Improved production method of N-phosphonomethyl glycine

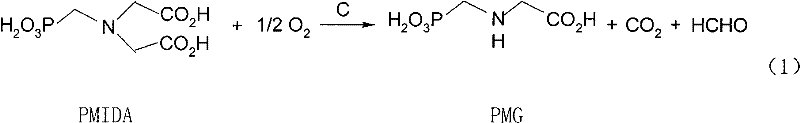

A technology of phosphonomethylglycine and a production method, which is applied in the field of N-phosphonomethylglycine, can solve the problems of decreased reaction yield, difficulty in transferring heat in time, poor heat transfer effect in a fixed bed, etc., so as to avoid excessive oxidation, The effect of even dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

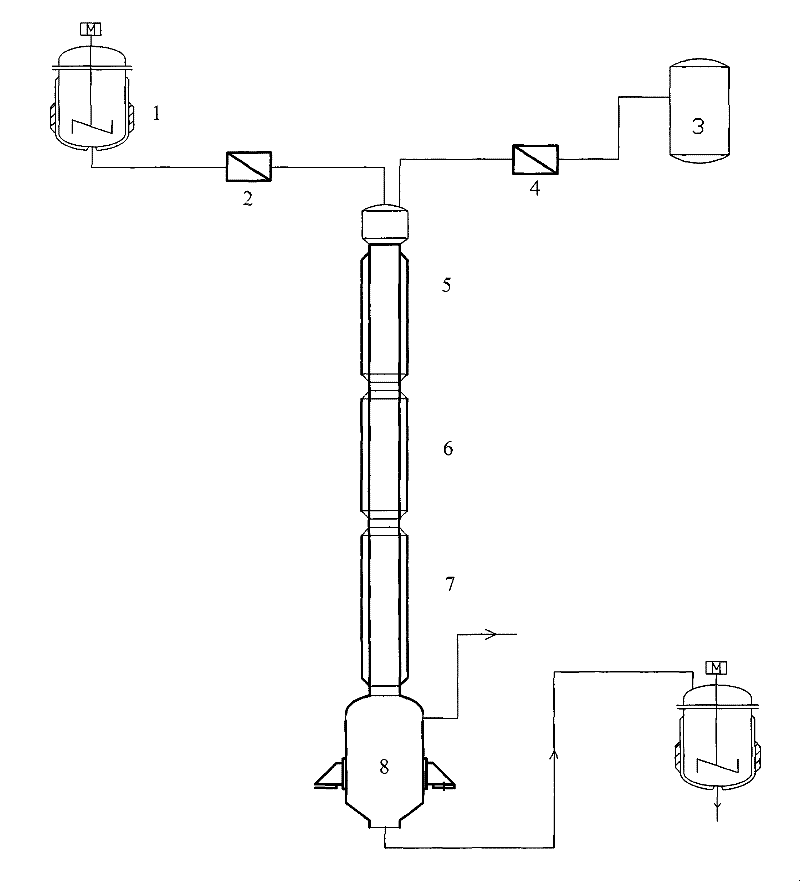

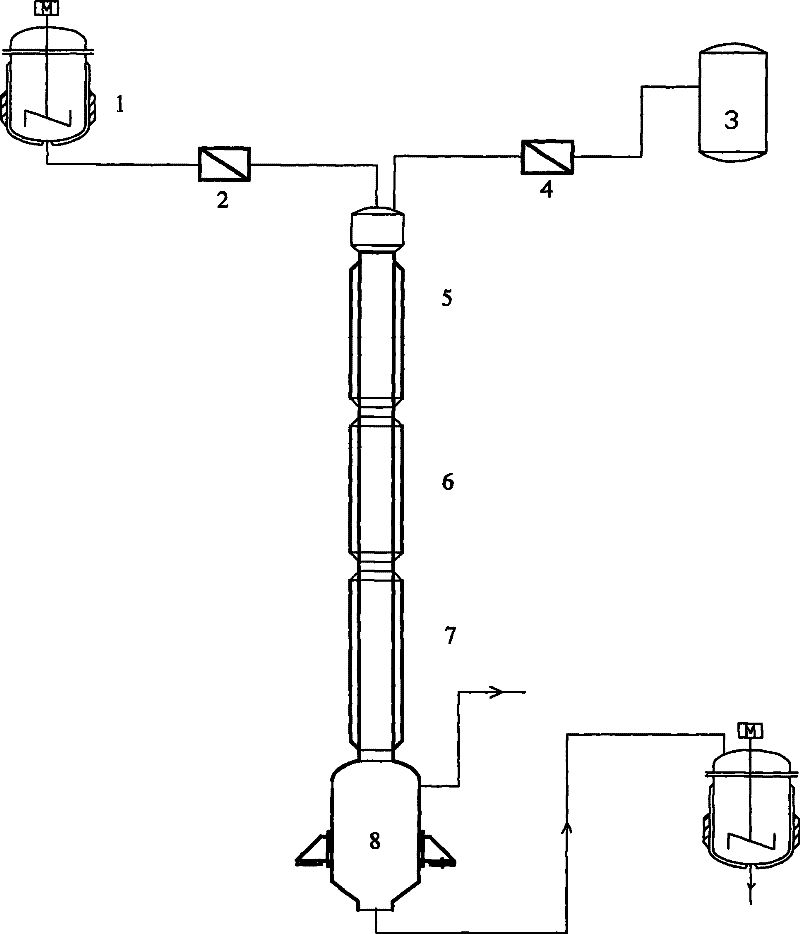

Method used

Image

Examples

Embodiment 1

[0036] Under the temperature of 100~110 ℃ and the pressure of 0.1~0.25MPa, put 98% PMIDA and deionized water into the dissolving kettle according to a certain ratio and be prepared with a solution of 2% diglyphosate by weight, and then use After the pump is metered, it is pumped into a total of three-stage fixed-bed reactors equipped with 4Kg of activated carbon catalyst at each stage. Pure oxygen gas is metered into the fixed bed reactor at a rate of 3.9Kg / h. The reactor pressure was maintained at about 0.7 MPa, and the reactor temperature at each stage was maintained at 120°C. Experiments were carried out at various liquid feed rates. The reaction results are shown in Table 1.

[0037] Table 1

[0038]

[0039]

Embodiment 2

[0041] Under the temperature of 100~110 ℃ and the pressure of 0.1~0.25MPa, put 98% PMIDA and deionized water into the dissolving kettle according to a certain ratio and be prepared with a solution of 2% diglyphosate by weight, and then use After the pump is metered, it is pumped into a total of three-stage fixed-bed reactors equipped with 4Kg of activated carbon catalyst at each stage. Pure oxygen gas is metered into the fixed bed reactor at a rate of 3.4Kg / h. The reactor pressure is maintained at about 0.55MPa, the primary reactor temperature is maintained at 115°C, the secondary reactor temperature is maintained at 110°C, and the tertiary reactor temperature is maintained at Experiments were performed at various liquid feed rates. The reaction results are shown in Table 2.

[0042] Table 2

[0043]

Embodiment 3

[0045] Under the temperature of 120~140 ℃ and the pressure of 0.2~0.4MPa, put 98% PMIDA and deionized water into the feed mixer according to a certain proportion and be mixed with the aqueous solution of 6% diglyphosate in weight percent concentration, Squeeze into the total two-stage fixed-bed reactor that every stage is equipped with 9Kg active carbon catalyst after metering with pump then. Pure oxygen gas is metered into the fixed bed reactor at a rate of 14.0Kg / h. The reactor pressure was maintained at about 0.55 MPa, the primary reactor temperature was maintained at 120°C, and the secondary reactor temperature was maintained at 90°C. Experiments were carried out at various liquid feed rates. The reaction results are shown in Table 3.

[0046] table 3

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com