Automatic material taking and placing machine for detecting radial runout of gear rings

A radial runout and automatic detection technology, applied in sorting and other directions, can solve the problems of low detection efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

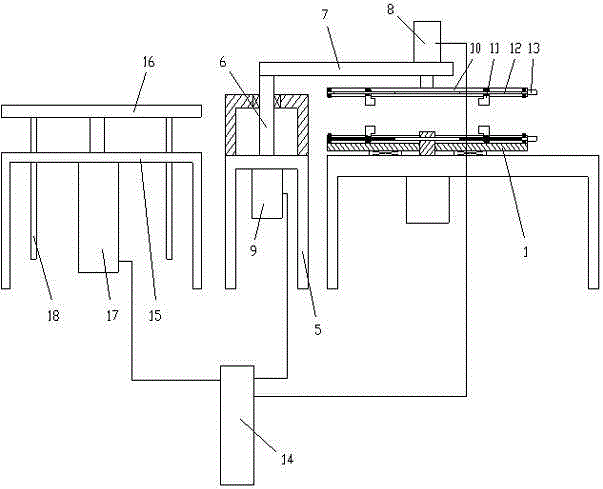

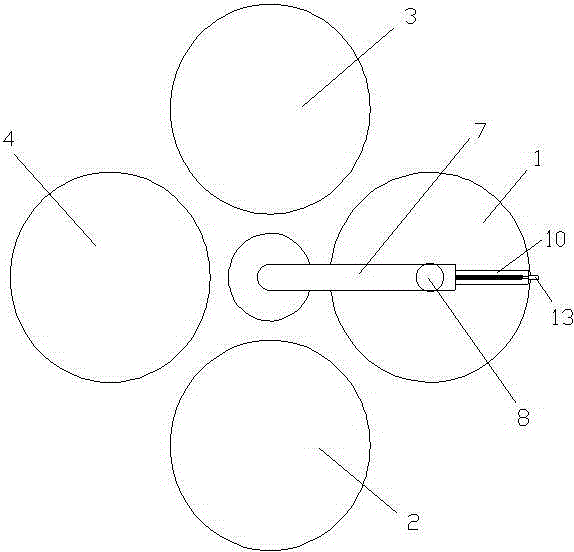

[0011] As shown in the figure, the automatic picking-and-discharging machine for detecting the radial runout of the ring gear in this embodiment includes a rotating claw device, a detection workbench device 1, a material placement device 2 to be inspected, a qualified material placement device 3 and a disqualified material placement device 4. The rotary material claw device includes a support 5, a rotating shaft 6 vertically arranged on the support and rotatably matched with the support, a beam 7 fixed on the rotating shaft, and a telescopic rod fixed on the beam vertically downward. The first electric cylinder 8, the mechanical claw connected to the end of the telescopic rod of the first electric cylinder, and the first servo motor 9 that drives the rotating shaft to rotate. The mechanical claw includes a straight guide rail 10 and two splints arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com