Patents

Literature

56results about How to "Uniform residence time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

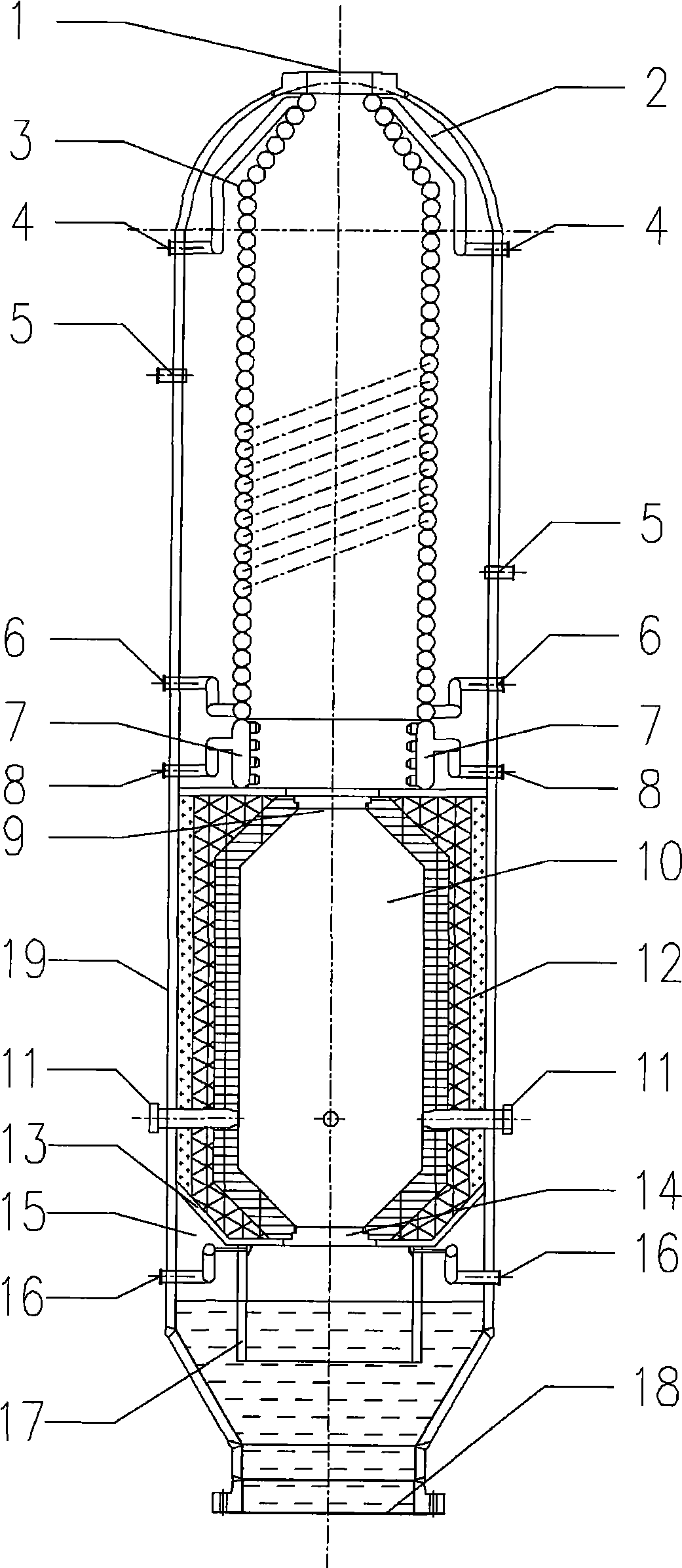

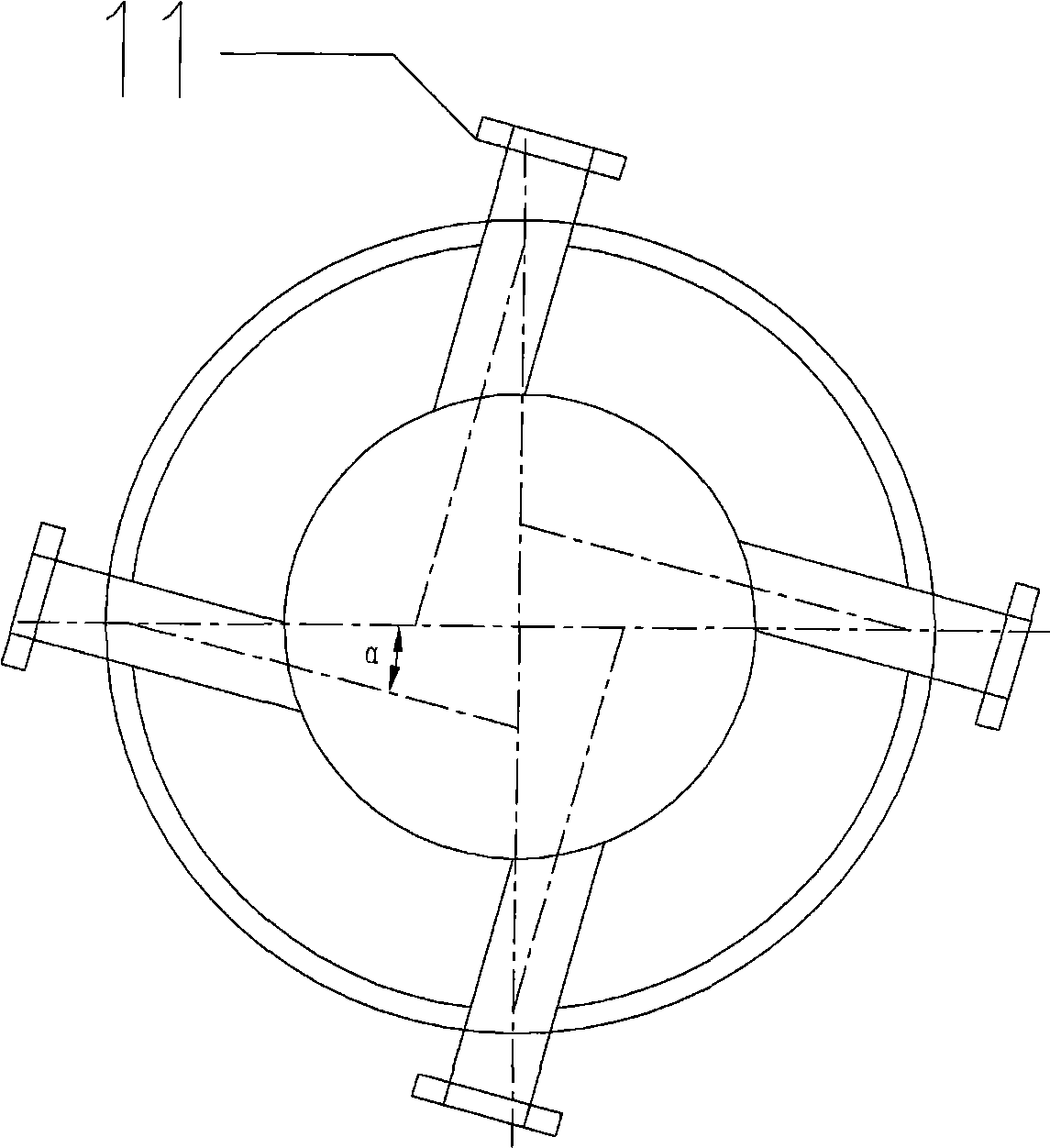

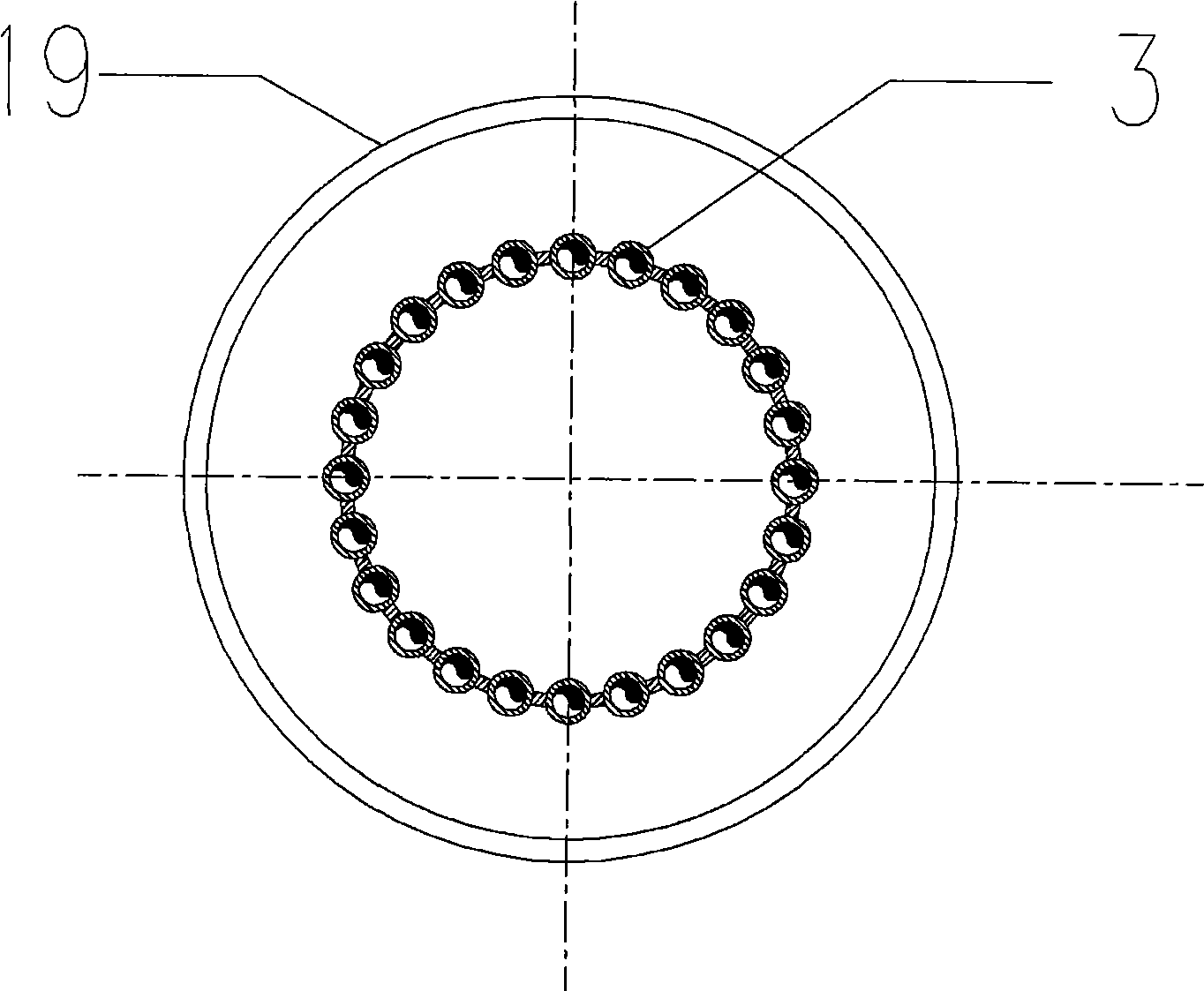

Gasifying device for liquid fuel or solid fuel aqueous slurry

ActiveCN101508915AImprove sensible heat utilization efficiencyEasy to processCombined combustion mitigationGranular/pulverulent flues gasificationCooling chamberSolid fuel

The invention relates to a gasifying device of liquid fuel or solid fuel water slurry. The gasifying device comprises a gasification furnace housing (19) that is a right cylinder, and the internal structure is divided into three segments that are respectively a gas cooling chamber (2), a vaporizing chamber (10) and a cinder collection chamber (15) from top to bottom; the three chambers are vertically and axially connected in the gasification furnace housing (19); the top of the gasification furnace housing (19) is provided with a gas outlet (1), and the bottom is provided with a cinder equipment interface (18). Compared with the prior art, the gasifying device has the advantages of simple structure, easy manufacture, low investment cost, etc.

Owner:WISON ENG +1

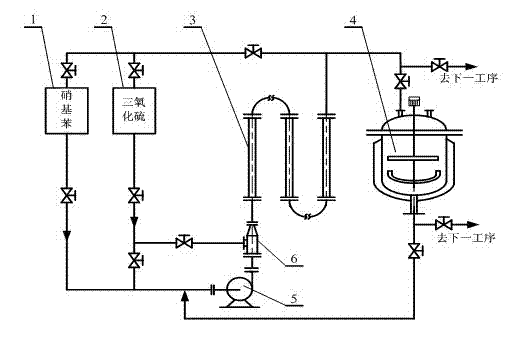

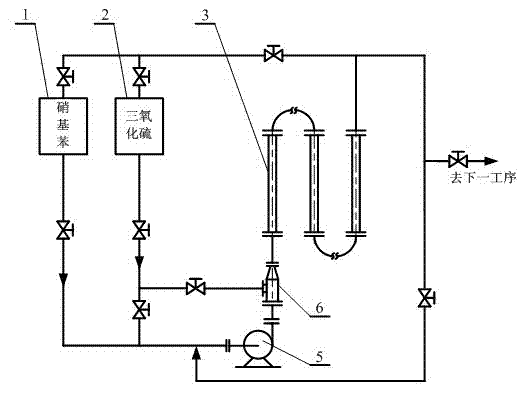

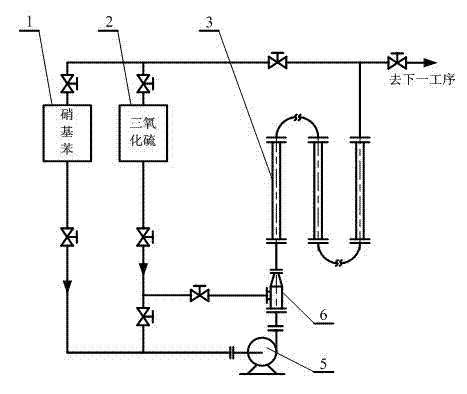

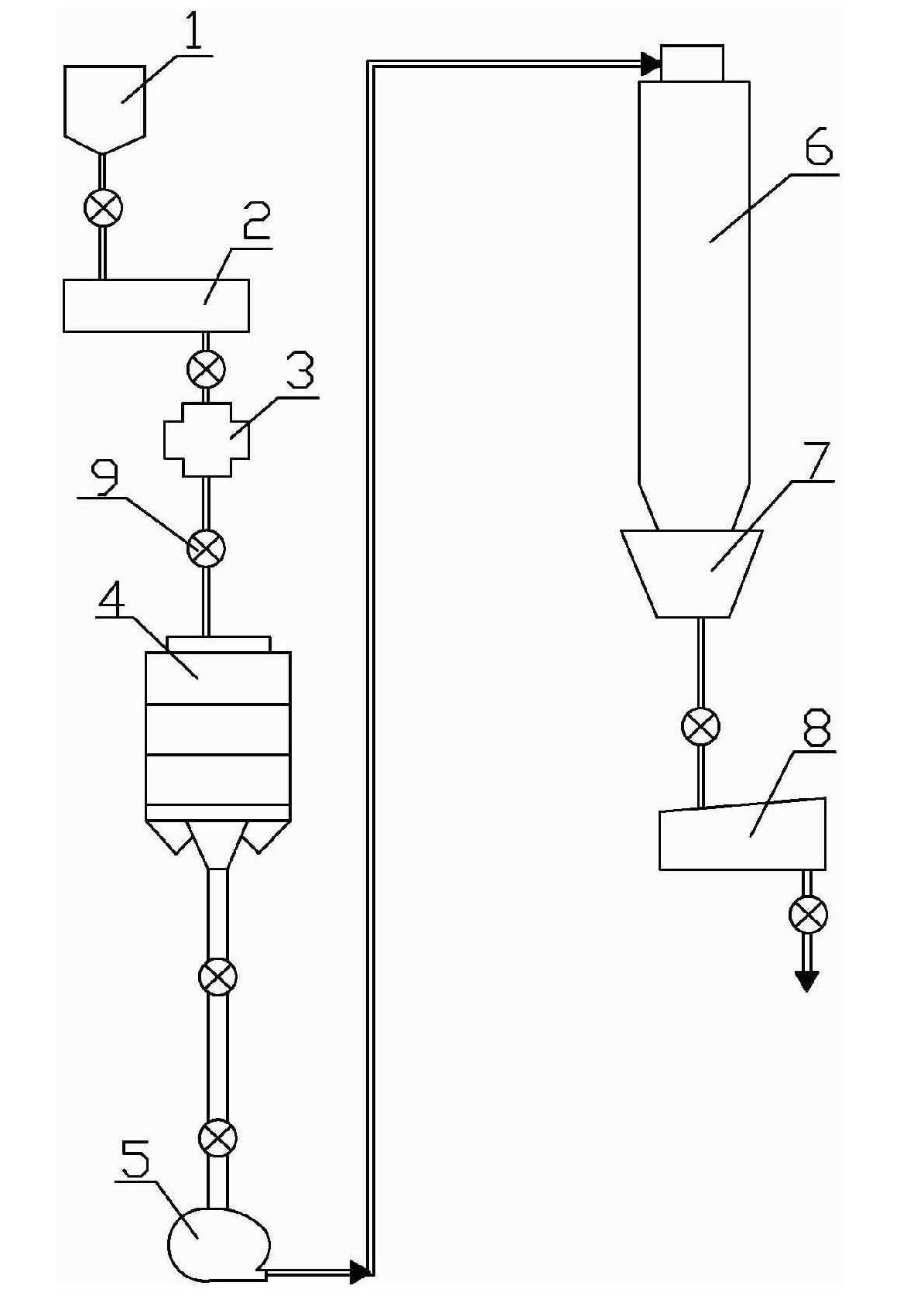

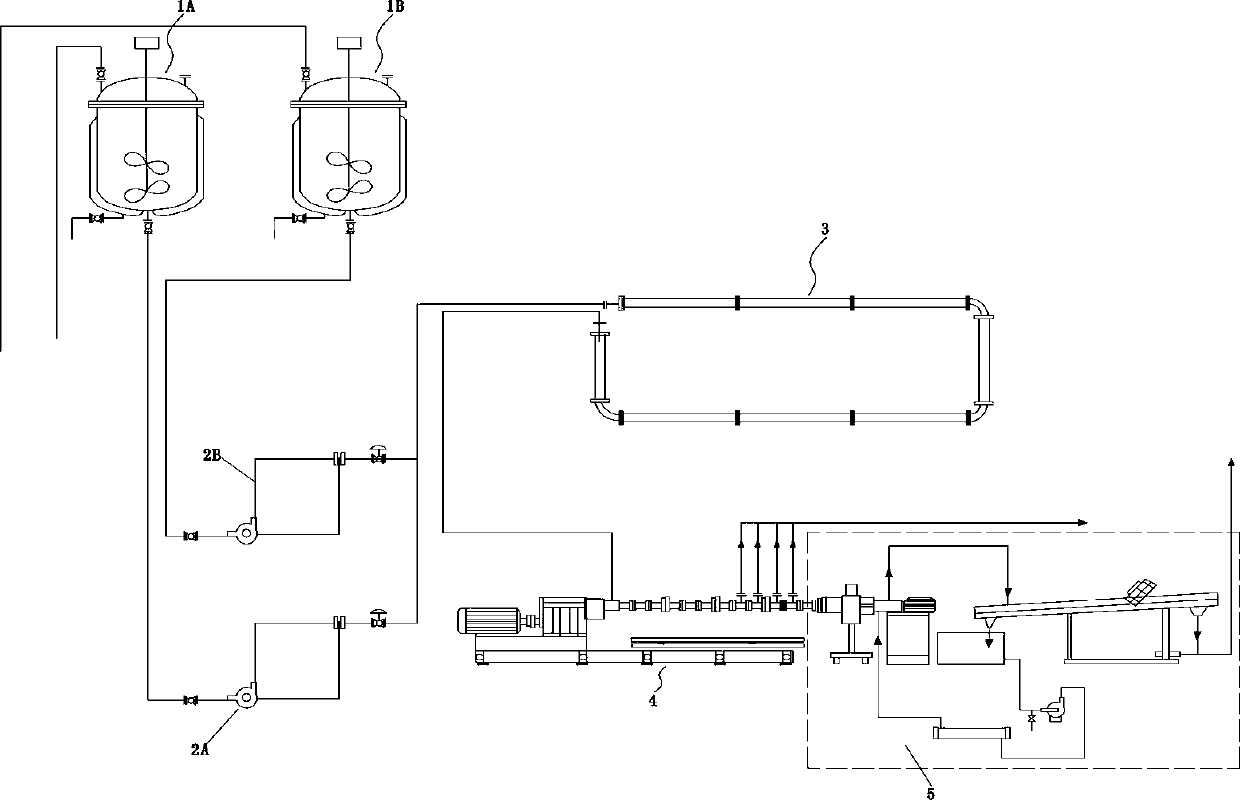

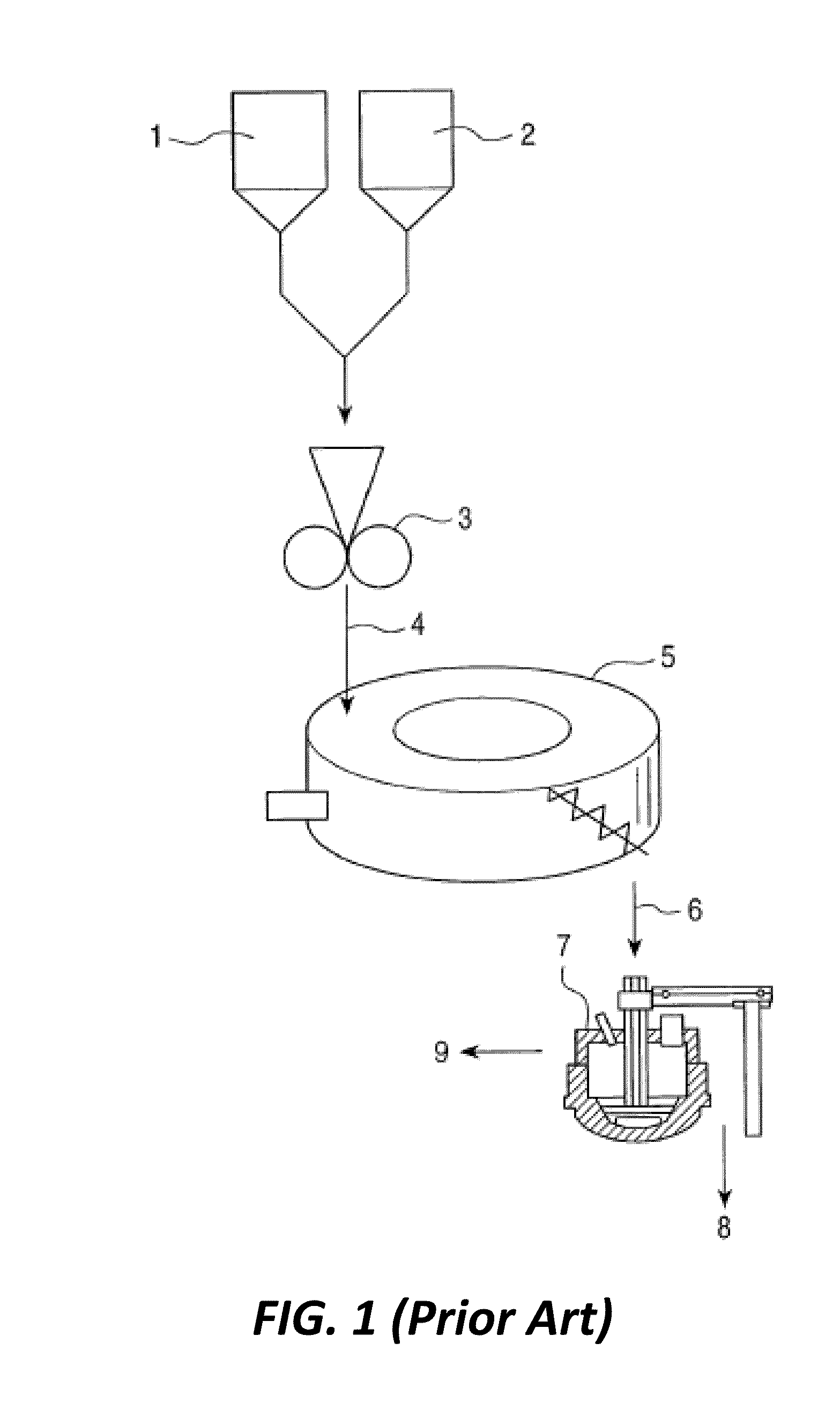

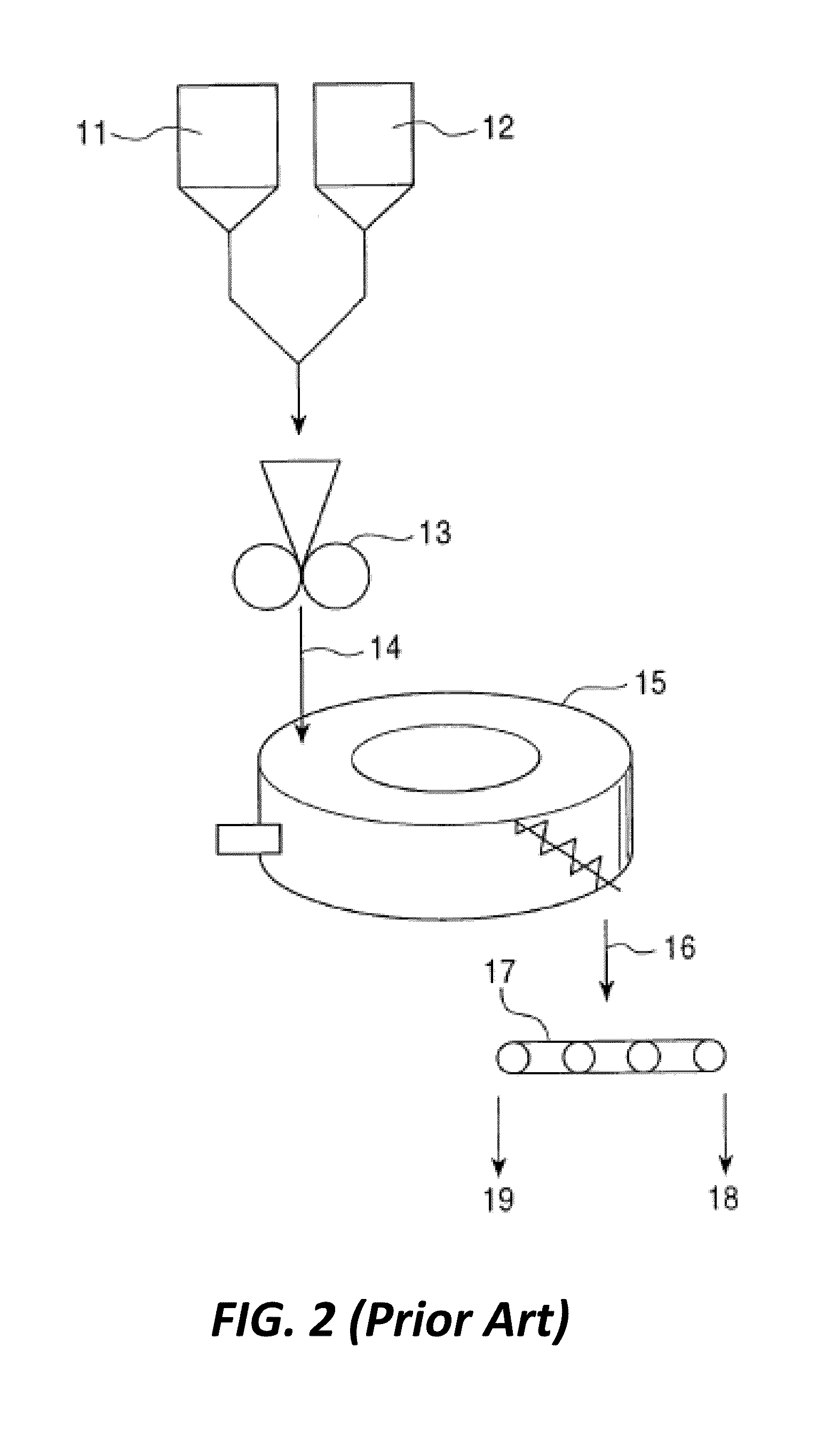

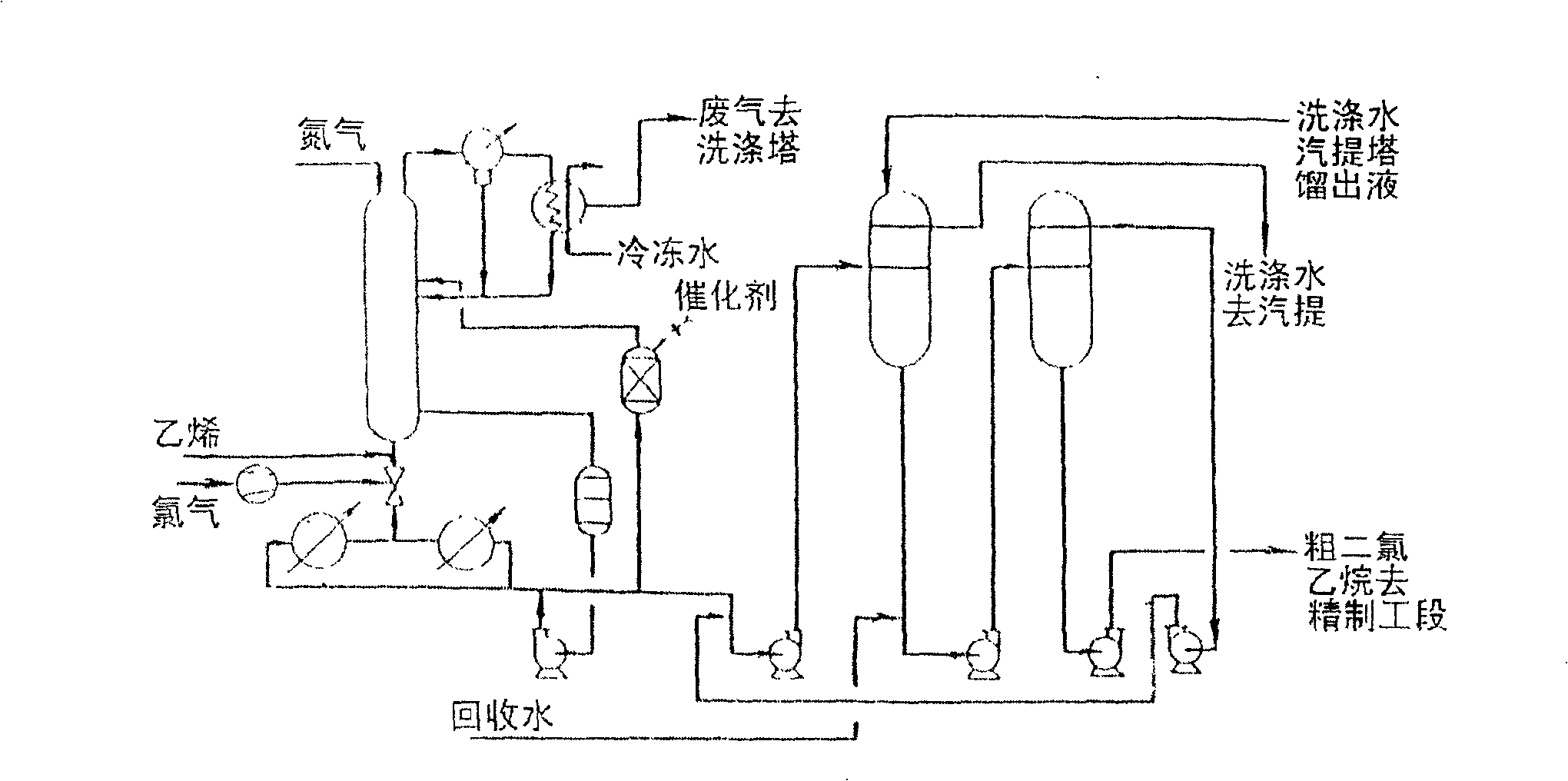

Production method for preparing m-nitrobenzenesulfonic acid by tubular sulfonation reactor

ActiveCN102188942AImprove heat transfer efficiencyRemoved in timeSulfonic acid preparationLiquid-liquid reaction processesNitrobenzeneSulfur trioxide

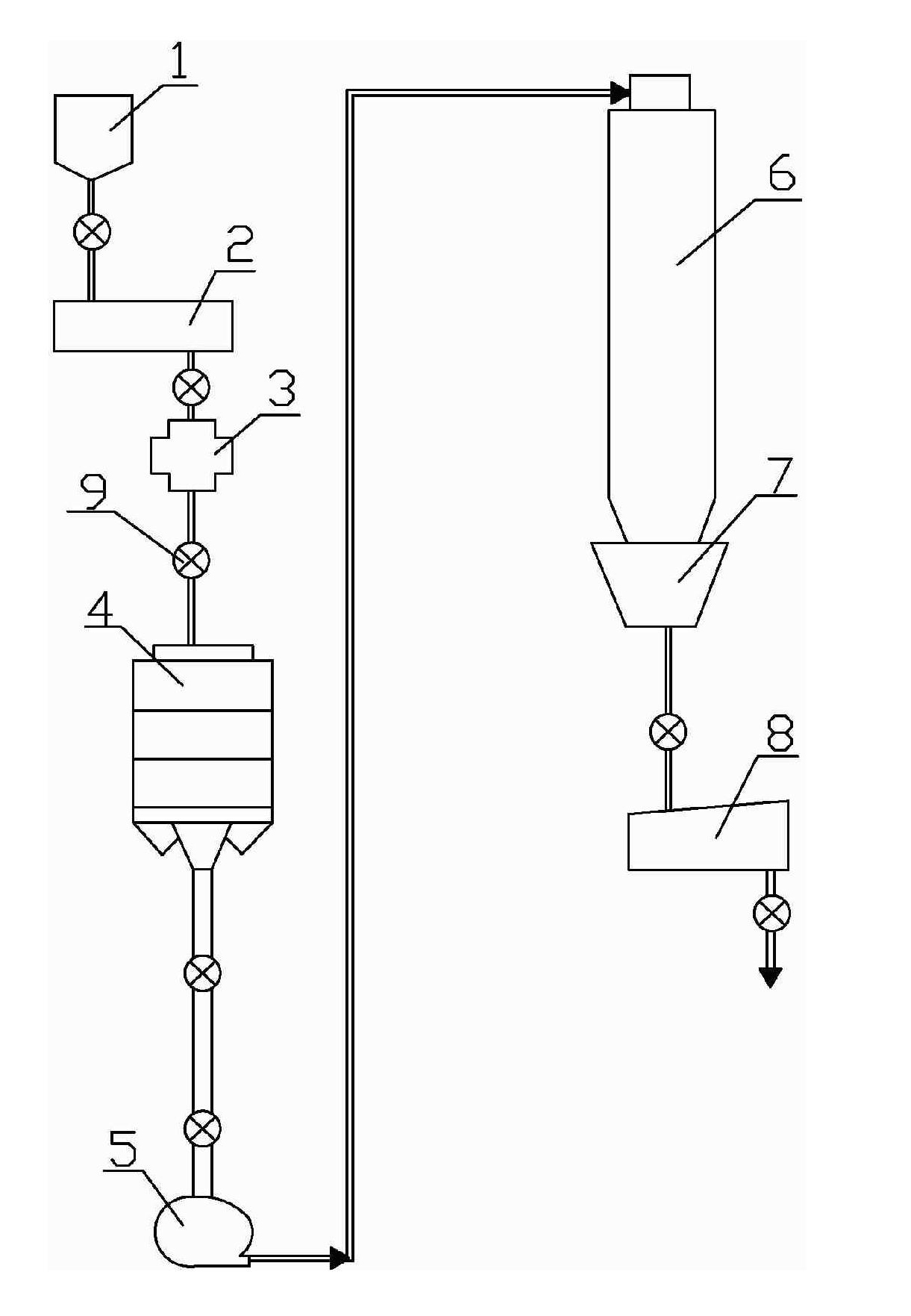

The invention discloses a production method for preparing an m-nitrobenzenesulfonic acid by a tubular sulfonation reactor and relates to the production method of a chemical product. A production device comprises a nitrobenzene storage tank (1), a sulphur trioxide storage tank (2), the tubular sulfonation reactor (3), a kettle sulfonation reactor (4), a material delivery pump (5), a spraying pump (6), a connecting pipeline and accessories (a valve, a flow meter, a thermometer, an anti-explosion film, sight glass and the like). Nitrobenzene and a sulphur trioxide sulfonating agent enter the tubular sulfonation reactor (3) in proportion, the tubular sulfonation reactor (3) and the kettle sulfonation reactor (4) are used in series, or the tubular sulfonation reactor (3) is used independently.The invention is applied to continuous or discontinuous sulfonation reaction, good in mixing and heat transfer effects, high in reaction speed, high in production efficiency and high in operational flexibility. The production device and the production method which are provided by the invention are applied to various sulfonation reaction production processes.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

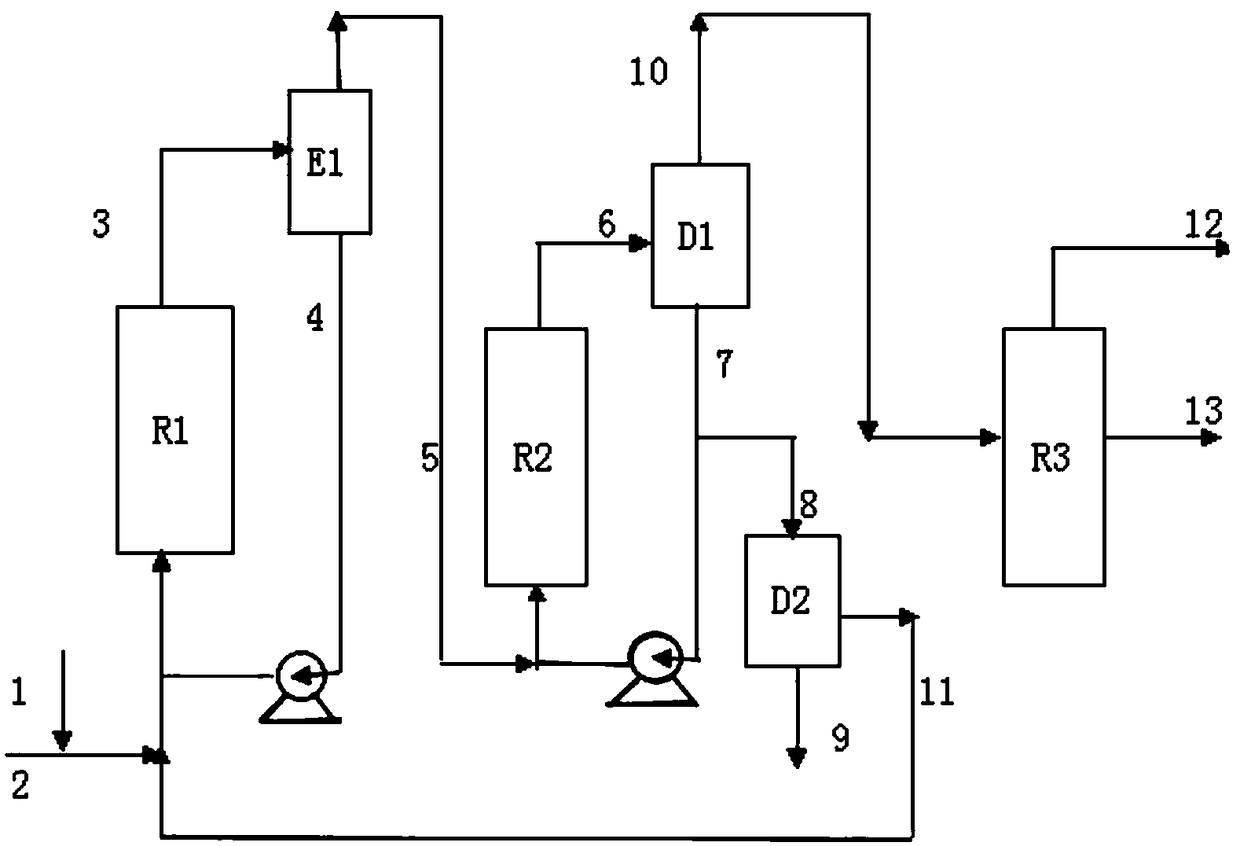

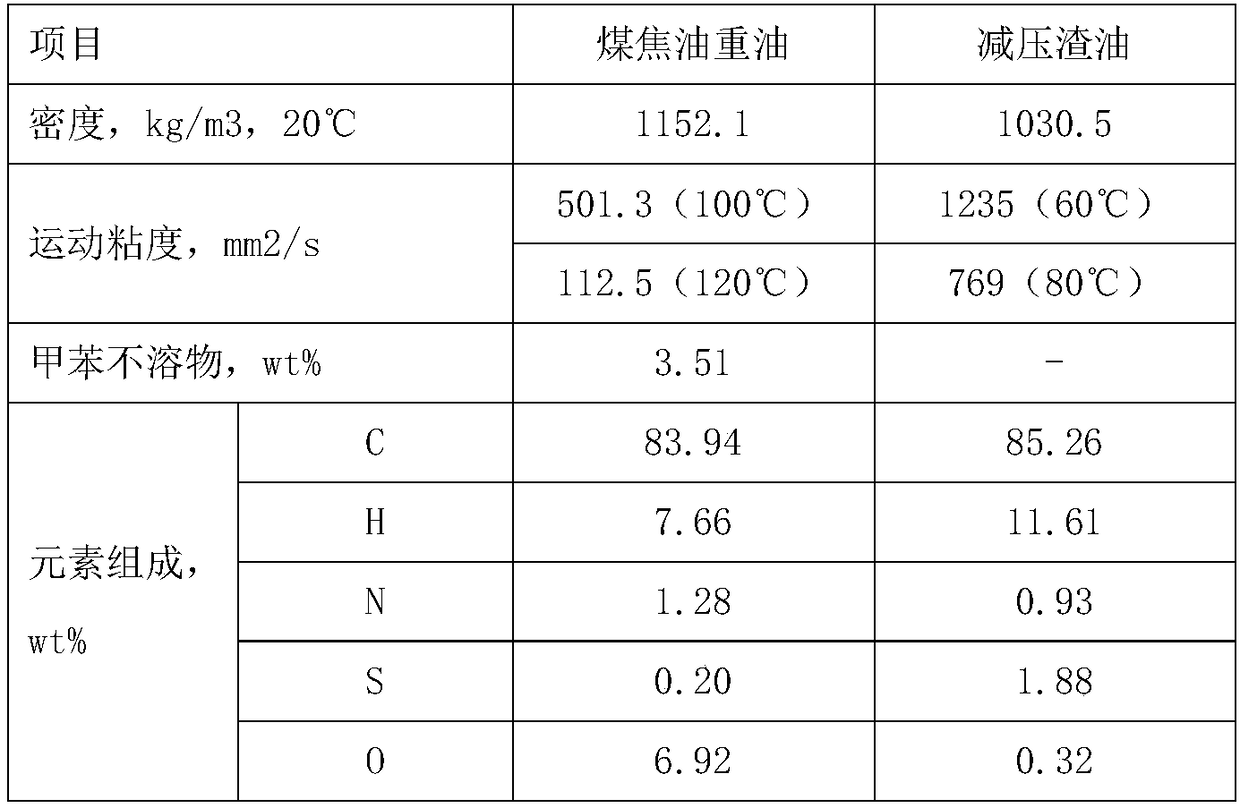

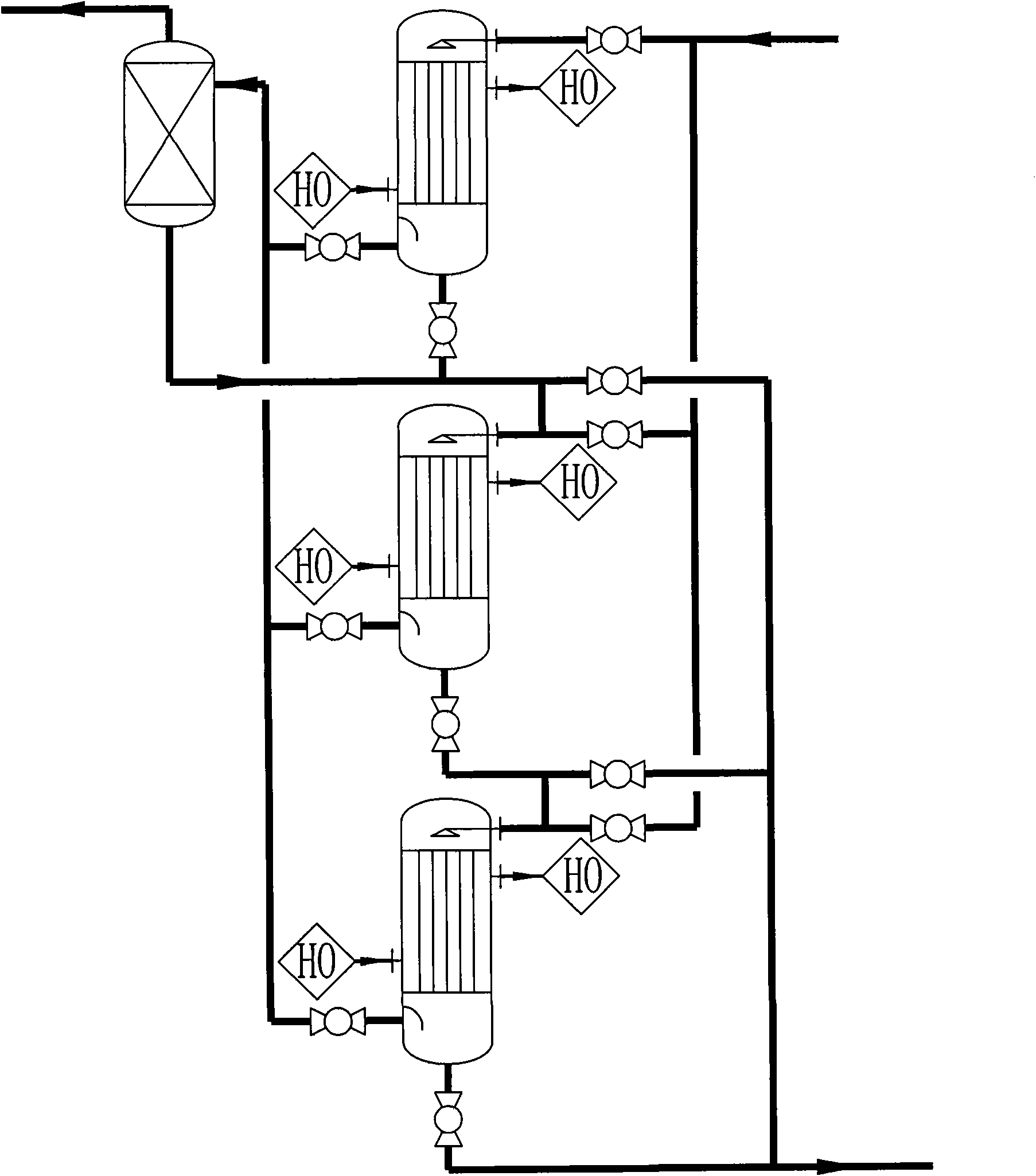

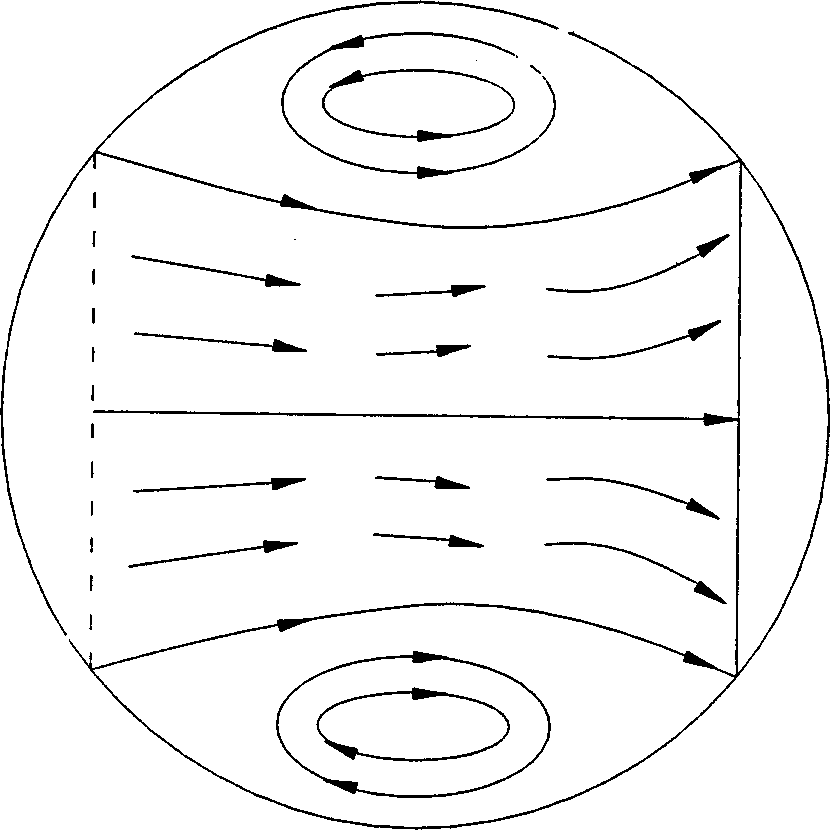

Heavy oil hydrogenation method and hydrogenation system

ActiveCN108659882AEnough time to stayGuaranteed conversion rateTreatment with hydrotreatment processesHydrogenRetention time

The invention relates to a heavy oil hydrogenation method and a hydrogenation system. The heavy oil hydrogenation method comprises the steps of mixing heavy oil, circulation oil, a valcanizer and a catalyst, performing hydrocracking on the heavy oil, the circulation oil, the valcanizer, the catalyst and hydrogen in a first reactor to form a first reaction product, allowing part of first reaction product to return to the first reactor, performing hydrocracking on the rest of the first reaction product in a second reactor to form a second reaction product, dividing the second reaction product into a light component and a heavy component, returning part of the heavy component to the second reactor, separating the rest of the heavy component to form distillate oil as the circulation oil, and hydrofining the light component in a third reactor to form a light oil product. The method improves heat transfer and mass transfer efficiency, ensures retention time of the material in the reactors, and increases a heavy oil conversion rate and a light oil yield. According to the hydrogenation system for the method, internal members of the reactors are simplified, and equipment investment and operation energy consumption are reduced.

Owner:CCTEG CHINA COAL RES INST

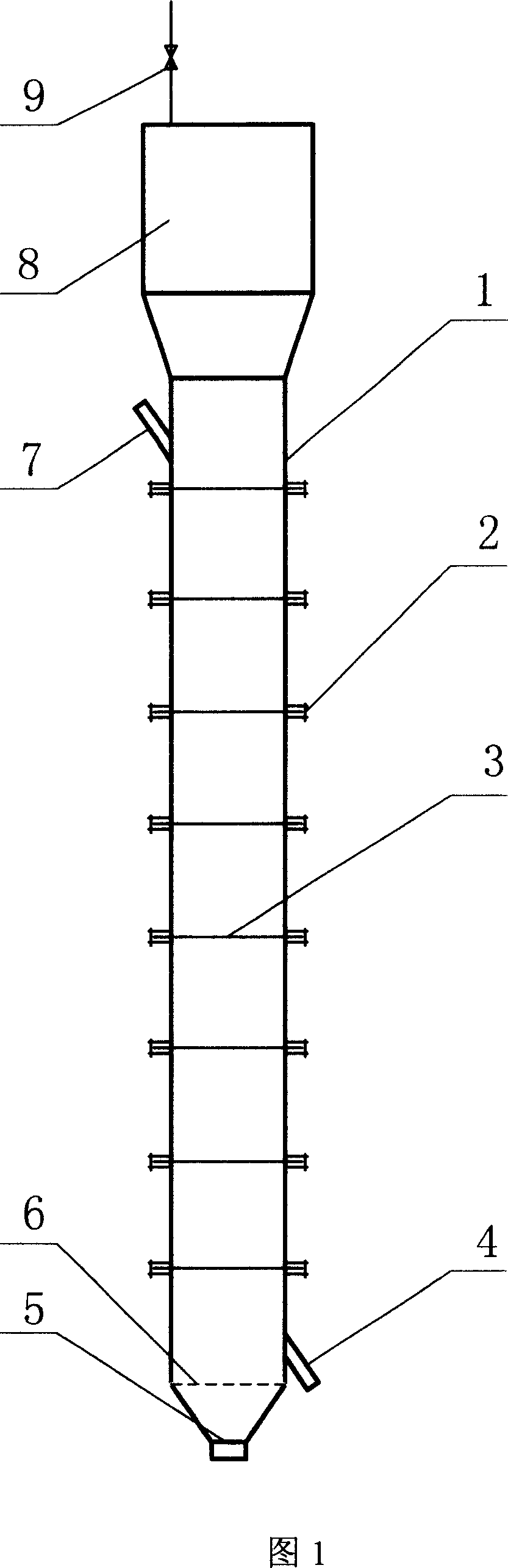

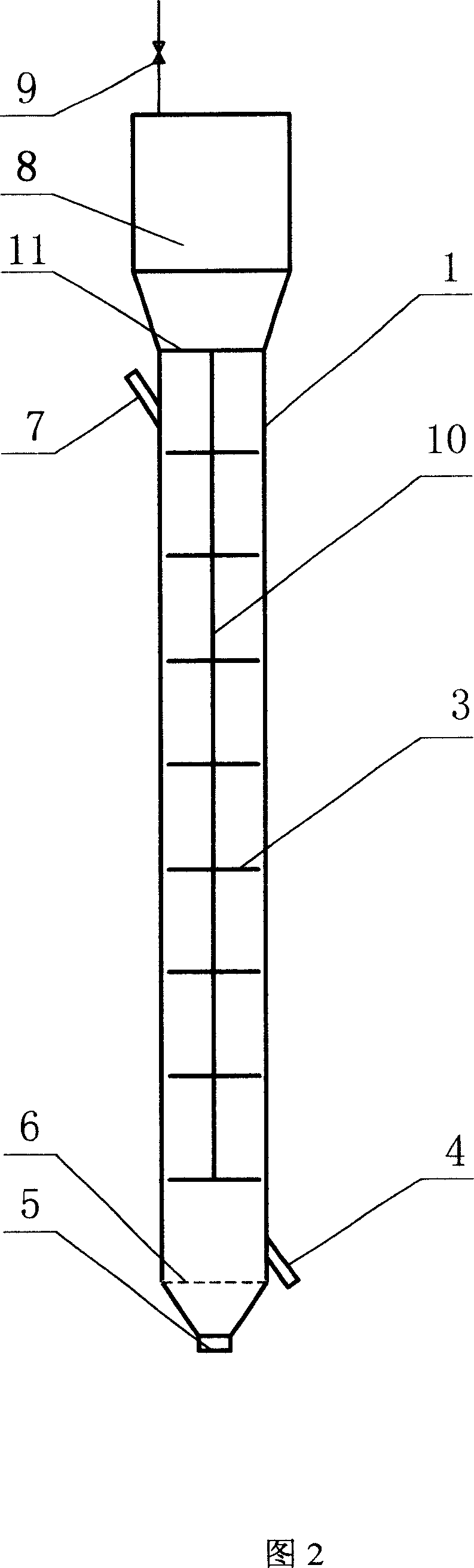

Fluidized-bed reactor for oxidizing carbon black through ozone

InactiveCN1958145AEliminate channelingElimination of Broken AgglomeratesPigmenting treatmentChemical/physical processesFluidized bedProduct gas

A fluidized-bed reactor for oxidizing carbon black by ozone with stable fluidizing and no coagulation of carbon black particles has a main body with lower carbon black discharging outlet, gas inlet on its bottom, upper carbon black inlet, gas outlet on its top, internal barrier plate with slits, and gas distributing plate under the carbon black discharging outlet.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Hydrogenation process for coal direct liquefaction circulation solvent

InactiveCN1844318AUniform temperature distributionHomogenization of temperature distributionLiquid hydrocarbon mixture productionBrown coalChemical reaction

The invention adopts a catalyst grading technology and installs adequate chemical reaction environment to carry out incompletely saturated hydrogenation in a mild technological condition, which not only mildly hydrogenates the unsaturated compound in dissolvent, but also mildly hydrogenates the saturated compound. The affected compounds of the hydrogenated dissolvent reach even degree of unsaturation on molecular structure, which improves transferable hydrogen content of molecule, accordingly the free hydrogen(-H) released by cycle dissolvent just can meet the need of hydrogen consumption of direct liquefaction of brown coal in a mild technological condition. The invention can simplify the industrial process of lignite liquification and solvent hydrogenation, reduce the device requirement, and save investment and operating cost.

Owner:ZHAOQING SHUNXIN COAL CHEM TECH

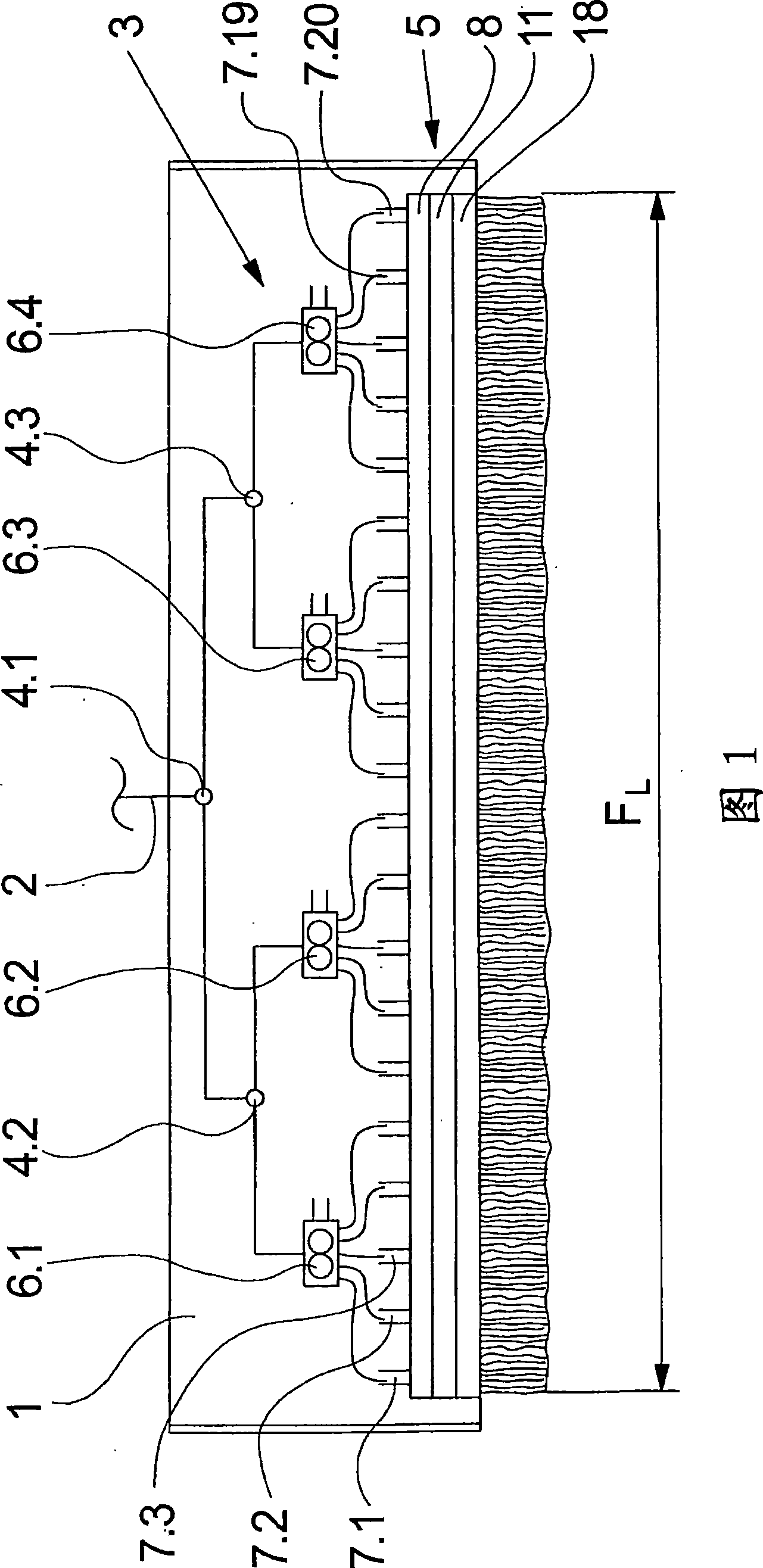

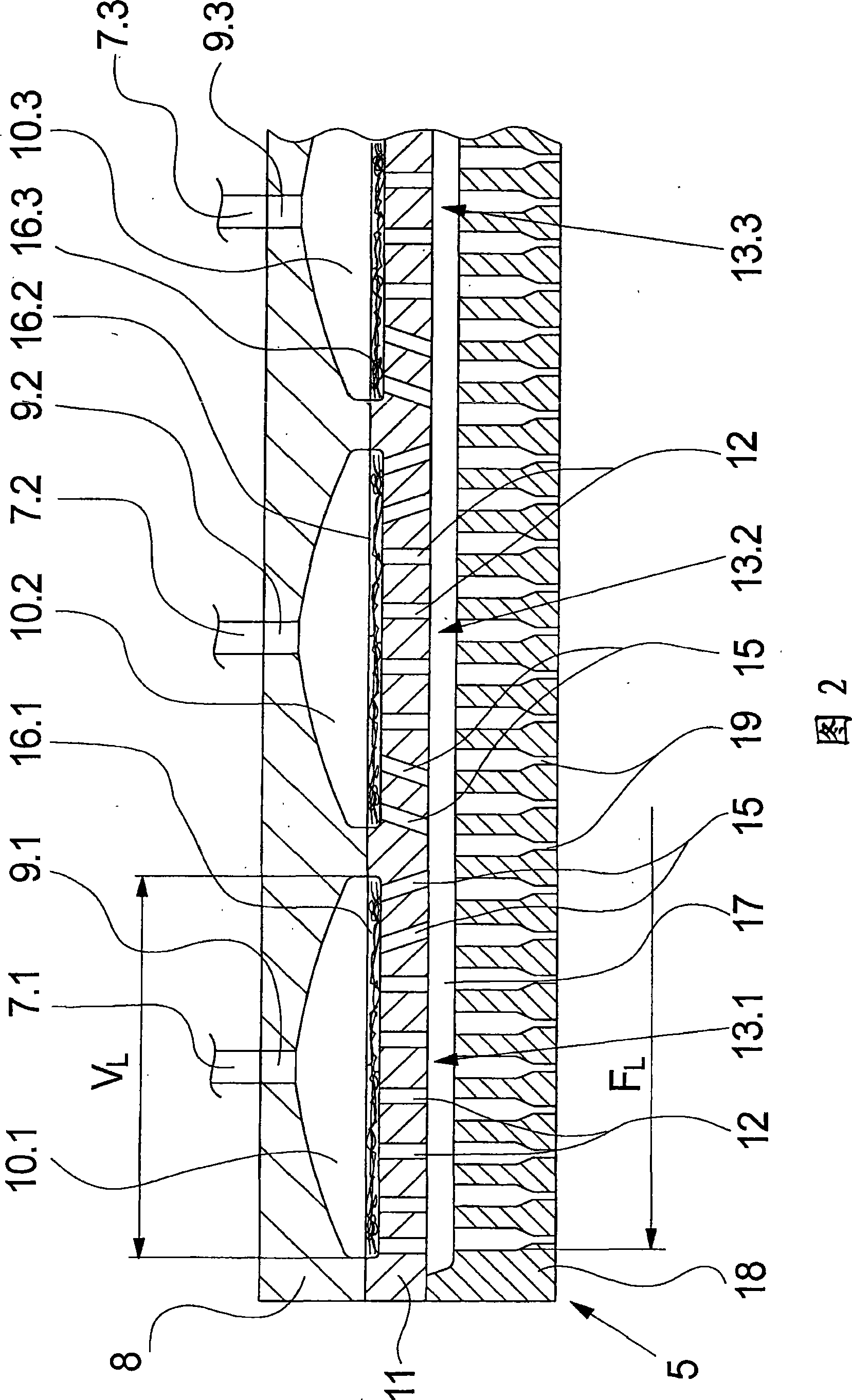

Device for melt spinning of a linear filament bundle

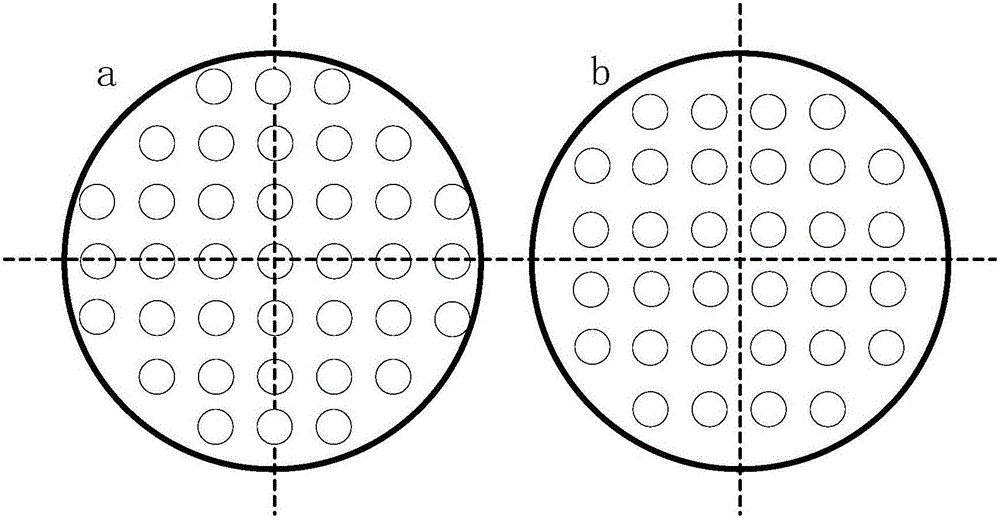

ActiveCN101443489AEvenly distributedConstant dwell timeSpinnerette packsMelt spinning methodsPolymer meltMelt spinning

The invention relates to a device for melt spinning of a linear filament bundle with a spinning beam for mounting a longitudinal spinning nozzle group. The spinning nozzle group comprises a nozzle plate on an underside with a number of nozzle drillings and an inlet plate on an upper side with at least one inlet channel, a distribution chamber being arranged between the inlet plate and the nozzle plate, connected to the inlet channel in the inlet plate and the nozzle drillings in the nozzle plate. According to the invention, a residence time for the polymer melt within the nozzle group is kept as constant as possible with a large production range by means of the inlet plate having several residence chambers connected to inlet channels, arranged at a separation from each other in the longitudinal direction of the spinning beam.

Owner:OERLIKON TEXTILE GMBH & CO KG

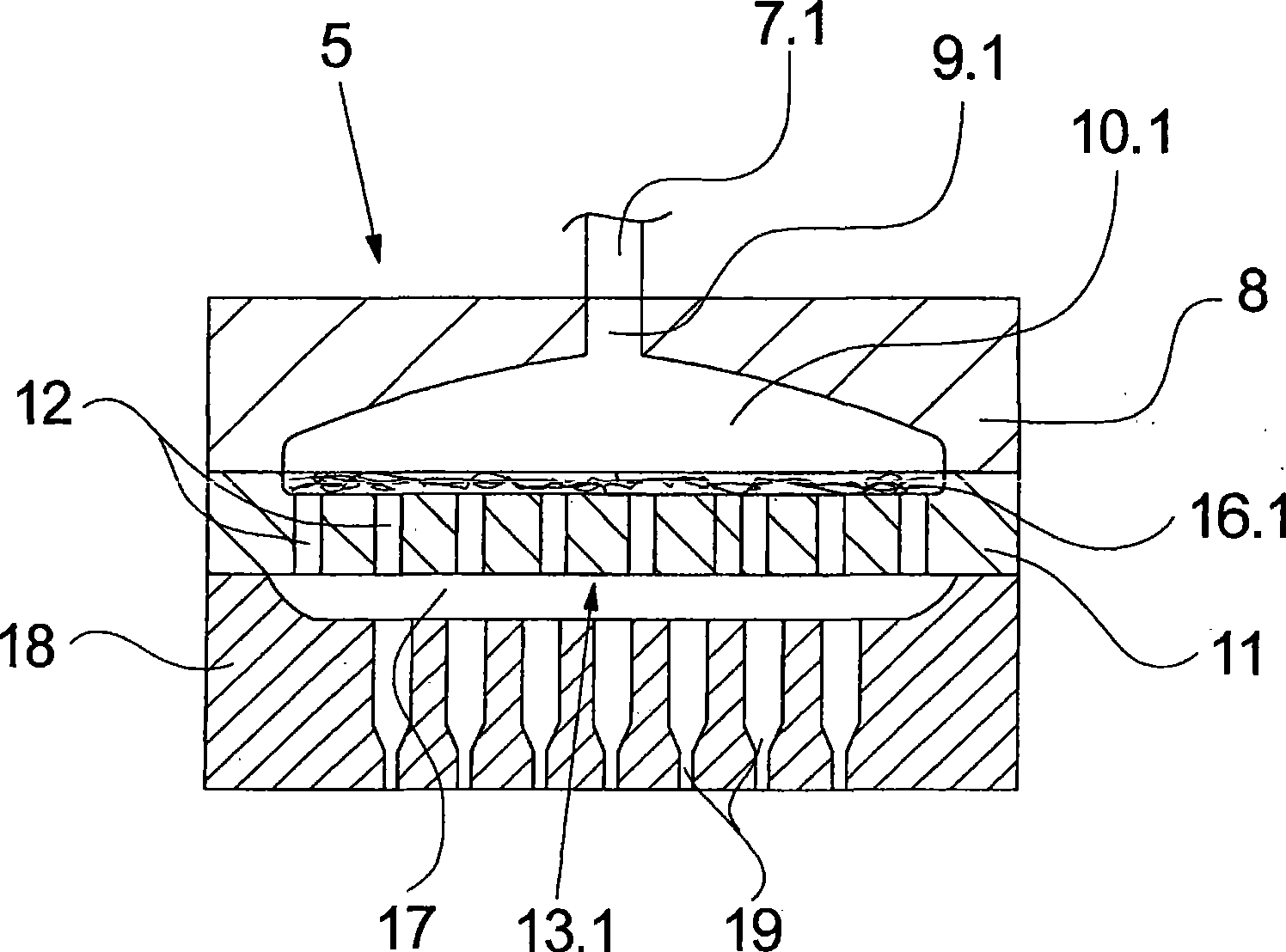

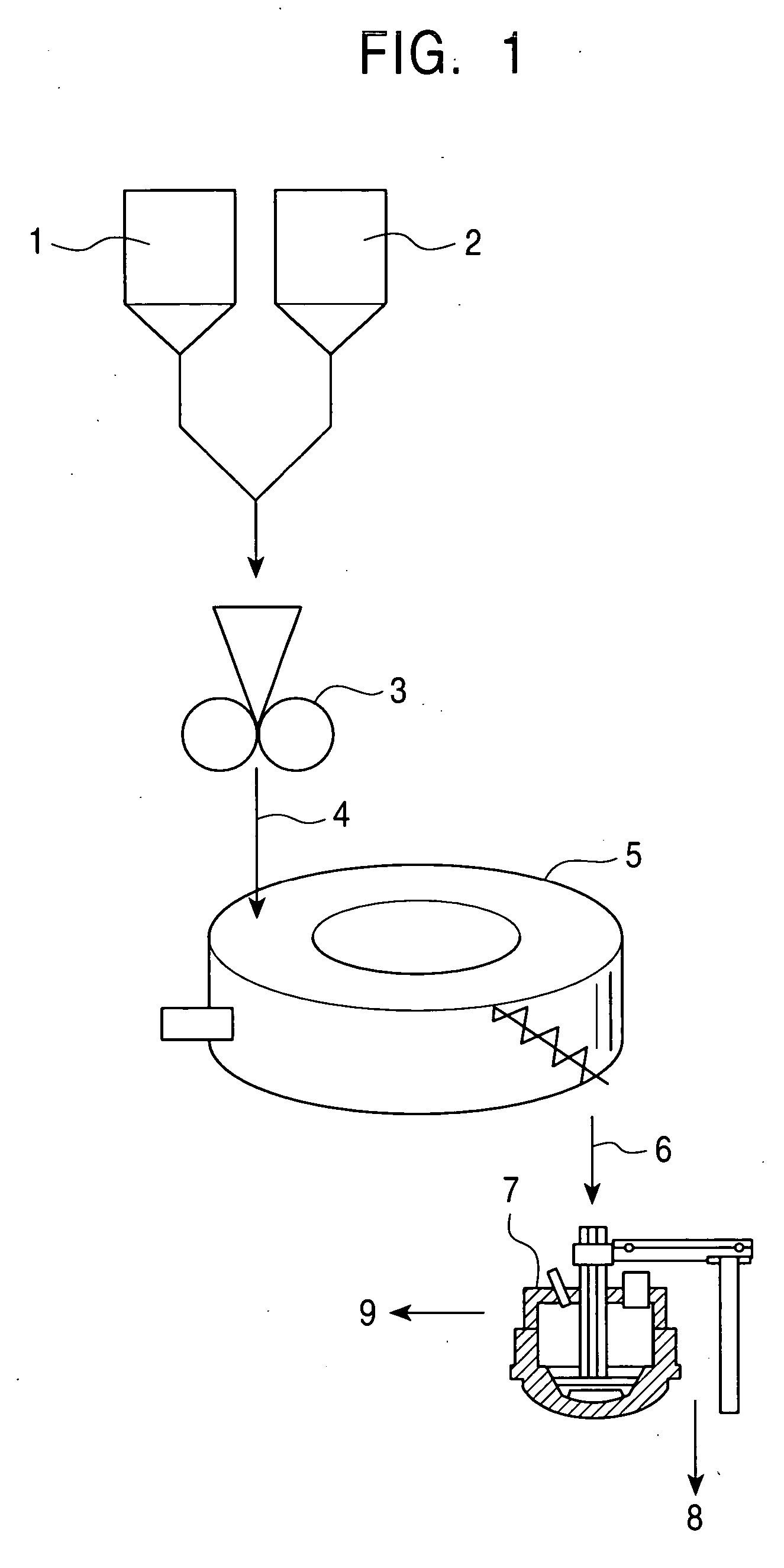

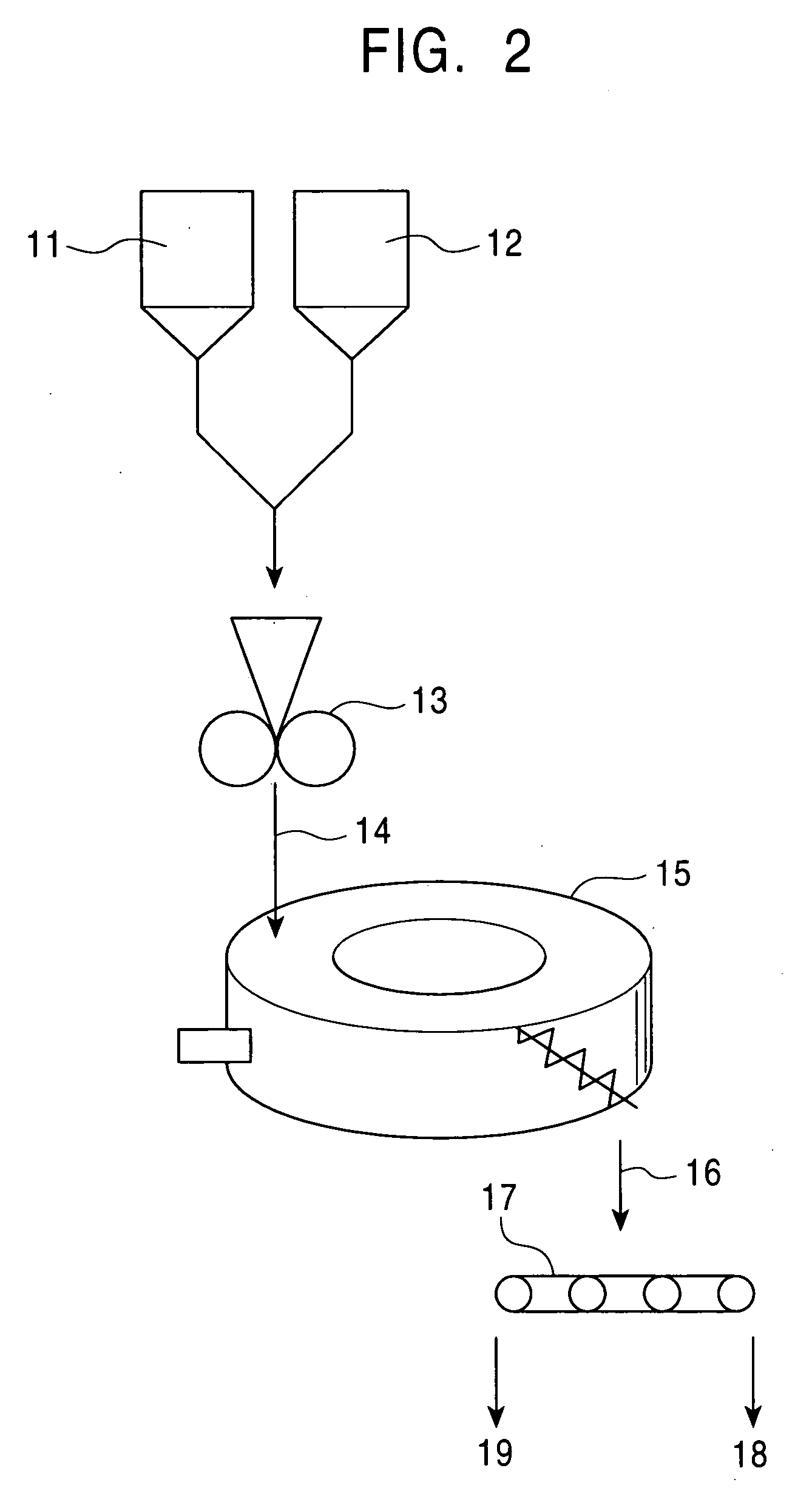

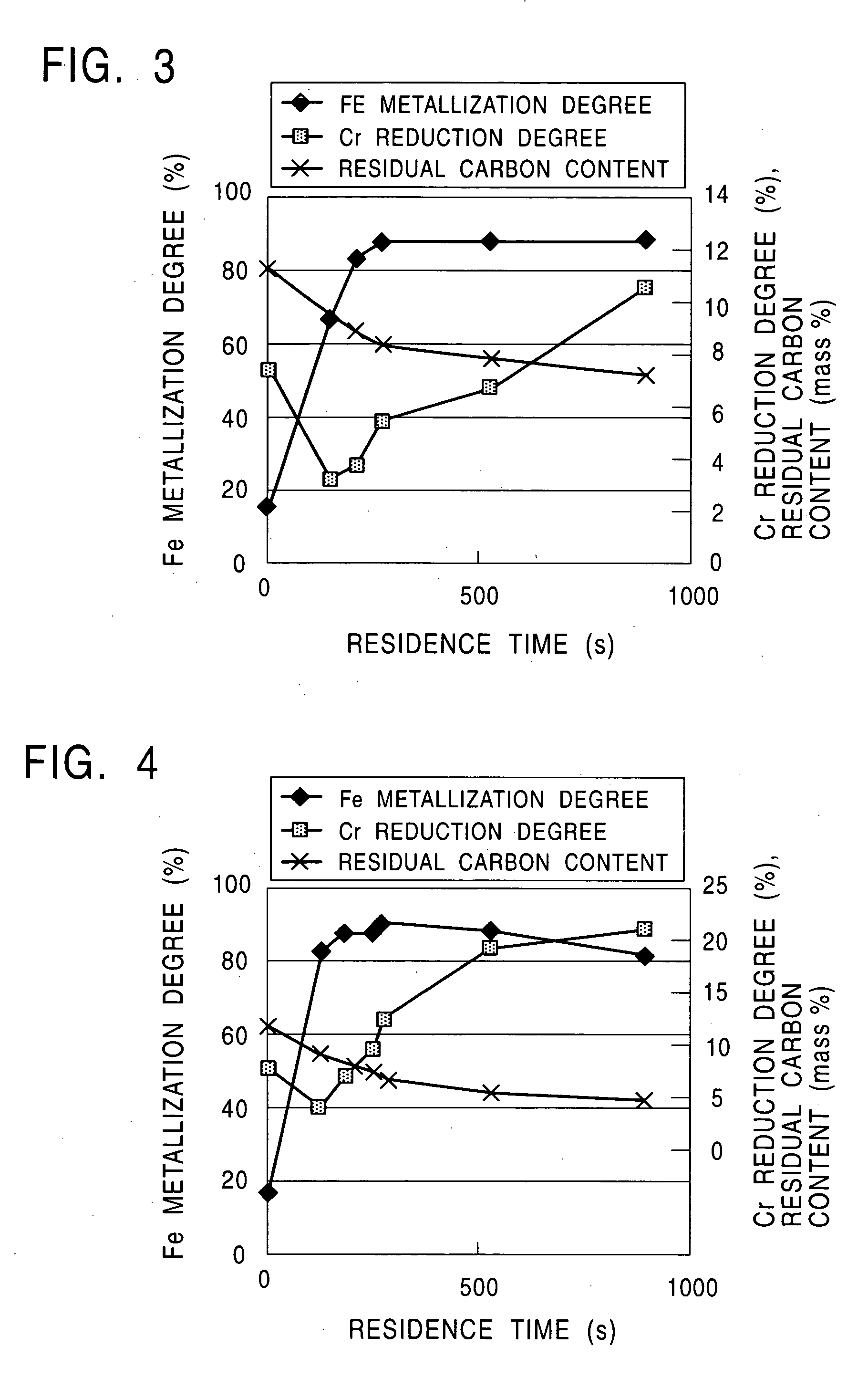

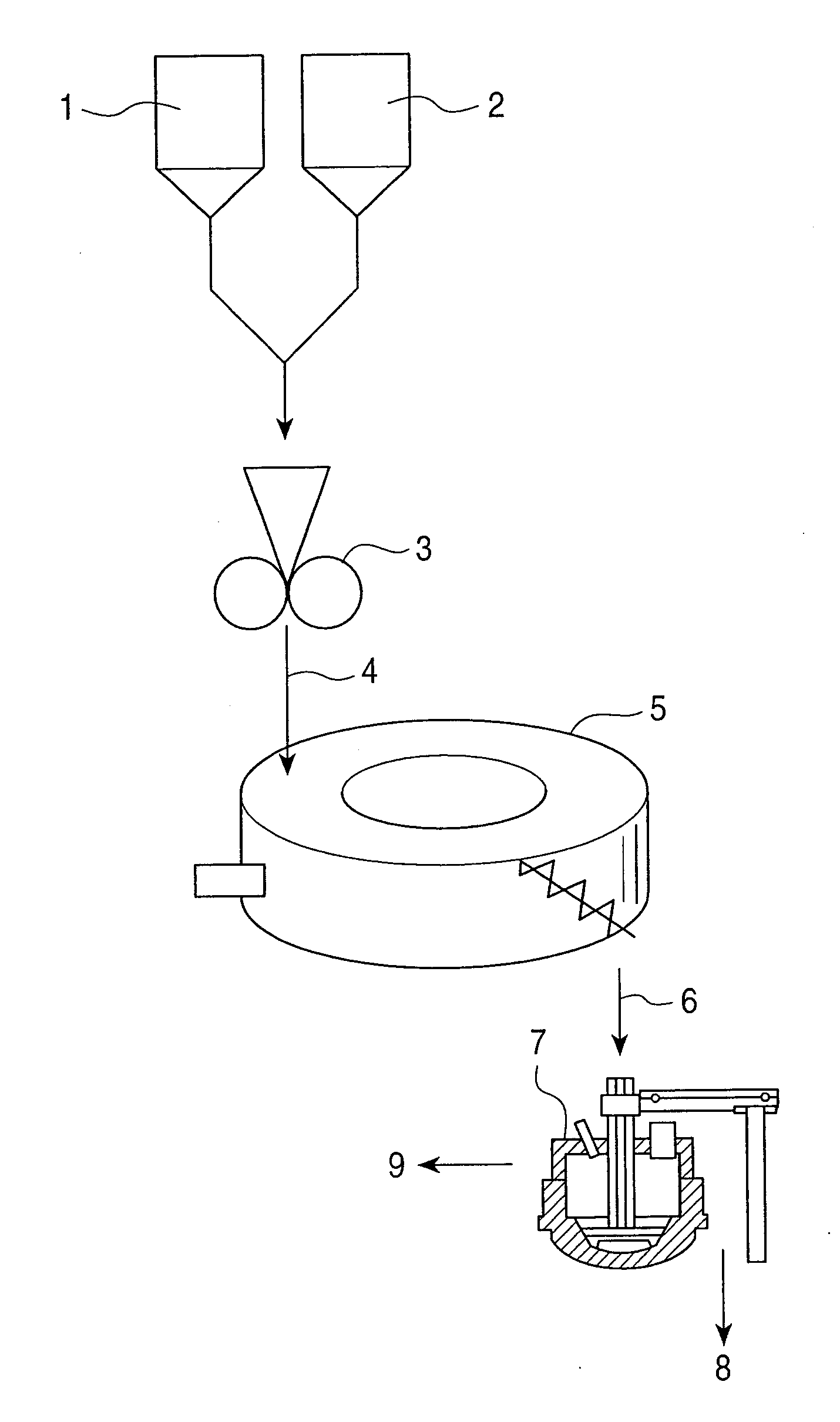

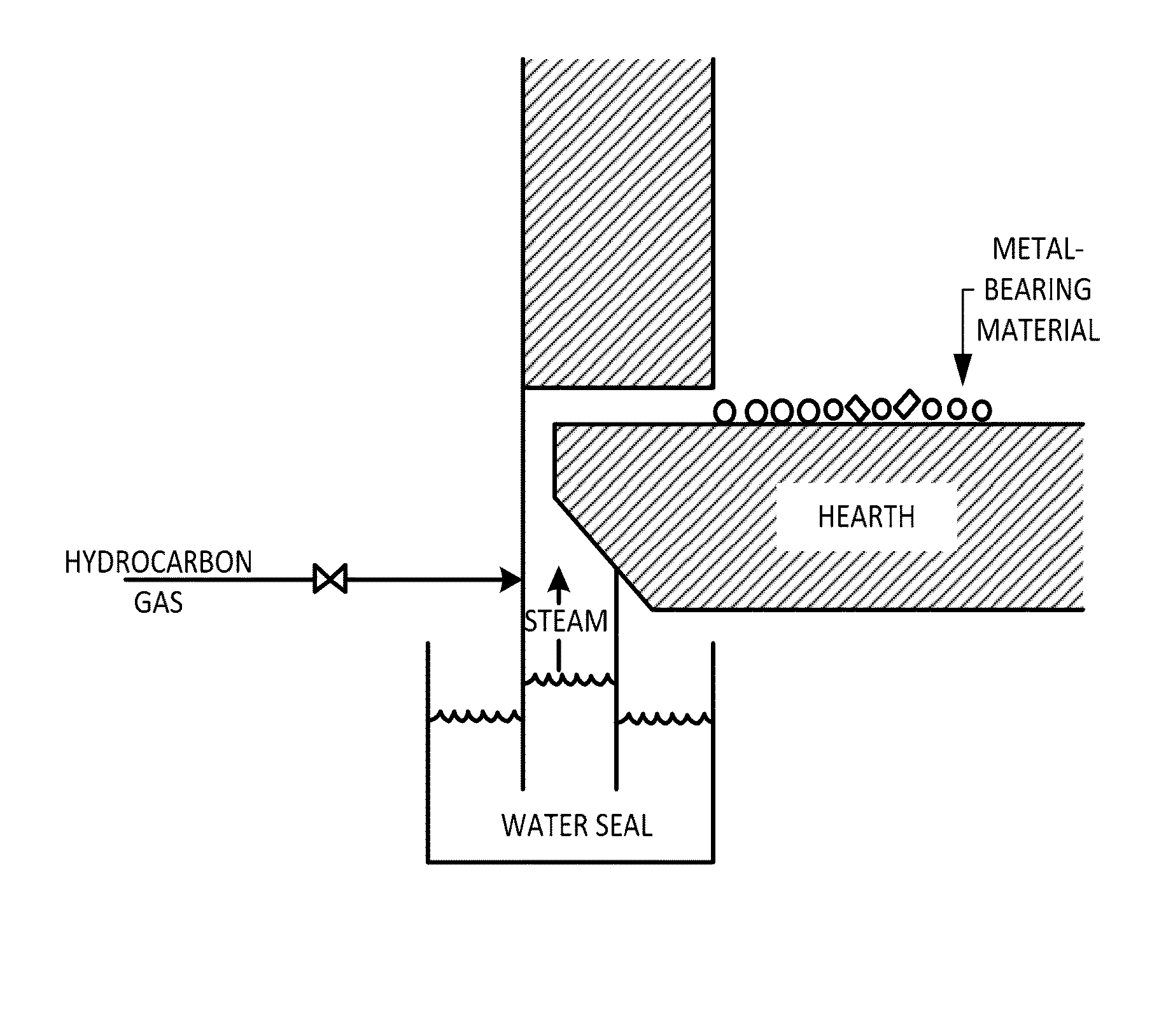

Method for reducing chromium containing raw material

InactiveUS20060096420A1Prevent oxidationReduce fuel consumptionGas emission reductionHearth type furnacesMaterials scienceRaw material

An object of the present invention is to provide a method for reducing a chromium-containing material at a high chromium reduction degree. In the method of the present invention, a mixture of a feedstock containing chromium oxide and a carbonaceous reductant is heated and reduced by radiation heating in a moving hearth furnace. The average rate of raising the temperature of the mixture in the reduction is preferably 13.6° C. / s or higher in the period from the initiation of the radiation heating of the mixture until the mixture reaches 1,114° C.

Owner:SUGITATSU HIROSHI +4

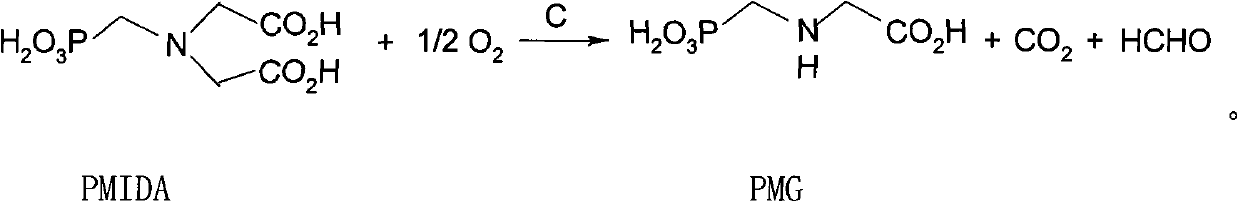

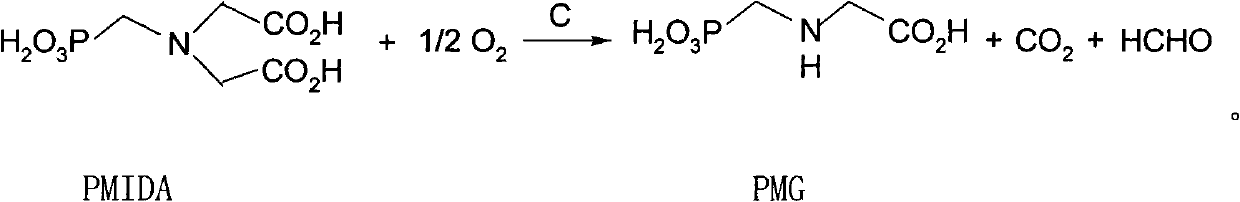

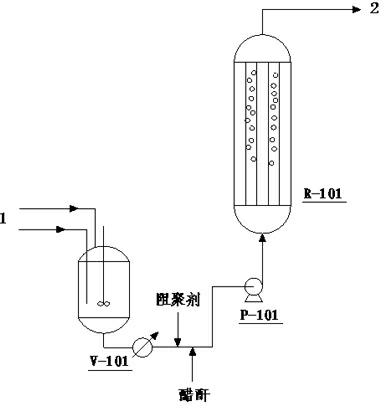

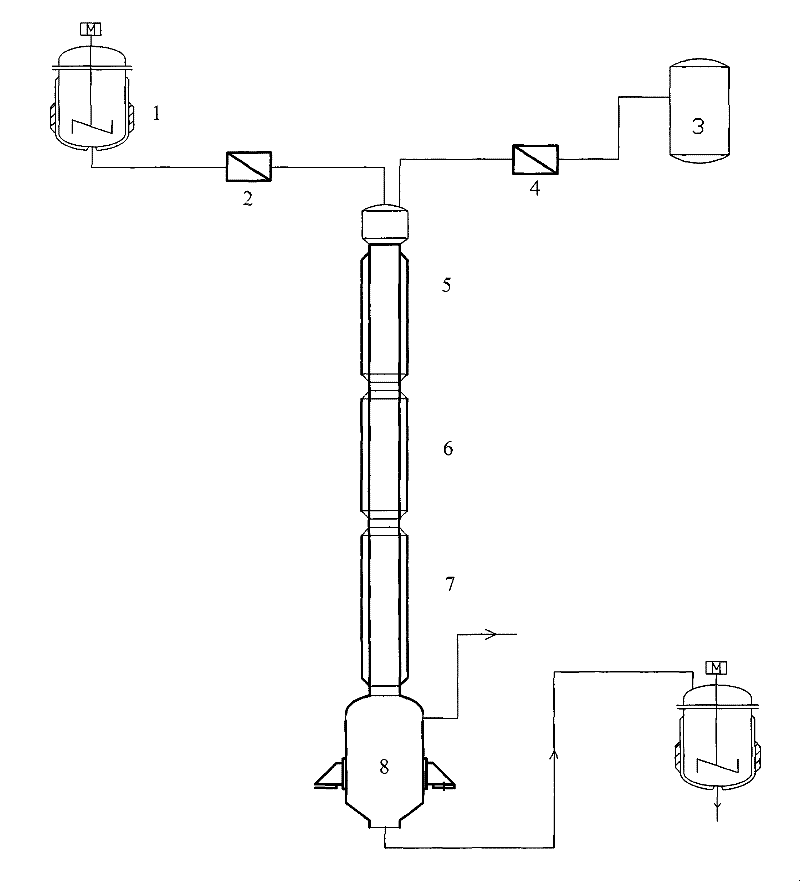

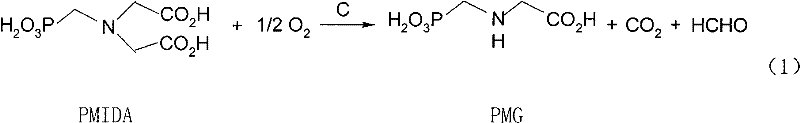

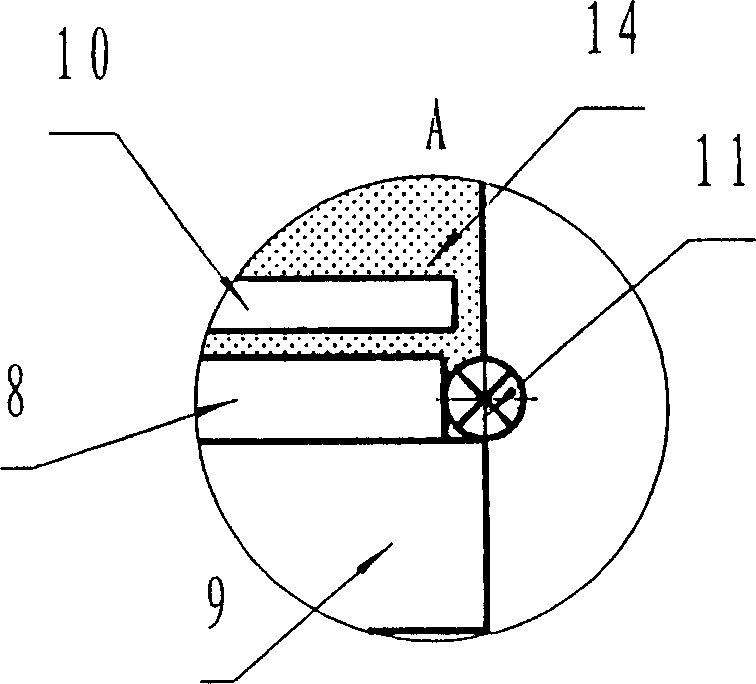

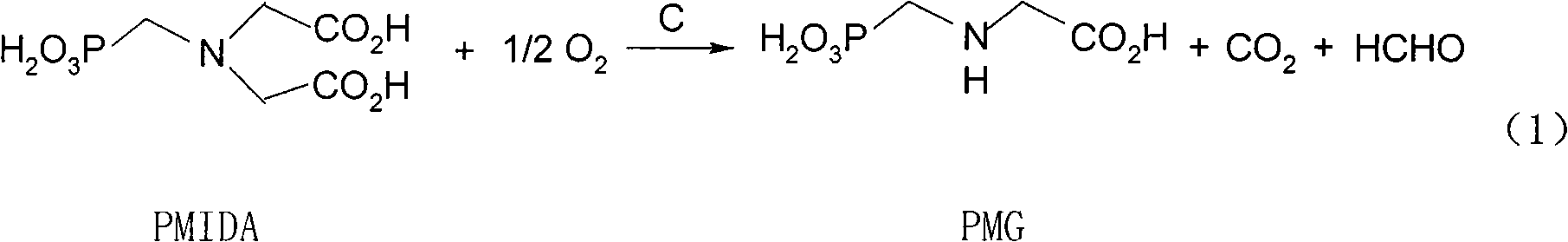

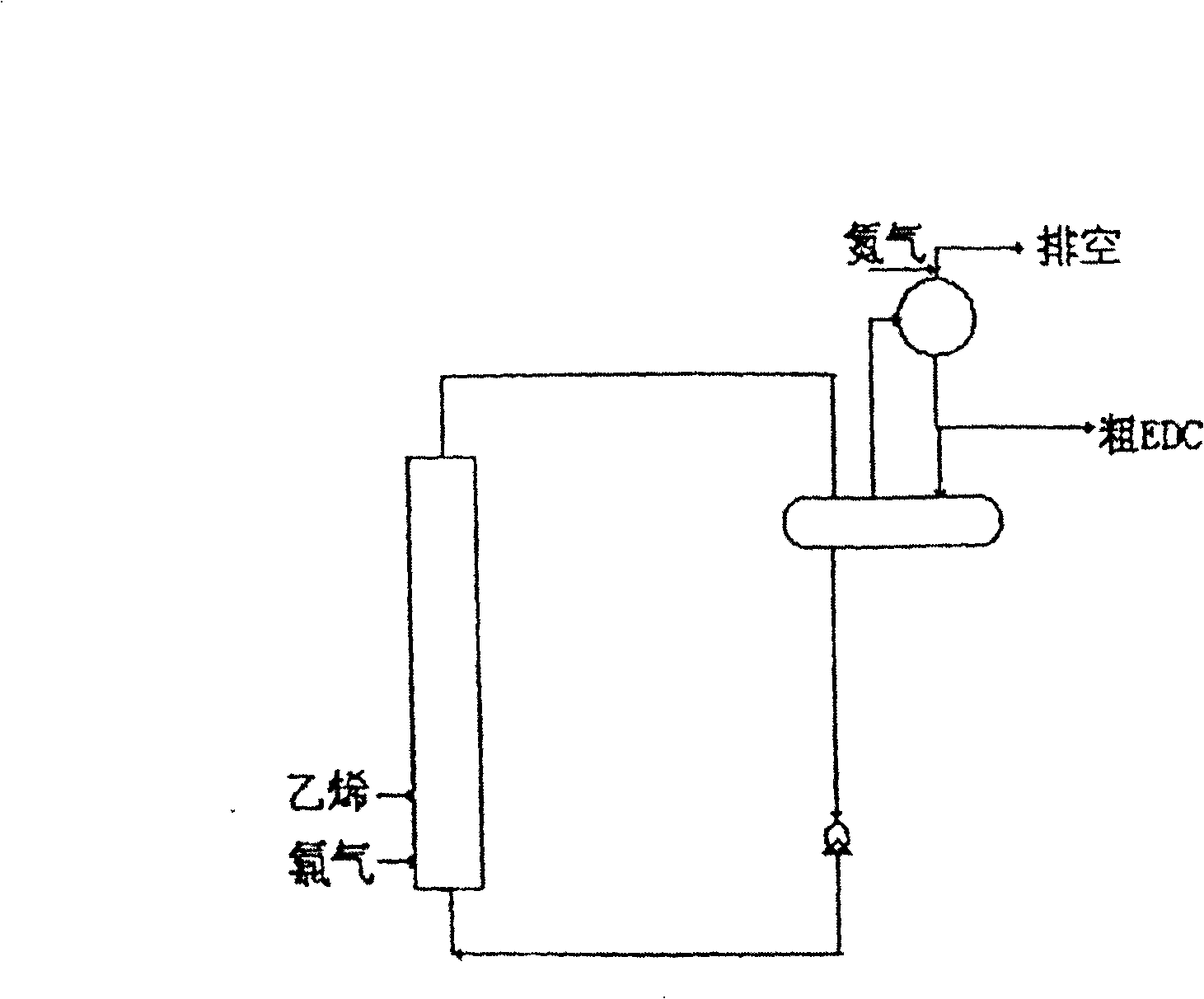

Method and device for producing N-phosphono methyl glycine

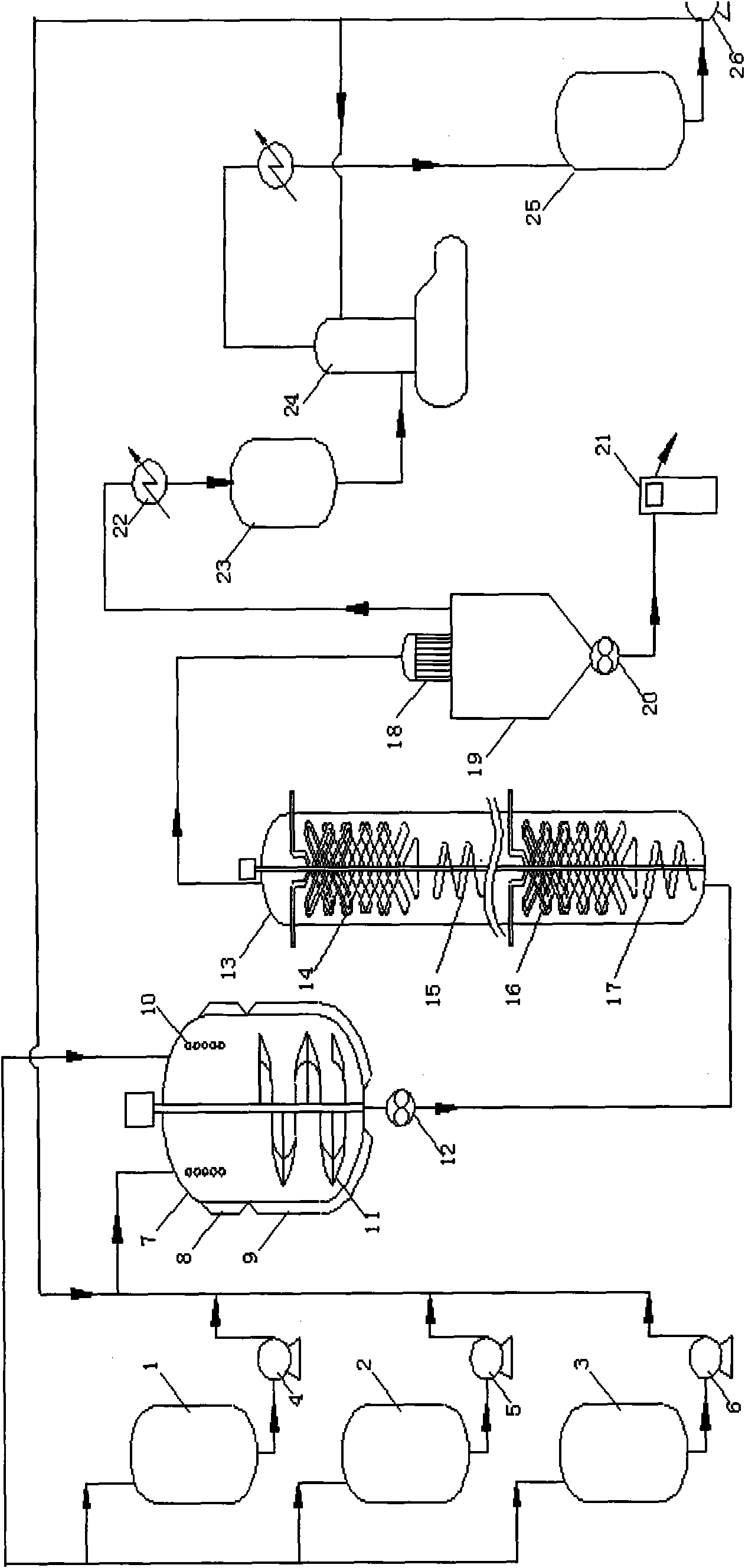

ActiveCN101928298AUniform residence timeHigh yieldBiocidePhysical/chemical process catalystsGastric tube feedingActivated carbon

The invention relates to a method for continuously producing N-phosphono methyl glycine. The method comprises the following steps of: inputting reaction feed liquor into a reactor under the condition of oxidizing PMIDA into glyphosate to make an activated carbon catalyst suspend in the reaction feed liquor in the reactor; fully contacting the PMIDA with molecular oxygen; continuously oxidizing the PMIDA into the glyphosate under a selected reaction condition; and performing a PMIDA oxidizing reaction. The invention also relates to a device for continuously producing the N-phosphono methyl glycine. The device mainly comprises a power generator, a tubular reactor and a gas-liquid separator. The device is characterized in that: the power generator is connected with the bottom of the tubular reactor through a pipeline; the gas-liquid separator is connected with the top of the tubular reactor; the lower part of the tubular reactor is provided with an oxygen containing gas feed tube orificeand is connected with a gas distributor in the tube; and the power generator is connected with a feed tube of the PMIDA feed liquor and catalyst activated carbon or a feed tube of the mixed liquor ofthe PMIDA feed liquor and catalyst activated carbon through pipelines.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

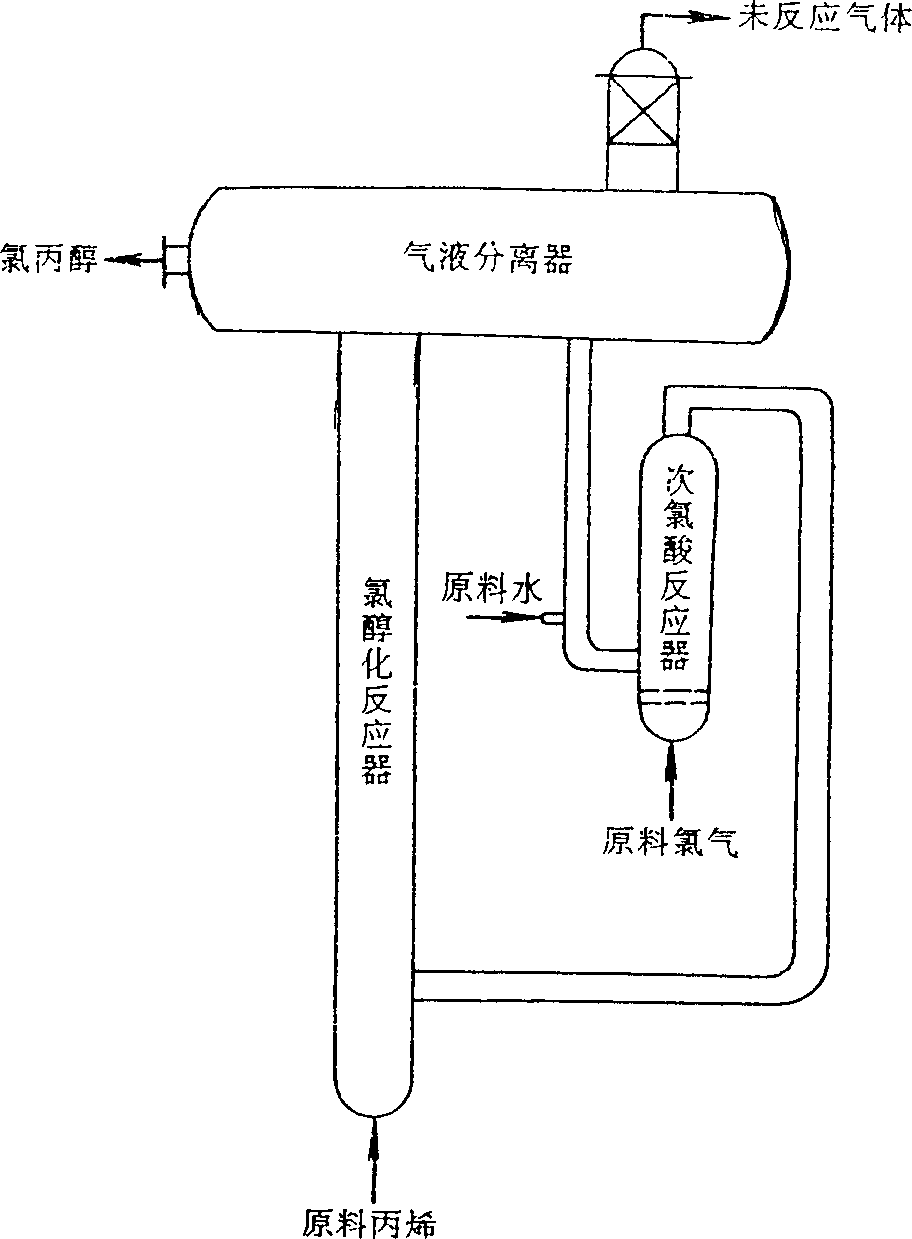

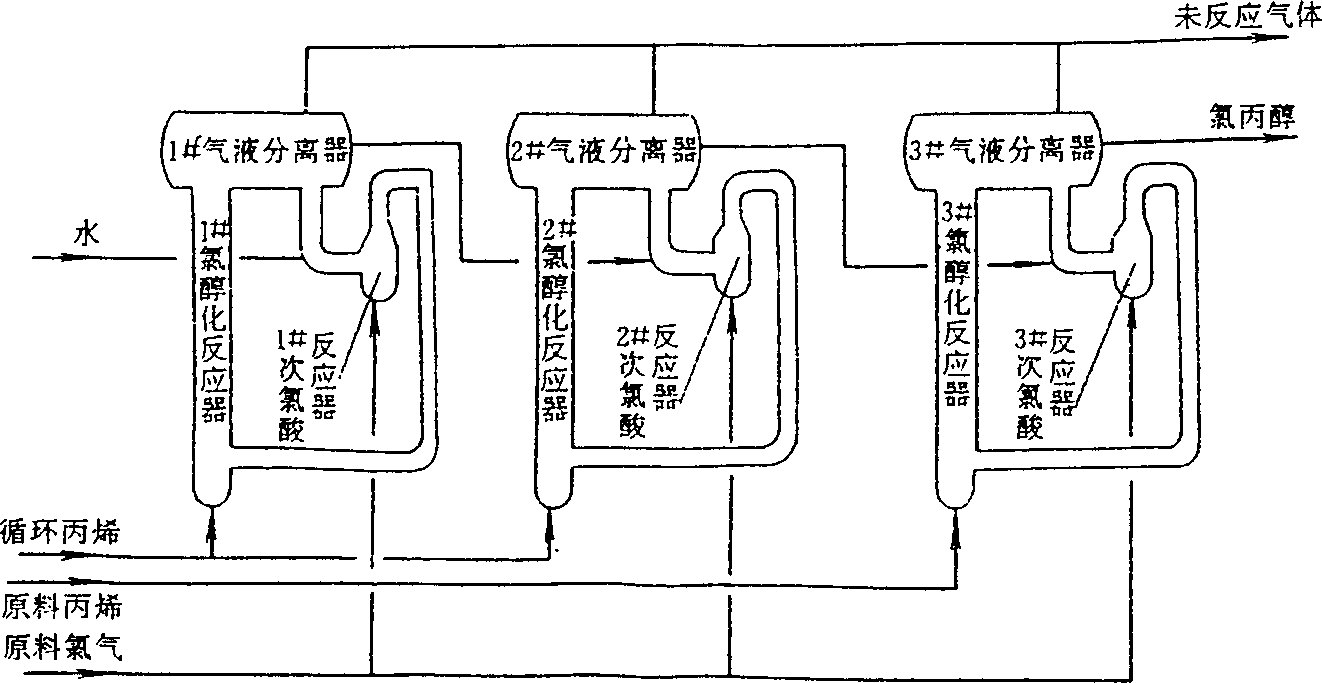

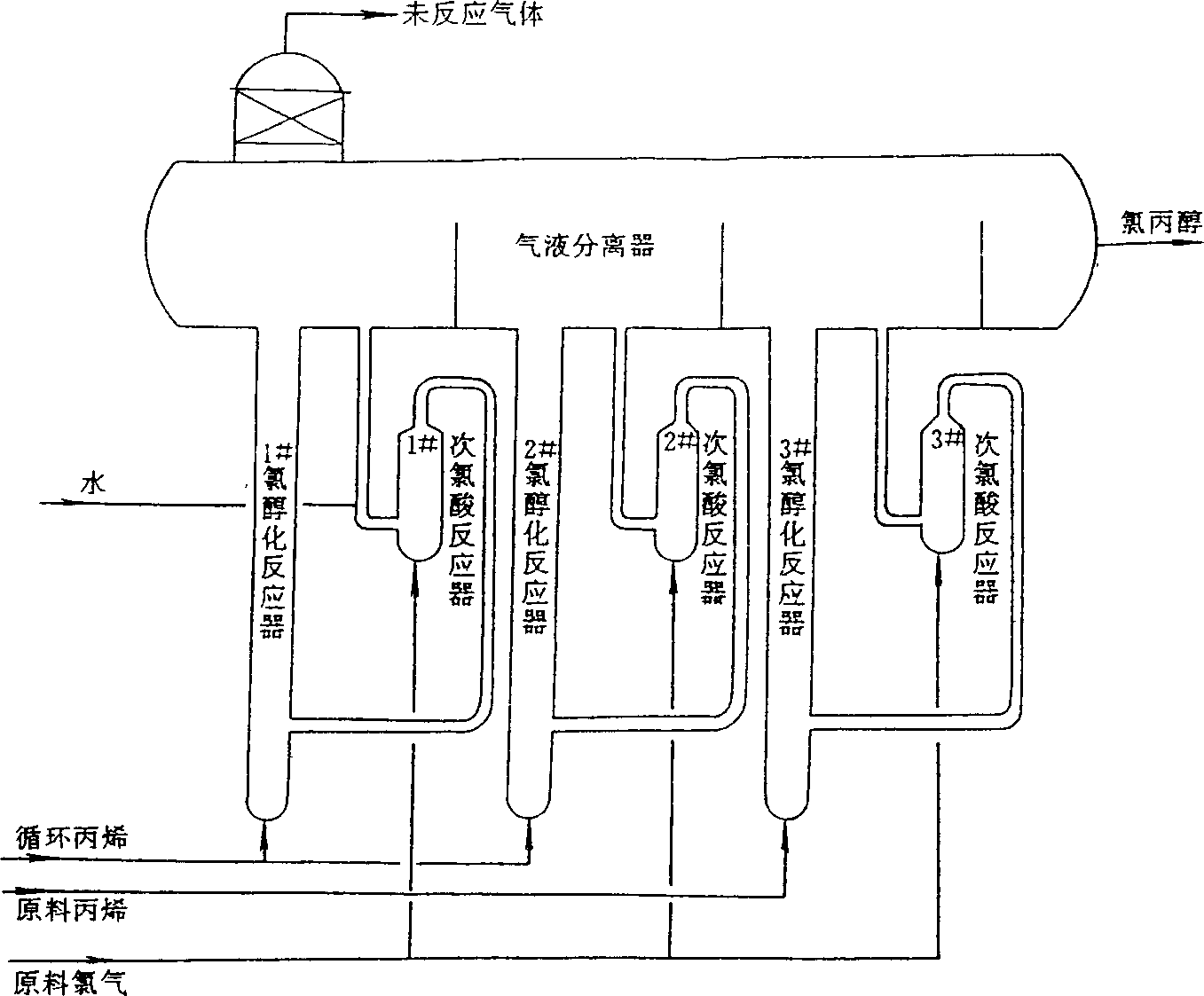

Apparatus and method for monotubular multi-spiral static mixed tube style chlorohydrination of propene for production of epoxypropane

InactiveCN1680346ALess investmentIncrease production capacityPreparation by OH and halogen introductionHigh concentrationGas phase

A monotubular multiple rotary static mixing tubing propenyl chlorine alcoholizing reacting producer of propylene epoxide production and its production are disclosed. The producer consists of an inlet pipeline of material water and chlorine, a tubing chlorine instant hypochloric acid reactor, an outlet pipeline of hypochloric acid, a confluent pipeline of hypochloric acid and propylene, a tubing chlorohydrination reactor, an outlet pipeline of chloralcohol, an outlet pipeline of propylene mixed liquid, an instant mixing tube of propylene, and an inlet pipeline of propylene and circulating chloralcohol. Its advantages include low cost, more operating elasticity, no gas-phase contact, higher concentration and less by-product.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

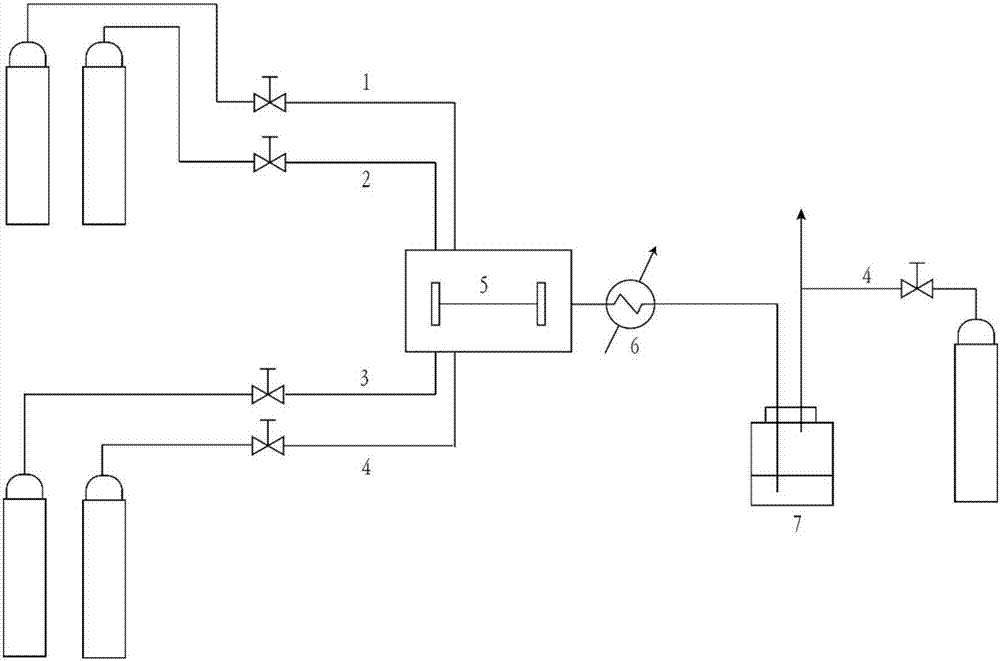

Method for preparing epoxypropane in microchannel reactor

ActiveCN107216296APrecise control of dwell timePrecise control of reaction timeOrganic chemistryChemical/physical/physico-chemical microreactorsState of artHydrogen

The invention relates to a method for preparing epoxypropane in a microchannel reactor. The method mainly solves the problems of existence of explosive danger, low conversion rate and low selectivity in the prior art. The technical scheme is as follows: by adopting the method for preparing epoxypropane in a microchannel reactor, gas-phase propylene contacts hydrogen peroxide generated by hydrogen and oxygen in-situ compounding in the microchannel reactor to directly generate the epoxypropane under the action of a catalyst; and propylene and oxygen directly react under the action of a catalyst to generate the epoxypropane, the epoxypropane is collected at the lower reach of the microchannels in the liquid-phase form, and the unreacted gas cyclically enters the microchannel reactor inlet or is evacuated after being diluted. The microchannel reactor comprises at least one microchannel, wherein the sectional dimension of each microchannel is 1 micrometer-1 centimeter, and the sectional dimensions of the microchannel in positions of different lengths are identical or different; and the catalyst is positioned in at least one part of the axial length of the microchannel. The technical scheme well solves the problems, and can be used for preparing epoxypropane.

Owner:CHINA PETROLEUM & CHEM CORP +1

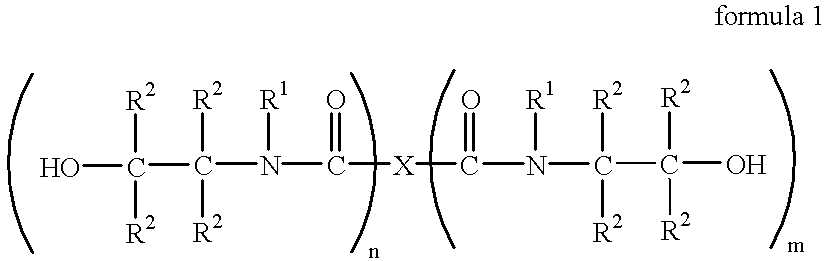

Process for the continuous preparation of hydroxyalkylamides

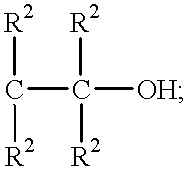

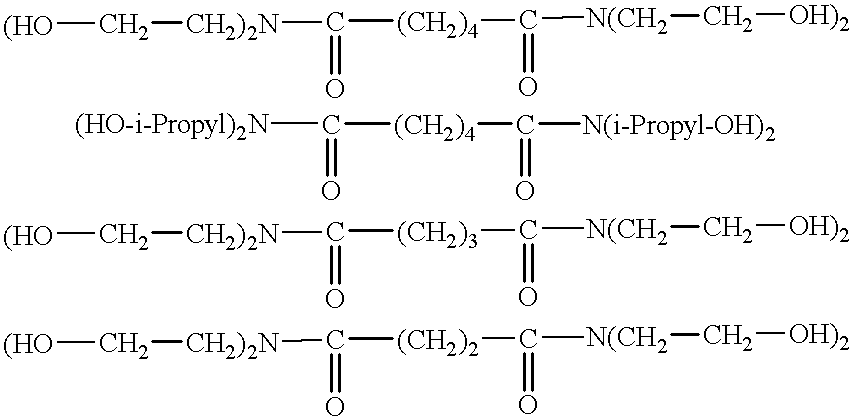

InactiveUS6194613B1Intensive and rapid mixingUniform residence timeOrganic compound preparationCarboxylic acid amides preparationAlcoholAlkanolamine

Process for the continuous preparation of hydroxyalkylamides Process for the continuous preparation of hydroxyalkylamides from carboxylic esters and alkanolamines, wherein the reaction of the starting materials is carried out in an extruder or intensive mixer by intensive mixing and brief reaction with supply of heat and simultaneous removal of the alcohol formed and the final product is then isolated.

Owner:EVONIK DEGUSSA GMBH

Method for continuously preparing polymer and device thereof

The invention relates to a method for continuously preparing a polymer and a device thereof. The device is formed by connecting at least one completely mixed reactor and at least one tower reactor in series. The method comprises: lowering the mass content of oxygen dissolved in a vinyl monomer to 1 to 3ppm; filling the vinyl monomer into the completely mixed reactor, wherein the polymerization temperature is 130 to 150 DEG C, an inert solvent of which the mass is 5 percent based on that of the vinyl monomer is added, and the conversion rate of the polymerization is continuously controlled to be 35 to 60 percent; delivering the obtained reaction mixture to the tower reactor, wherein the reaction temperature is 140 to 160 DEG C, and the final conversion rate of the polymerization is controlled to be 55 to 90 percent; and delivering the obtained polymer mixture to a flash evaporation devolatilization kettle to remove volatiles, and granulating in a granulator to form plastic molded products. In the invention, the energy consumption is low, the product performance is high, the product purity is high, the production efficiency is high, and safety and environment protection are realized.

Owner:PETROCHINA CO LTD

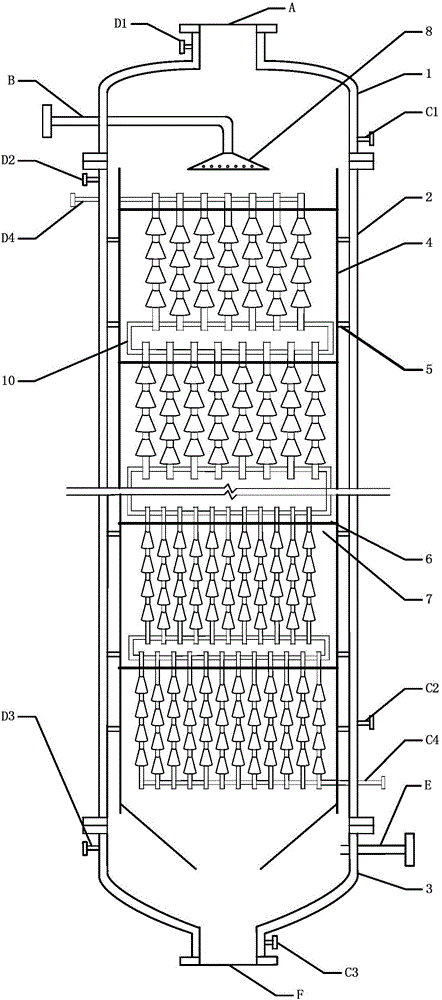

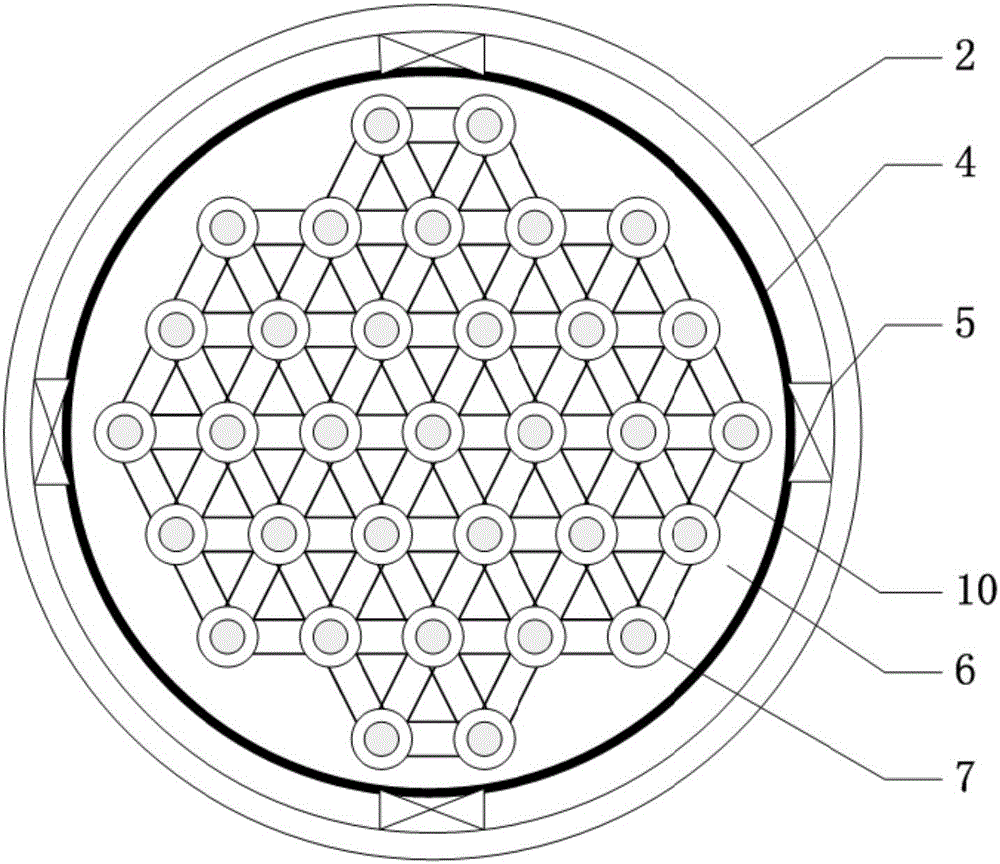

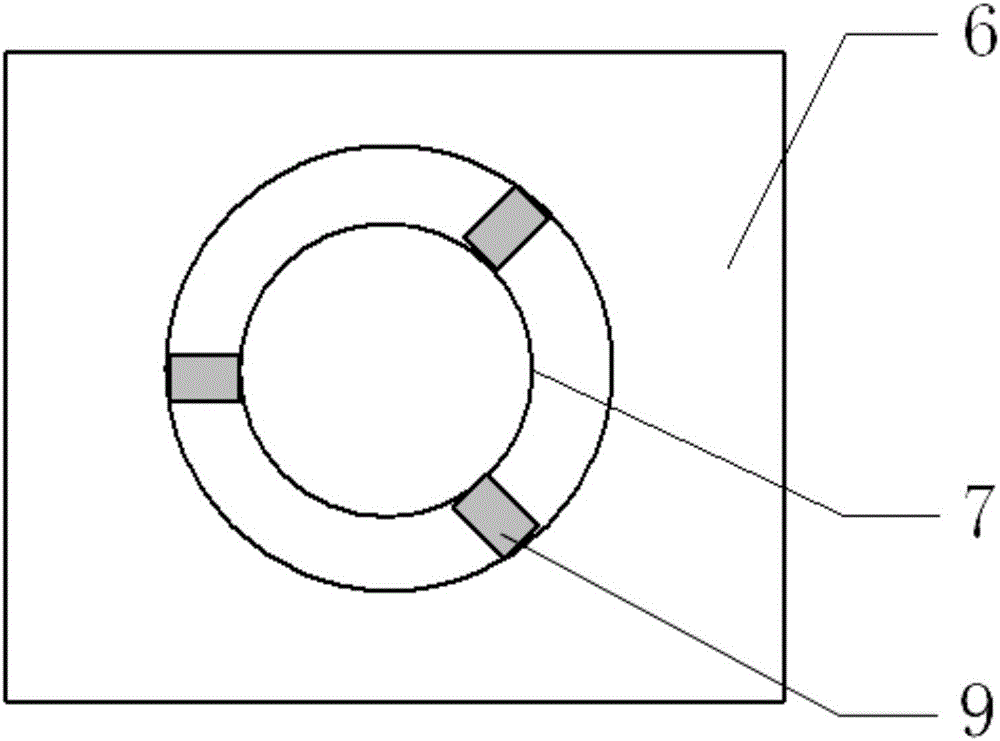

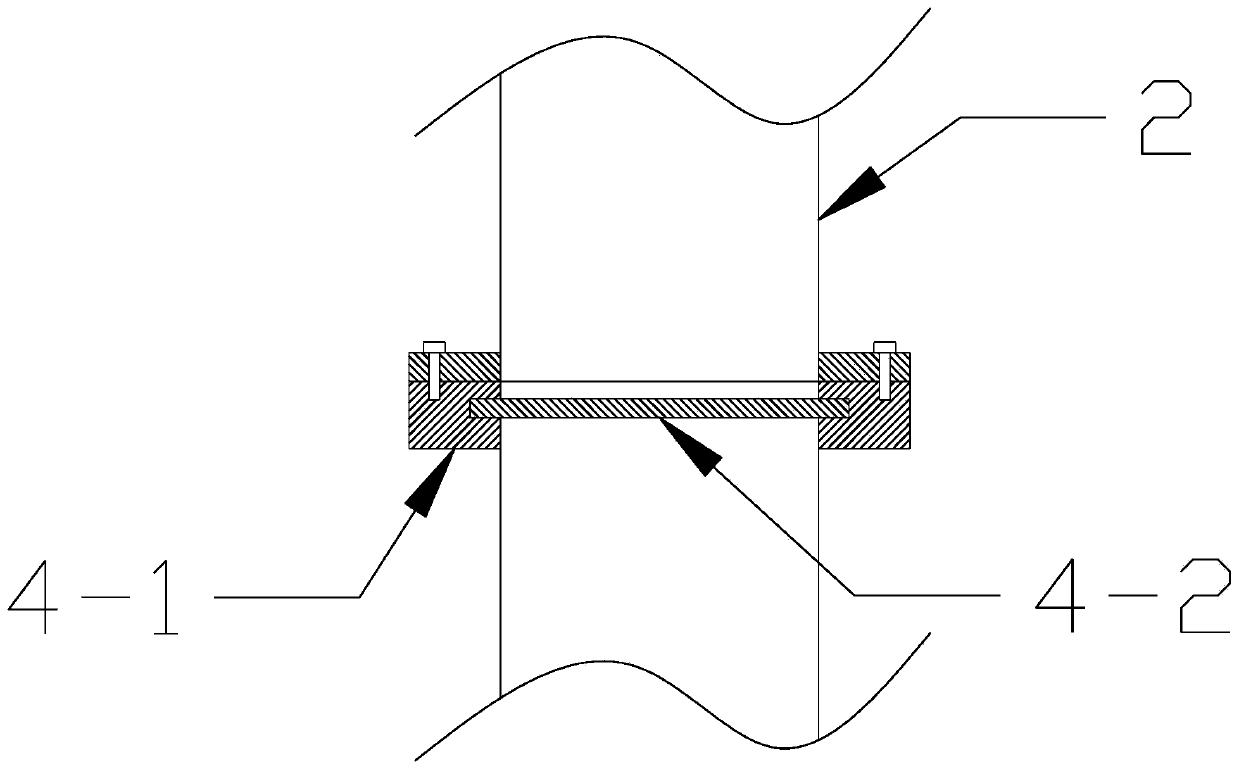

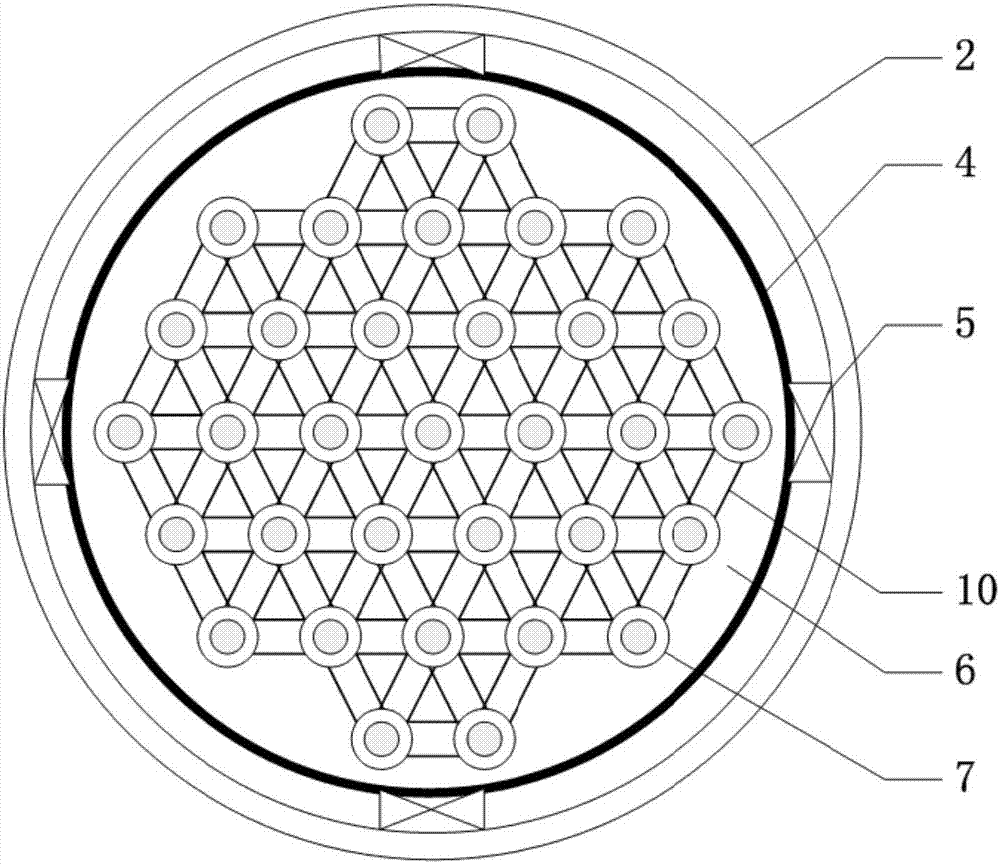

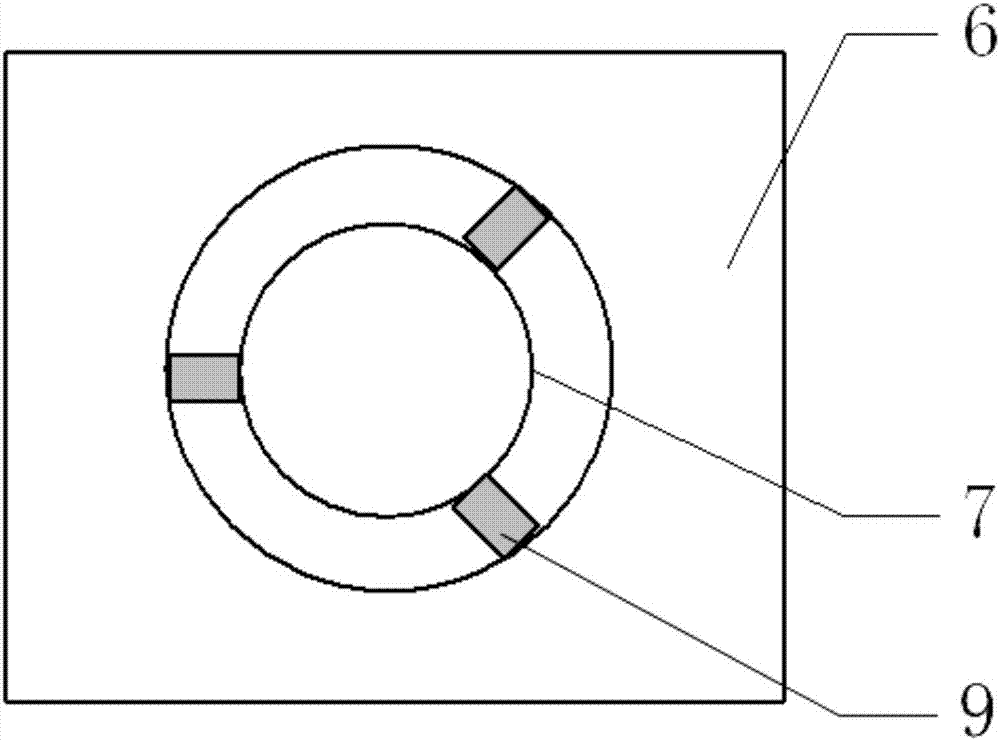

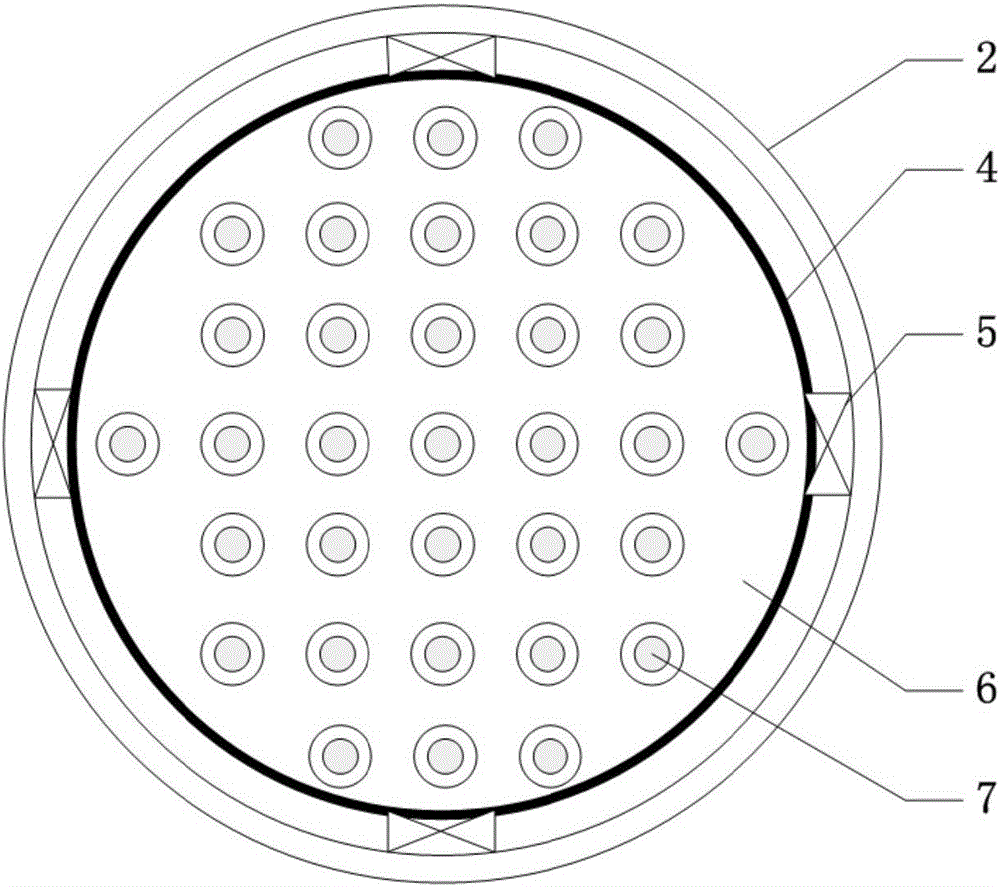

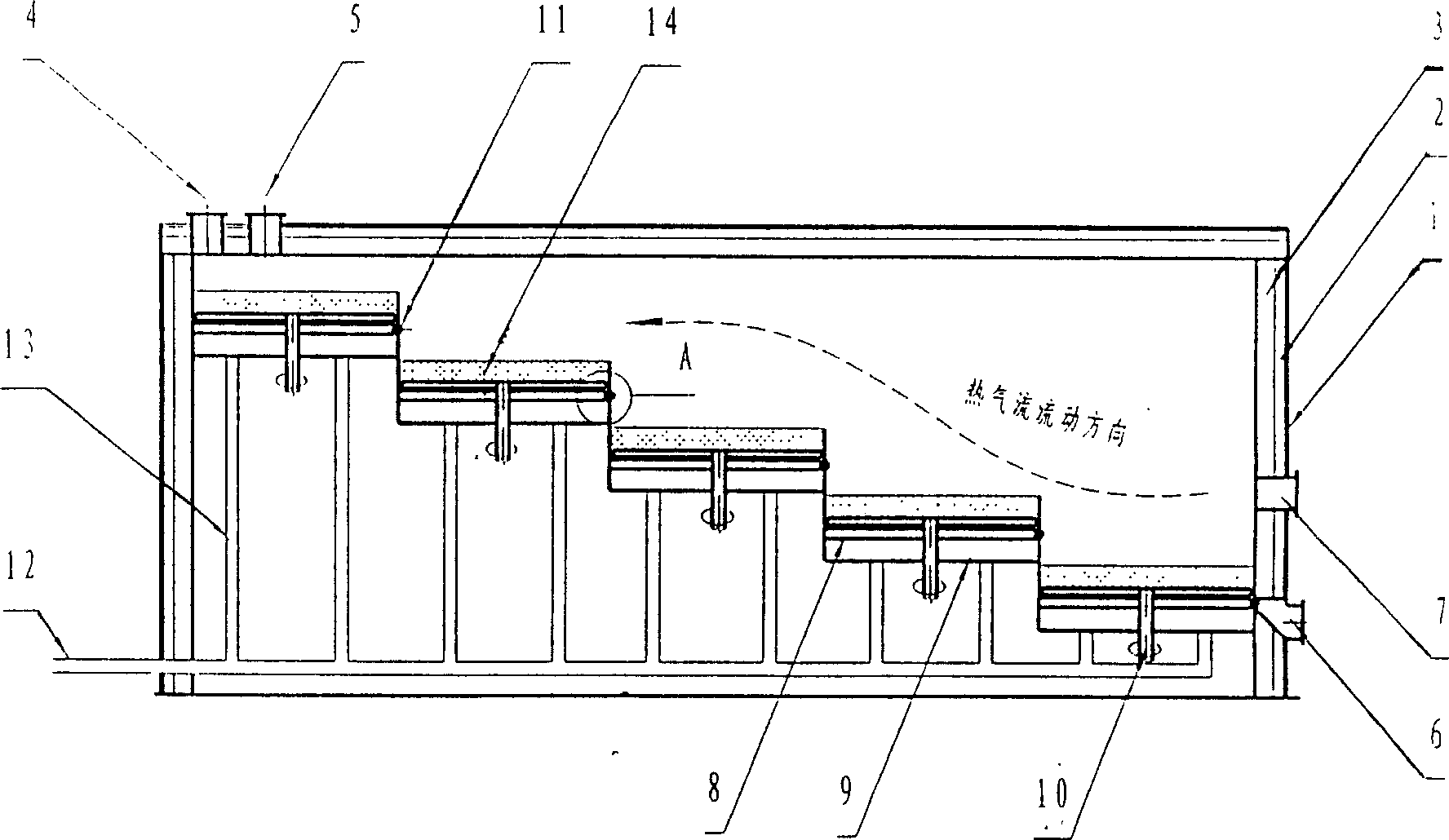

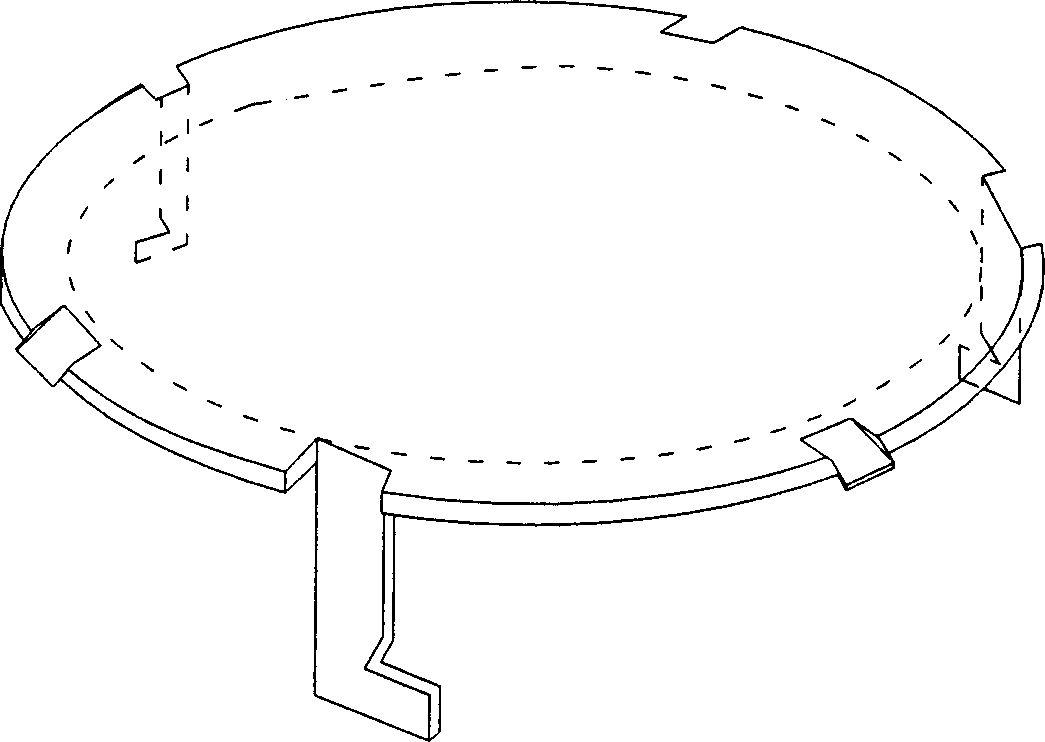

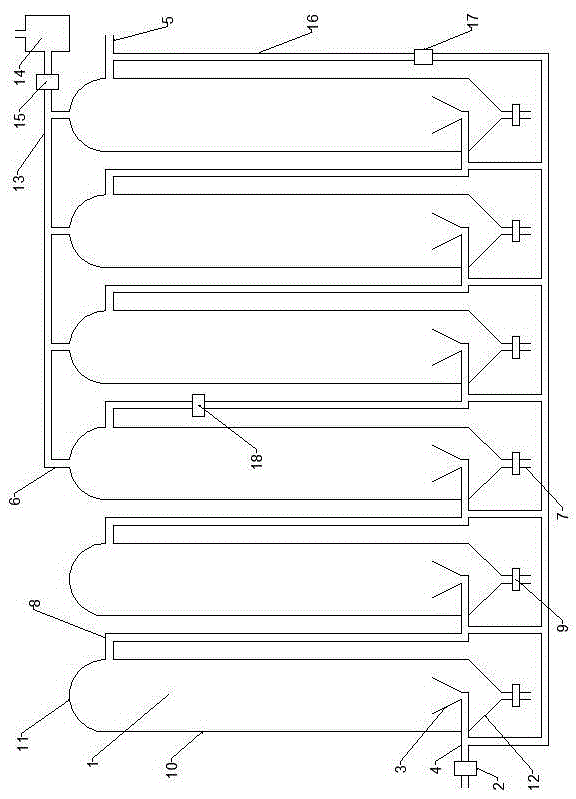

Multilayer falling pipe type falling film devolatilization reactor

ActiveCN105903424AEliminate dead zoneUniform residence timeChemical/physical/physico-chemical stationary reactorsPower equipmentHeat transfer efficiency

The invention relates to a multilayer falling pipe type falling film devolatilization reactor, which mainly comprises an outer tower and a plurality of tower cores, wherein the outer tower consists of a tower top, a tower body and a tower bottom; the plurality of tower cores arranged inside the outer tower are in sequential arrangement from top to bottom; each tower core consists of a tower plate and a plurality of falling film falling pipes in parallel arrangement; each falling film falling pipe consists of hollow pipes and a plurality of umbrella skirt-shaped falling sleeves which are provided with downward openings and are fixed on the outer side wall of the hollow pipes; the hollow pipes are mutually connected; heat media are introduced into the hollow pipes; a heat exchange pipeline is used for connection. Compared with a conventional reactor, the multilayer falling pipe type falling film devolatilization reactor has the advantages that the structure is simple; a large gas-liquid interface is realized; the stretching effect is generated on the film surface; the surface updating speed is high; the flow rate is high; the dwell time is controllable; the structure is simple; the additional power equipment is not used; the reaction energy consumption is low; the heat transfer efficiency is high.

Owner:ZHEJIANG UNIV

A kind of method for preparing isobornyl acetate by esterification of camphene

InactiveCN102276453AExtended service lifeImprove adsorption capacityOrganic compound preparationCarboxylic acid esters preparationAcetic acidIsobornyl acetate

The invention relates to a continuous preparation method for synthesizing isobornyl acetate by esterification of camphene and acetic acid. Using camphene and acetic acid as raw materials, using solid acid as a catalyst, and adding a certain amount of polymerization inhibitor and acetic anhydride, the esterification reaction is carried out under certain process conditions in a catalyst bed filled with suspension, and the target product acetic acid is obtained. Isobornyl. The invention has the advantages of mild reaction conditions, long service life of the catalyst, good product quality, high raw material conversion rate, continuous production and simple operation, and can be widely used in large-scale industrial production of isobornyl acetate.

Owner:FUZHOU UNIV

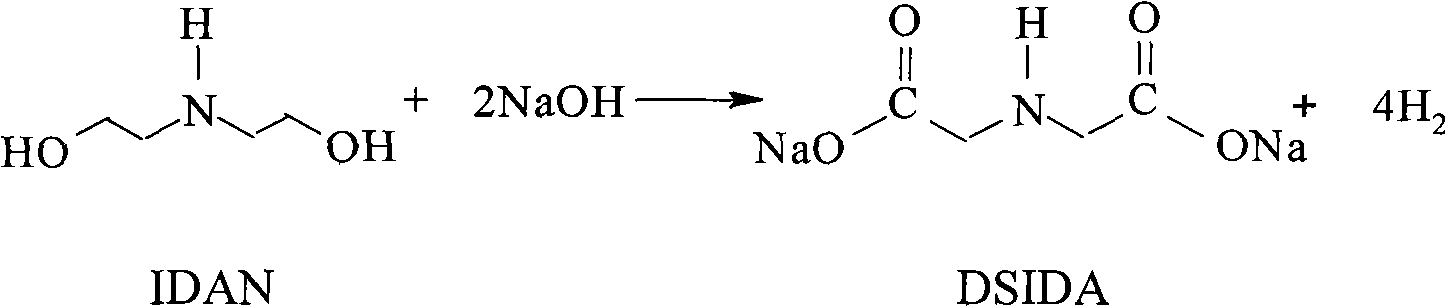

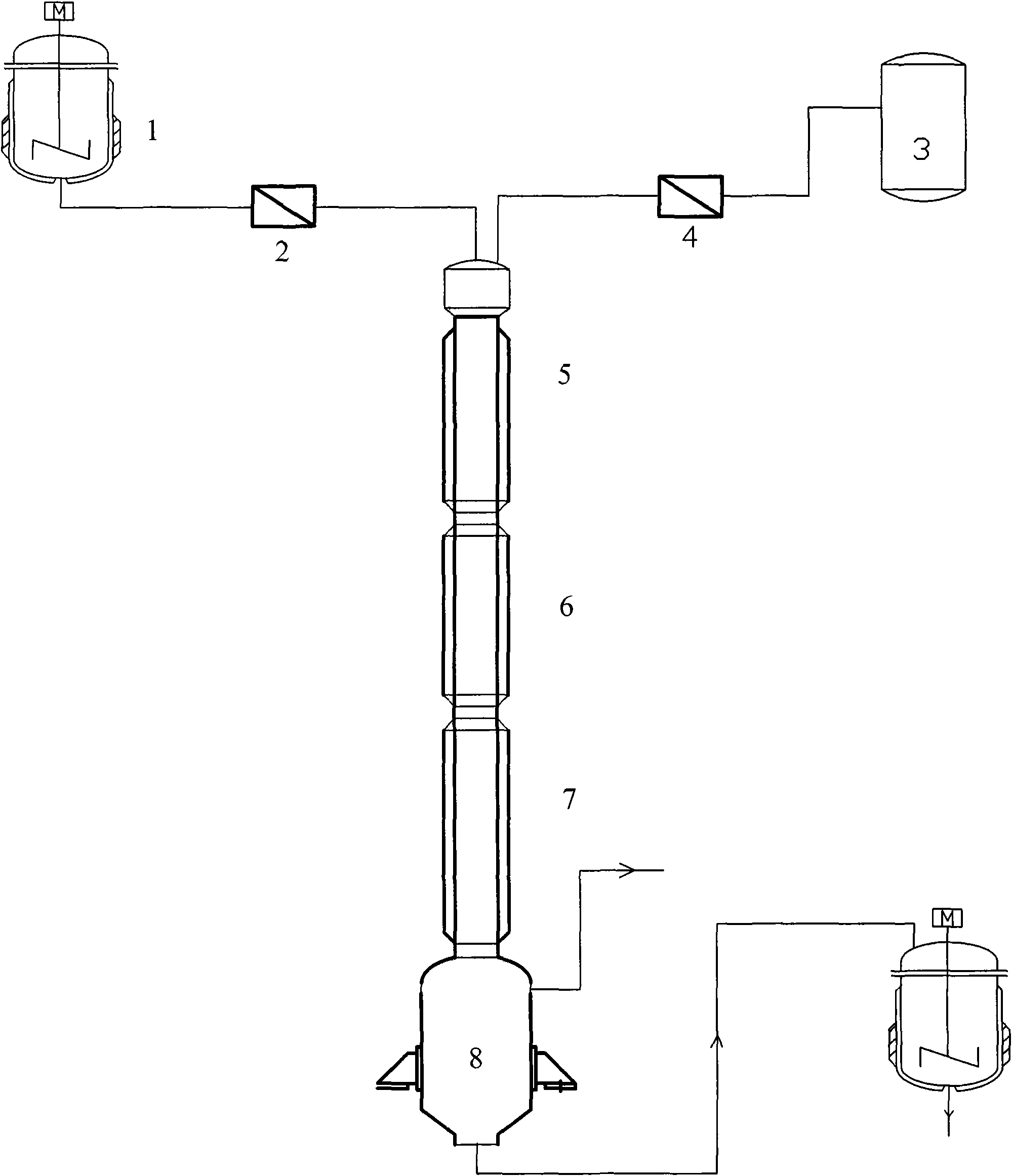

Synthesis as well as tail gas treatment technology and device of iminodiacetate

InactiveCN102050751AReduce typesEfficient removalOrganic compound preparationHydrogen separation using liquid contactDehydrogenationDiethanolamine

The invention relates to a synthesis technology and device of iminodiacetate. The technology uses diethanol amine as a main raw material and comprises the following steps: dissolving the diethanol amine, mixing with a caustic soda solution and deionized water evenly to prepare a feed liquid the mass concentration of which is 10-30%, and transferring the feed liquid into a multistage tubular reactor loaded with a solid catalyst through a metering pump to perform catalytic dehydrogenation reaction to obtain iminodiacetate; and treating the gas generated through catalytic dehydrogenation and the tail gas separated from the discharged liquid to recycle hydrogen. The device comprises the multistage tubular reactor which is designed on the basis of a kinetic model of isothermal constant-pressure reaction, wherein the multistage tubular reactor is formed by connecting 2 to 5 tubular reactors in series; each reactor is formed by a plurality of tubes; the same amount of catalyst is evenly filled in each tube; the upper part or lower part of each reactor is provided with a gas-liquid separator which is used for separating the gas generated through the dehydrogenation reaction from the discharged liquid; and the back of the gas-liquid separator is connected with a demister which is connected with a tail gas treatment device used for purification treatment through a regulating valve. The device provided by the invention has the characteristics that the technological operation is simple, the product yield is no less than 98%, the continuous production can be realized, the work efficiency can be increased, and the like.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Solid state polymerization technique of polyester industry

The invention discloses a solid phase polymerization technique of the polyester industry. The technique comprises the following steps: the pre-crystallization processing of raw materials, then on-line dust removal, recrystallization, heat transport, main reaction, discharging of machinery, cooling and dust removal to obtain a finished product. The solid phase polymerization technique adopts a reasonable technological route and technological parameters and the whole technique is provided with reasonable production equipment for the solid phase polymerization of the polyester industry, thereby realizing high output, low energy consumption, convenient quality control and regulation and stable product quality.

Owner:ZHEJIANG UNIFULL IND FIBER

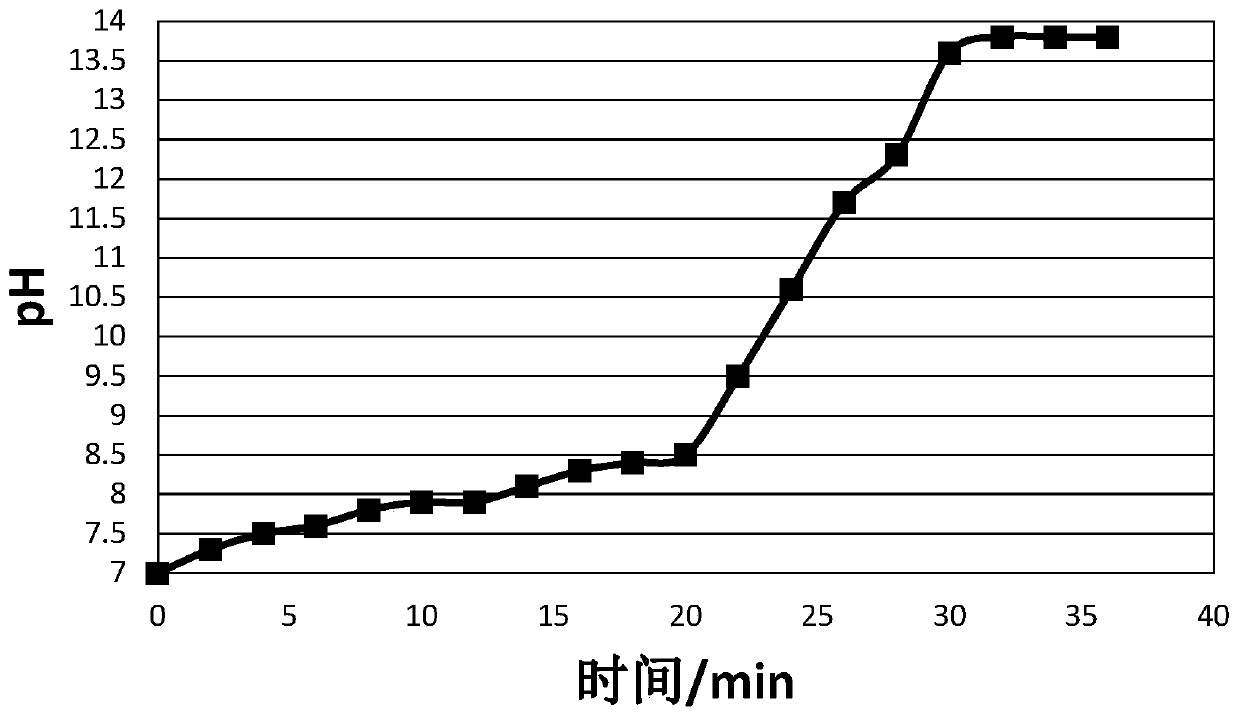

Ventilation method for accelerating acid production in lactic acid fermentation

ActiveCN110904162AIncrease or decrease the air supplyIncrease or decrease the overlap areaBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyLactic acid bacterium

The invention discloses a ventilation method for accelerating acid production in lactic acid fermentation. The ventilation method comprises the steps of (A) at the early stage of fermentation, introducing sterile air carrying an oxygen supply agent into lactic acid fermentation feed liquid; and (B) at the later stage of fermentation, stopping introducing sterile air carrying the oxygen supply agent into the lactic acid fermentation feed liquid. According to the method, the oxygen content in the fermentation liquid can be effectively increased, and lactic acid bacteria are promoted to consume more glucose more quickly to generate lactic acid.

Owner:河南金丹乳酸科技股份有限公司

Method for reducing chromium containing raw material

InactiveUS20100037728A1High chromium reduction degreeReduce the amount requiredElectric furnaceGas emission reductionMaterials scienceRaw material

Owner:KOBE STEEL LTD

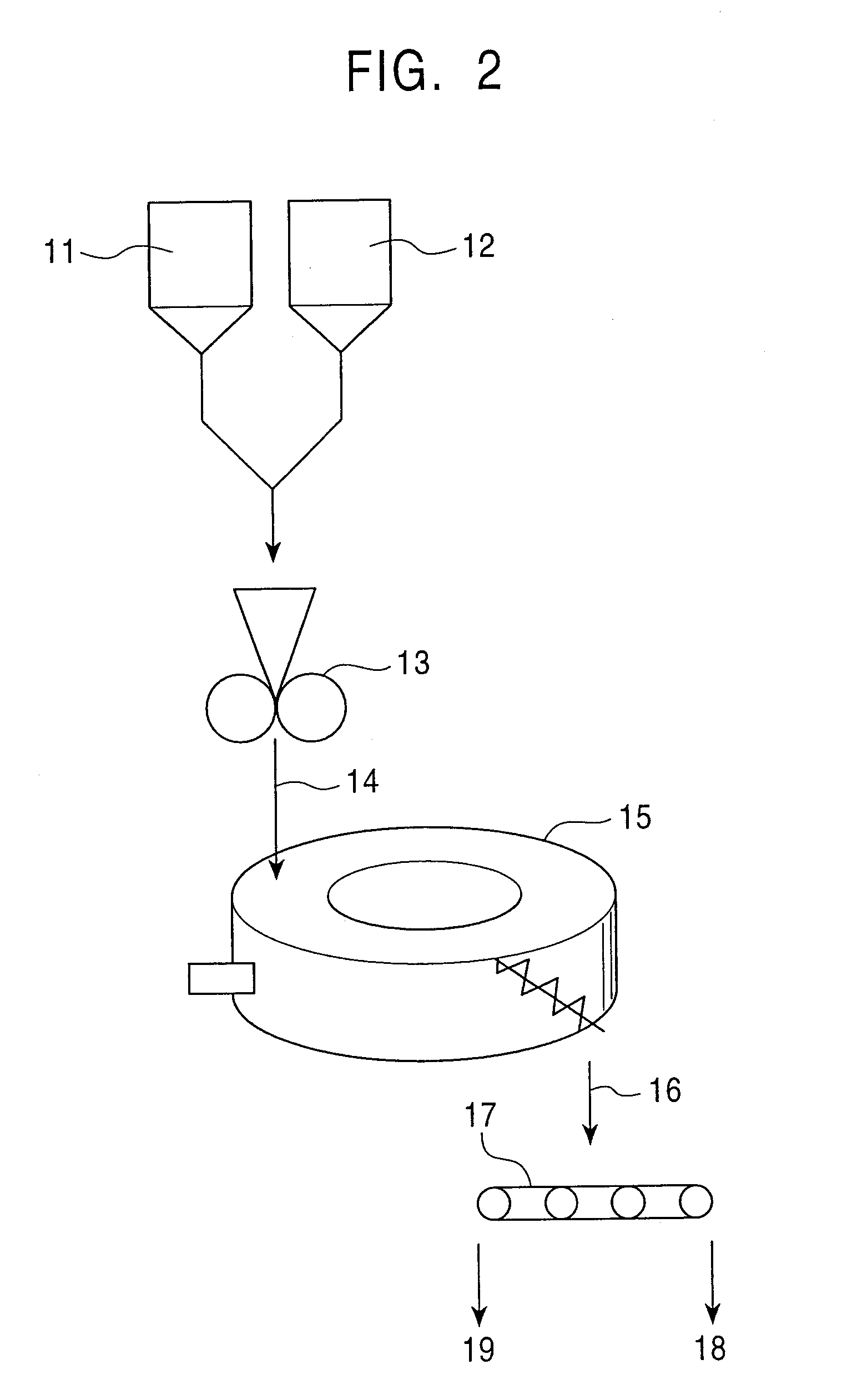

Method for preparing water-based crylic acid resin by continuous extruding process and production equipment for realizing method

The invention provides a method for preparing water-based crylic acid resin by a continuous extruding process and production equipment for realizing the method. The method is characterized in that anannular pipe type reactor and a twin-screw extrusion reactor are connected in series to be used as a continuous reactor; firstly, monomers, initiating agents and optional molecular weight modifiers are sucked into a mixed raw material preparation tank from each raw material barrel under the negative pressure; then, the materials in the preparation tank are conveyed to the annular pipe type reactorwith the temperature being 120 DEG C by a material conveying pump at the speed of 50 to 150kg / h; the detention time of the materials in the annular pipe type reactor is 15 minutes; after the materials enter the twin-screw extrusion reactor, the screw rotating speed is controlled to be 20 to 50 turns / min; a devolatilization section valve is opened so that the materials are subjected to vacuum devolatilization at the third stage; the product after devolatilization is subjected to underwater pelleting and drying at the temperature being 30 DEG C or below, and then passes through a cyclone separator; next, packaging is performed. The crylic acid resin prepared by the method has the characteristics that the quality stability is good; the molecular weight is great; the distribution is narrow. The invention also provides the production equipment for realizing the method.

Owner:广东龙湖科技股份有限公司

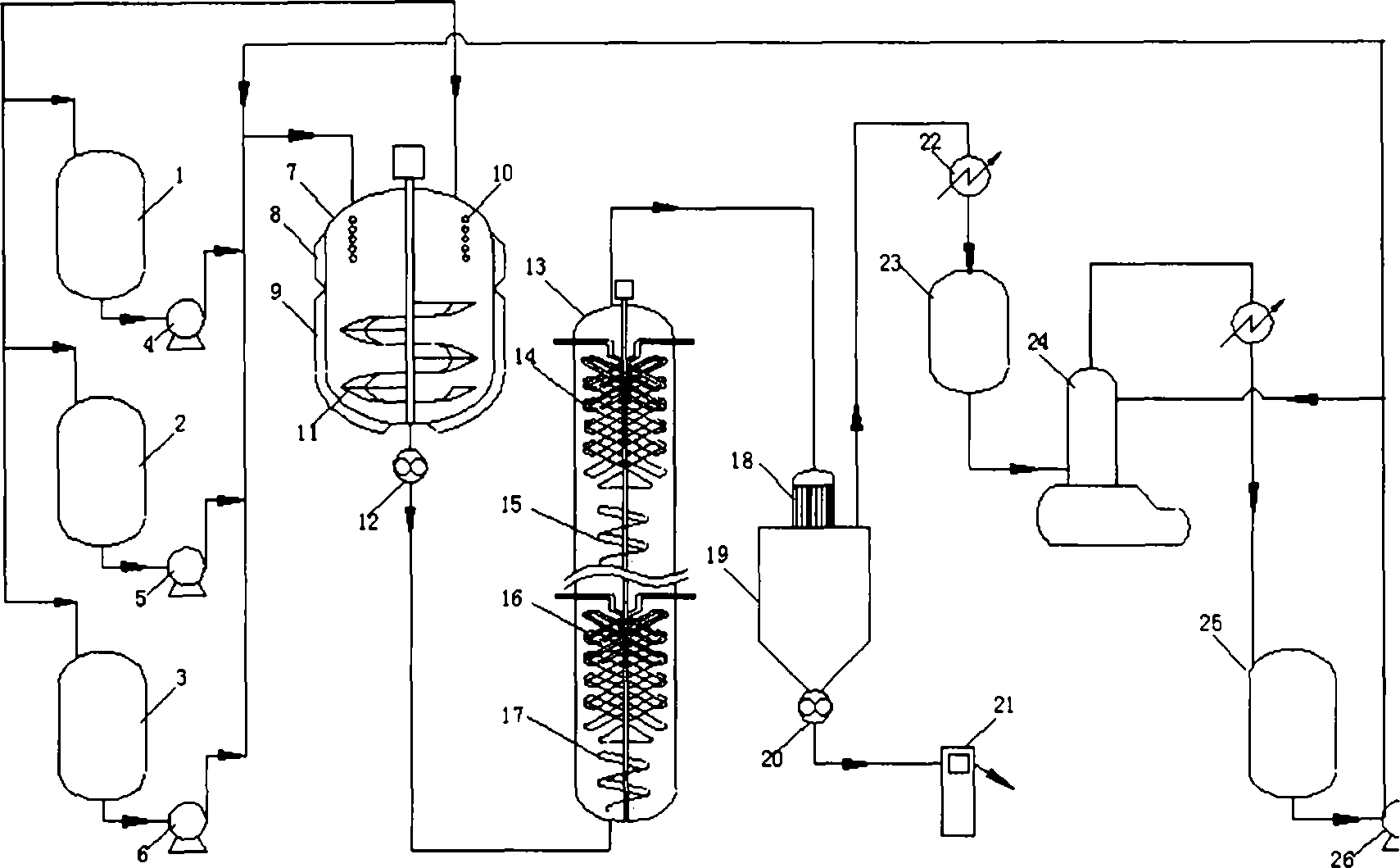

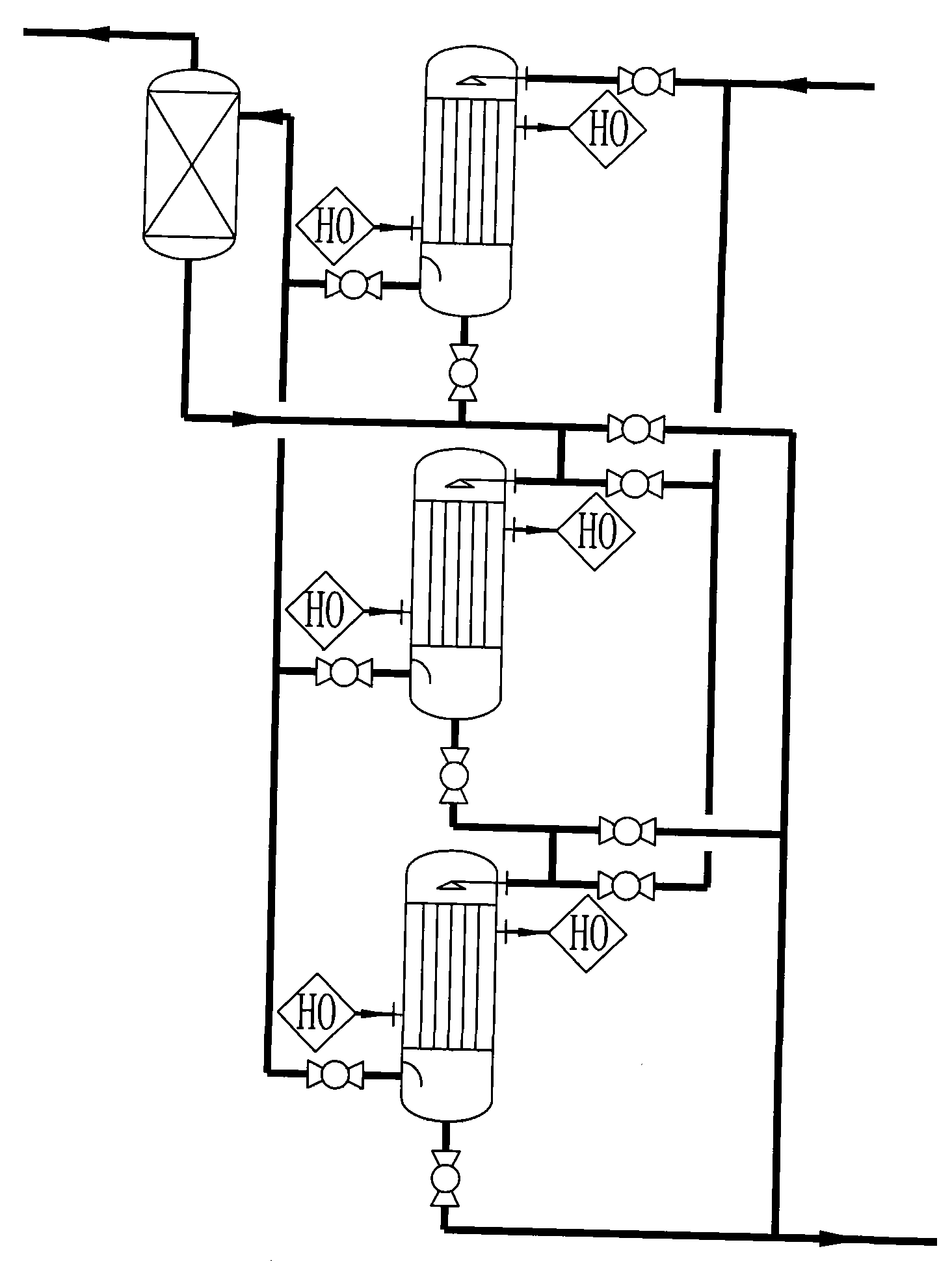

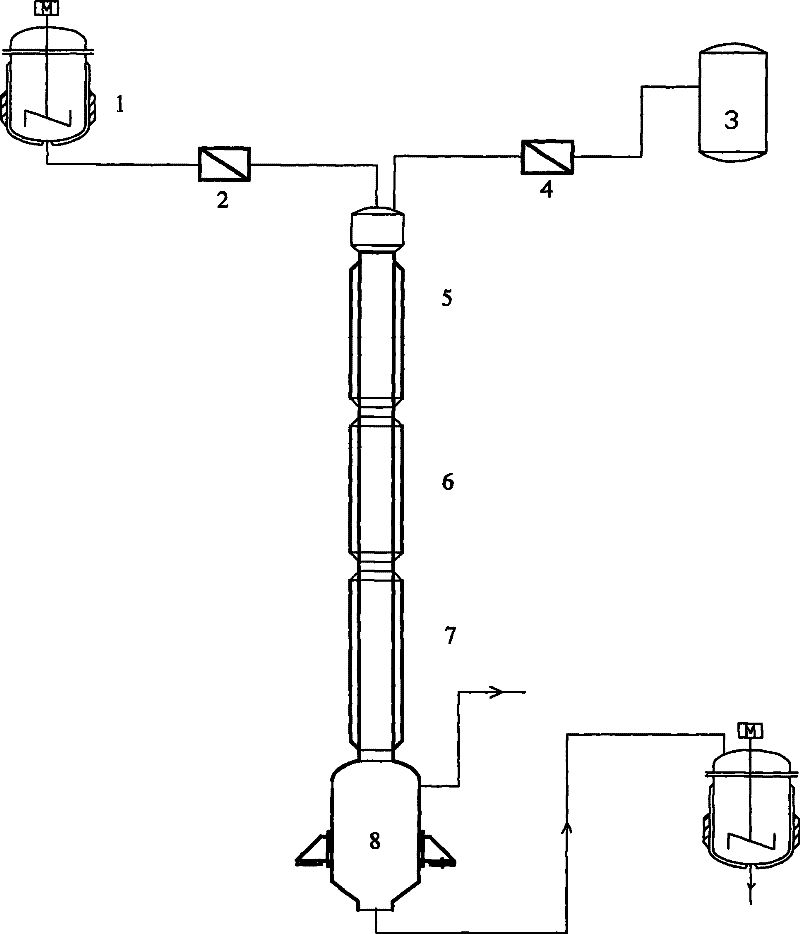

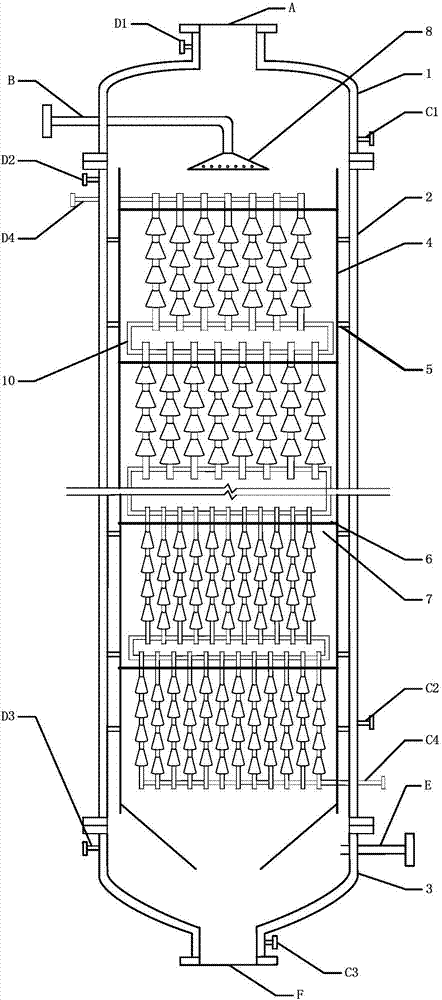

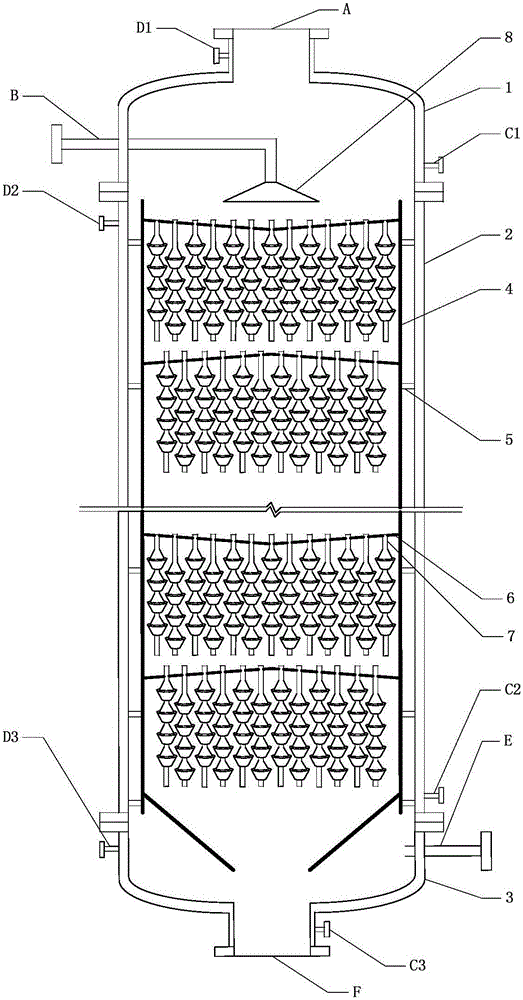

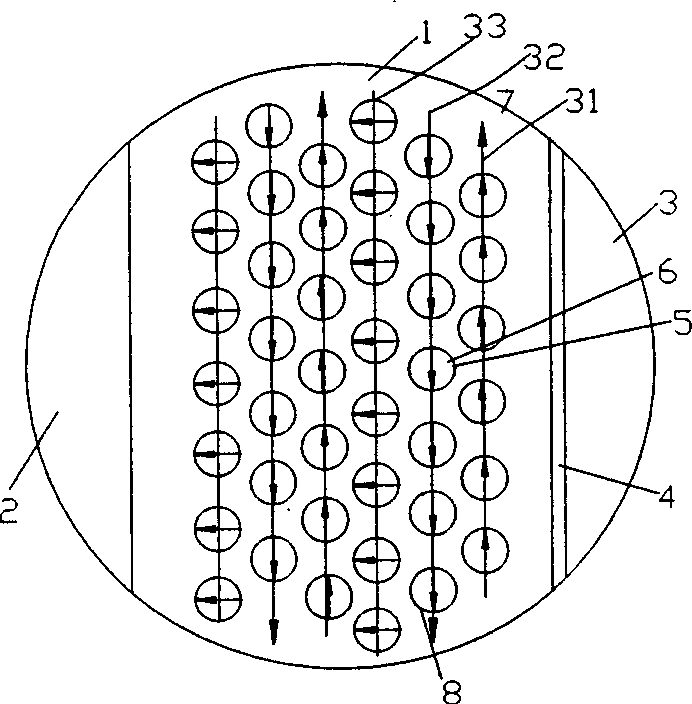

Improved production method of N-phosphonomethyl glycine

ActiveCN101880293BHigh yieldUniform residence timeBiocideGroup 5/15 element organic compoundsRetention timeReaction temperature

The invention relates to an improved production method of N-phosphonomethyl glycine, in which a carbon catalyst is filled in a multi-stage fixed bed reactor; phosphonomethyl iminodiacetic acid slurry with the concentration in percentage by weight of 2-10% is used as a feed liquid to be mixed and heated firstly, then is sent into the fixed bed reactor after being pumped and metered, and is fully contacted with oxygen-containing gas which is supplied into the fixed bed reactor via a gas distributor so as to carry out catalytic oxidation reaction to continuously oxidize the phosphonomethy liminodiacetic acid into glyphosate; and the multi-stage fixed bed reactor is an isothermal reaction system formed by a plurality of stages of reactors connected in series, the top of each stage of reactor is provided with the feed liquid and the gas distributor, and the temperature of each stage of reactor is provided by heating or cooling media. A reaction pressure of 0-1.5 MPa and a reaction temperature of 30-180 DEG C are maintained in each stage of fixed bed reactor, and gas, liquid and solid in the reactor are fully contacted to carry out oxidizing reaction to obtain glyphosate feed liquid. The invention has the advantages of finding a multi-stage series isothermal reactor mode which has more uniform retention time than the existing fixed bed reactor and avoids excessive oxidation, and provides an application process which can keep ideal yield of glyphosate after being amplified.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

A multi-layer drop tube falling film devolatilization reactor

ActiveCN105903424BEliminate dead zoneUniform residence timeChemical/physical/physico-chemical stationary reactorsHeat transfer efficiencyPower equipment

Owner:ZHEJIANG UNIV

Multi-layer drop tube type falling film polycondensation reactor

ActiveCN105944651AUniform residence timeClosely arrangedChemical/physical/physico-chemical stationary reactorsRetention timePower equipment

The invention relates to a multi-layer drop tube type falling film polycondensation reactor. The polycondensation reactor mainly comprises an outer tower and a plurality of tower cores arranged sequentially from top to bottom, wherein each tower core comprises a tower plate and a plurality of falling film drop tubes arranged side by side; each falling film drop tube comprises a hollow pipe and a plurality of drop sleeves fixed on the outer side wall of the hollow pipe; each drop sleeve comprises an upper separation sleeve and a lower separation sleeve. Depending on the action of gravity of materials, a very large gas-liquid phase interface is formed on the falling film drop tubes, and removal of small molecules is facilitated; when fluids pass through each pair of separation sleeves on each falling film drop tube, the fluid in an internal wall surface area and the fluid in a surface area exchange, and a good surface renewal effect is realized to increase the mass transfer rate. The reactor is simple in structure and high in surface renewal rate and has very large gas-liquid interface; the flow is large, and retention time is controllable; reaction energy consumption is low, and externally added power equipment is avoided.

Owner:ZHEJIANG UNIV

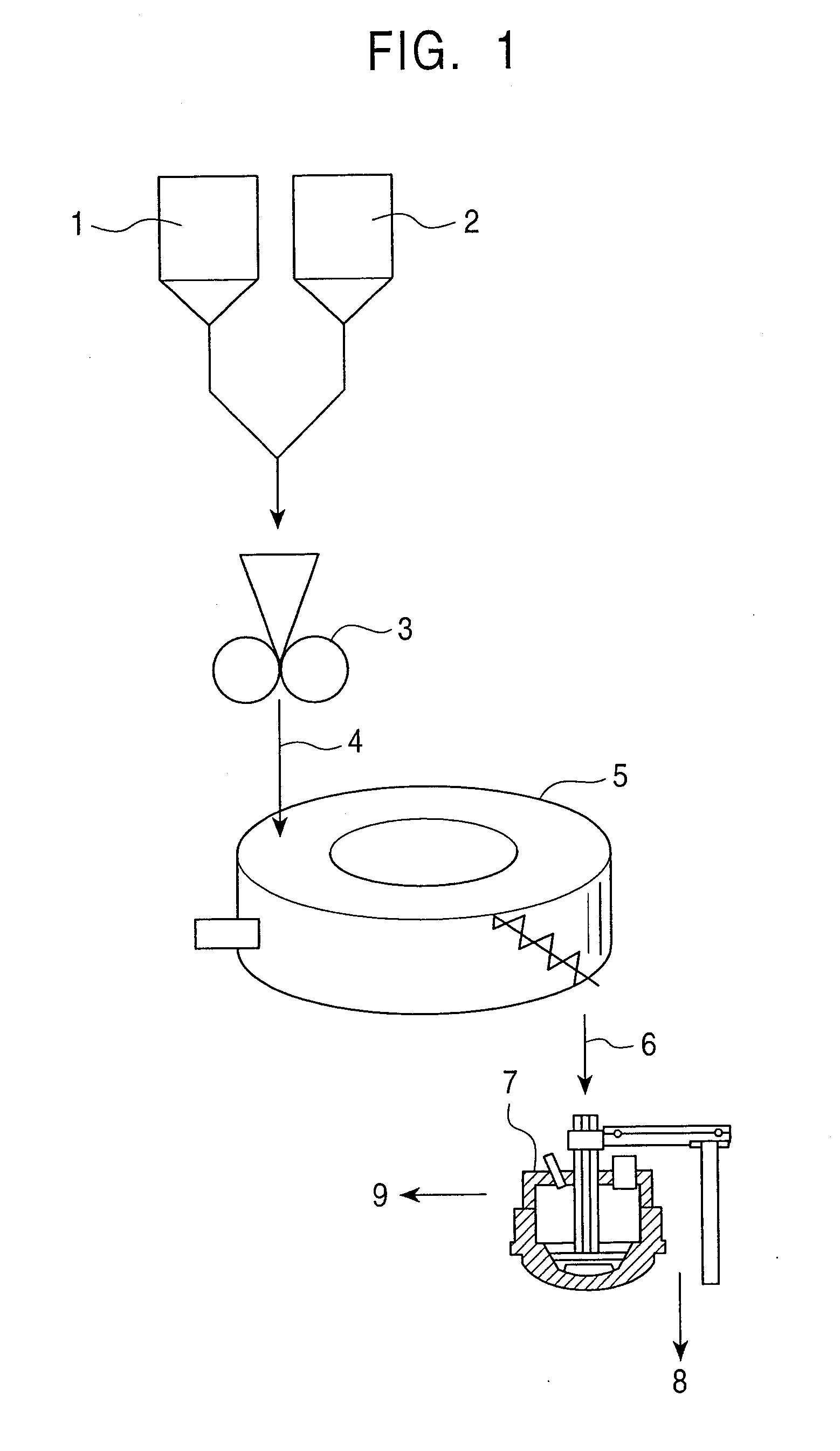

Methods and systems for reducing chromium containing raw material

InactiveUS20140251084A1High chromium reduction degreeReduce the amount requiredRotary drum furnacesElectric furnaceSlagMetal

A method for reducing a chromium containing material, comprising: combining the chromium containing material comprising chromium oxide with a carbonaceous reductant to form a chromium containing mixture; delivering the chromium containing mixture to a moving hearth furnace and reducing the chromium containing mixture to form a reduced chromium containing mixture; delivering the reduced chromium containing mixture to a smelting furnace; and separating the reduced chromium containing mixture into chromium metal and slag. The method also comprises agglomerating the chromium containing mixture in a granulator or the like. The chromium containing mixture has an average particle size of less than about 200 mesh (about 75 μm).

Owner:MIDREX TECH INC

A process and device for continuous production of polybutene-1

The invention discloses a technology for producing polybutylene-1 through a continuous method. The technology comprises the following steps that butene-1 is taken as a raw material in a prepolymerization kettle, titanium serving as a catalyst, aluminum alkyl serving as a cocatalyst, silane serving as an electron donor and hydrogen serving as a molecular weight regulator enter the prepolymerization kettle through a quantifier and then enter a slurry polymerization reaction kettle after being prepolymerized for 5-15 minutes, and slurry polymerization is performed at the temperature of 25 DEG C-55 DEG C under the pressure of 0.6 MPa-1.6 MPa; slurry liquid generated through slurry polymerization enters a gas-phase horizontal reaction kettle with the help of the differential pressure, gas-phase polymerization is performed at the temperature of 30 DEG C-60 DEG C under the pressure of 0.5 MPa-1.5 MPa, and gasified butene-1 is condensed through a condenser and then sent back to the gas-phase horizontal reaction kettle; gas-solid separation is performed; slurry liquid generated through gas-phase polymerization enters a material receiving tank, pressure reduction and separation are performed, and the polybutylene-1 powder is obtained. According to the technology and device for producing the polybutylene-1 through the continuous method, the requirement for equipment is low, no solvent removing process exists, and the device is simple in process, easy to operate and smooth and steady in operation.

Owner:SHANDONG ORIENT HONGYE CHEM

Dynamic calcinator for inorganic material

The dynamic inorganic material calcining furnace has one furnace body comprising outer casing, heat insulating layer and refractory material. The furnace body has feeding port and fume exhausting port on one side in the upper part, discharge port and burner nozzle on the other side in the lower part, gas distributing plates with fluidized air distributing chamber and stirrer on two sides, material lowering vane wheel device between the gas distributing plates, main fluidized air distributing pipe in the bottom, and fluidized air distributing branches in the luidized air distributing chamber and the main fluidized air distributing pipe. The present invention has the advantages of low cost, high heat efficiency, homogeneous calcined material staying time, homogeneous temperature and stable product quality.

Owner:TAIYUAN UNIV OF TECH

Improved production method of N-phosphonomethyl glycine

ActiveCN101880293AHigh yieldUniform residence timeBiocideGroup 5/15 element organic compoundsRetention timeReaction temperature

The invention relates to an improved production method of N-phosphonomethyl glycine, in which a carbon catalyst is filled in a multi-stage fixed bed reactor; phosphonomethyl iminodiacetic acid slurry with the concentration in percentage by weight of 2-10% is used as a feed liquid to be mixed and heated firstly, then is sent into the fixed bed reactor after being pumped and metered, and is fully contacted with oxygen-containing gas which is supplied into the fixed bed reactor via a gas distributor so as to carry out catalytic oxidation reaction to continuously oxidize the phosphonomethy liminodiacetic acid into glyphosate; and the multi-stage fixed bed reactor is an isothermal reaction system formed by a plurality of stages of reactors connected in series, the top of each stage of reactor is provided with the feed liquid and the gas distributor, and the temperature of each stage of reactor is provided by heating or cooling media. A reaction pressure of 0-1.5 MPa and a reaction temperature of 30-180 DEG C are maintained in each stage of fixed bed reactor, and gas, liquid and solid in the reactor are fully contacted to carry out oxidizing reaction to obtain glyphosate feed liquid. The invention has the advantages of finding a multi-stage series isothermal reactor mode which has more uniform retention time than the existing fixed bed reactor and avoids excessive oxidation, and provides an application process which can keep ideal yield of glyphosate after being amplified.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

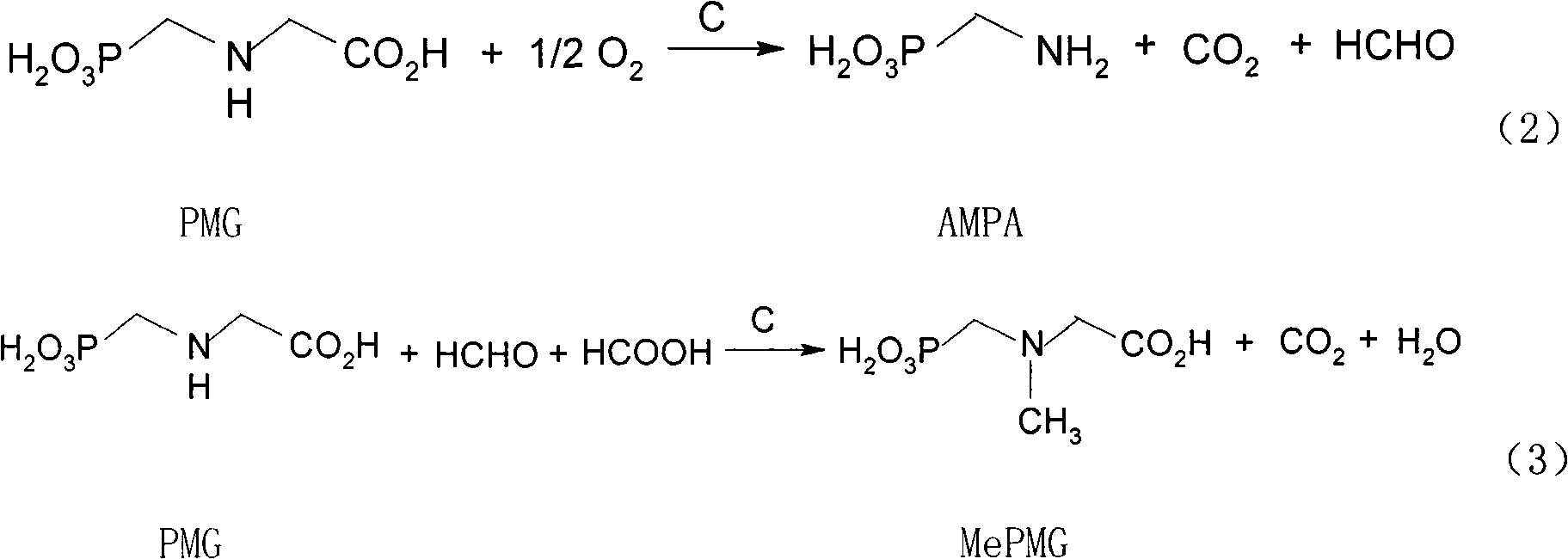

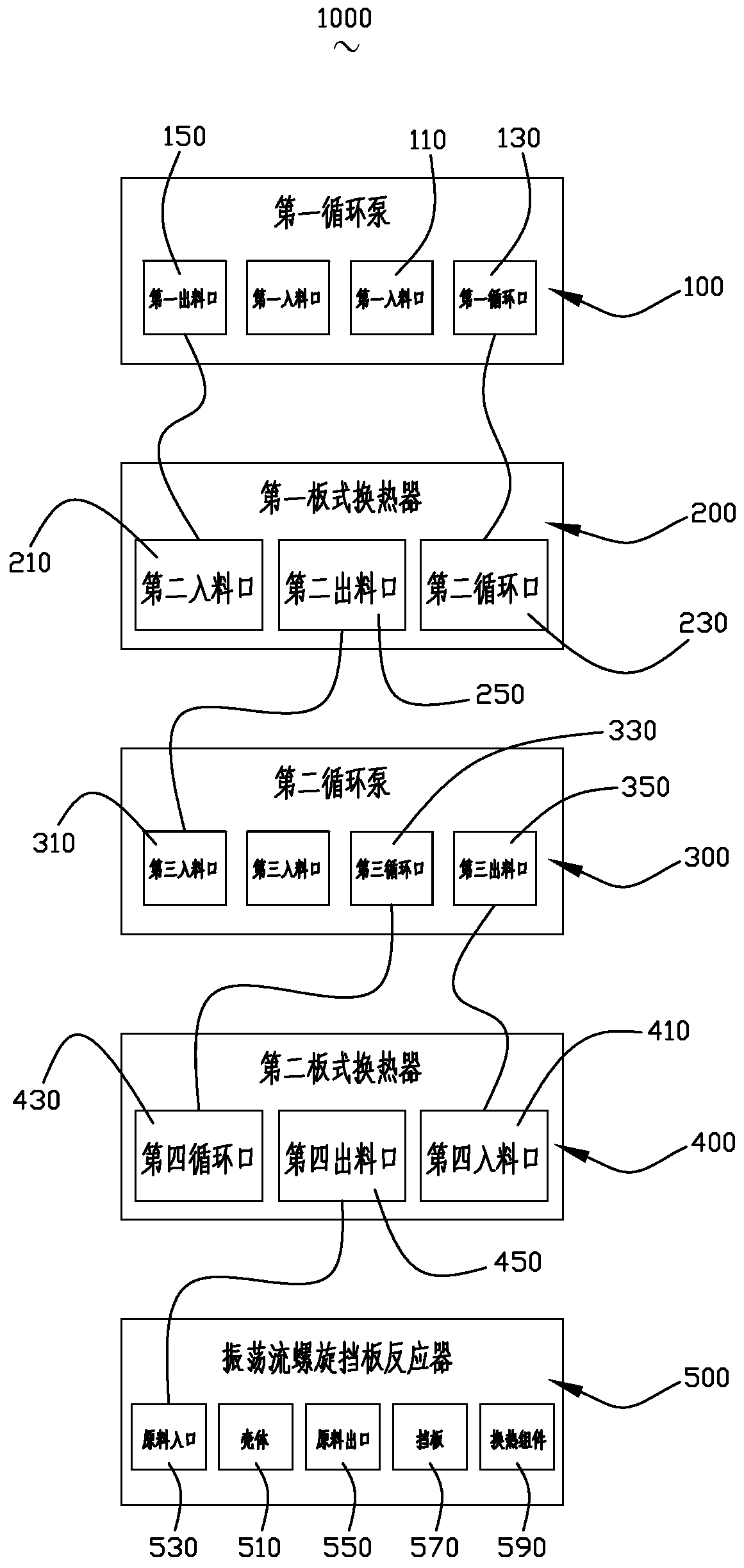

Device and synthesis method for continuously synthesizing 4-bromo-2-p-chloro-5-trifluoromethyl pyrrole-3-nitrile

PendingCN109776376AImprove heat transfer efficiencyImprove production efficiencyOrganic chemistrySynthesis methodsBromine

The invention provides a device for continuously synthesizing 4-bromo-2-p-chloro-5-trifluoromethyl pyrrole-3-nitrile, which comprises a first circulating pump, a first plate type heat exchanger, a second circulating pump, a second plate type heat exchanger and an oscillating flow spiral baffle reactor which are sequentially communicated, wherein the oscillating flow spiral baffle reactor comprisesa shell with an accommodating space, a raw material inlet and a raw material outlet provided in the shell and a baffle plate erected in the accommodating space; the baffle plate is a baffle board; two ends of the baffle plate are respectively communicated with the raw material inlet and the raw material outlet; the baffle plate cuts the accommodating space into a continuous bending structure. Compared with the related art, the device for continuously synthesizing 4-bromo-2-p-chloro-5-trifluoromethyl pyrrole-3-nitrile has the advantages that the reaction time is short; the reaction process iseasy to control with less by-products and high product yield.

Owner:XIANGTAN UNIV

Three direction guided valve tower tray

A tower tray with 3-pilot valves features that its float valves or fixed valves are arranged on tower tray in such manner that the central linking line of each valve row is parallel to the inlet dam, the spray direction of the first valve row is parallel to the inlet dam, the spray direction of the second valve row is reverse to that of the first one, the spray direction of the third valve row points to the down-flow tube, and so on. Its advnatages are longer stay time of liquid on tower plate, enhanced mixing and exchange of liquid in vertical direction, and high efficiency and productivity.

Owner:BEIJING ZEHUA CHEM ENG

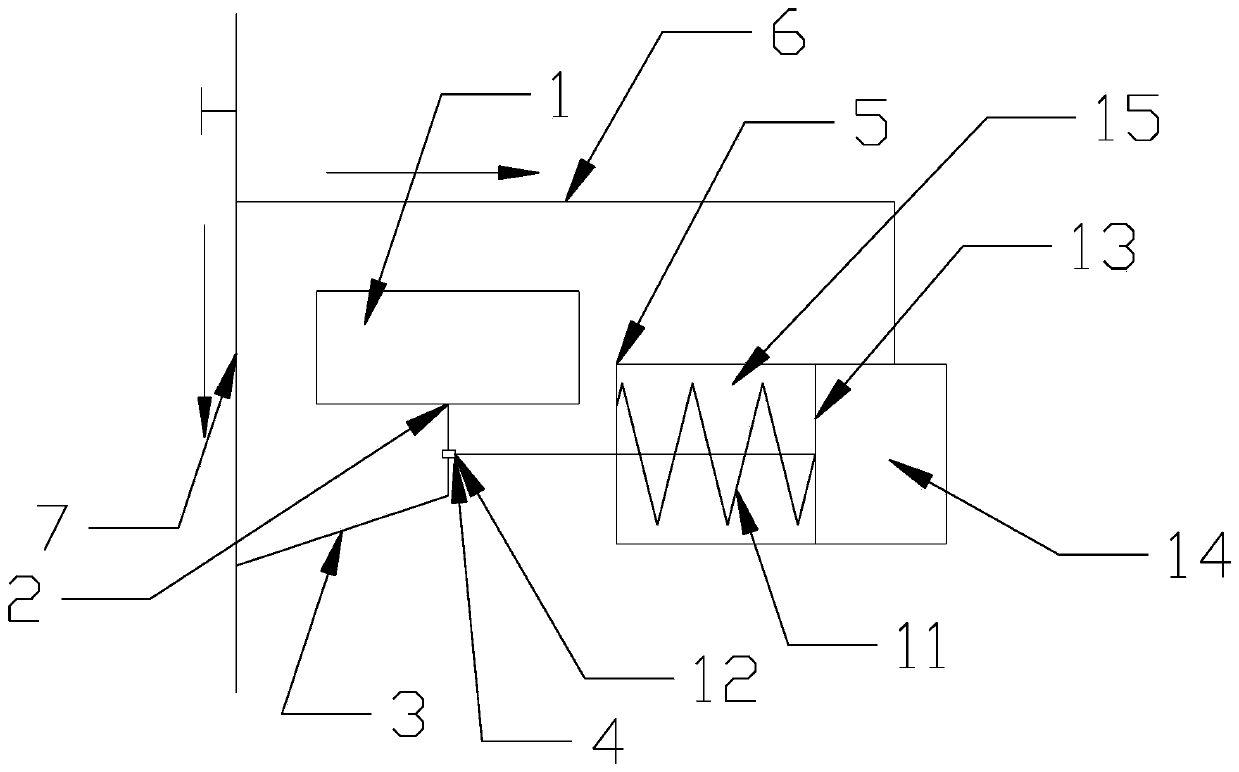

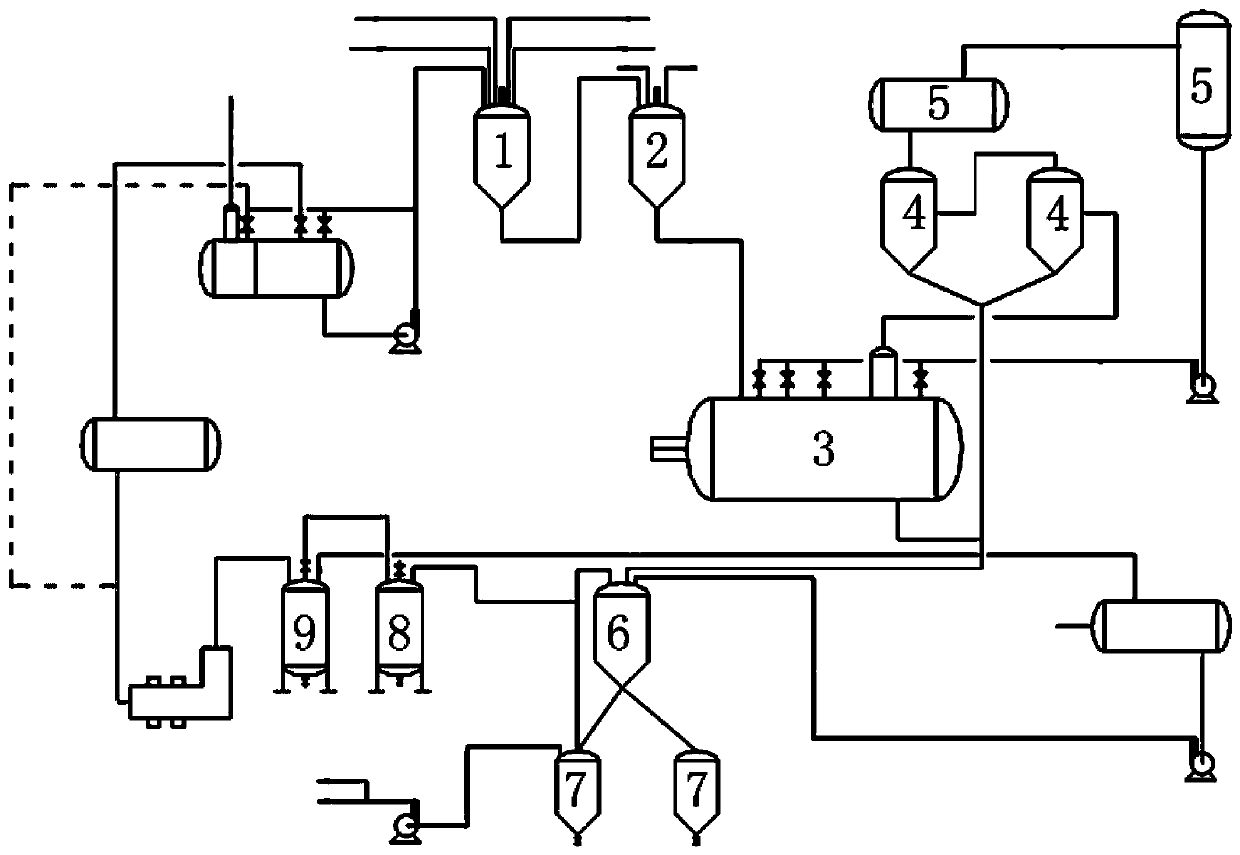

MASB multi-stage anaerobic sludge bed reactor

InactiveCN105523631AReduce areaReduce the overall heightBiological treatment apparatusTreatment with anaerobic digestion processesWater dischargeSewage

The invention relates to a sewage anaerobic biological treatment system, and especially relates to an MASB multi-stage anaerobic sludge bed reactor. The reactor comprises a plurality of anaerobic sludge bed reaction tanks connected in series, and comprises a sewage pump 1, solid-liquid separators, a water inlet pipe, a water discharge pipe, gas discharge pipes, sludge discharge pipes, and connection pipes. Compared with existing sewage anaerobic biological treatment technologies and especially existing anaerobic sludge bed reactor technologies, the technical scheme provided by the invention has the significant advantages of low project investment cost, low operation cost, good treatment effect, short treatment time, no dead corner, no blockage, easy maintenance, and controllable and adjustable treatment scale and effect. Also, system modularization is realized.

Owner:GUANGDONG BIQING ENVIRONMENT PROTECTION TECH CO LTD

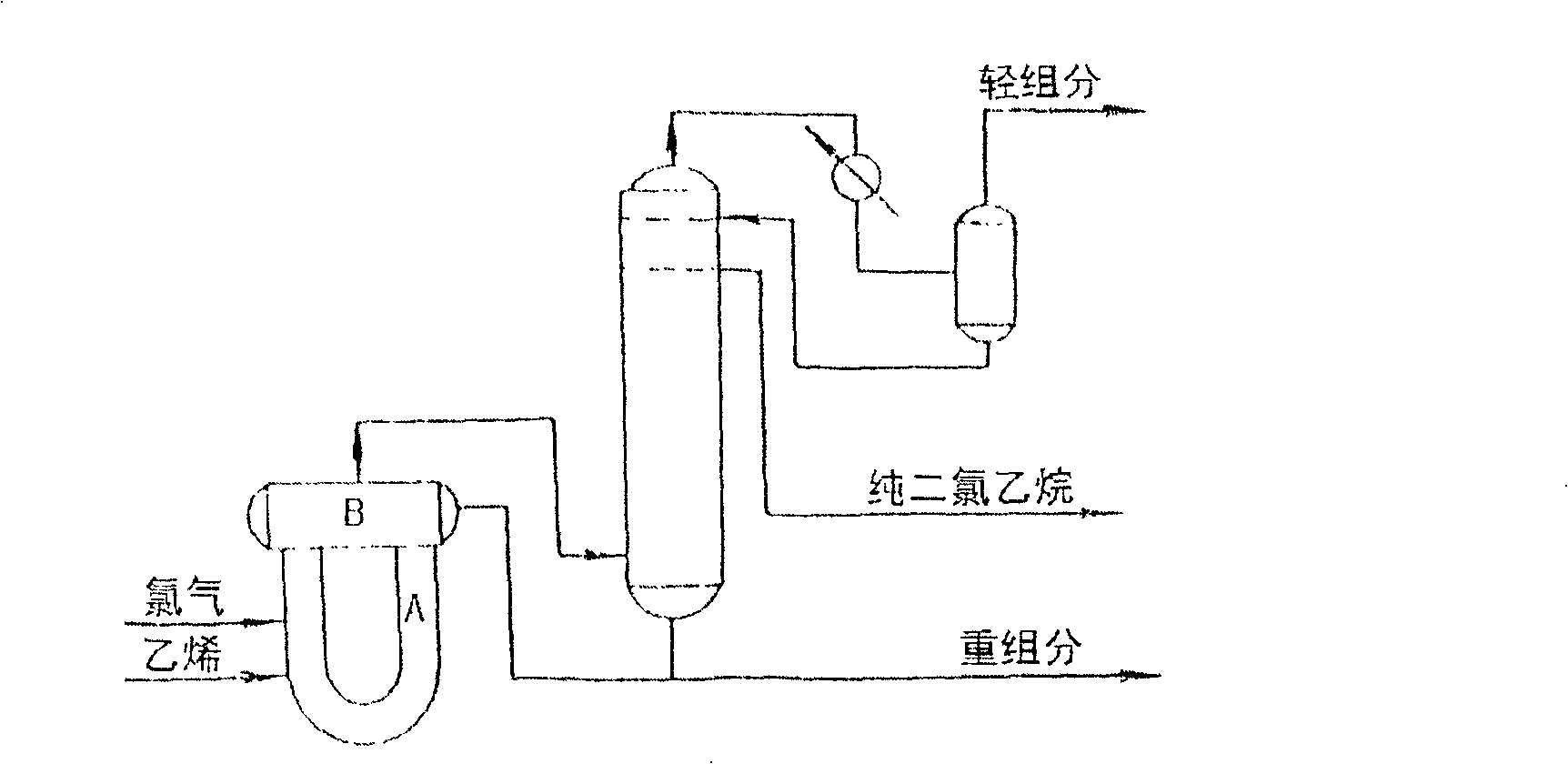

Single-tube multiple rotary static and mixed-piping reacotr with vinyl chlorination and method thereof

InactiveCN100450983CLess investmentIncrease production capacityChemical/physical/physico-chemical stationary reactorsPreparation by halogen additionGas phaseChloride

A multi-rotary static mixed piping ethane chloride reaction producer with single tube and its reaction are disclosed. The producer consists of circulation dichloroethane and chlorine inlet pipeline, piping chlorine quick-dissolving mixer, chlorine dissolving liquid outlet pipeline, merged pipeline with chlorine dissolving liquid and ethane mixed liquid, piping ethane chlorine reactor and dichloroethane outlet pipeline. It has less investment and by-product, higher purity of product and production efficiency. It can be used for liquid phase discharge, gas phase discharge and gas-liquid mixture discharge.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com