MASB multi-stage anaerobic sludge bed reactor

An anaerobic sludge bed and reactor technology, applied in the field of sewage anaerobic biological treatment system, can solve the problems of increasing project investment cost, increasing the volume of anaerobic sludge bed reactor, reducing the effect of anaerobic biological treatment, etc., achieving Reduce structural strength requirements and project investment costs, improve the effect of anaerobic biological treatment of sewage, and reduce the effect of horizontal cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

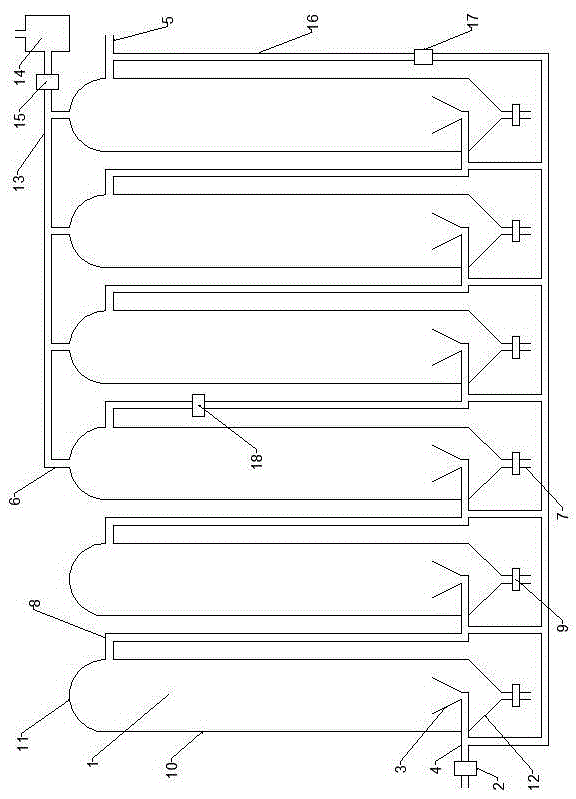

[0037] Attached below figure 1 And embodiment technical scheme of the present invention is described further.

[0038] Example.

[0039] 1. MASB multi-stage anaerobic sludge bed reactor, including six anaerobic sludge bed reaction tanks 1 connected in series, also includes sewage pump 1 2, solid-liquid separator 3, water inlet pipe 4, drain pipe 5, drainage pipe Air pipe 6, sludge discharge pipe 7, connecting pipe 8; sewage pump 1 2 communicates with the lower part of the first anaerobic sludge bed reaction tank 1 through the water inlet pipe 4; drain pipe 5 reacts with the last anaerobic sludge bed reaction tank The upper part of the tank 1 is connected; the upper part of the previous anaerobic sludge bed reaction tank 1 and the lower part of the latter anaerobic sludge bed reaction tank 1 are connected through the connecting pipe 8; the solid-liquid separator 3 is located in all six anaerobic sludge bed reaction tanks The lower part of the interior of the oxygen sludge bed r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com