Improved production method of N-phosphonomethyl glycine

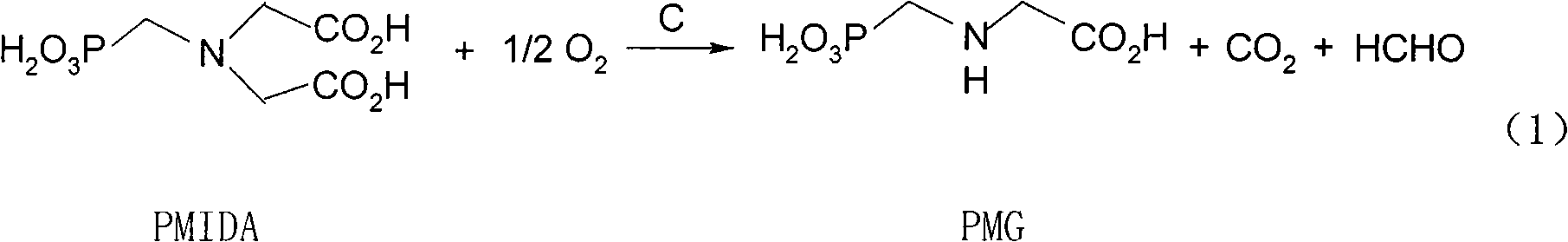

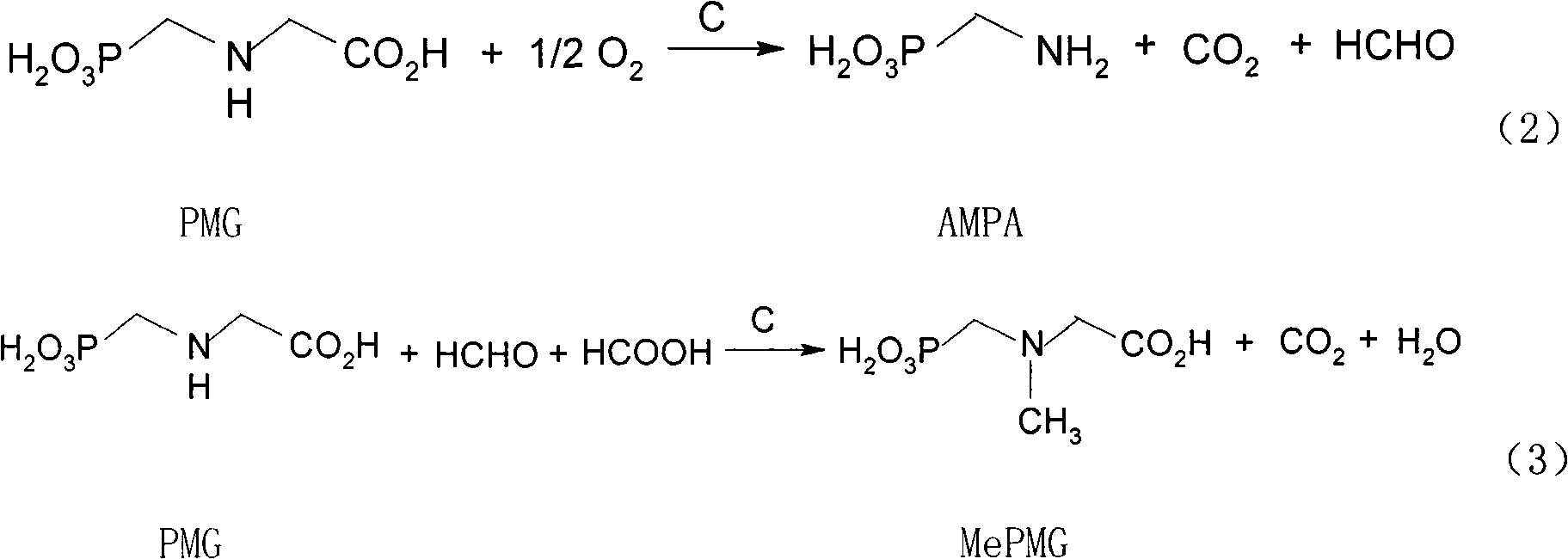

A technology of phosphonomethylglycine and its production method, which is applied in the field of N-phosphonomethylglycine, can solve the problems of decreased reaction yield, difficult heat transfer in time, poor heat transfer effect of fixed bed, etc., so as to avoid excessive oxidation, Uniform residence time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

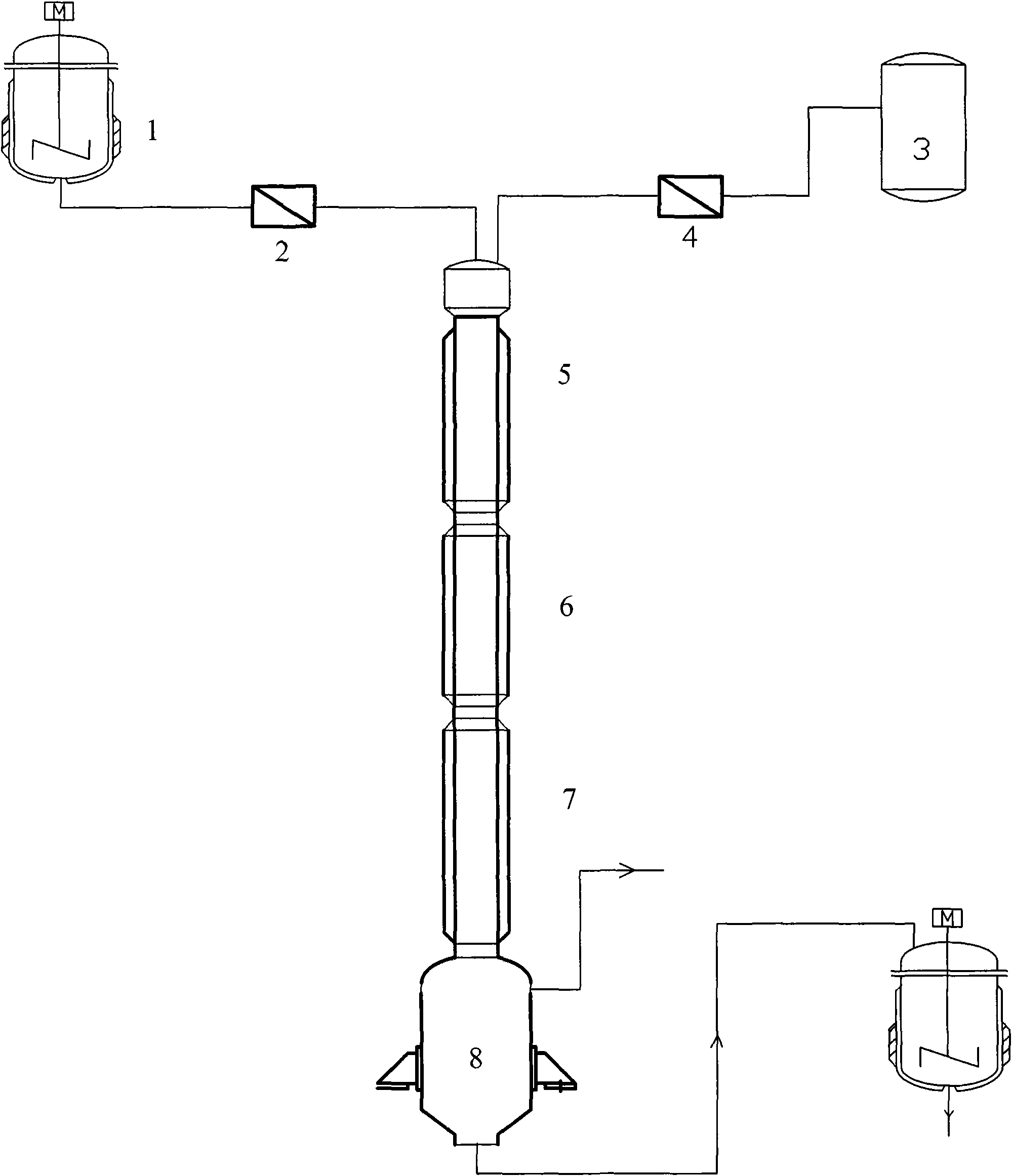

Method used

Image

Examples

Embodiment 1

[0036] Under the temperature of 100~110 ℃ and the pressure of 0.1~0.25MPa, put 98% PMIDA and deionized water into the dissolving kettle according to a certain ratio and be prepared with a solution of 2% diglyphosate by weight, and then use After the pump is metered, it is pumped into a total of three-stage fixed-bed reactors equipped with 4Kg of activated carbon catalyst at each stage. Pure oxygen gas is metered into the fixed bed reactor at a rate of 3.9Kg / h. The reactor pressure was maintained at about 0.7 MPa, and the reactor temperature at each stage was maintained at 120°C. Experiments were carried out at various liquid feed rates. The reaction results are shown in Table 1.

[0037] Table 1

[0038]

[0039]

Embodiment 2

[0041] Under the temperature of 100~110 ℃ and the pressure of 0.1~0.25MPa, put 98% PMIDA and deionized water into the dissolving kettle according to a certain ratio and be prepared with a solution of 2% diglyphosate by weight, and then use After the pump is metered, it is pumped into a total of three-stage fixed-bed reactors equipped with 4Kg of activated carbon catalyst at each stage. Pure oxygen gas is metered into the fixed bed reactor at a rate of 3.4Kg / h. The reactor pressure was maintained at about 0.55MPa, the primary reactor temperature was maintained at 115°C, the secondary reactor temperature was maintained at 110°C, and the tertiary reactor temperature was maintained at 90°C. Experiments were performed at various liquid feed rates conduct. The reaction results are shown in Table 2.

[0042] Table 2

[0043]

Embodiment 3

[0045] Under the temperature of 120~140 ℃ and the pressure of 0.2~0.4MPa, put 98% PMIDA and deionized water into the feed mixer according to a certain proportion and be mixed with the aqueous solution of 6% diglyphosate in weight percent concentration, Squeeze into the total two-stage fixed-bed reactor that every stage is equipped with 9Kg active carbon catalyst after metering with pump then. Pure oxygen gas is metered into the fixed bed reactor at a rate of 14.0Kg / h. The reactor pressure was maintained at about 0.55 MPa, the primary reactor temperature was maintained at 120°C, and the secondary reactor temperature was maintained at 90°C. Experiments were carried out at various liquid feed rates. The reaction results are shown in Table 3.

[0046] table 3

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com