Production method for preparing m-nitrobenzenesulfonic acid by tubular sulfonation reactor

A technology of nitrobenzenesulfonic acid and its production method, which is applied in the direction of chemical method for reacting liquid with liquid, chemical instrument and method, preparation of sulfonic acid, etc., which can solve the problem of inability to realize rapid dispersion of droppings and inability to effectively remove reaction heat , uneven distribution of material concentration, etc., to overcome the uneven residence time of the material, the uneven concentration in the kettle, and the effect of overcoming local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

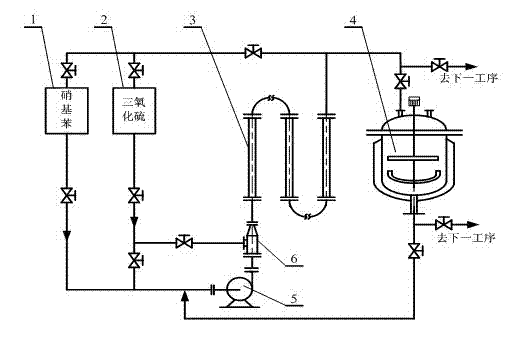

[0033] The production device and process in the production method of producing m-nitrobenzenesulfonic acid by tubular nitrobenzene sulfonation reaction include nitrobenzene storage tank (1), sulfur trioxide storage tank (2), tubular sulfonation reactor ( 3) There are 5 sets of tank-type sulfonation reactors (4), material transfer pumps (5), jet pumps (6), connected pipelines and accessories arranged vertically in series. The tubular sulfonation reactor (3) is connected in series with the kettle-type sulfonation reactor (4), and part of the reaction product, m-nitrobenzenesulfonic acid, re-enters the tubular sulfonation reactor (3), such as figure 1 .

Embodiment 2

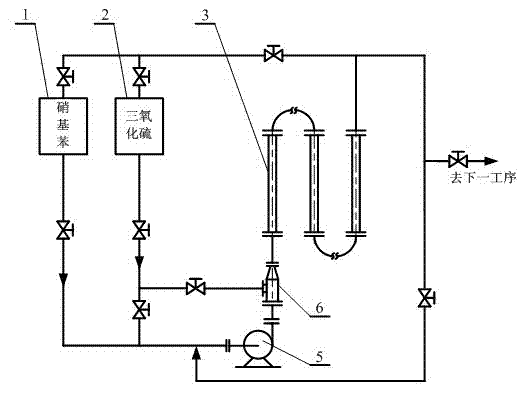

[0035] Embodiment 2 is basically the same as Embodiment 1, except that the tubular sulfonation reactor (3) is a single vertical arrangement.

Embodiment 3

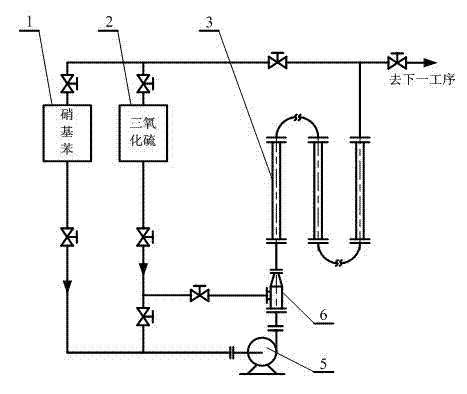

[0037] Embodiment 3 is basically the same as Embodiment 1, except that 5 tubular sulfonation reactors (3) are arranged in series and horizontally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com