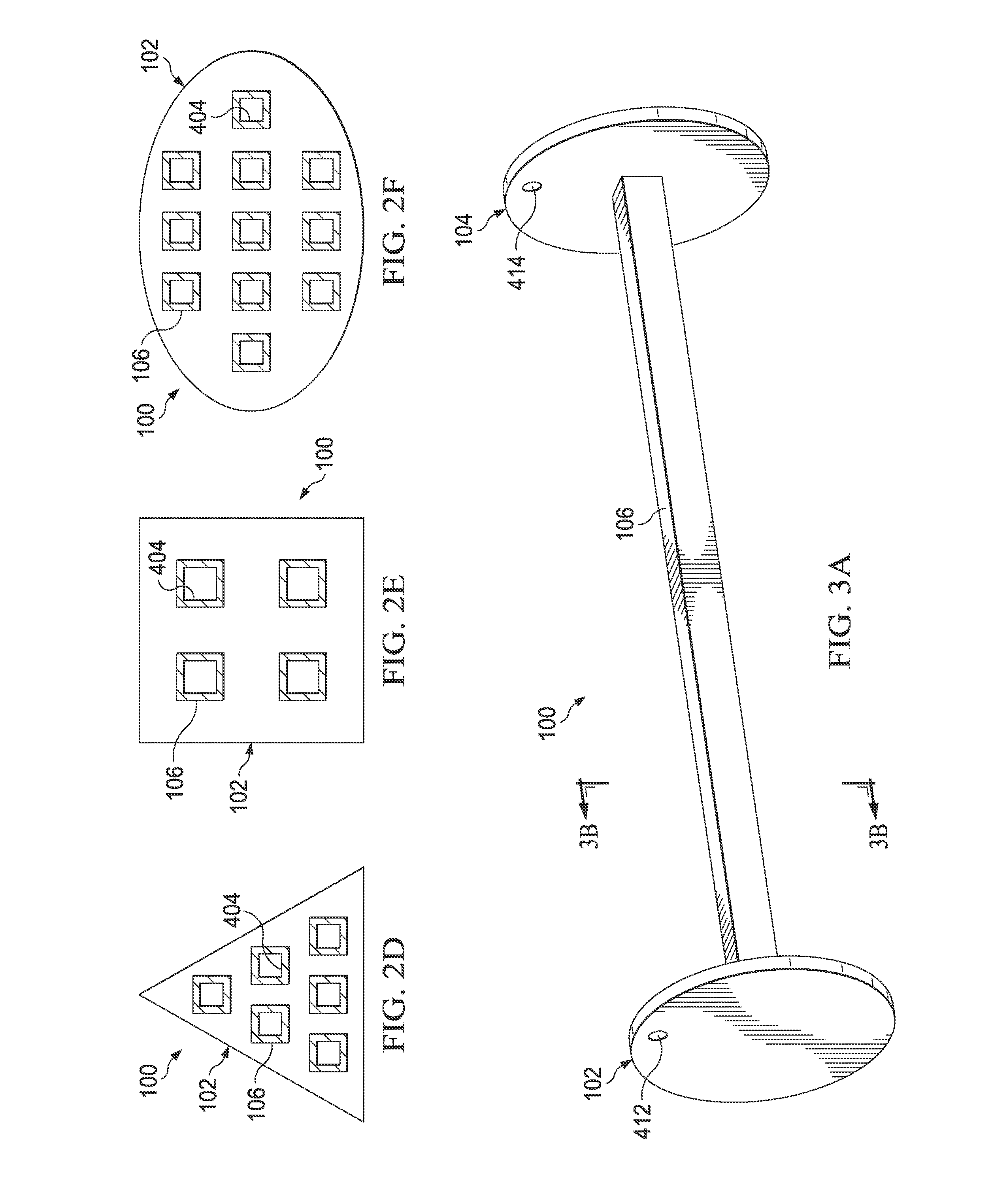

[0071]FIG. 1 is a perspective, front view of an embodiment of an apparatus 100 for removing metallic debris from a drilling fluid. The apparatus 100 may include a first end member 102, a second end member 104 spaced from the first end member 102, and one or more elongated members 106 extending between the first end member 102 and the second end member 104. As will be described in more detail below, the elongated members 106 may include one or more magnets 402 (see, e.g., FIGS. 3C, 5C and 8) or may otherwise exert a magnetic force to attract metallic debris from a drilling fluid that passes by the apparatus 100.

[0072]In some embodiments, the first and second end members 102 and 104 are located in a spaced apart relationship to allow drilling fluid to pass therebetween. As will be explained in more detail below, a distance between the end members 102 and 104 may be slightly less than the width of an outlet of a drilling fluid cleansing apparatus (see e.g., outlet 606 of drilling fluid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com