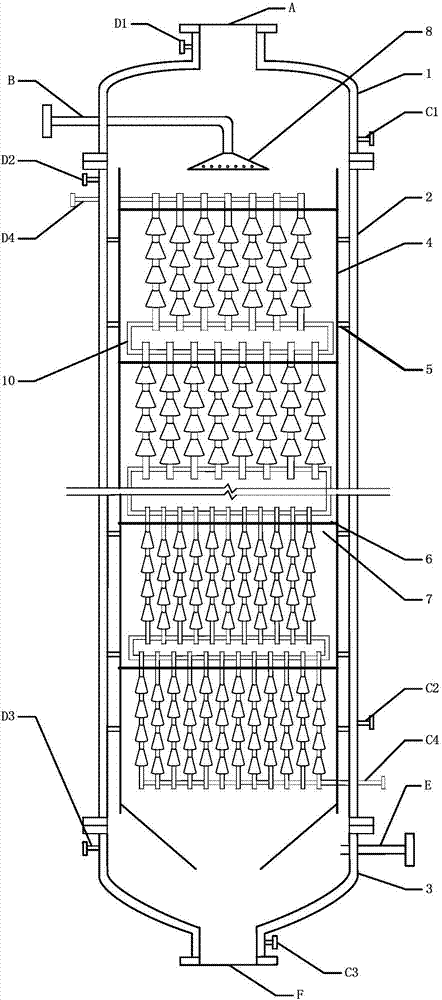

A multi-layer drop tube falling film devolatilization reactor

A reactor and drop-tube technology, applied in the field of multi-layer drop-tube falling film devolatilization reactor, can solve the problems of simplicity and low heat transfer efficiency, and achieve large flow rate, large specific surface area and good film-forming property Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

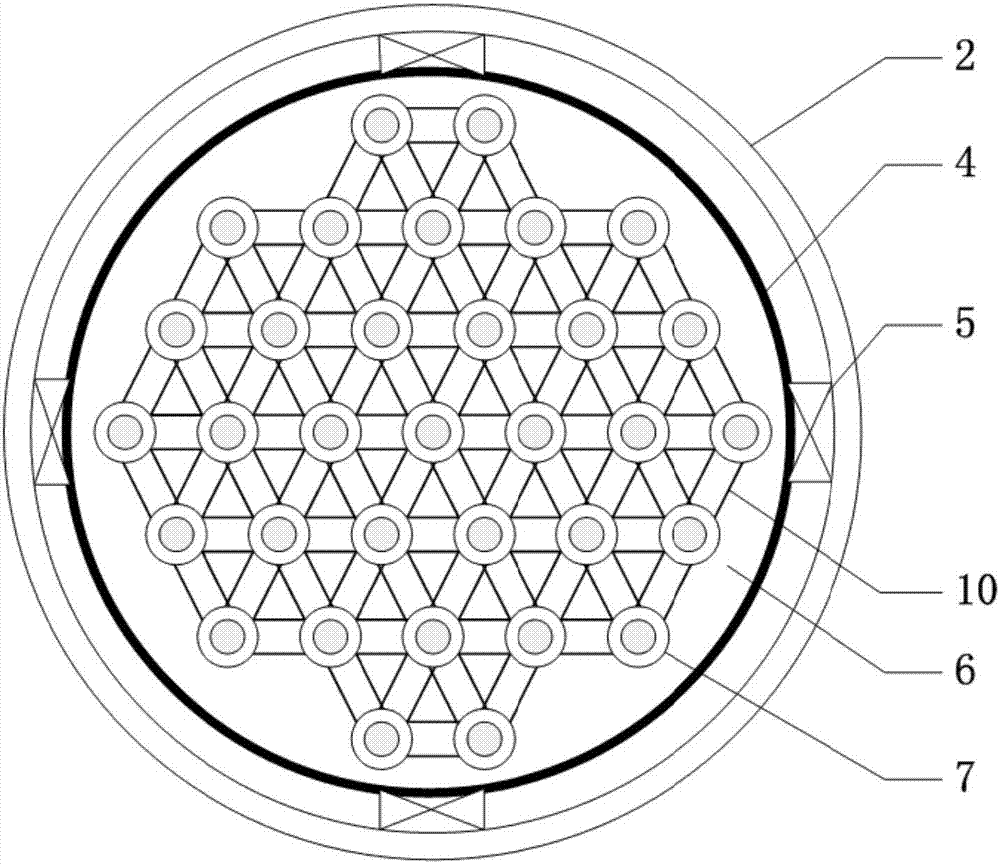

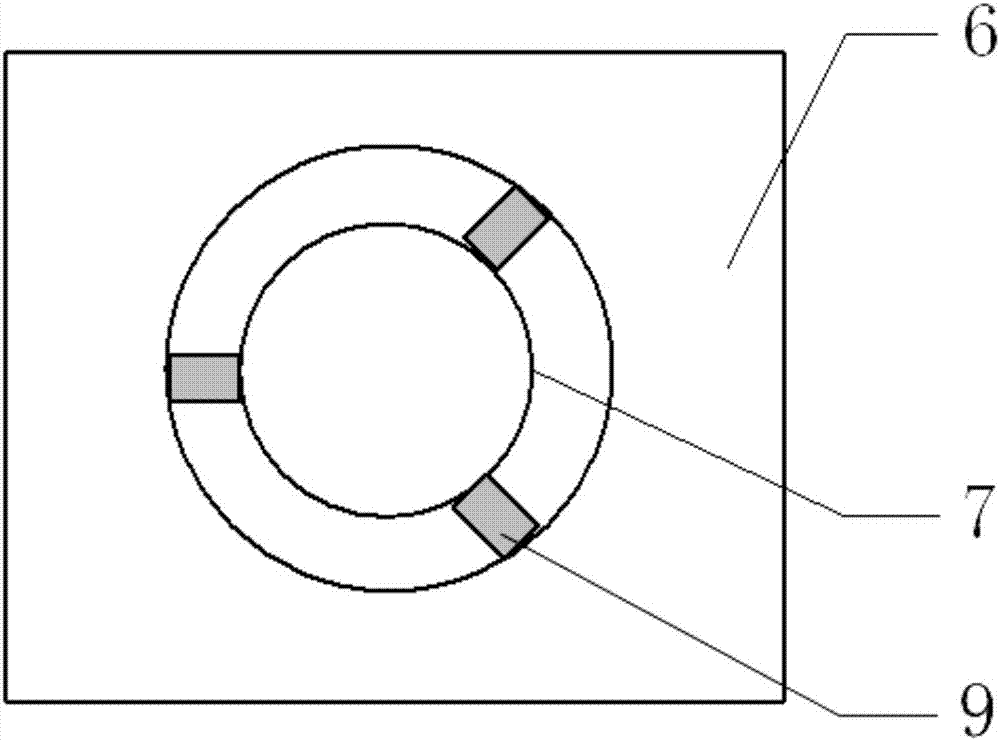

[0032] Embodiment 1: PET final polycondensation process.

[0033] The structure and principle of the reactor are as described above, and the structural parameters of some reactors are as follows: the number of openings is 10-100, the width of the leakage channel is 2-15mm, the vertical distance between two adjacent umbrella skirts is 20-100mm, and the falling film The taper of the umbrella skirt on the drop tube is from 2:1 to 1:5, the bottom diameter of the umbrella skirt is 20-100mm, and the number of layers is 10-30.

Embodiment 2

[0034] Example 2: Polymer devolatilization process.

[0035] The structure and principle of the reactor are as described above, and some structural parameters and operating parameters of the reactor are as follows: melt viscosity 10-100Pa·s, small molecule volatile content 2-5%, number of openings 10-100, leakage channel width 2 -10mm, the vertical distance between two adjacent umbrella skirts is 20-100mm, the taper of the umbrella skirt on the falling film drop tube is 2:1-1:5, and the bottom diameter of the umbrella skirt is 20- 50mm, the number of layers is 10-30; compared with the smooth drop tube devolatilizer under the same structural parameters, the volatilization removal efficiency is increased by 10-30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com