Magnetic retrieval apparatus and method for retaining magnets on a downhole magnetic retrieval apparatus

a magnetic retrieval and magnetic technology, applied in the direction of manufacturing tools, transportation and packaging, borehole/well accessories, etc., can solve the problem of metal-to-metal scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

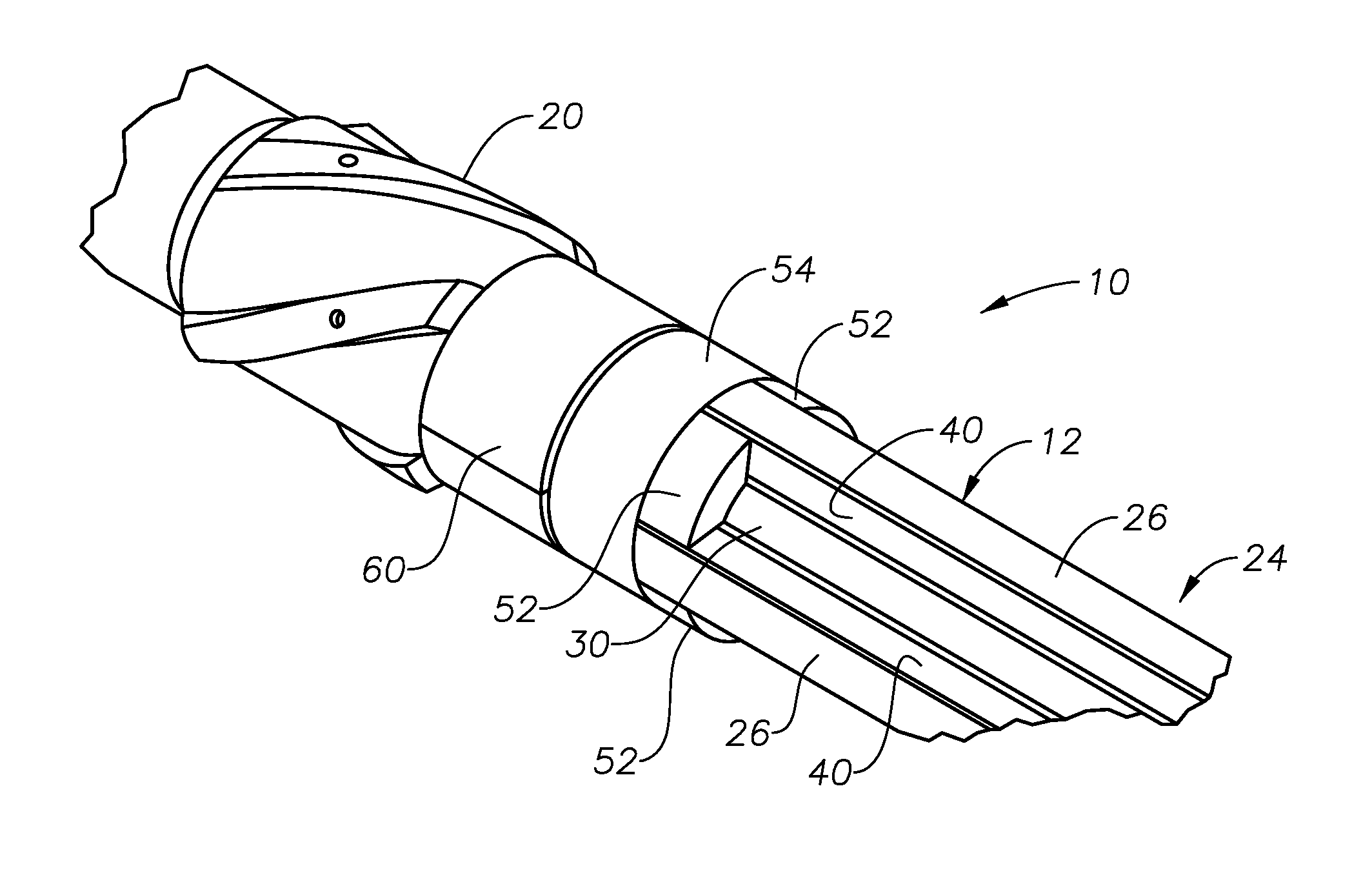

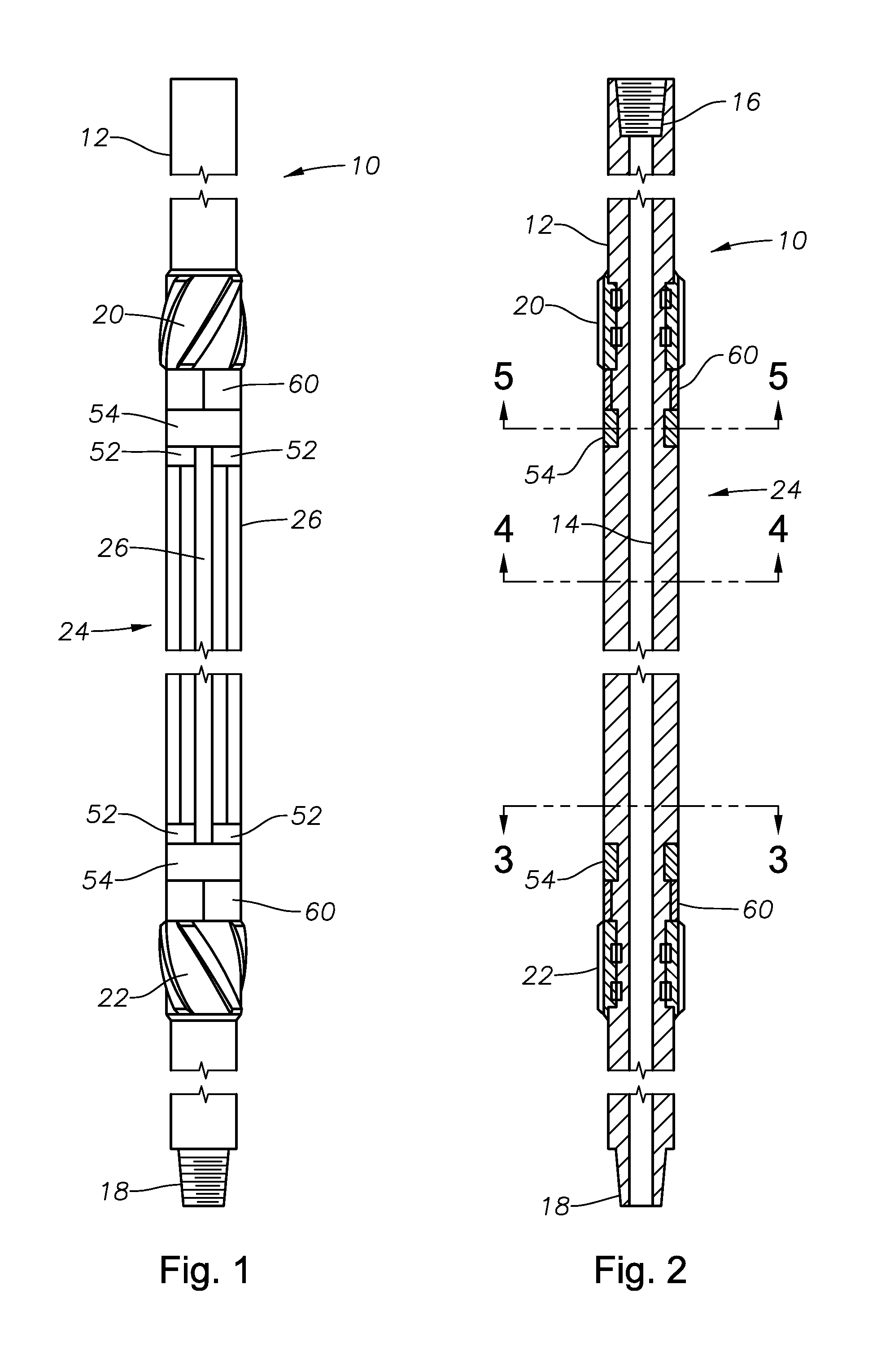

[0021]FIGS. 1-6 illustrate an exemplary magnetic retrieval tool 10 for use in removing metallic debris from a wellbore or other surrounding tubular. The tool 10 includes a generally cylindrical tool body 12 that defines a central axial flowbore 14. The exemplary tool 10 has an upper axial end with a box-type threaded portion 16 and a lower axial end with a pin-type threaded portion 18 for incorporating the tool 10 into a tool string, as is known in the art.

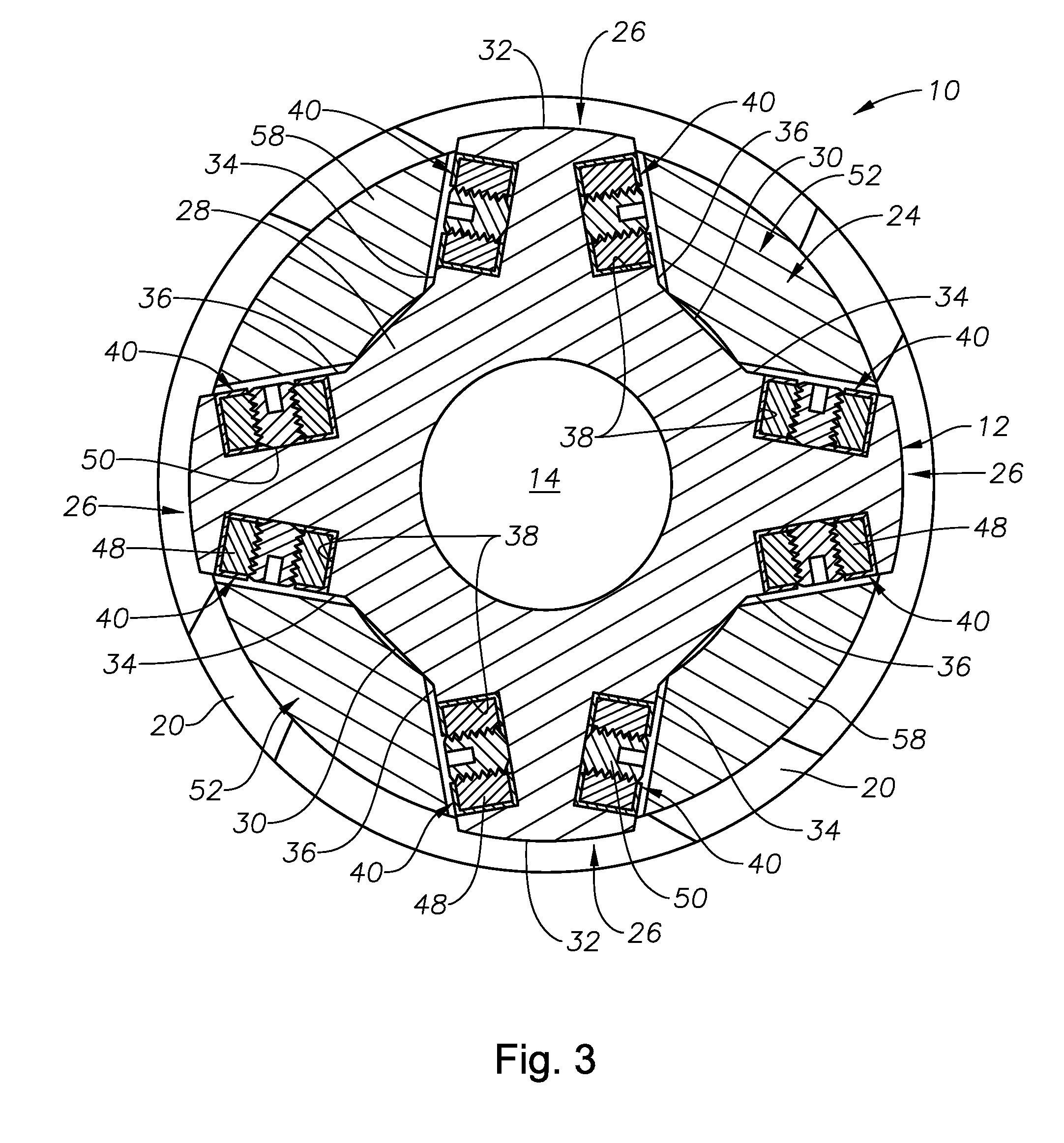

[0022]The tool body 12 carries upper and lower stabilizers 20, 22. The stabilizers 20, 22 are each rotatable with respect to the tool body 12 and may be identical in construction. A magnetic retrieval portion, generally shown at 24, is located axially between the upper and lower stabilizers 20, 22. As best seen in FIGS. 3 and 4, the magnetic retrieval portion 24 includes a plurality of axially extending ribs 26 that project radially outwardly from an inner shaft 28. The shaft 28 presents radially reduced recesses 30 that are locat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic | aaaaa | aaaaa |

| axial movement | aaaaa | aaaaa |

| metallic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com