Serrated shaft debris collector

A collector and sawtooth technology, applied in the direction of couplings, rigid shaft couplings, metal processing equipment, etc., can solve the problems of component complexity, falling off, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following description is merely exemplary in nature and is not intended to limit the invention, application or use.

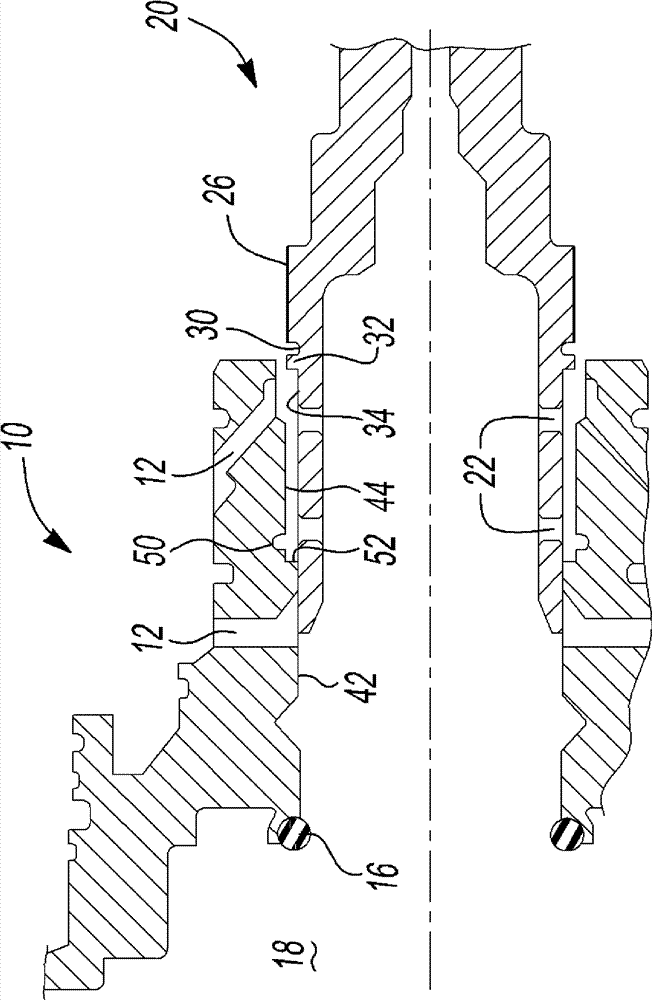

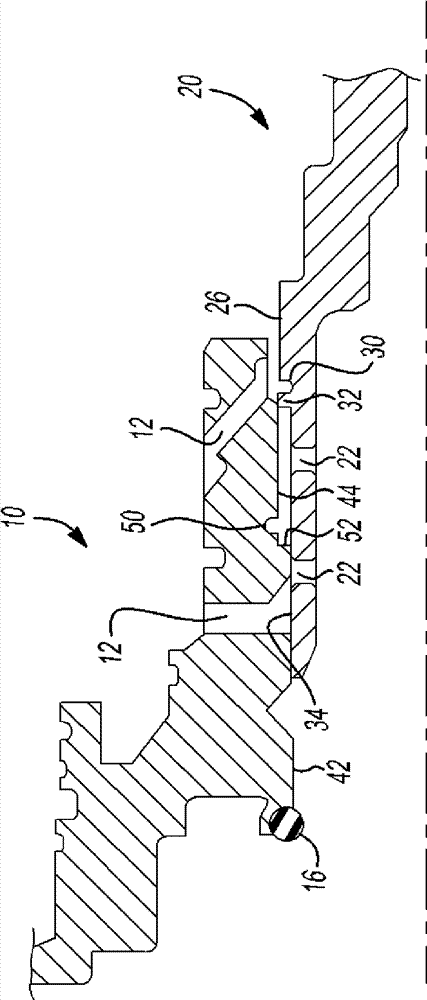

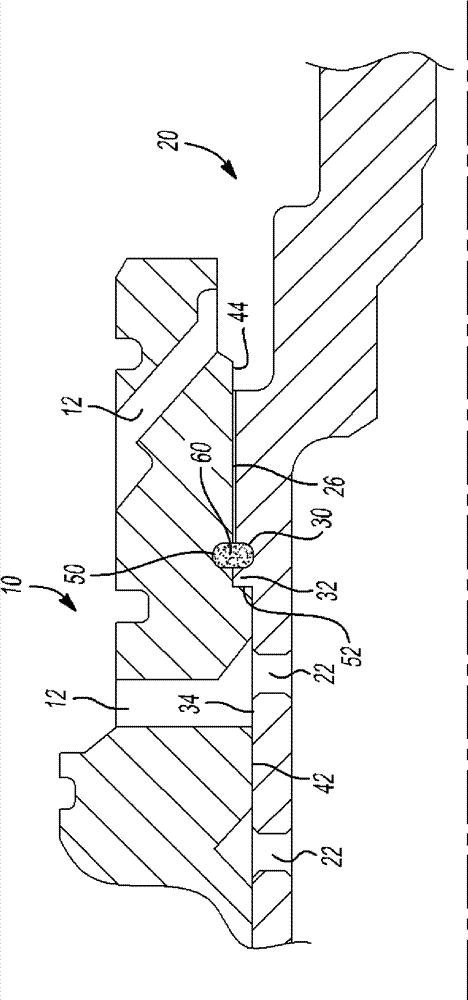

[0053] refer to figure 1 , 2 and 3 , show a housing, which may be, for example, a rotating component of an automatic transmission or other power transmission or transmission device, and is generally designated with reference number 10 . It will be appreciated that housing 10 is exemplary and illustrative only and that other components such as gears, pulleys, bearings, etc. may be used in its place. The housing 10 is circular, preferably made of a light and soft material such as aluminum, and includes a plurality of radially inclined channels 12 and external features such as splines or gear teeth (not shown) and can be accommodated in associated A cylindrical outer wall 14 within the component (also not shown). The housing 10 may also include an annular resilient seal 16 that engages and seals against a central region 18 of the housing 10 .

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com