Single-tube multiple rotary static and mixed-piping reacotr with vinyl chlorination and method thereof

A technology of static mixing and chlorination reactors, which is applied in chemistry/physics/physicochemistry fixed reactors, organic chemistry, halogen addition preparation, etc., and can solve problems such as low production capacity, low operating flexibility, and insufficient purity of reactants, etc. problems, to achieve the effect of uniform residence time, large production capacity, and large operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

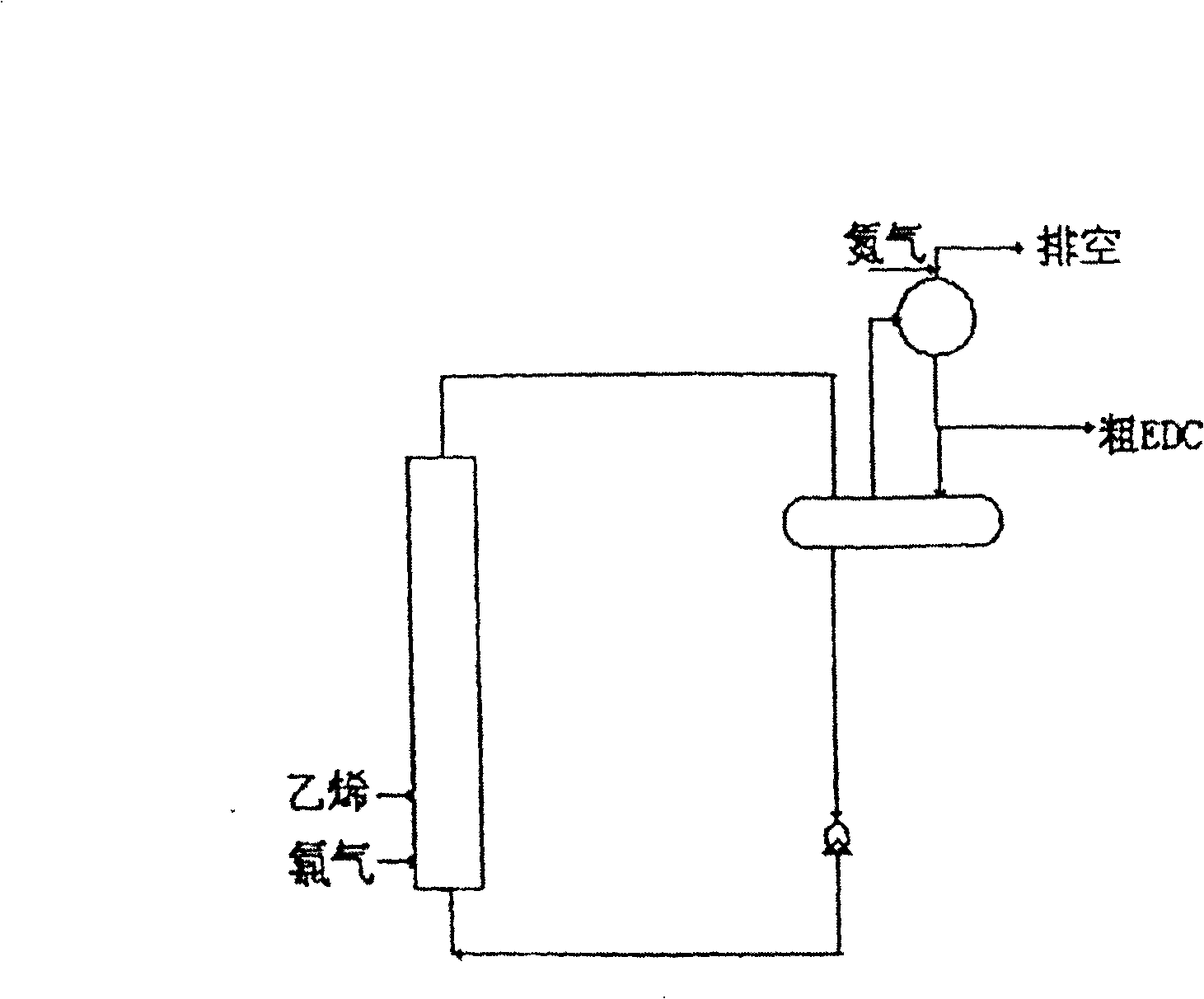

[0030] Single-tube multi-rotary static mixing tubular ethylene chlorination reaction production device for dichloroethane production, such as Figure 5 , 6 , 7, 8, 9, and 10, including circulating dichloroethane and chlorine gas inlet pipeline 1, tubular chlorine gas instant mixer 2, chlorine gas dissolving solution outlet pipeline 3, chlorine gas dissolving solution and ethylene mixed solution confluence pipeline 4, pipe Ethylene chlorination reactor 5, ethylene dichloride outlet pipeline 6, ethylene mixed liquid outlet pipeline 7, ethylene dispersion mixing pipe 8, ethylene and circulating dichloroethane inlet pipeline 9. The above-mentioned tubular chlorine instant mixer 2, tubular ethylene chlorination reactor 5, and ethylene dispersion mixing tube 8 are provided with hollow mandrels and helical pieces, and each group of three helical pieces are arranged along the cross section, and the angle between the helical pieces is α = 120°, two sets of axially adjacent helical she...

Embodiment 2

[0033] Embodiment 2 is basically the same as Embodiment 1, except that the mixing components installed in the tubular chlorine instant mixer 2, tubular ethylene chlorination reactor 5, and ethylene dispersion mixing tube 8 are chemical packing Pall rings.

Embodiment 3

[0035] The third embodiment is basically the same as the first embodiment, except that the tubular chlorine instant mixer 2, the tubular ethylene chlorination reactor 5, and the mixing components installed in the ethylene dispersion mixing tube are corrugated chemical packing plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com