Method and device for producing N-phosphono methyl glycine

A technology of phosphonomethylglycine and production method, applied in the field of N-phosphonomethyliminodiacetic acid, can solve the problems of uneven distribution, high catalyst cost, heavy catalyst loading and unloading work and the like

Active Publication Date: 2010-12-29

ZHEJIANG XINAN CHEM INDAL GROUP

View PDF2 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But there is deficiency in this method equally, at first, 1) when using fixed bed as continuous reactor, catalyst is piled up in fixed bed, and after oxygen enters fixed bed, forms big bubble to occupy catalyst surface space, causes diglyphosate feed liquid in catalyst The uneven distribution on the surface results in incomplete conversion of diglyphosate or increased side reactions; 2) the heat transfer effect of the fixed bed is poor, and the heat released during the catalytic oxidation of diglyphosate is difficult to transfer in time, so the temperature is too high and there are by-products The generation of aminomethyl phosphoric acid reduces the reaction yield

3) There is a requirement for the particle size of the carbon catalyst supported in the fixed bed reactor, and the carbon catalyst with small particles will generate a large pressure drop, which will eventually lead to the blockage of the fixed bed

However, after choosing a carbon catalyst with large particles, its catalytic efficiency will decrease, and the cost of the catalyst will be higher; 4) due to the short service life of the carbon catalyst used, usually within 20 days, large-scale production equipment adopts fixed-bed reactors. , the filling and unloading of the catalyst is heavy, and the production equipment needs to be shut down, which affects the production capacity of the equipment

Method used

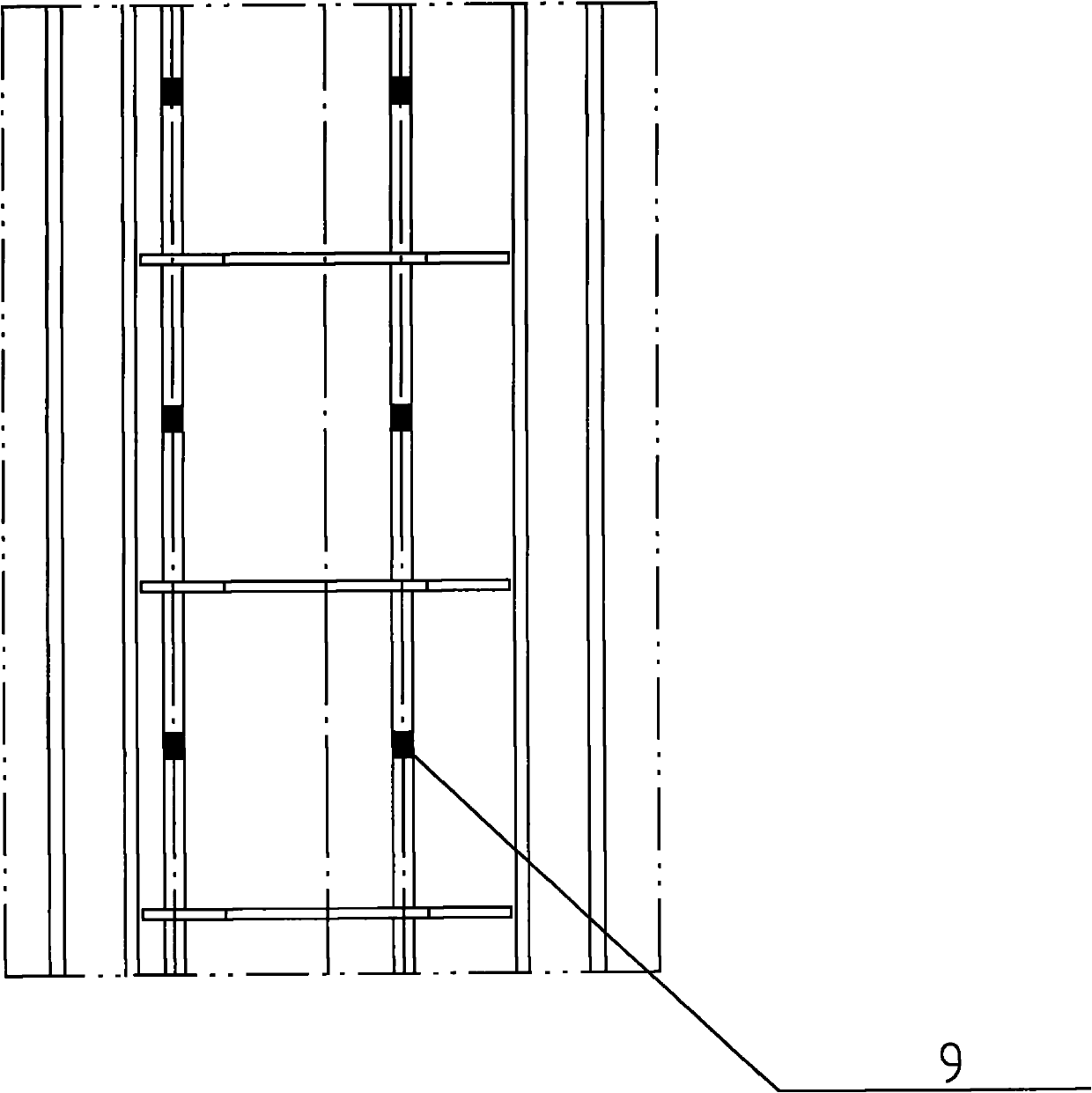

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

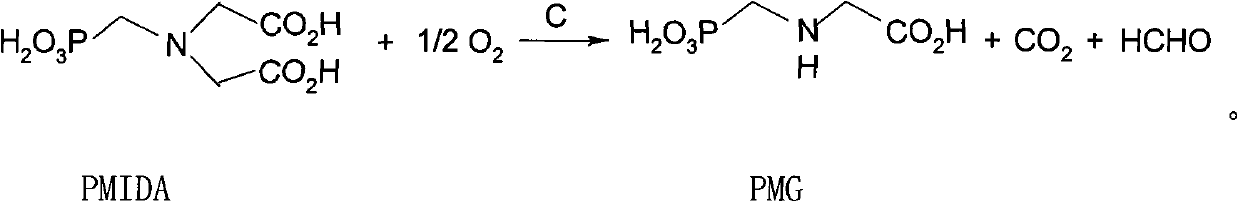

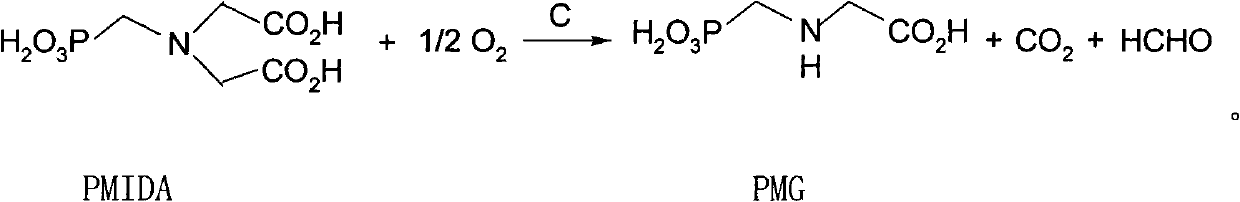

The invention relates to a method for continuously producing N-phosphono methyl glycine. The method comprises the following steps of: inputting reaction feed liquor into a reactor under the condition of oxidizing PMIDA into glyphosate to make an activated carbon catalyst suspend in the reaction feed liquor in the reactor; fully contacting the PMIDA with molecular oxygen; continuously oxidizing the PMIDA into the glyphosate under a selected reaction condition; and performing a PMIDA oxidizing reaction. The invention also relates to a device for continuously producing the N-phosphono methyl glycine. The device mainly comprises a power generator, a tubular reactor and a gas-liquid separator. The device is characterized in that: the power generator is connected with the bottom of the tubular reactor through a pipeline; the gas-liquid separator is connected with the top of the tubular reactor; the lower part of the tubular reactor is provided with an oxygen containing gas feed tube orificeand is connected with a gas distributor in the tube; and the power generator is connected with a feed tube of the PMIDA feed liquor and catalyst activated carbon or a feed tube of the mixed liquor ofthe PMIDA feed liquor and catalyst activated carbon through pipelines.

Description

technical field The present invention relates to a method and device for preparing glyphosate by catalytic oxidation continuous reaction of N-phosphonomethyliminodiacetic acid, i.e., bisglyphosate (PMIDA), which belongs to N-phosphonomethylglycine, i.e. grass The field of preparation of glycine (PMG). Background technique Glyphosate is a systemic conductive broad-spectrum herbicide with the advantages of high efficiency, broad-spectrum, low toxicity and no residue. In recent years, due to the expansion of global planting of genetically modified crops, the recovery and modernization of global agriculture, especially in developing countries, and the production of renewable energy, the market demand for glyphosate has grown rapidly, and the sales volume has increased by nearly 15% per year. , has occupied the first place in the world's pesticide sales for many years, and has become the fastest growing pesticide variety. There are currently two production routes for glyphosat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07F9/38B01J21/18A01N57/20A01P13/00

Inventor 王伟任不凡周曙光吴嘉陈静屠民海林少耕杨旭张海良叶志凤韩鑫

Owner ZHEJIANG XINAN CHEM INDAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com