Patents

Literature

160results about "Preparation by OH and halogen introduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

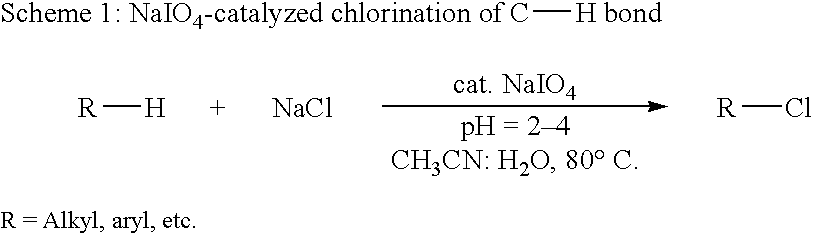

Catalytic process for regiospecific chlorination of alkanes, alkenes and arenes

InactiveUS6825383B1Save energyOrganic compound preparationPreparation by OH and halogen introductionMetal chlorideAlkene

The present invention provides a process for regiospecific chlorination of an aromatic or aliphatic compound with a chlorine source comprising a metal chloride and other than Cl2 and SO2Cl2 in presence of hypervalent iodine catalyst and in acidic medium.

Owner:COUNCIL OF SCI & IND RES

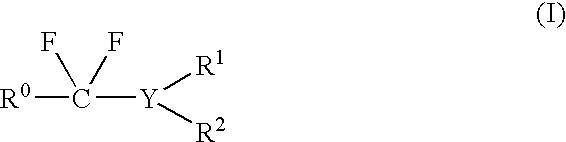

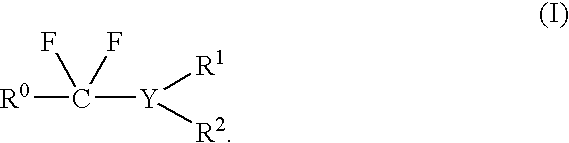

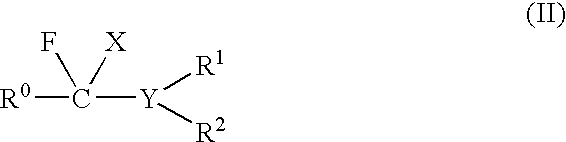

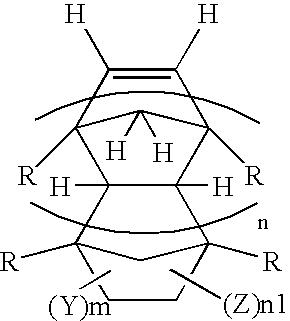

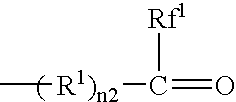

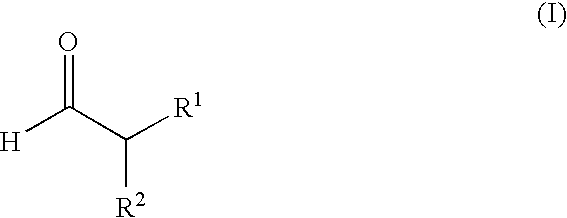

Method of fluorination

InactiveUS20060014972A1Short timeProcess safetyEsterified saccharide compoundsSugar derivativesLipid formationPolyol

A method of fluorination comprising reacting monosaccharides, oligosaccharides, polysaccharides, composite saccharides formed by bonding of these saccharides with proteins and lipids and saccharides having polyalcohols, aldehydes, ketones and acids of the polyalcohols, and derivatives and condensates of these compounds with a fluorinating agent represented by general formula (I) thermally or under irradiation with microwave or an electromagnetic wave having a wavelength around the microwave region. In accordance with the method, the fluorination at a selected position can be conducted safely at a temperature in the range of 150 to 200° C. where the reaction is difficult in accordance with conventional methods. The above method comprising the irradiation with microwave or an electromagnetic wave having a wavelength around the microwave region can be applied to substrates other than saccharides. When a complex compound comprising HF and a base is reacted under irradiation with microwave, fluorination at a specific position which is difficult in accordance with conventional methods proceeds highly selectively, efficiently in a short time and safely.

Owner:MITSUBISHI GAS CHEM CO INC

Method of fluorination

A method of fluorination comprising reacting monosaccharides, oligosaccharides, polysaccharides, composite saccharides formed by bonding of these saccharides with proteins and lipids and saccharides having polyalcohols, aldehydes, ketones and acids of the polyalcohols, and derivatives and condensates of these compounds with a fluorinating agent represented by general formula (I) thermally or under irradiation with microwave or an electromagnetic wave having a wavelength around the microwave region. In accordance with the method, the fluorination at a selected position can be conducted safely at a temperature in the range of 150 to 200° C. where the reaction is difficult in accordance with conventional methods. The above method comprising the irradiation with microwave or an electromagnetic wave having a wavelength around the microwave region can be applied to substrates other than saccharides

Owner:MITSUBISHI GAS CHEM CO INC

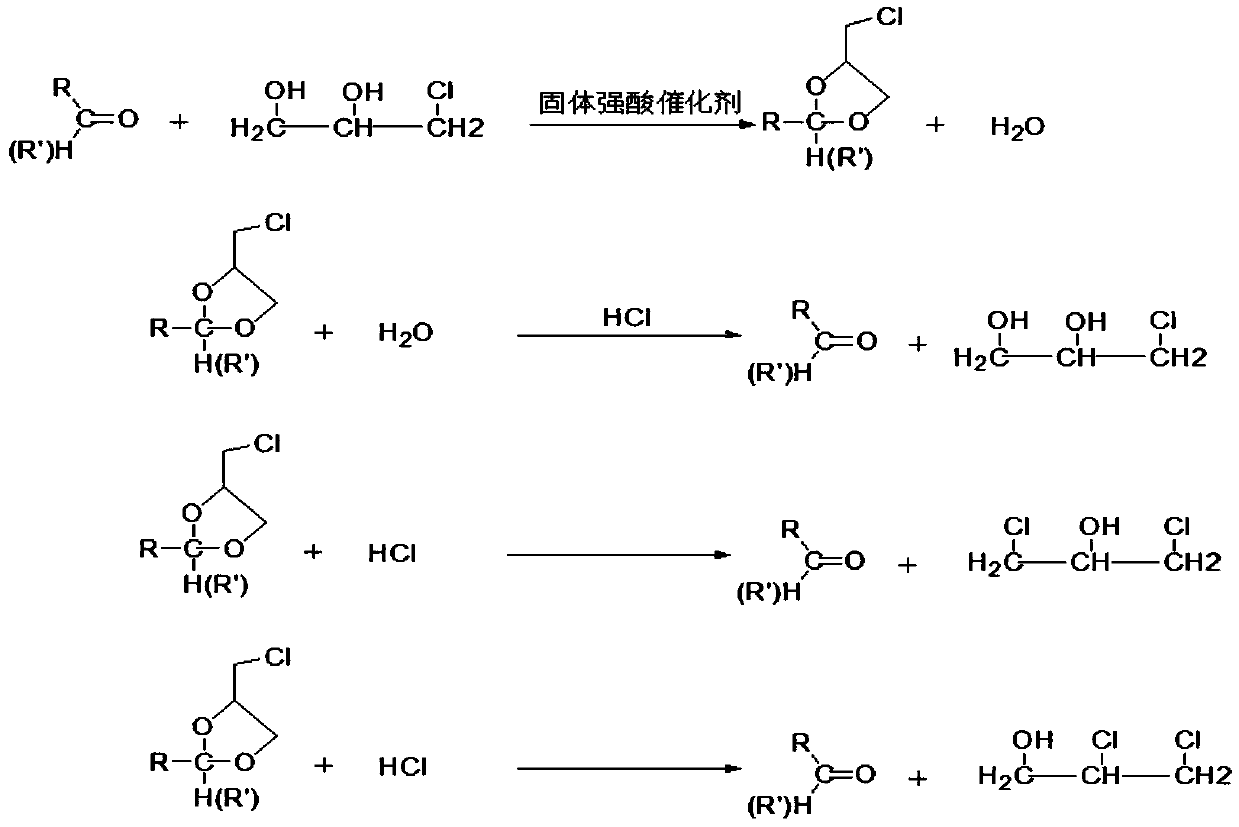

Preparation method of butoconazole nitrate intermediate suitable for industrial production

ActiveCN103880596AHigh yieldReduce bumpsPreparation by OH and halogen introductionMagnesium organic compoundsGrignard reactionEthyl Chloride

The invention provides a method for industrial production of a butoconazole nitrate intermediate, that is 1-chloro-4-p-chlorophenyl-2-butanol (a compound in formula II). The method of the invention comprises: 1. a Grignard reaction, that is, adopting p-chlorobenzyl chloride as a raw material, and performing a Grignard reaction with magnesium powder in a mixed solvent of methyl tertiary butyl ether and tetrahydrofuran; 2. a condensation reaction, that is, continuing reaction by adding epichlorohydrin to obtain the compound II which is an important intermediate for preparing butoconazole nitrate. According to the method, the raw materials are cheap and easily available, the reaction solvent is safer, and the method is suitable for industrial production.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

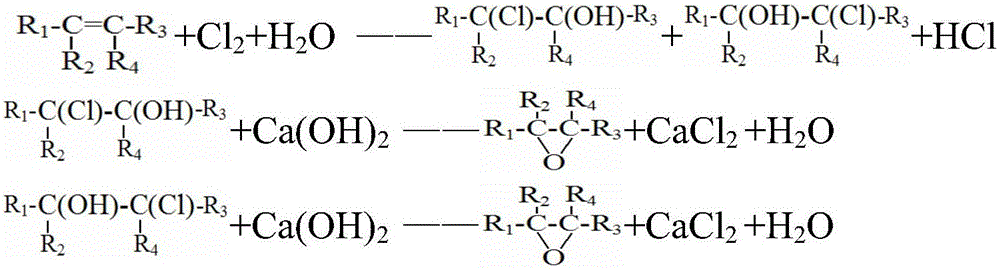

Method for preparing halogenohydrin and epoxide

ActiveCN106518624AEasily damagedSolve intractableWater contaminantsDispersed particle separationHalogenWastewater

Owner:JIANGXI SUKEER NEW MATERIAL

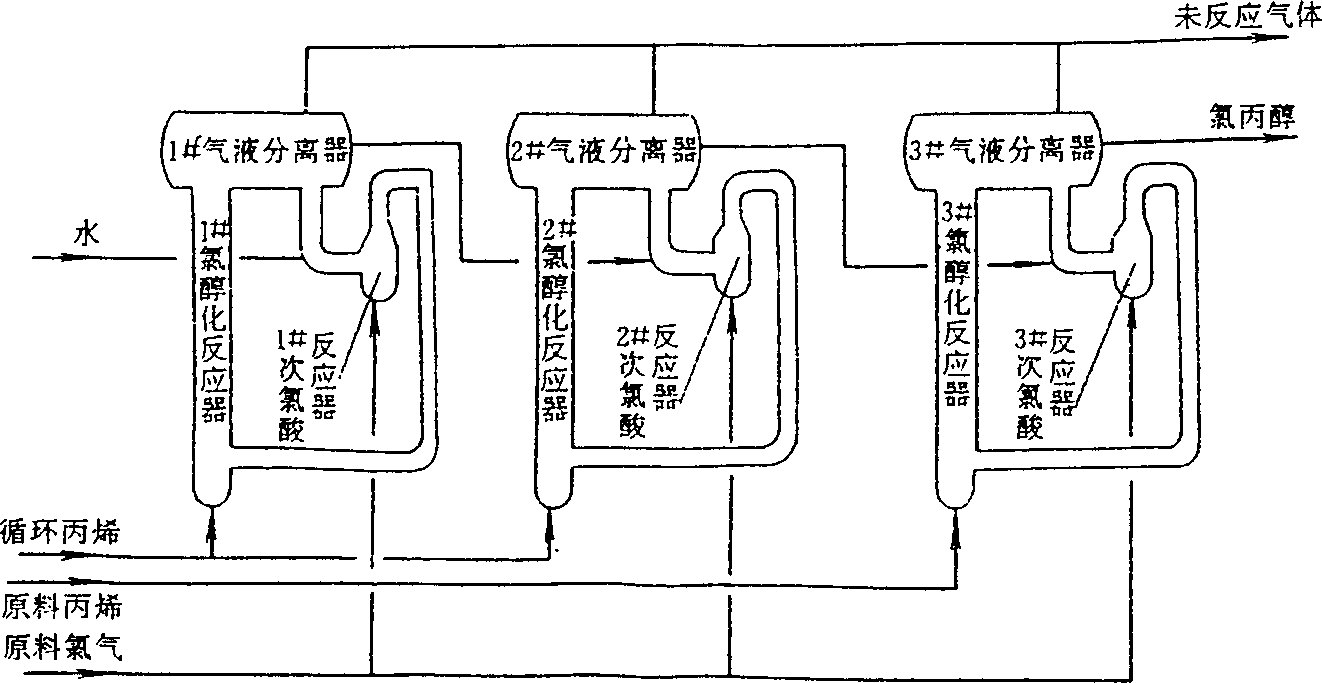

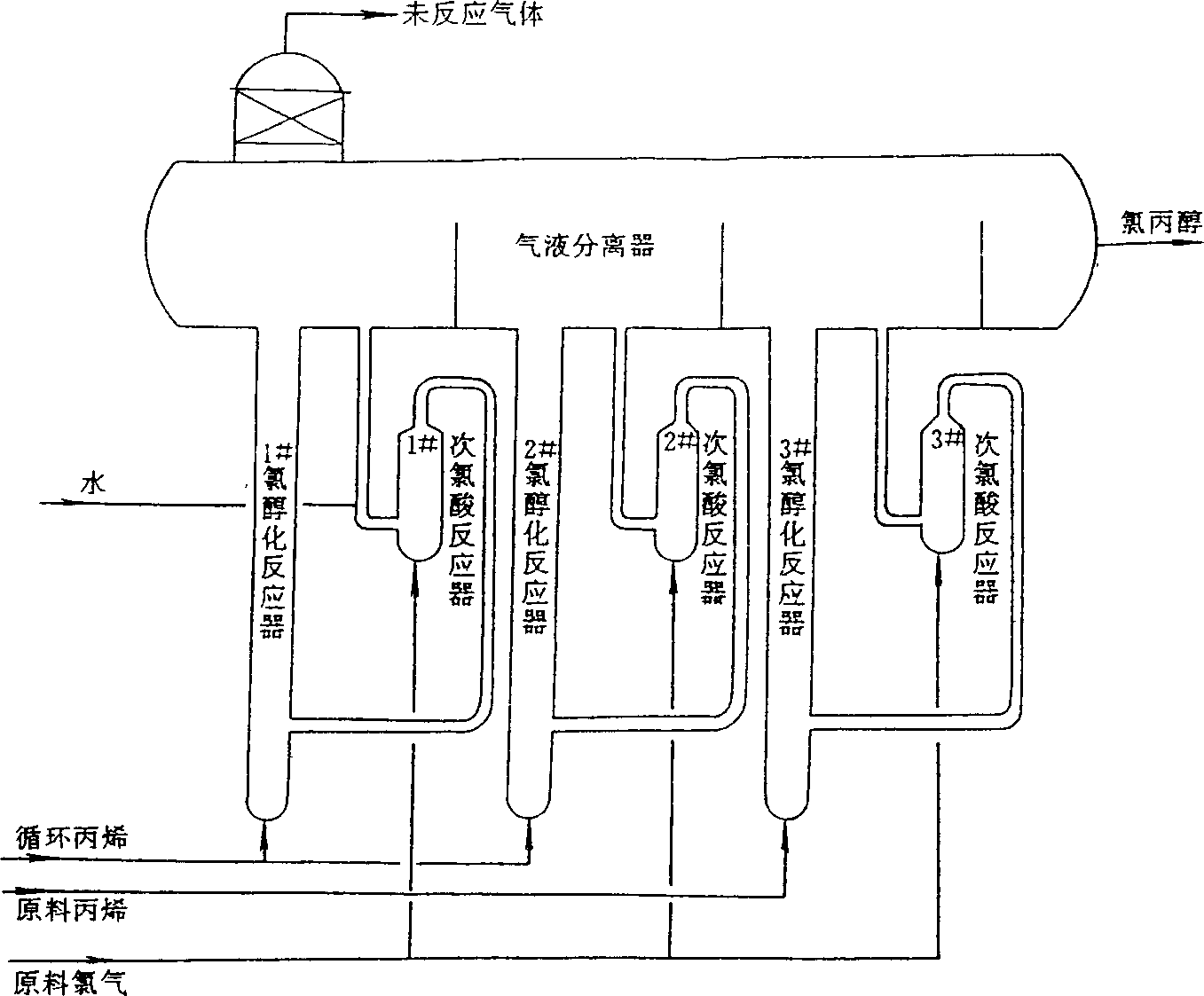

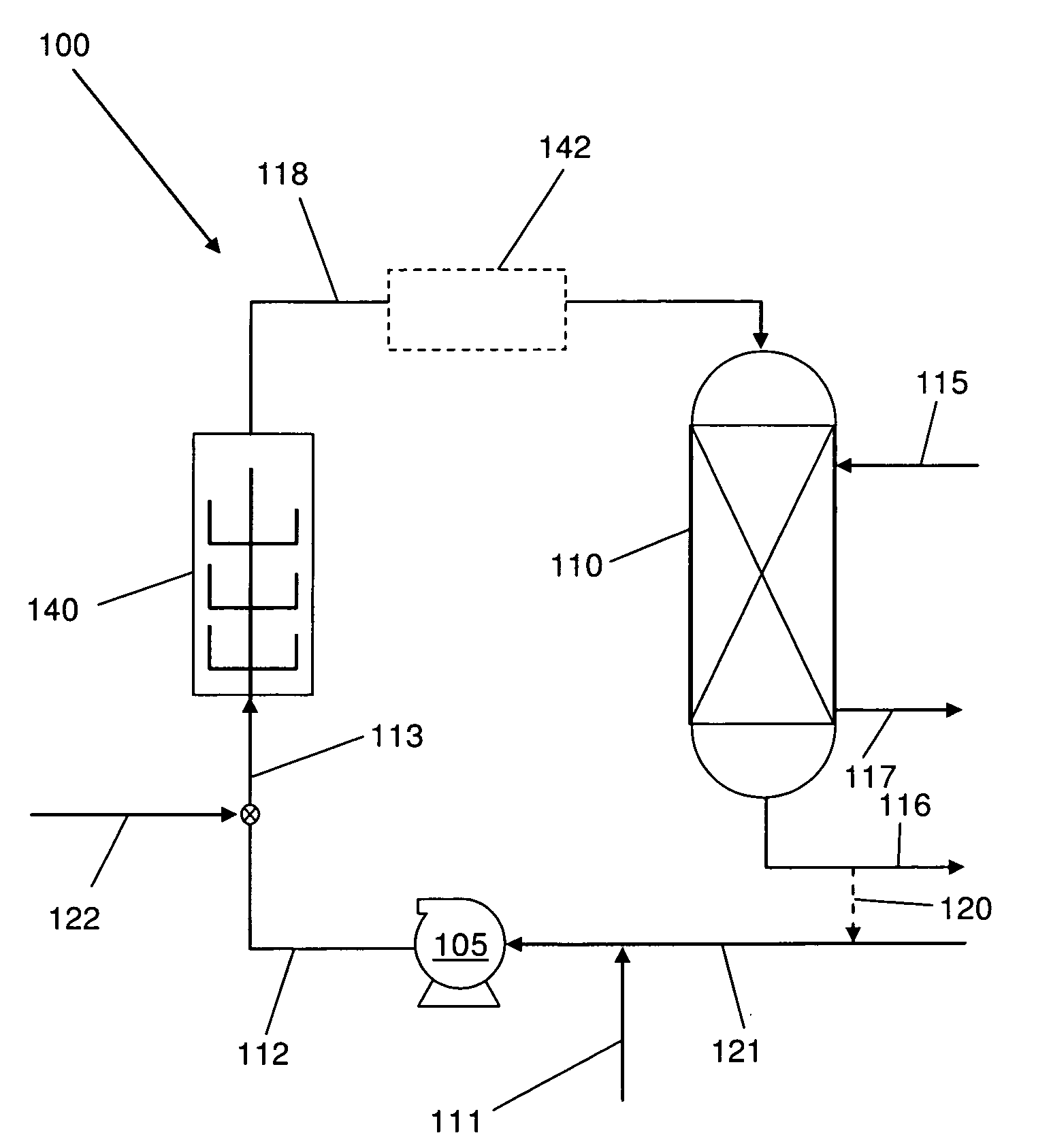

Chlorohydrin process

InactiveUS6043400AIncrease productionIncrease concentrationOrganic compound preparationPreparation by OH and halogen introductionButeneOrganic compound

This invention is a process for preparing chlorohydrins by reacting a chlorinating species, such as hypochlorous acid, with at least one unsaturated organic compound, such as propylene or butylene, at a pH of greater than 6.0. The chlorinating species is formed in a first step by reacting a source of chlorine, such as Cl2 gas, with an aqueous pH adjusting source, such as aqueous NaOH.

Owner:THE DOW CHEM CO

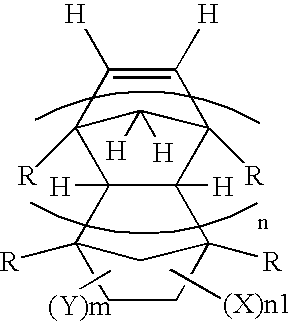

Process for preparing fluorine-containing norbornene derivative

There are provided a novel norbornene derivative which is a material for a chemically amplifying type photoresist for F2 laser, possesses excellent transparency and improved dry etching resistivity and has a fluorine-containing ketone unit or fluorine-containing tertiary alcohol unit directly bonded to the norbornene backbone; a fluorine-containing polymer obtained by using the norbornene derivative as a copolymerizable monomer; and a chemically amplifying type photoresist composition comprising the fluorine-containing polymer, a photoacid generator and a solvent.

Owner:DAIKIN IND LTD

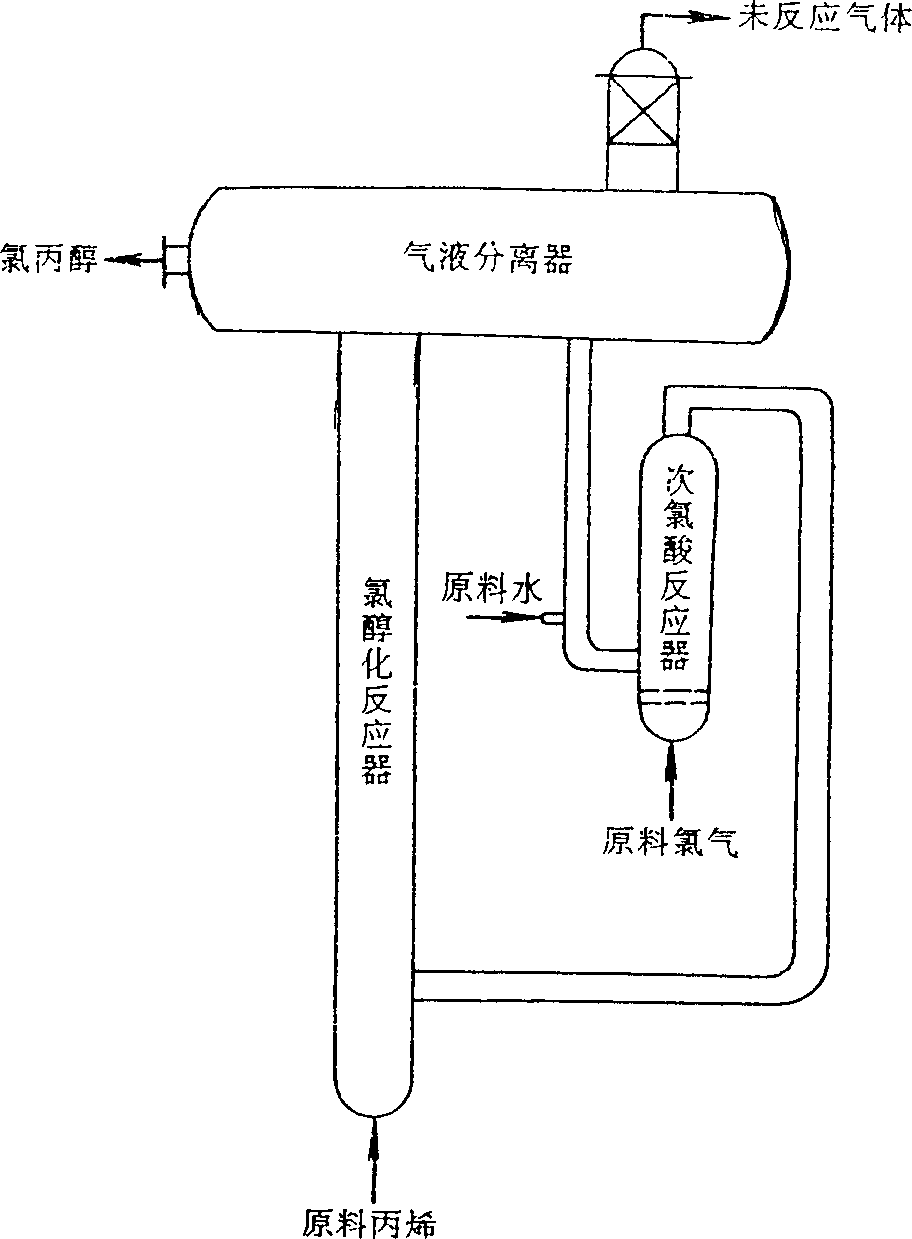

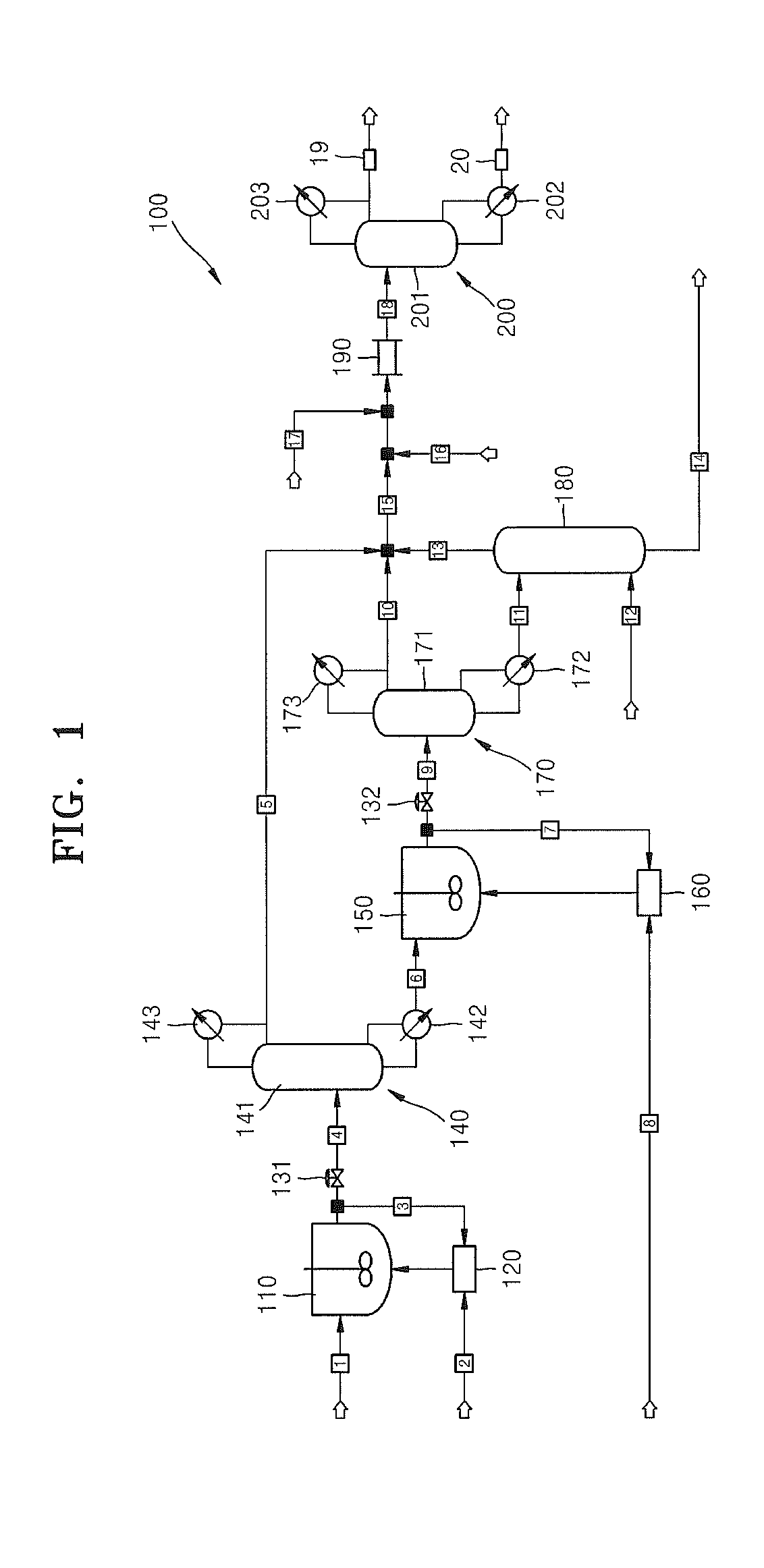

Apparatus and method for monotubular multi-spiral static mixed tube style chlorohydrination of propene for production of epoxypropane

InactiveCN1680346ALess investmentIncrease production capacityPreparation by OH and halogen introductionHigh concentrationGas phase

A monotubular multiple rotary static mixing tubing propenyl chlorine alcoholizing reacting producer of propylene epoxide production and its production are disclosed. The producer consists of an inlet pipeline of material water and chlorine, a tubing chlorine instant hypochloric acid reactor, an outlet pipeline of hypochloric acid, a confluent pipeline of hypochloric acid and propylene, a tubing chlorohydrination reactor, an outlet pipeline of chloralcohol, an outlet pipeline of propylene mixed liquid, an instant mixing tube of propylene, and an inlet pipeline of propylene and circulating chloralcohol. Its advantages include low cost, more operating elasticity, no gas-phase contact, higher concentration and less by-product.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

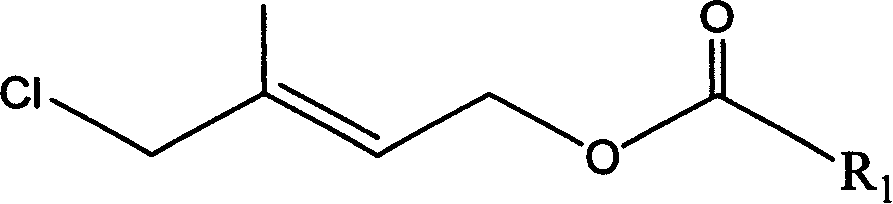

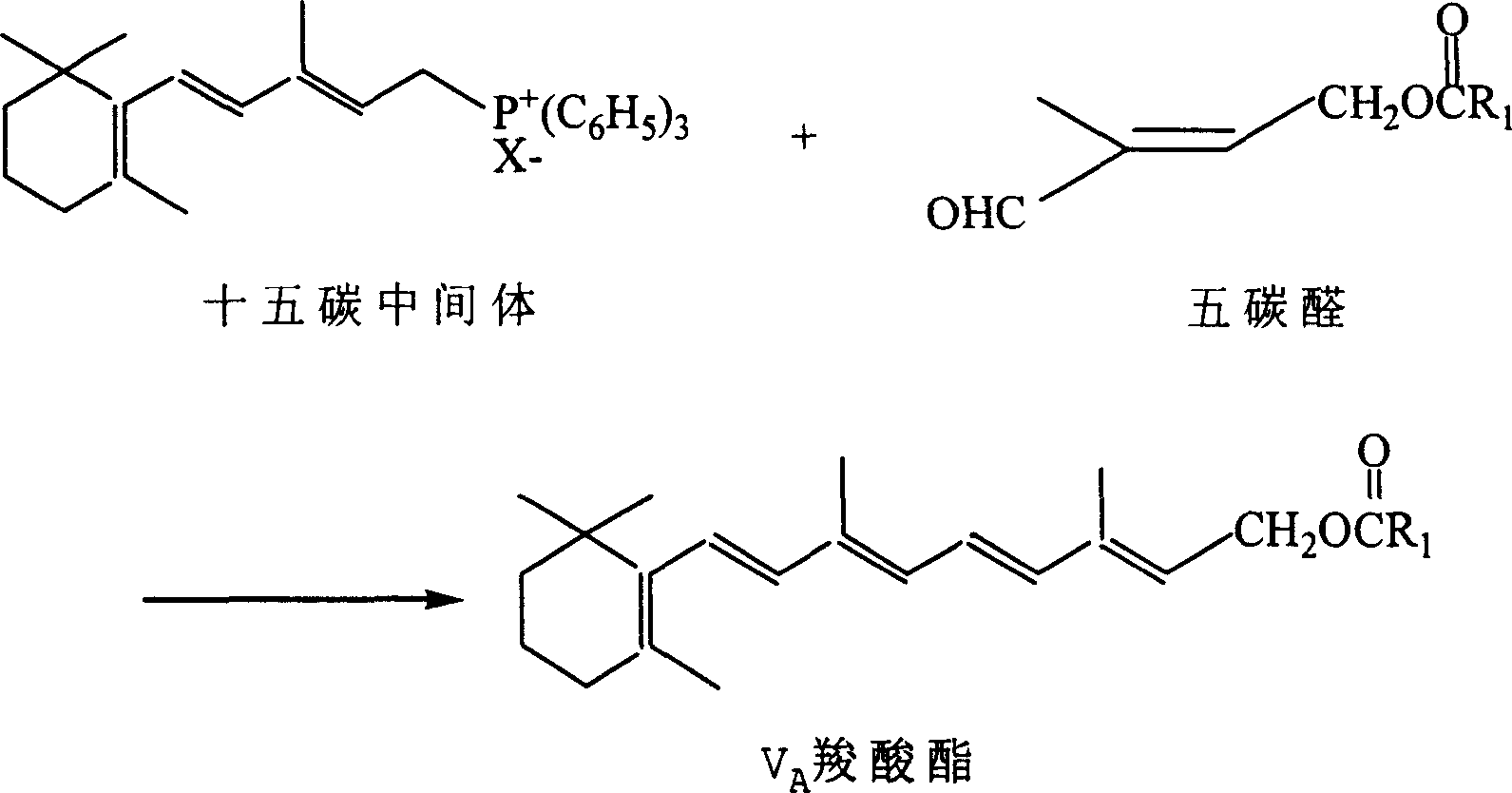

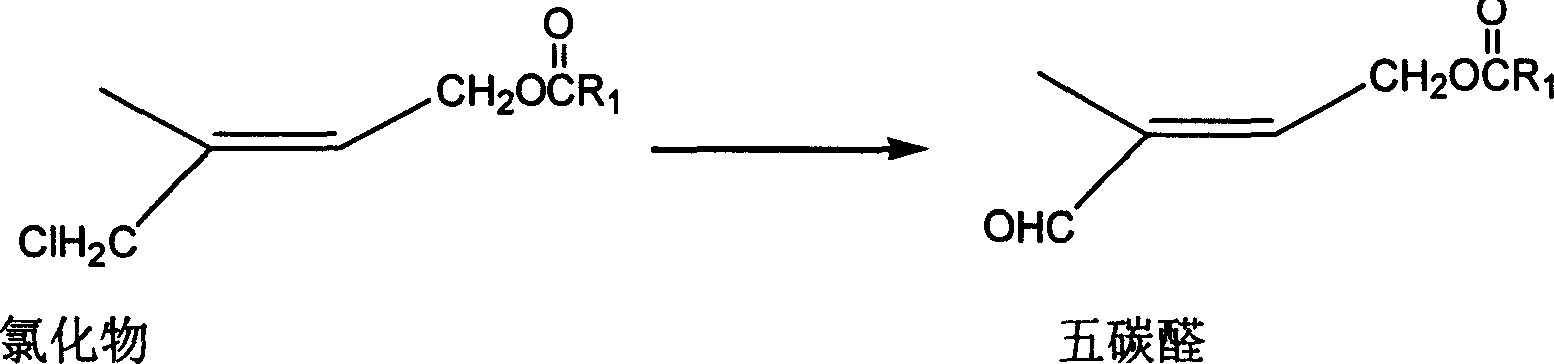

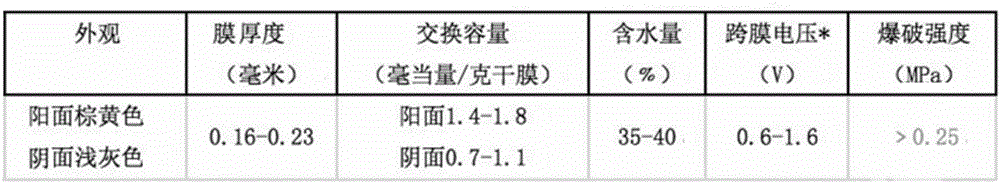

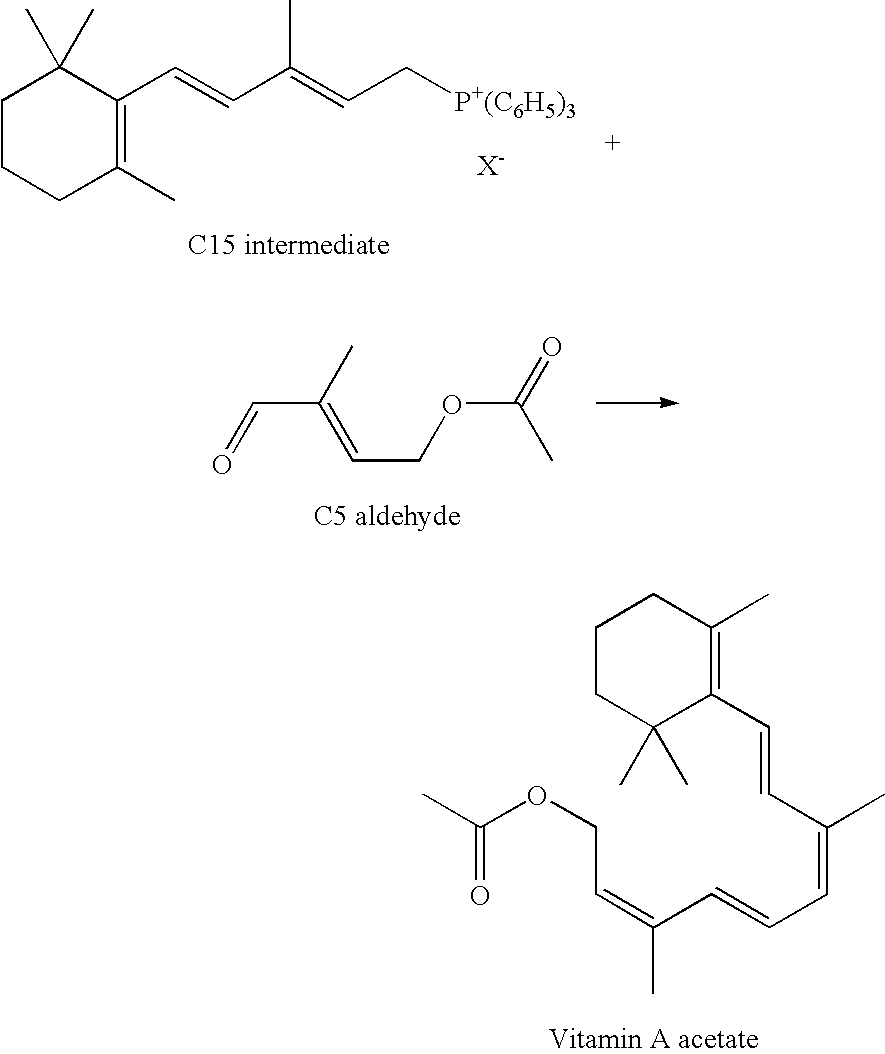

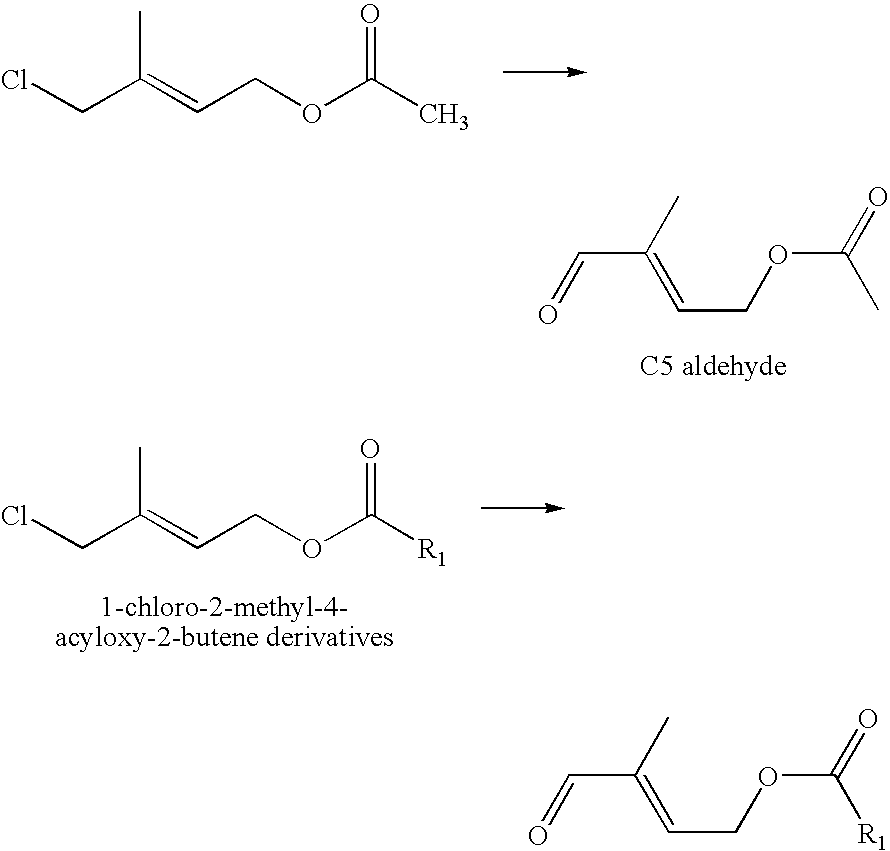

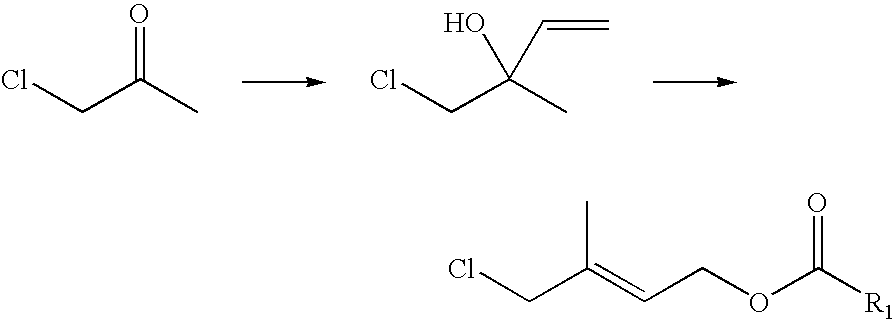

Method for preparing 1-chloro-2-methyl-4-alkylacyloxy-2-butene

ActiveCN1844077AHigh content of available chlorineLess hetero ionsPreparation from carboxylic acid halidesOrganic compound preparationPolymer science2-Butene

The method provides a Method for preparation of vitaminA derivant's important intermediate- 1-chloro-2-methyl-4-hydrocarbon acyloxy-2-butylene, this invention adopting isoprene as material to carry through chlorohydrination reaction; the getted product has high content, high produce rate, convenierce operate, little waste and easy to commercial manufacture.

Owner:SHAOXING UNIVERSITY +1

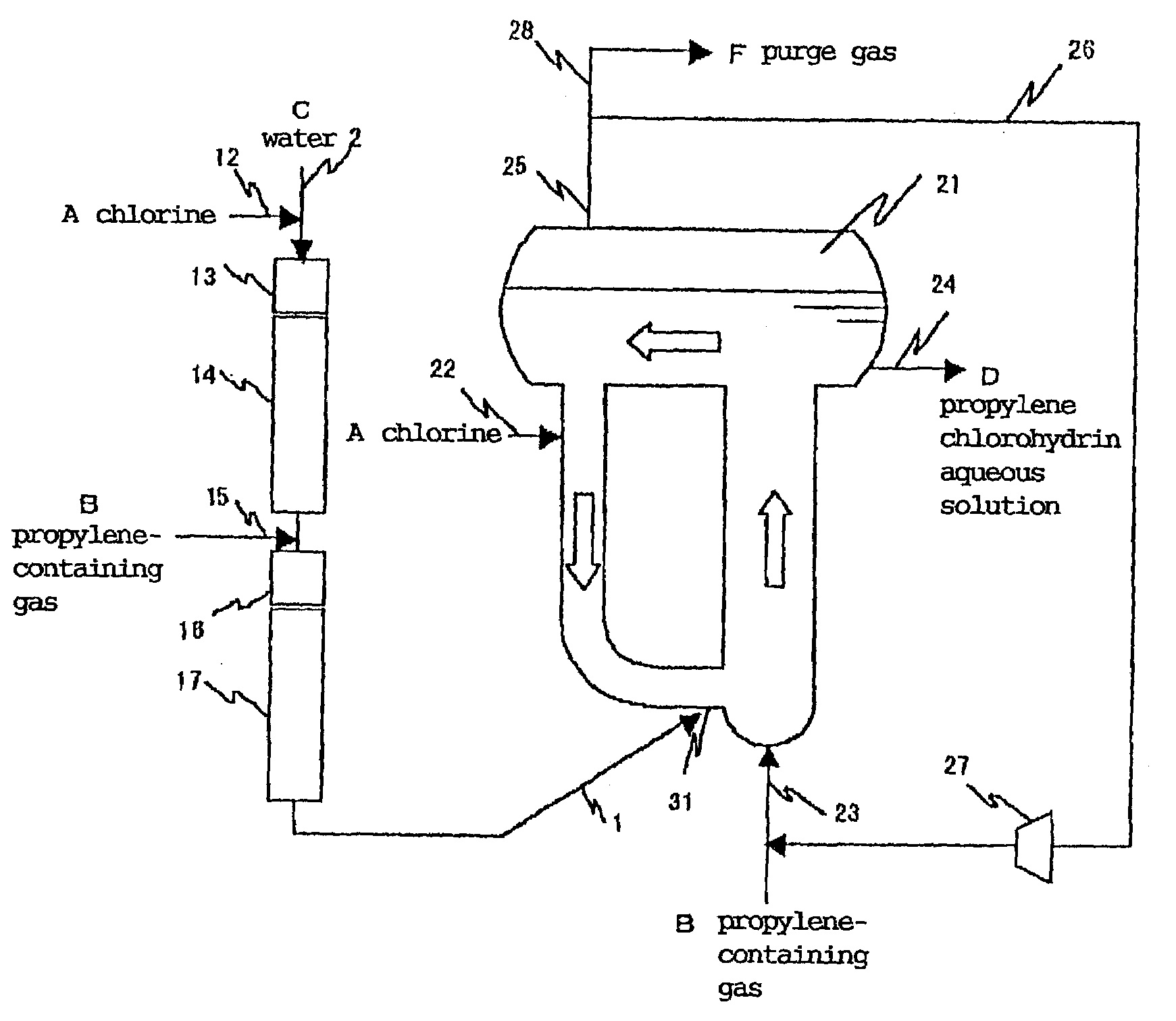

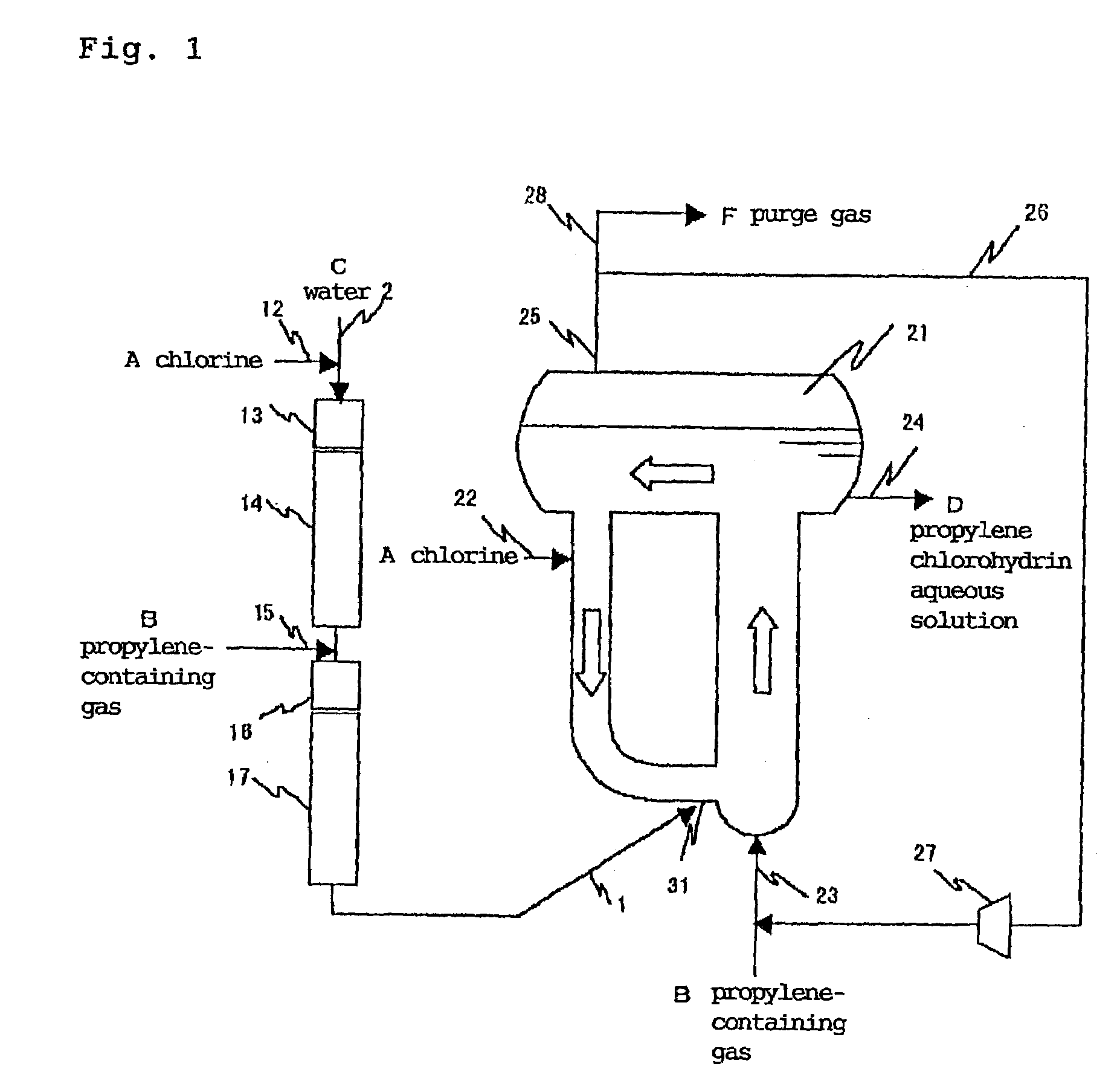

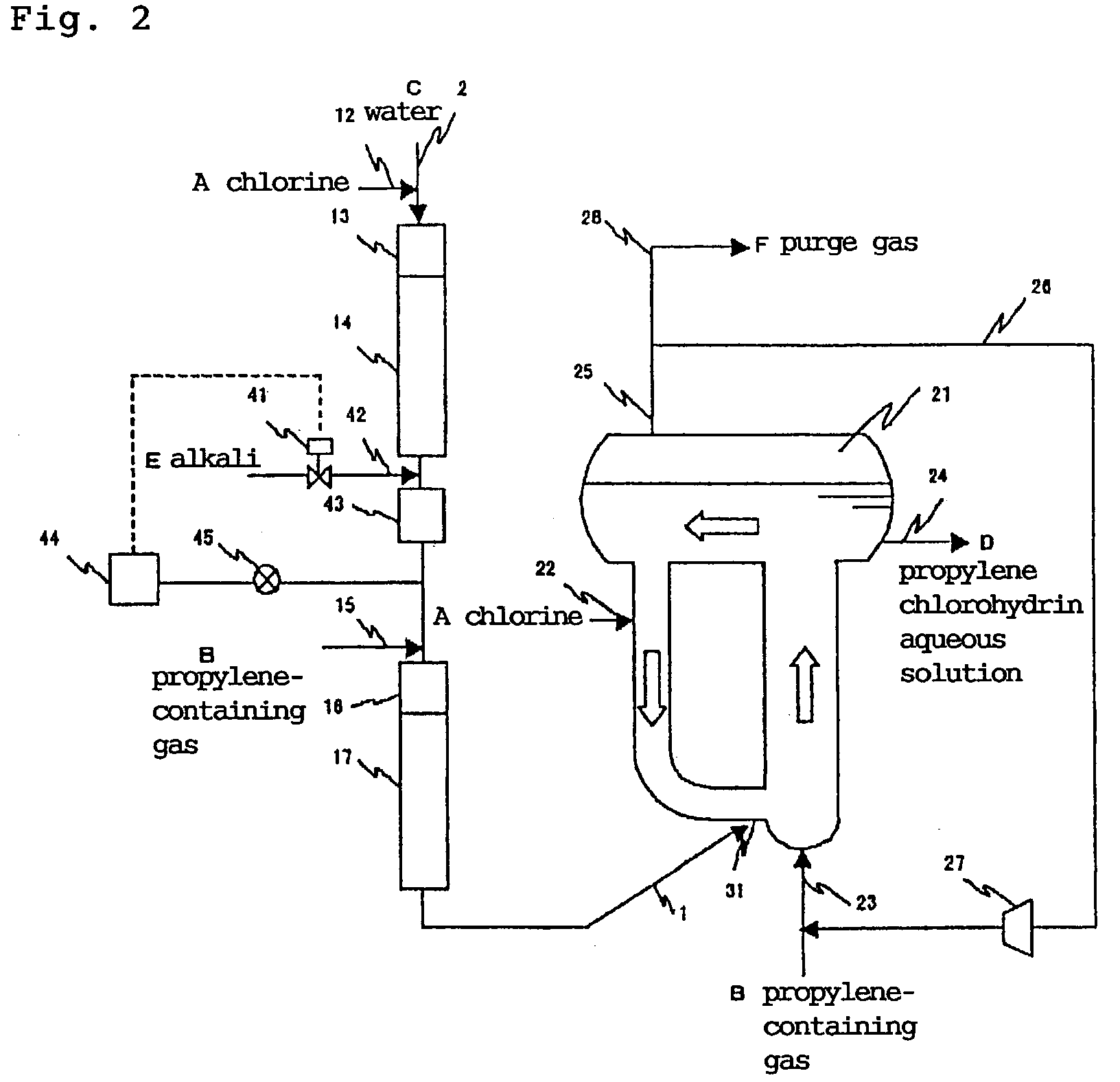

Process for producing propylene chlorohydrin

InactiveUS7157609B2High selectivityReduce the amount of processingOrganic compound preparationPreparation by OH and halogen introductionPropylene chlorohydrinAqueous solution

Owner:TOKUYAMA CORP

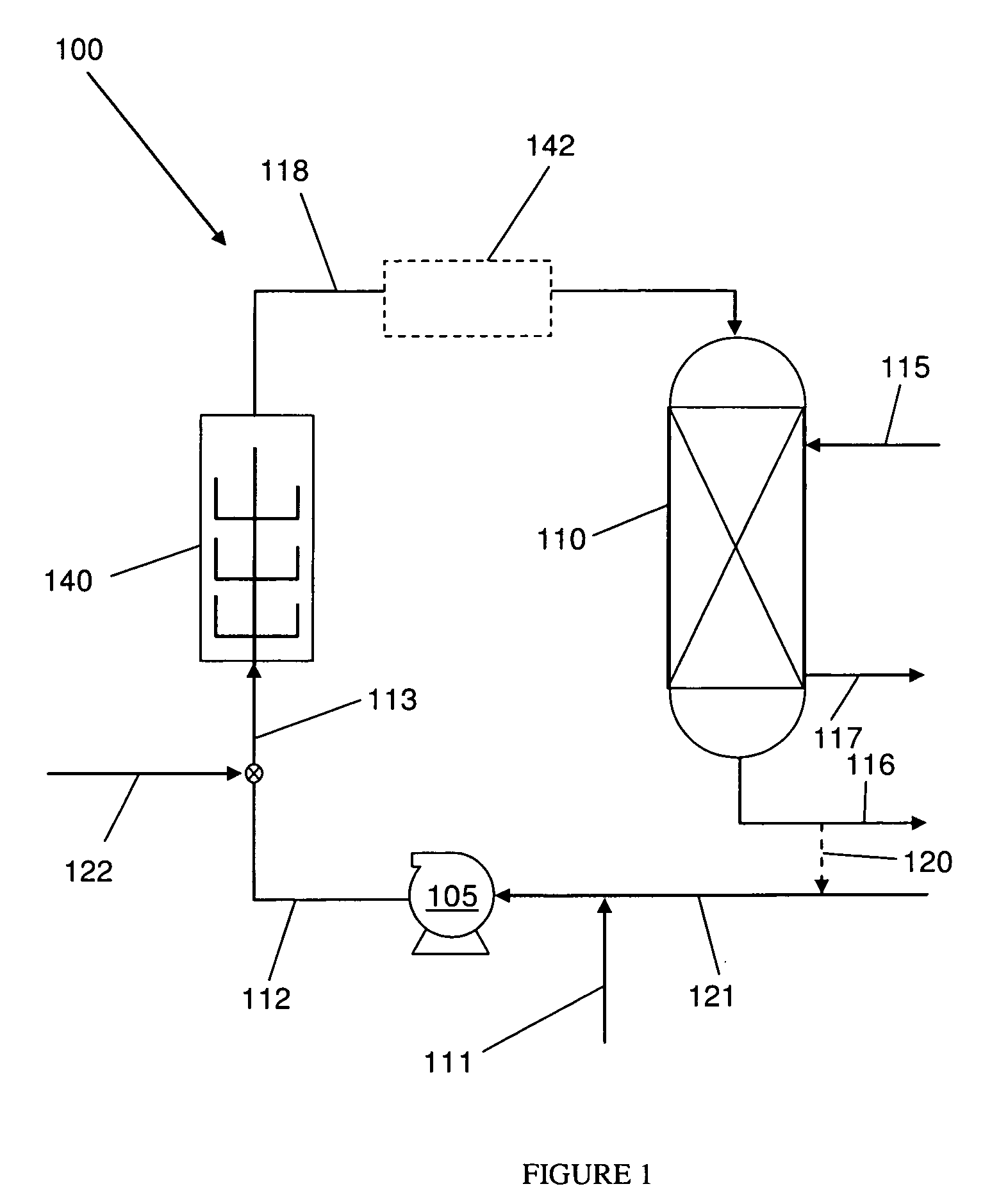

Method for making chlorohydrins

InactiveUS20090005609A1Good dispersionImprove solubilityRotary stirring mixersTransportation and packagingSolubilityReaction temperature

Methods and systems for the preparation of chlorohydrins are described herein. The methods and systems incorporate the novel use of a high shear device to promote dispersion and solubility of olefins into the chlorinating phase. The high shear device may allow for lower reaction temperatures and pressures and may also reduce chlorination time.

Owner:HRD CORP

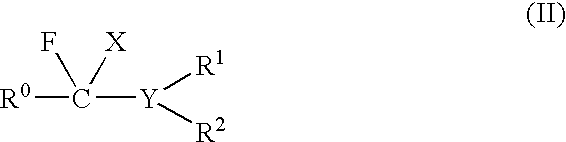

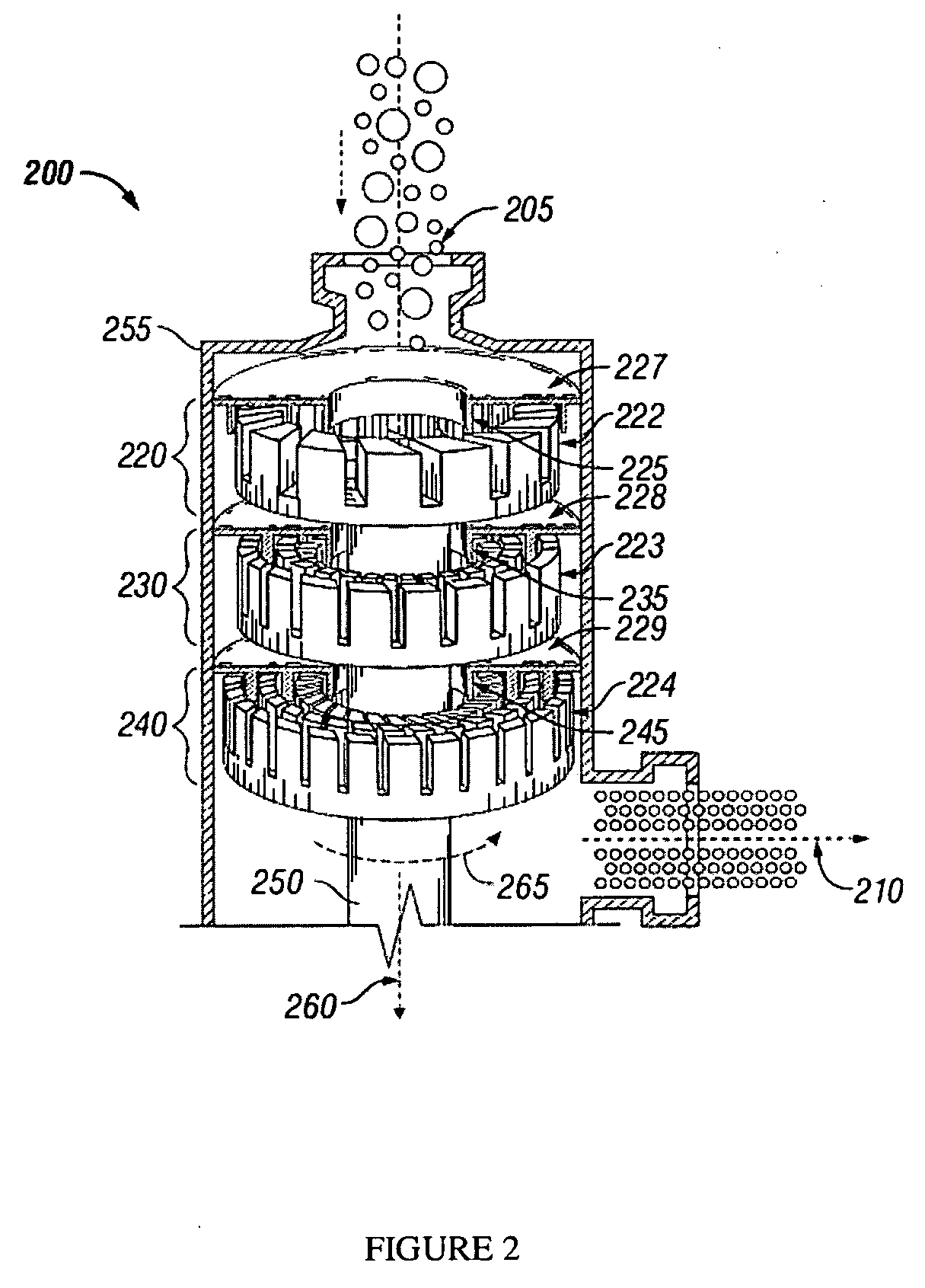

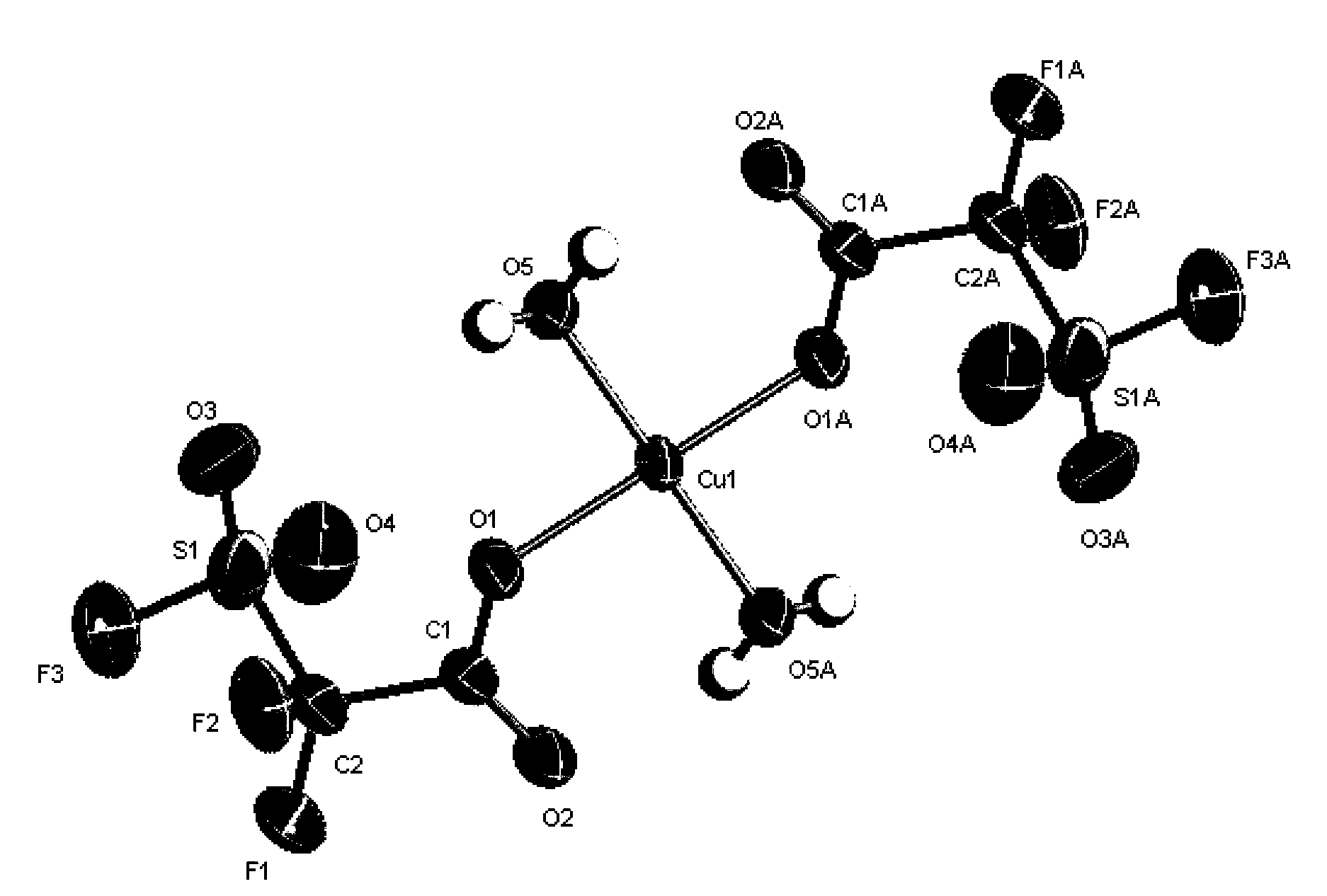

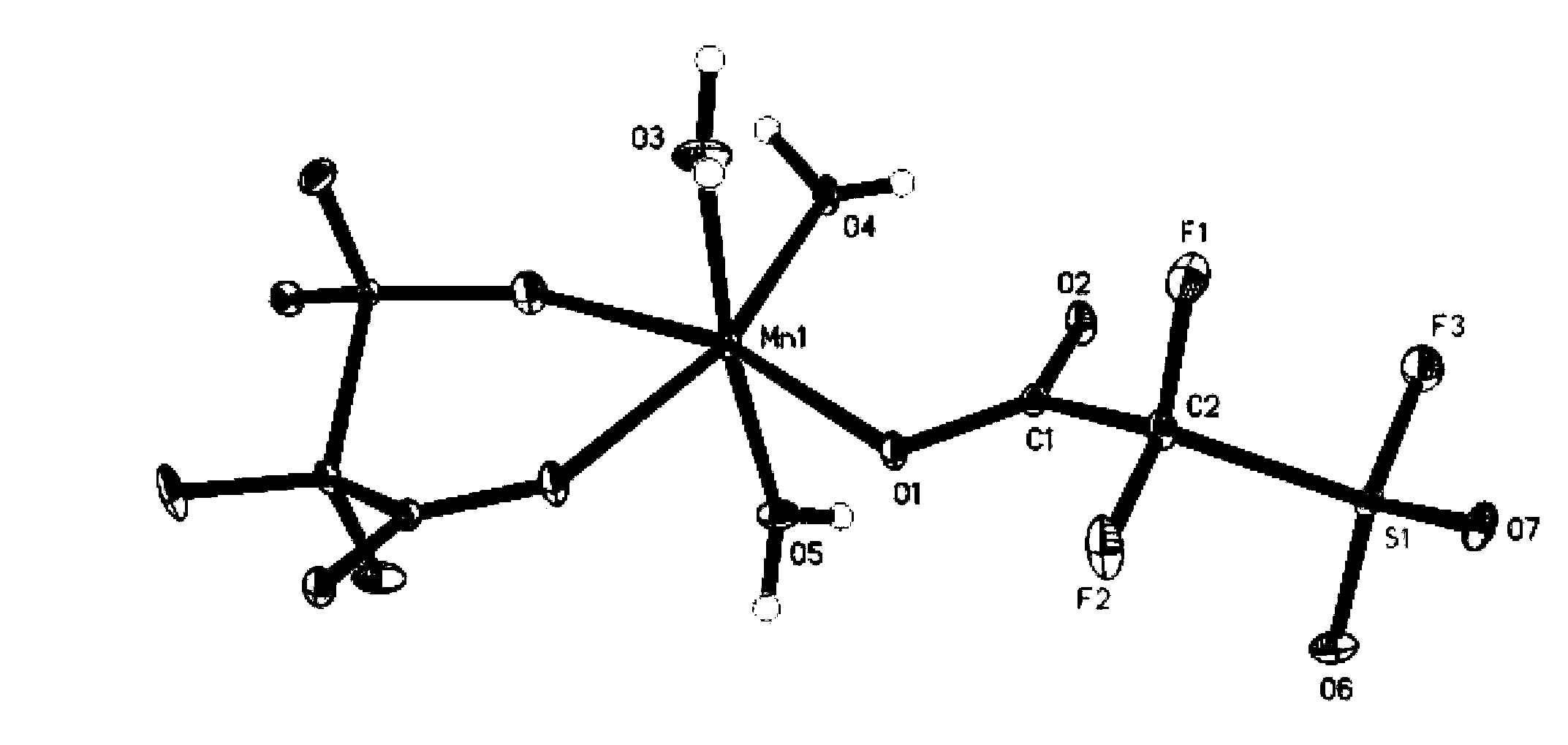

New trifluoro methylation reagent and preparation and application thereof

ActiveCN104045585APreparation by OH and halogen introductionOrganic halogenationTrifluoromethylationReagent

The invention relates to a new trifluoro methylation reagent and preparation and application thereof, and in particular relates to a compound with a structure shown as a formula I, a preparing method thereof and application thereof as a trifluoro methylation reagent. In the formula, the definition of each group is as defined in the specification. The starting materials of the new trifluoro methylation reagent are cheap and easy to obtain, the reaction condition is mild, the post treatment is simple, the product can be used as a variety of potential trifluoro methylation reagents, the yield is high, the equipment requirement is low, and the new trifluoro methylation reagent has wide prospects of industrial application. (FSO2CF2COO) zM I.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

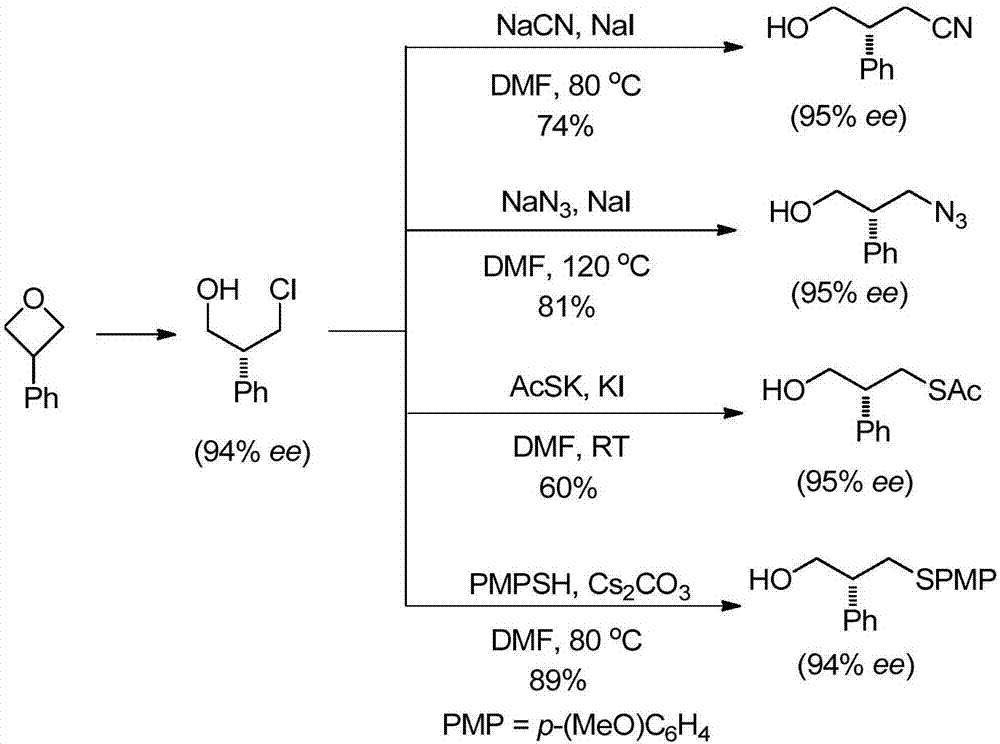

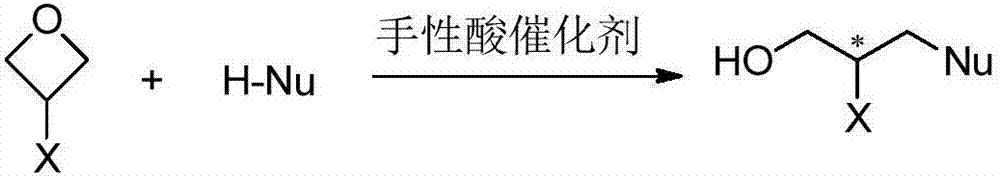

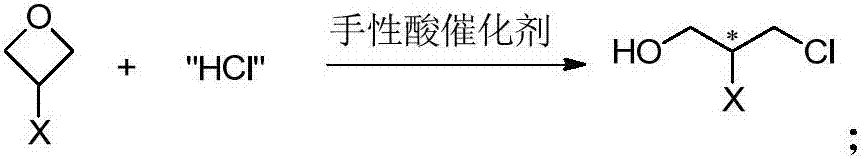

Method for asymmetrically opening ring of 3-substituted oxetane and application

ActiveCN107141188AAchieve preparationGroup 4/14 element organic compoundsOrganic compound preparationHalogenSynthesis methods

The invention discloses a method for catalytically asymmetrically opening a ring of 3-substituted oxetane by using halogen. The method comprises the following steps: with 3-substituted oxetane and a halogen nucleophile as reaction substrates, under the action of a chiral acid catalyst, performing an asymmetric ring opening reaction to highly selectively synthesize chiral 2-substituted-3-halogenated propanol. The invention further provides preparation of a variety of chiral 2-substituted-3-Nu-propanol products through a reaction performed on the chiral 2-substituted-3-halogenated propanol product obtained in the asymmetric ring opening reaction and a variety of nucleophiles Nu. After adoption of the chiral ring opening method, the reaction for catalytically asymmetrically opening the ring of 3-substituted oxetane with the halogen nucleophile is achieved for the first time; through functional group transformation of halogenated groups in the products, the asymmetric ring opening reaction performed on the variety of nucleophiles and 3-substituted oxetane can be directly achieved; and a high-efficiency synthesis method is provided for preparing chiral 2-substituted-3-Nu-propanol compounds.

Owner:HKUST SHENZHEN RES INST

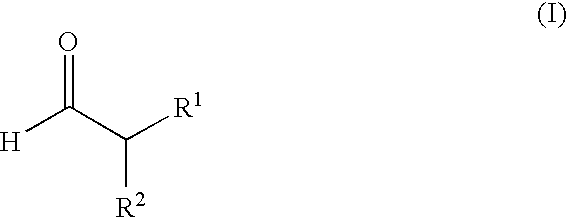

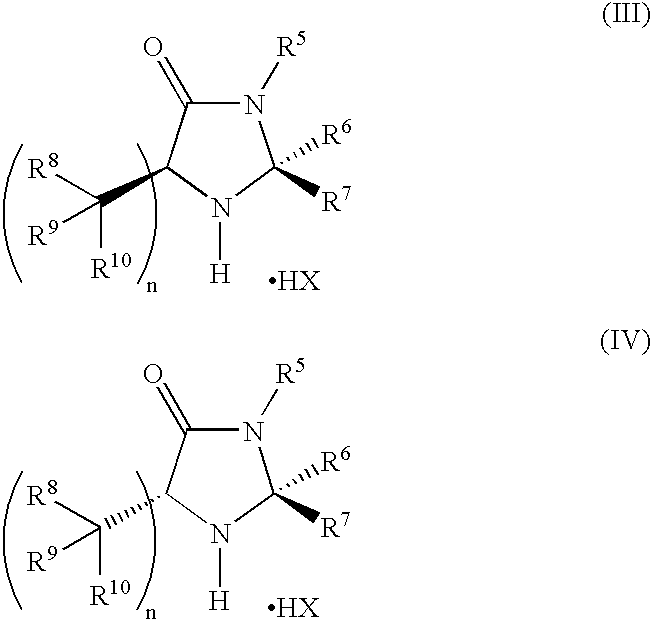

Enantioselective alpha-fluorination of aldehydes using chiral organic catalysts

InactiveUS20060189830A1Easy to operateEasy to synthesizeOrganic compound preparationCarboxylic acid esters preparationElectrophilic fluorinationOrganocatalysis

Nonmetallic, chiral organic catalysts are used to catalyze enantioselective fluorination of enolizable aldehydes. Reaction systems composed of an enolizable aldehyde, an electrophilic fluorination reagent, and a nonmetallic chiral catalyst in the form of an imidazolidinone salt are also provided.

Owner:CALIFORNIA INST OF TECH

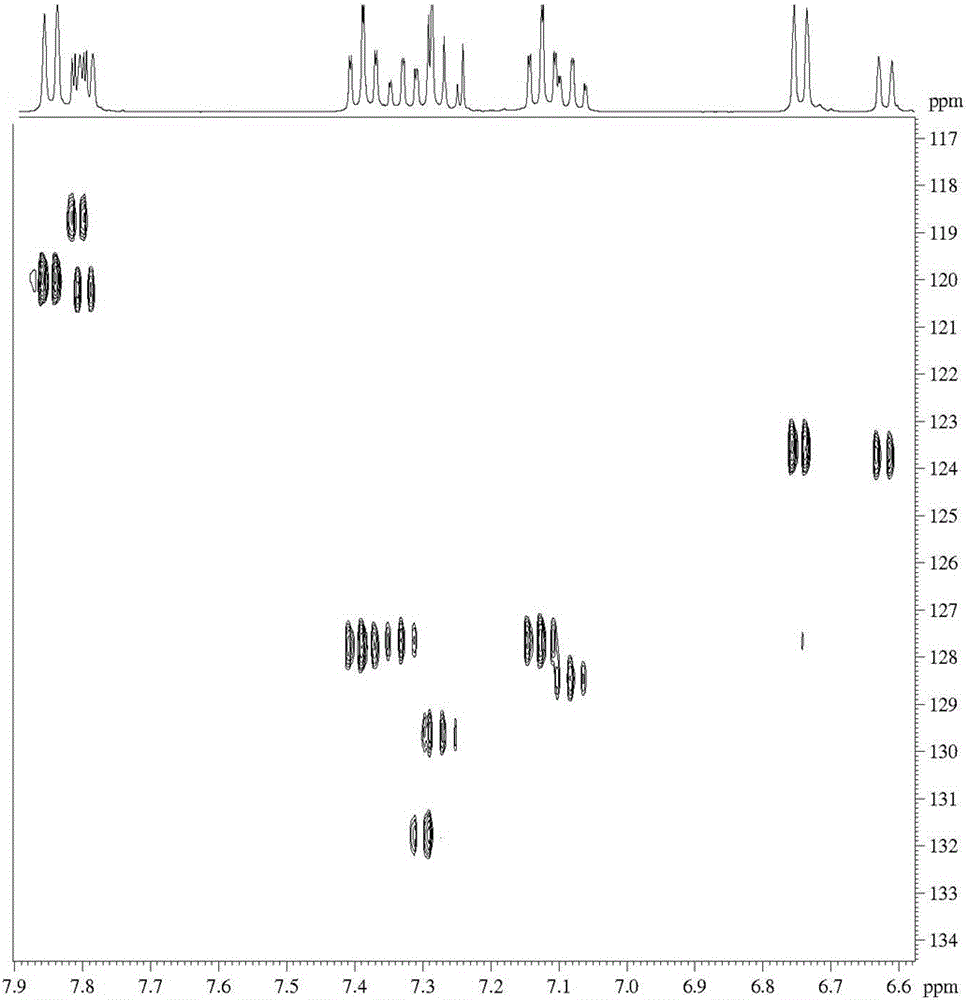

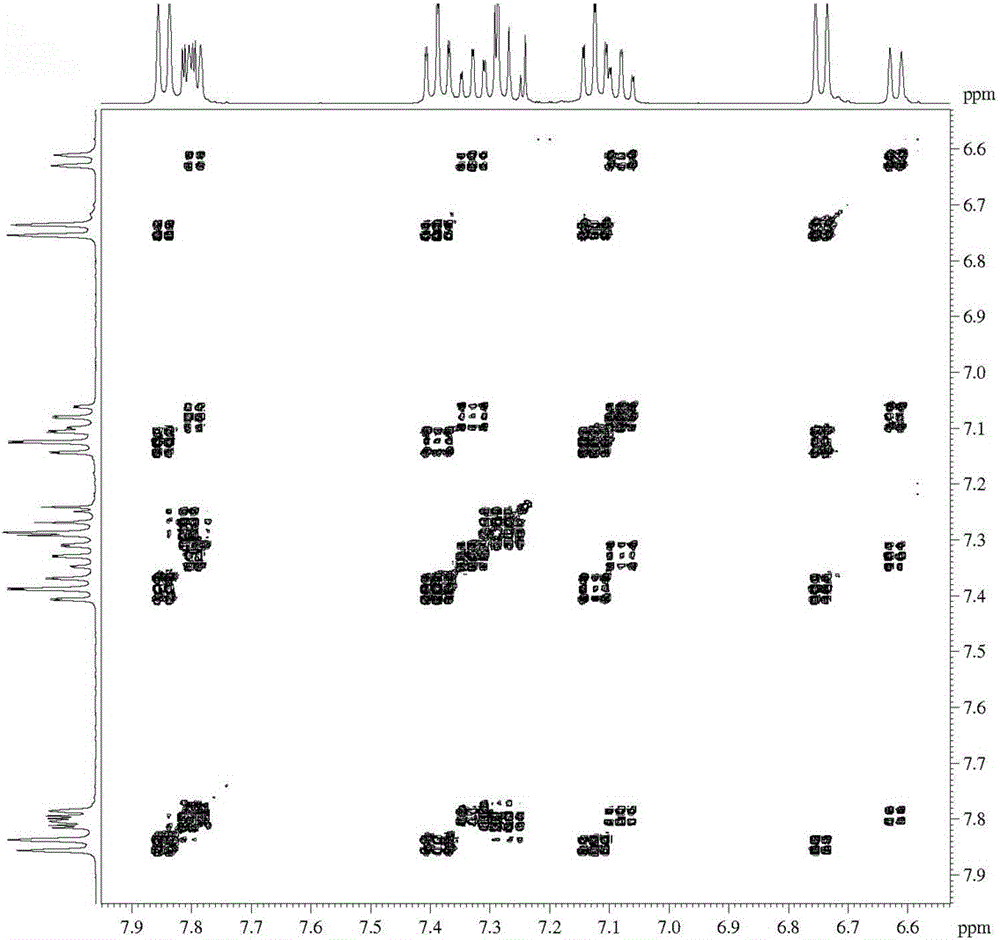

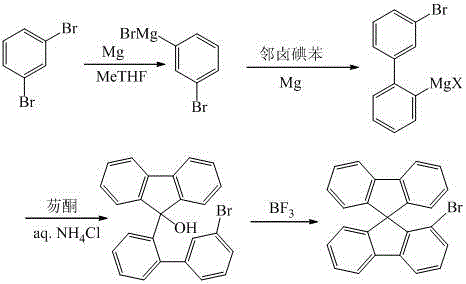

Synthesis method of 1-bromo-9,9'-spirodifluorene

ActiveCN105732298AImprove solubilityReduce synthesisPreparation by OH and halogen introductionMagnesium organic compoundsChemical synthesisZinc bromide

The invention discloses a synthesis method of 1-bromo-9,9'-spirodifluorene, belonging to the field of organic chemical synthesis. The method comprises the following steps: in an inert gas protective atmosphere, preparing a Grignard reagent in a methyl tetrahydrofuran solvent by using 1,3-dibromobenzene as an initial raw material, continuing reacting with ortho-halogen iodobenzene and magnesium powder under the catalytic action of zinc bromide, carrying out reaction with fluorenone, carrying out hydrolysis, and carrying out intramolecular closed loop synthesis under the catalytic action of boron trifluoride to obtain the 1-bromo-9,9'-spirodifluorene. The synthesis method has the advantages of simple process and cheap and accessible raw material, obviously lowers the production cost of the product, and widens applicability of fluorene derivatives as an intermediate in organic photoelectric material design and synthesis.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

Propylene recovery method in epoxypropane refining process

InactiveCN105399606AReduce manufacturing costReduce unit consumptionPreparation by OH and halogen introductionRecovery methodChemistry

The invention relates to a propylene recovery method in epoxypropane refining process. In the propylene recovery method, non-condensable gas obtained from the tower top of a light-fraction removing tower is washed with water, and is mixed with gas generated in chlorohydrination, and an obtained mixture is subjected to pressure recovery. The propylene recovery method is simple, and is convenient in operation; the tower top gas of the light-fraction removing tower is introduced into chlorohydrination treatment for recovery, propylene raw material unit consumption of epoxypropane equipment is reduced, and production cost of epoxypropane is reduced.

Owner:SHANDONG BLUSR DONGDA CHEM

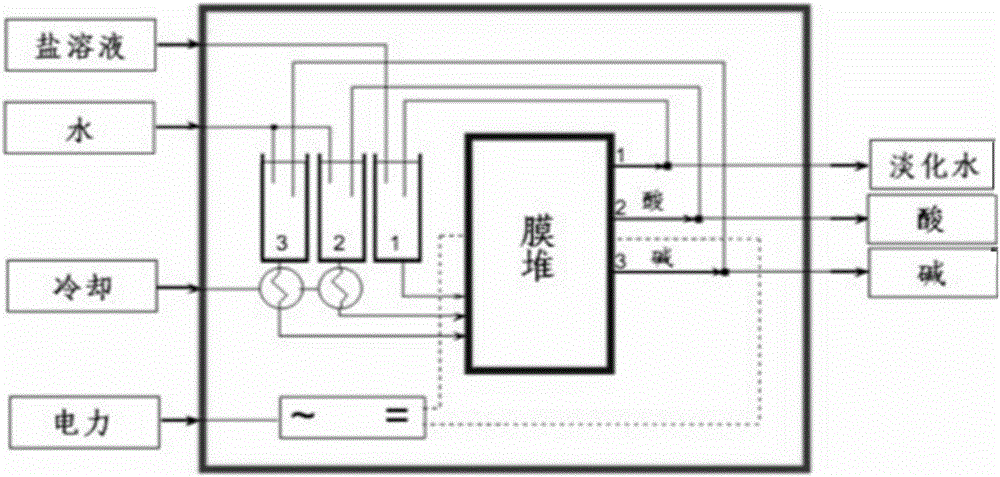

Method for preparing halopropyl alcohol and propylene oxide

ActiveCN106560466ASolve intractableDifficult problems to overcomeDispersed particle separationPreparation by OH and halogen introductionHydrogen halideAlcohol

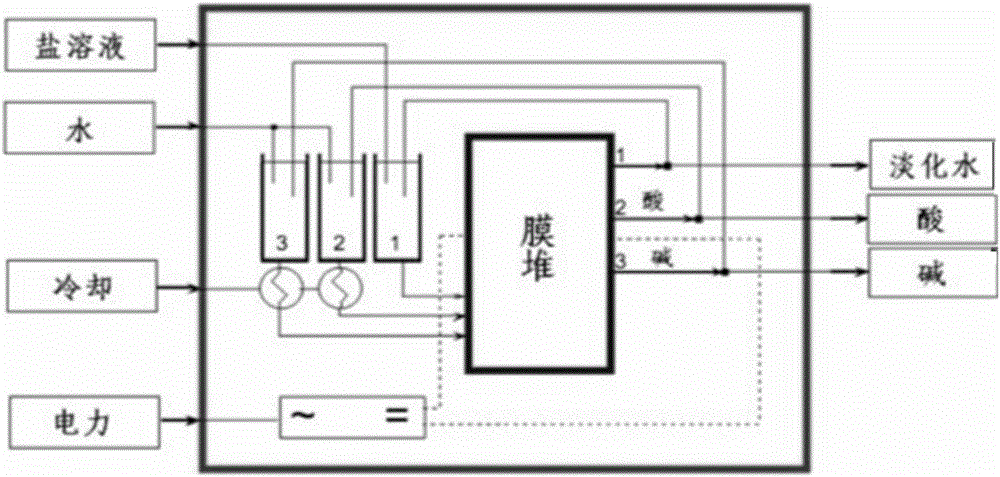

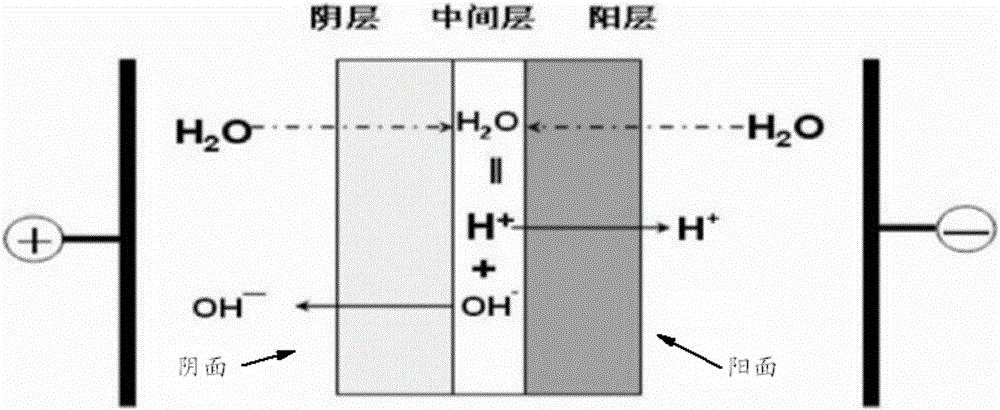

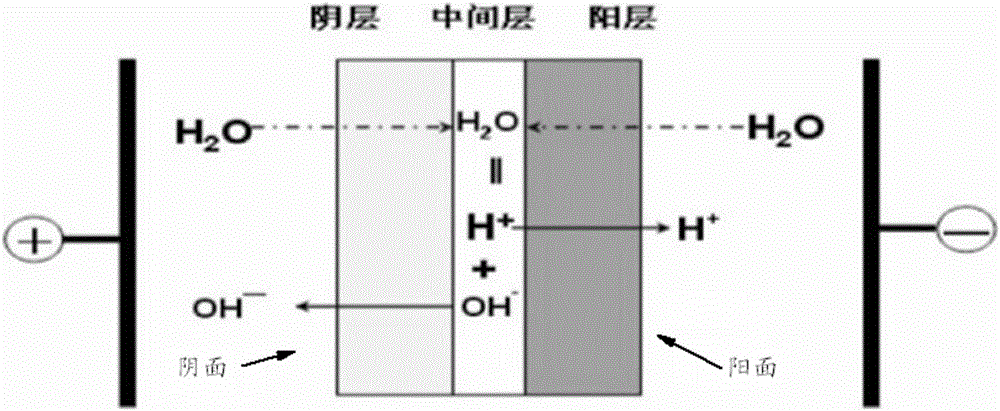

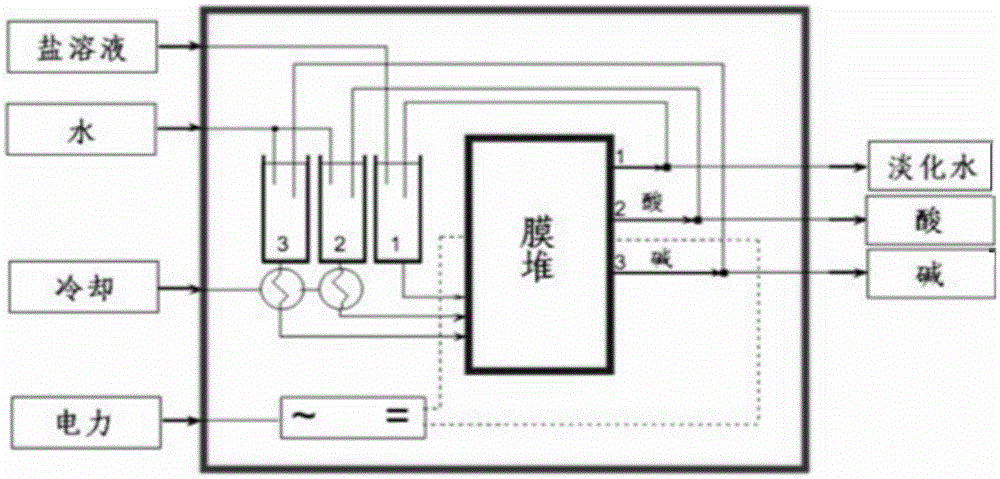

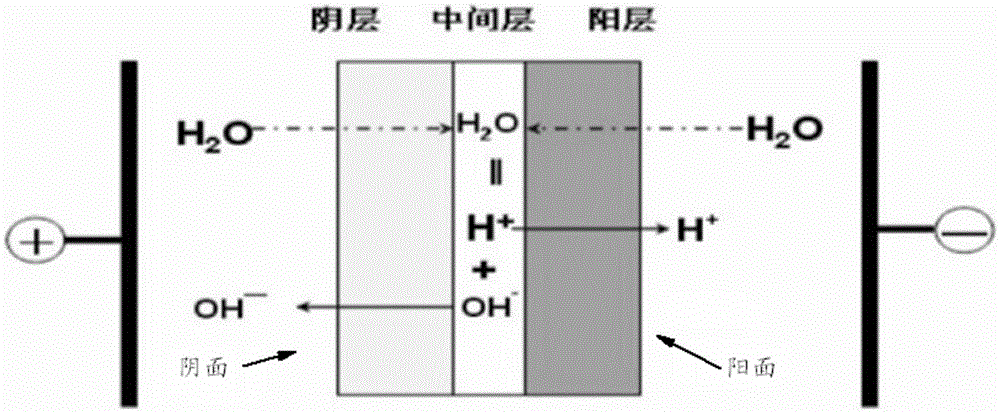

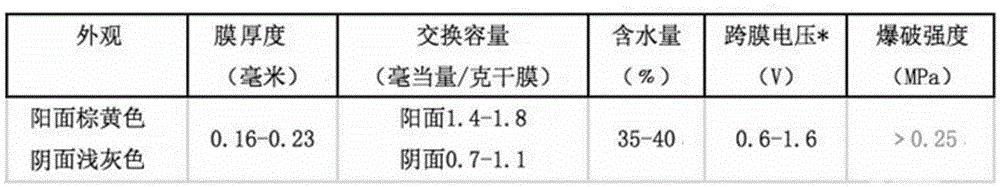

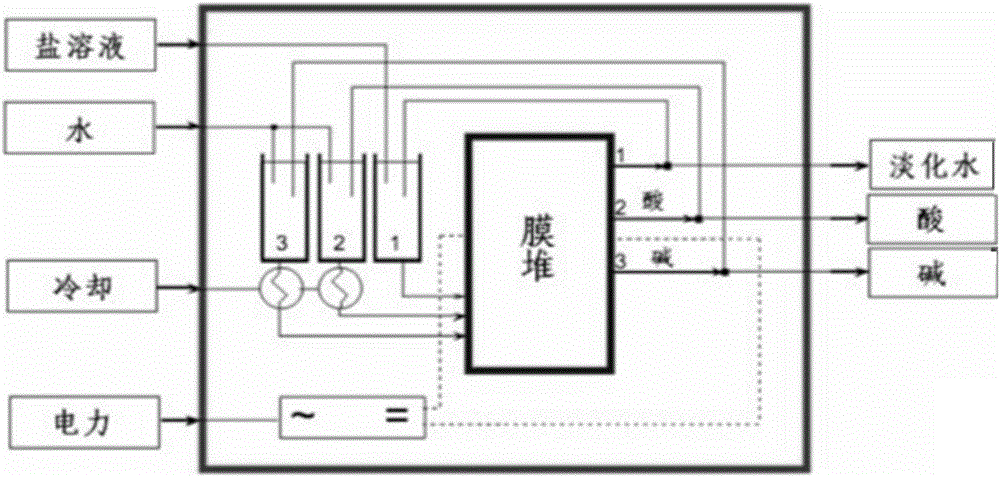

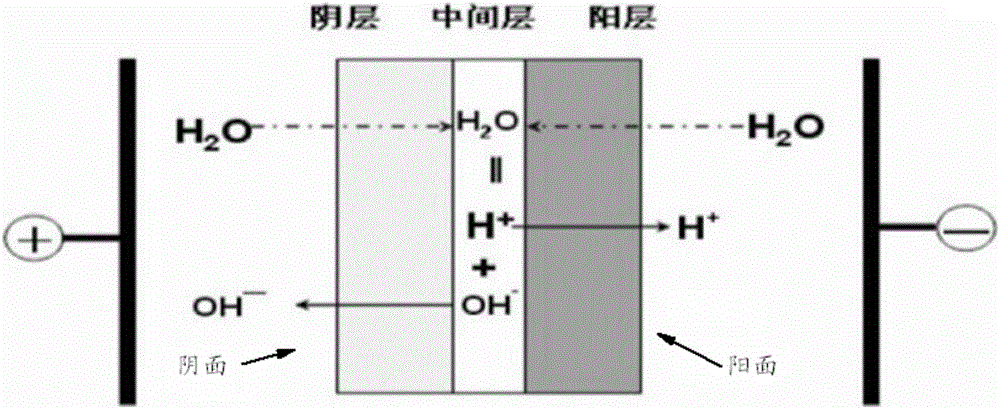

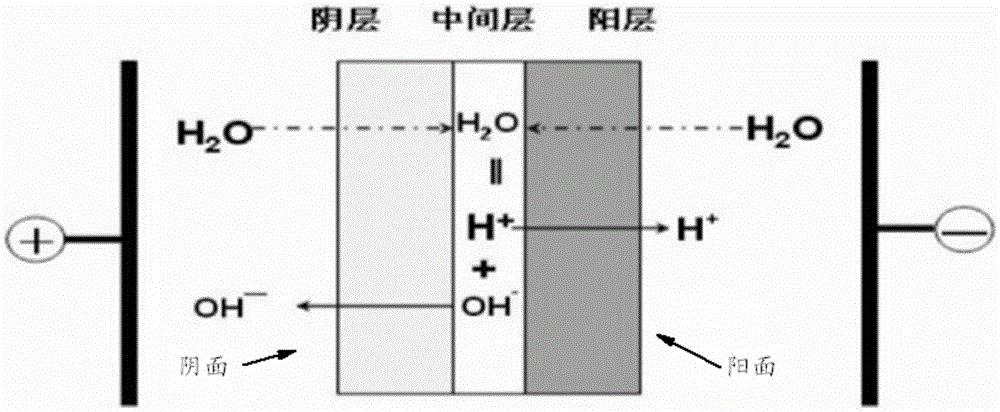

The invention provides a halopropyl alcohol preparation method, which comprises: (1) a catalyst acid treatment: soaking a catalyst in an acid, washing the catalyst, and drying the catalyst; (2) halo alcoholization: adding hydrogen halide, H2O2, propylene and the catalyst treated in the step (1) to a reaction device, and carrying out a halo alcoholization reaction to obtain halopropyl alcohol; optionally, (3) saponification: carrying out a saponification reaction on the halopropyl alcohol obtained in the step (2) and an alkali metal hydroxide, and separating to obtain propylene oxide and a halogenated alkali metal salt; and optionally, (4) electrodialysis: carrying out bipolar membrane electrodialysis on the halogenated alkali metal salt obtained in the step (3) to obtain the hydroxide of the alkali metal and the hydrogen halide. With the method of the present invention, the halopropyl alcohol can be produced in the extremely high selectivity and extremely high yield manner, and the emissions of wastewater and waste residue are substantially reduced.

Owner:JIANGXI SUKEER NEW MATERIAL

Method of manufacturing 1-chloro-2-methyl-4-acyloxy-2-butene derivatives

InactiveUS20070270607A1High yieldHigh purityPreparation from carboxylic acid halidesOrganic compound preparationAcid derivative2-Butene

1-Chloro-2-methyl-4-acyloxy-2-butene derivatives can be synthesized in good yields and high purity starting from isoprene and employing a chlorohydrin formation reaction in a system made of N-chloroisocyanuric acid derivatives and water, followed by esterification and rearrangement of the crude product mixture.

Owner:SHAOXING UNIVERSITY +1

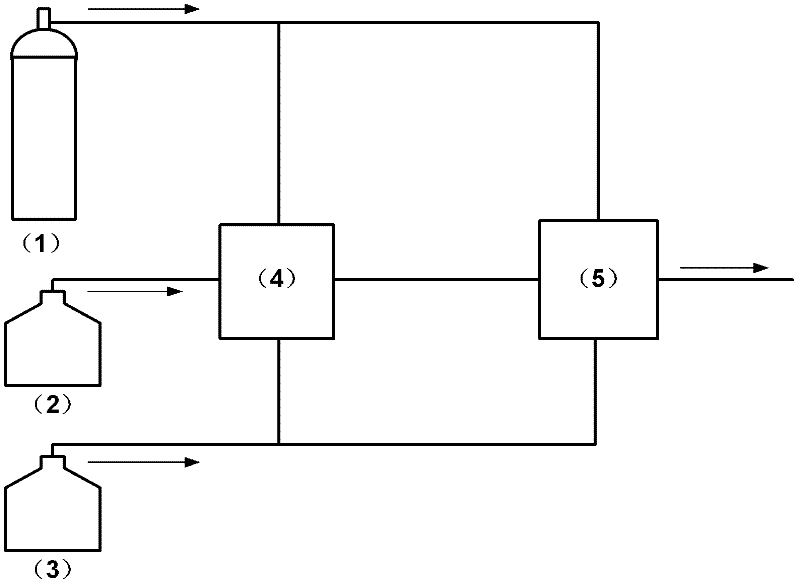

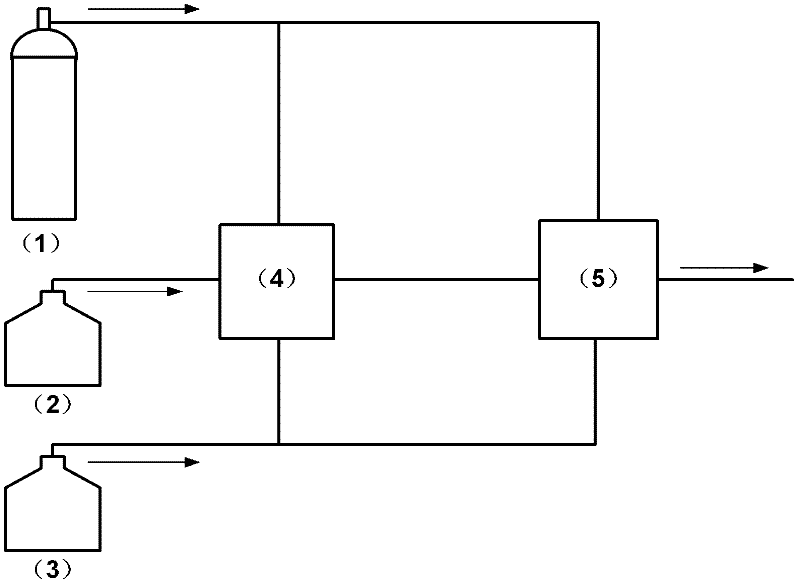

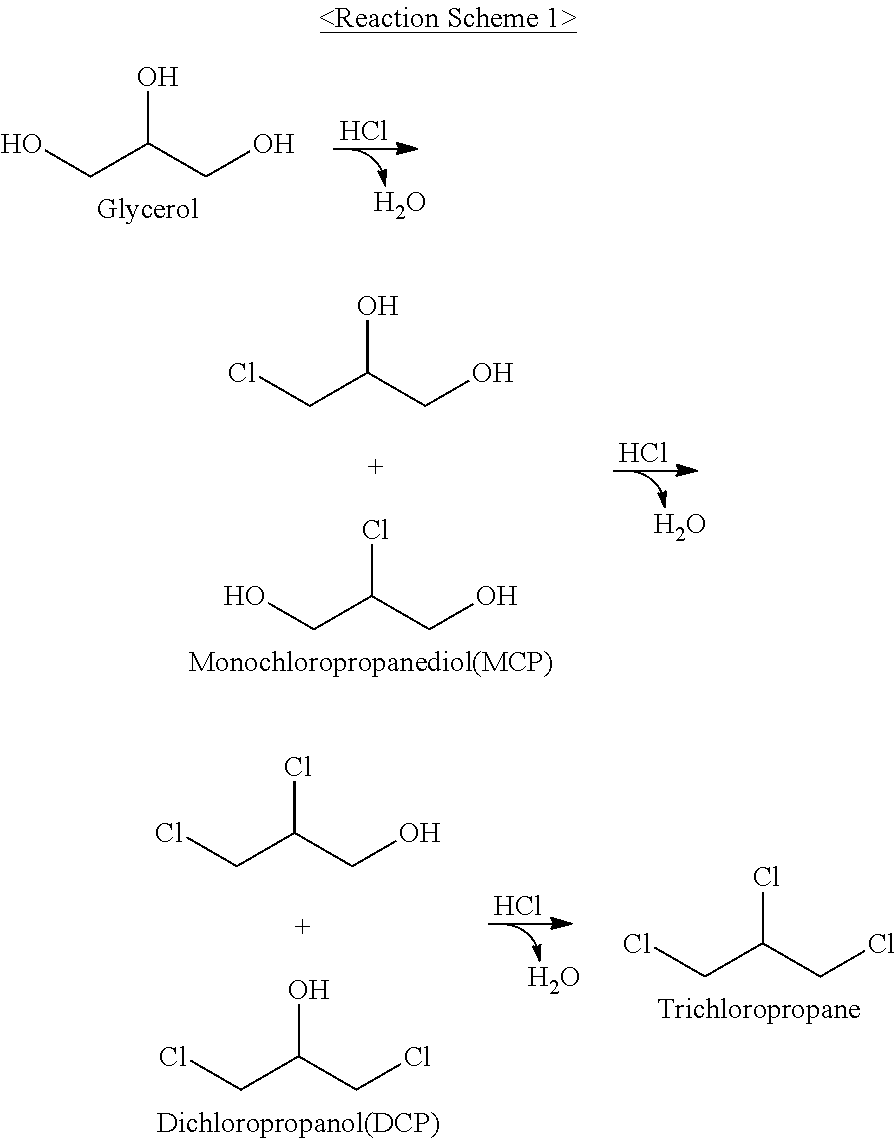

Micro reaction system and method for chlorohydrination of chloropropene

ActiveCN102603481AAvoid loopsReduce energy consumptionPreparation by OH and halogen introductionCyclic processHigh concentration

The invention discloses a micro reaction system and a method for chlorohydrination of chloropropene, belonging to the technical field of synthesis of organic compounds. The micro reaction system comprises one or more microreactor units connected in series, wherein water is injected from the first microreactor unit in one time, and then flows through 0-3 subsequent microreactor units in sequence. Chlorine and chloropropene are injected into each microreactor unit according to a certain distribution ratio. Inside each microreactor unit, chlorine injected firstly is dissolved in a liquid phase, contacts with chloropropene injected later to carry out a chlorohydrination reaction, and the reaction solution outflows from the last microreactor unit, and is aged through a pipeline to obtain the product. The system provided by the invention adopts a multistage series system, can prepare high-concentration dichloropropanol solution, and avoids a cyclic process and reduces the process energy consumption at the same time. Meanwhile, due to the enhanced mixing effect of the microreactor, the method disclosed by the invention can improve the selectivity and the yield of the chlorohydrination process of chloropropene.

Owner:JIANGSU ANPON ELECTROCHEM +1

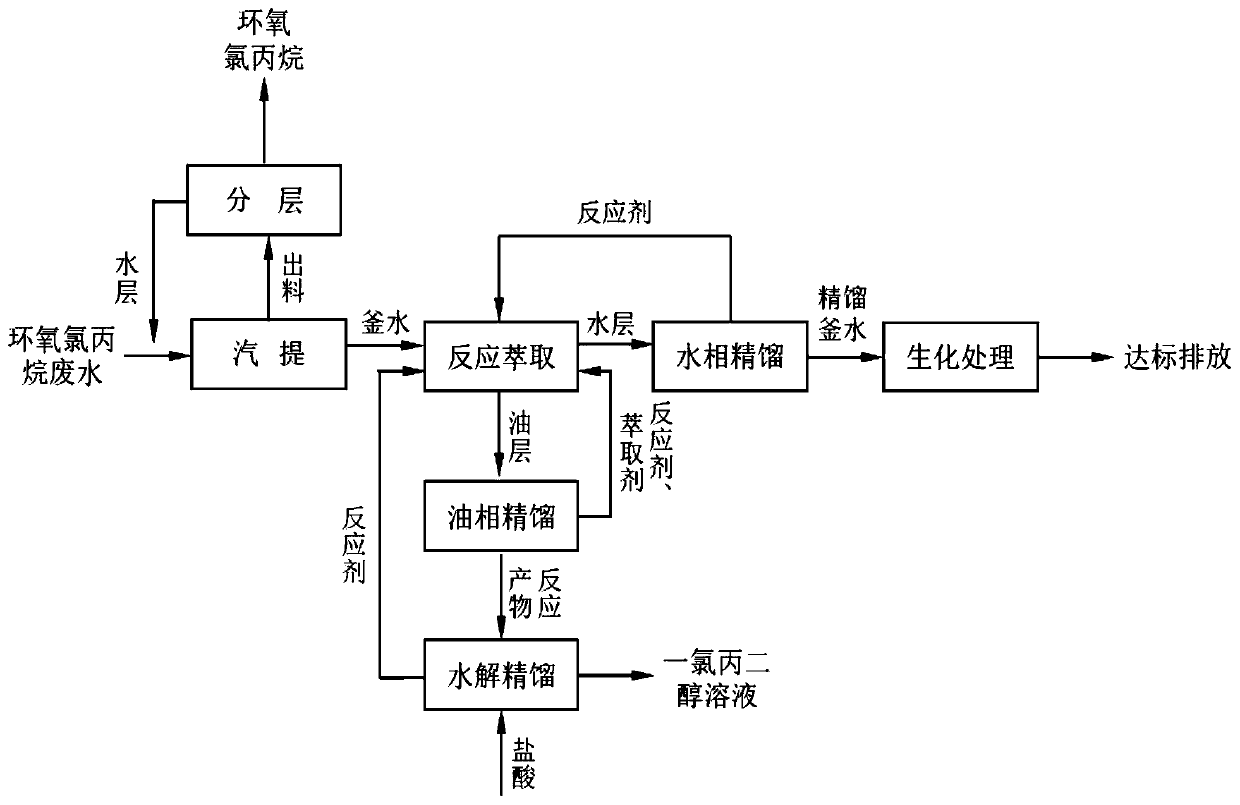

Method of resource utilization of epichlorohydrin wastewater

ActiveCN110746270AReduce energy consumptionImprove economyOrganic compound preparationPreparation by OH and halogen introductionWastewaterProcess engineering

The invention provides a method for treating epichlorohydrin wastewater. The method comprises the working procedures of steam stripping, reaction extraction, rectification, hydrolysis rectification and the like, and monochloropropanediol in wastewater and can be effectively recovered. According to the invention, energy consumption in the process is reduced by adopting a reaction extraction method,and an extracting agent and a reaction agent in an extraction reaction process can be recycled, so that resource utilization is realized, and economy is enhanced. The whole process flow is simple, iseasy for industrial implementation, and has a wide application prospect.

Owner:JIANGSU YANGNONG CHEM GROUP +2

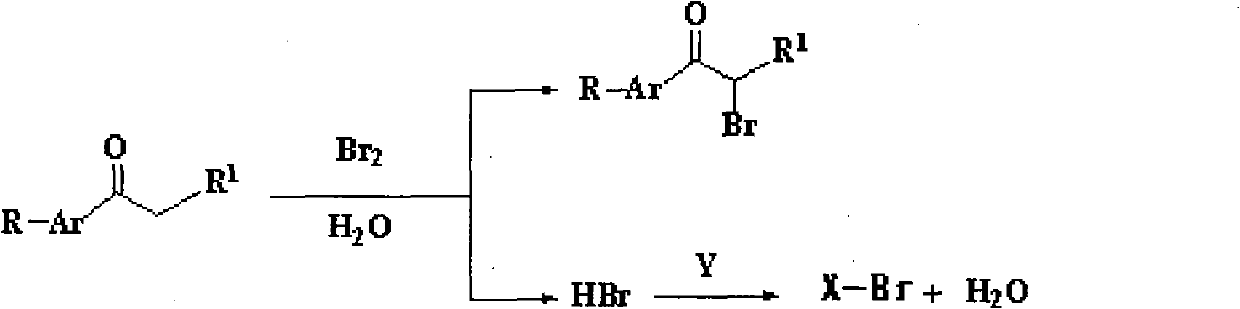

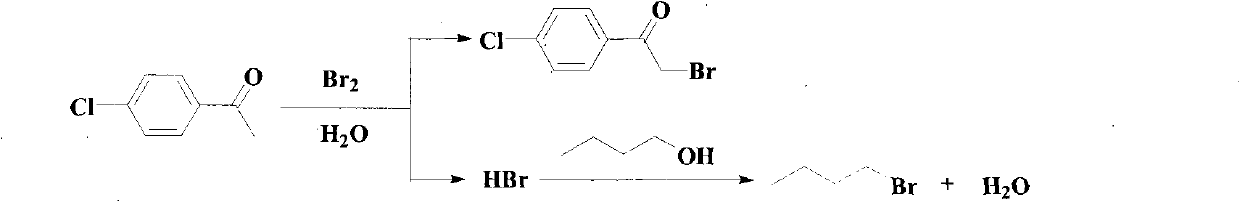

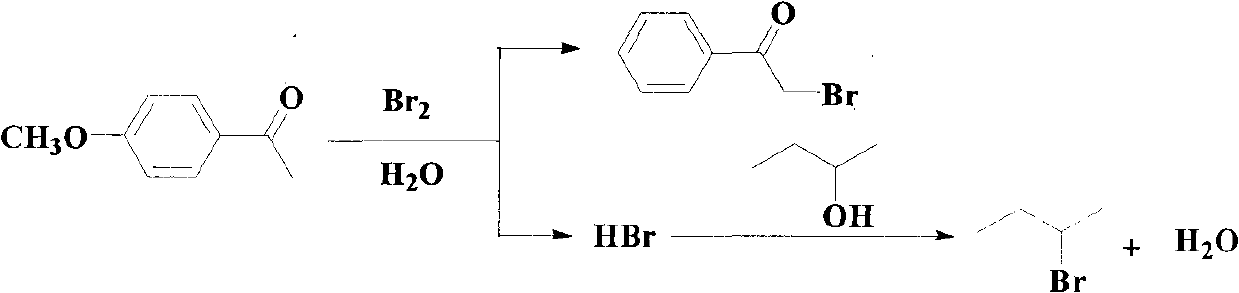

Method for synthesizing alpha-bromoketone and coproducing bromohydrocarbon

InactiveCN101948374AIncrease profitAvoid emissionsOrganic compound preparationPreparation by OH and halogen introductionWater vaporOrganic layer

The invention discloses a method for synthesizing alpha-bromoketone and coproducing bromohydrocarbon. The technical scheme comprises the following steps of: adding arylalkyl ketone compounds, alcohol or epoxy compounds and water into a flask first; dripping bromine into the flask slowly under the conditions of stirring and heating; performing a bromo-reaction on the bromine and the ketone compounds to obtain alpha-bromoketone and bromine hydride; dissolving the bromine hydride in the water to form hydrobromic acid; performing a reaction on the hydrobromic acid and the alcohol or epoxy compounds to obtain bromohydrocarbon ketone compounds; after the reaction is completed, performing steam distillation to obtain a raffinate serving as an alpha-bromoketone crude product after distillation; cooling for separating crystals out; washing and drying the crystals to obtain an alpha-bromoarylalkyl ketone product; separating an aqueous layer from a distillate serving as a bromohydrocarbon crude product; washing an organic layer until the organic layer is neutral; drying by using anhydrous calcium chloride; and distilling to obtain a bromohydrocarbon product. In the method, the water is takenas a solvent, and the bromohydrocarbon is coproduced while the alpha-bromoketone compounds are synthesized; and the gross products of the reaction are the alpha-bromoketone, the bromohydrocarbon and the water, so the method has the characteristics that: the high atom utilization rate of the reaction is high, the generation or the discharging of noxious substances such as bromine hydride gas, strong acid waste water and the like is avoided, and the effects of environmental protection, energy conservation and reduction emission are achieved.

Owner:HEBEI UNIVERSITY

Method for preparing halohydrin and ethylene oxide

ActiveCN106518623AReduce loadReduce dosageDispersed particle separationPreparation by OH and halogen introductionHalohydrinSaponification

The invention provides a method for preparing halohydrin. The method comprises the following steps: 1) halogen alcoholization: halogen hydride, H2O2, and a catalyst are added in a reaction apparatus, and ethylene is added for a halogen alcoholization reaction to obtain halohydrin. The invention also provides a method for preparing ethylene oxide by a halogen alcoholization method, which comprises the step 1) in right claim 1, the method also comprises a step of 2) saponification: halohydrin in the step 1) and hydroxide of alkali metal are subjected to a saponification reaction, then separated to obtain ethylene oxide and alkali halide metal salt; and an optional step of 3) electrodialysis: the obtained alkali halide metal salt is subjected to bipolar membrane electrodialysis to obtain the hydroxide of alkali metal and the halogen hydride. The method is used for preparing halohydrin or ethylene oxide with high selectivity and yield, and greatly reduces the discharge of waste water and waste residue.

Owner:JIANGXI SUKEER NEW MATERIAL

Method for producing 4-chloro-3-hydroxyl-1-butene

InactiveCN101456794ASolve precipitationReduce investmentPreparation by OH and halogen introductionOxidizing agentHypochlorous acid

The invention relates to a method for producing 4-chlorine-3-hydroxyl-1-butylene, which is to take 1,3-butadiene as a raw material, and perform addition reaction under the action of hypochlorous acid to obtain the 4-chlorine-3-hydroxyl-1-butylene, wherein the temperature of the addition reaction is between 10 DEG C below zero and 10 DEG C. The method prepares the target product by directly taking the hypochlorous acid as a catalyst and performing addition reaction on the 1,3-butadiene, and can completely avoid the precipitation phenomenon, reduce the equipment investment, improve the utilization rate of equipment, and simplify the operation.

Owner:SUZHOU HUAYI NEW ENERGY TECH CO LTD

Methods for preparing halogen ethanol and ethylene oxide

ActiveCN106518611ASolve intractableDifficult problems to overcomeDispersed particle separationPreparation by OH and halogen introductionHydrogen halideSaponification

The invention provides a method for preparing halogen ethanol, wherein the method comprises: (1) acid treatment of a catalyst, wherein a catalyst is soaked in an acid, the soaked catalyst is washed, and the washed catalyst is dried; (2) halogen alcoholization, wherein hydrogen halide, H2O2, ethylene and the catalyst treated in the step (1) are added to a reaction device, and a halogen alcoholization reaction is performed to obtain the halogen ethanol; optionally (3) saponification, wherein the halogen ethanol obtained in the step (2) and the hydroxide of an alkali metal are subjected to a saponifying reaction, and separation is performed to obtain ethylene oxide and a halogenated alkali metal salt; and optionally, (4) electrodialysis, wherein the halogenated alkali metal salt obtained in the step (3) is subjected to bipolar membrane electrodialysis to obtain the hydroxide of the alkali metal and the hydrogen halide. According to the present invention, the halogen ethanol is prepared in the forms of the extremely high yield and the extremely high selectivity, and the emission of wastewater and waste residue is substantially reduced.

Owner:JIANGXI SUKEER NEW MATERIAL

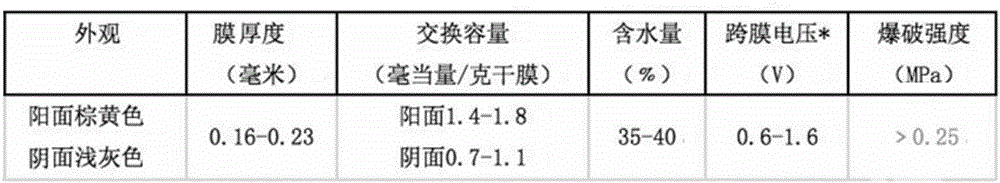

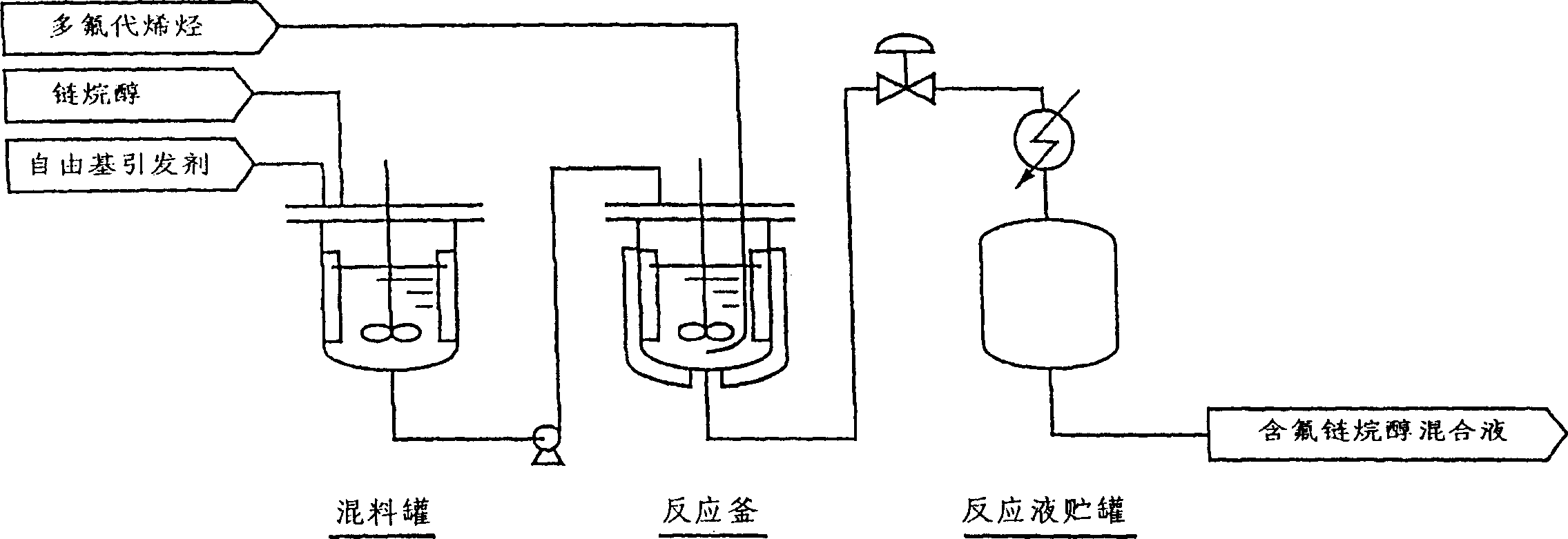

Process for producing fluoroalkanol

InactiveCN1454197AEasy to prepareOrganic compound preparationPreparation by OH and halogen introductionHydrogen atomFluorine containing

The present invention provides a method for producing fluorinated alkanols that can be industrially easily implemented with high selectivity. CHR1R2OH, free radical initiator and CF2=CFRf react at 105-135°C while supplying continuously, and discharge the generated H-(CFRfCF2)n-CR1R2-OH continuously. Wherein R1 and R2 are a hydrogen atom or an alkyl group with 1 to 3 carbon atoms, Rf is a fluorine atom or a polyfluoroalkyl group with 1 to 4 carbon atoms, and n is an integer of 1 to 4.

Owner:ASAHI GLASS CO LTD

Method for preparing halogen ethyl alcohol and ethylene oxide

ActiveCN106518622AReduce loadReduce dosagePreparation by OH and halogen introductionSaponificationHigh selectivity

The invention provides a method for preparing halogen ethyl alcohol. The method comprises the following step: (1) halogen alcoholization: adding halogen hydride, H2O2, ethylene and a Ti heteroatom-containing molecular sieve into a reaction device, and carrying out halogen alcoholization reaction to obtain the halogen ethyl alcohol. The invention also provides a method for preparing ethylene oxide with a halogenohydrin method. The method comprises the following steps: (1) halogen alcoholization: adding halogen hydride, H2O2, ethylene and a Ti heteroatom-containing molecular sieve into the reaction device, and carrying out the halogen alcoholization reaction to obtain the halogen ethyl alcohol; (2) saponification: carrying out saponification reaction on the halogen ethyl alcohol in the step (1) and a hydroxide of alkali metal, and separating to obtain the ethylene oxide and alkali halide metal salt; optionally (3) electroosmosis: carrying out bipolar membrane electroosmosis on alkali halide metal salt obtained in step (2) to obtain the hydroxide of alkali metal and the halogen hydride. According to the methods, the halogen ethyl alcohol or the ethylene oxide can be prepared at extremely high selectivity and yield, and the discharging of waste water and waste residues can be drastically lowered.

Owner:JIANGXI SUKEER NEW MATERIAL

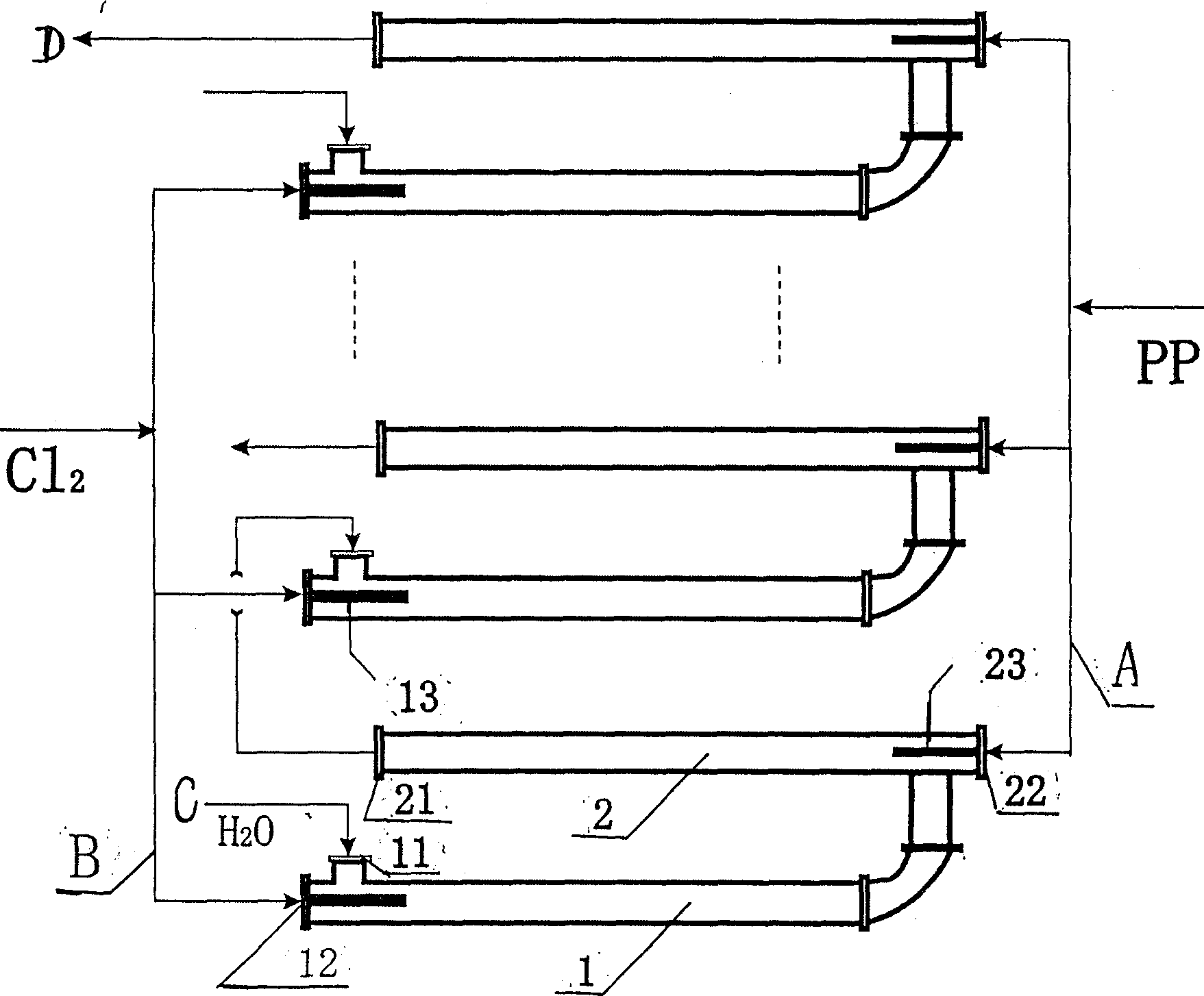

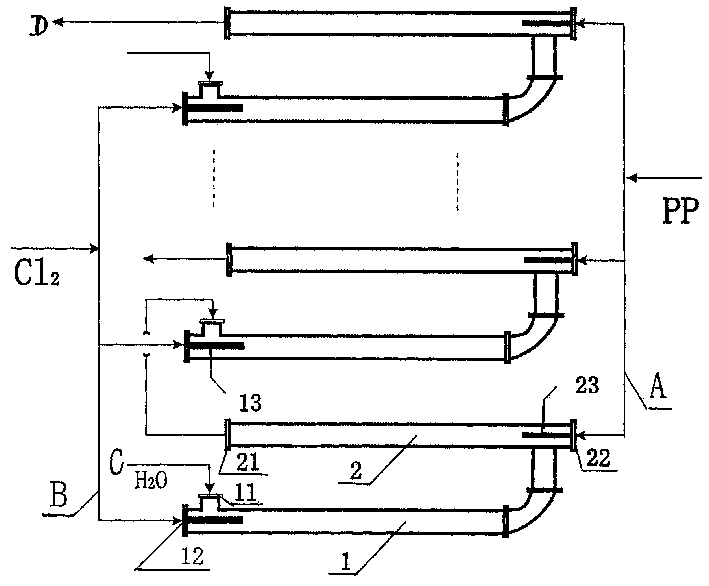

Tubular reactor and reaction method for alcoholizing propenyl chloride

InactiveCN1388106AImprove solubilityGood dispersionPreparation by halogen introductionPreparation by OH and halogen introductionChloridePropenyl

The present invention relates to industrial production of epoxy propane. The tubular reactor consists of 5-80 serially connected reaction units, and each unit consists of one piece of chlorine predissolving reaction tube and one piece of propylene chlorohydrinizing reaction tube. The outlet of the last propylene chlorohydrinizing reaction tube is the outlet of the propylene chloride, the chlorine inlet of the first chlorine predissolving reaction tube is the inlet of the technological water, all the inlets of the propylene chlorohydrinizing reaction tubes are connected to the propylene material pipe, all the gas inlets of the chlorine predissolving reaction tubes are connected to the chlorine material pipe, and propylene material and chlorine material are fed into all reaction units simultaneously.

Owner:SINOPEC JINLING PETROCHEMICAL CO LTD

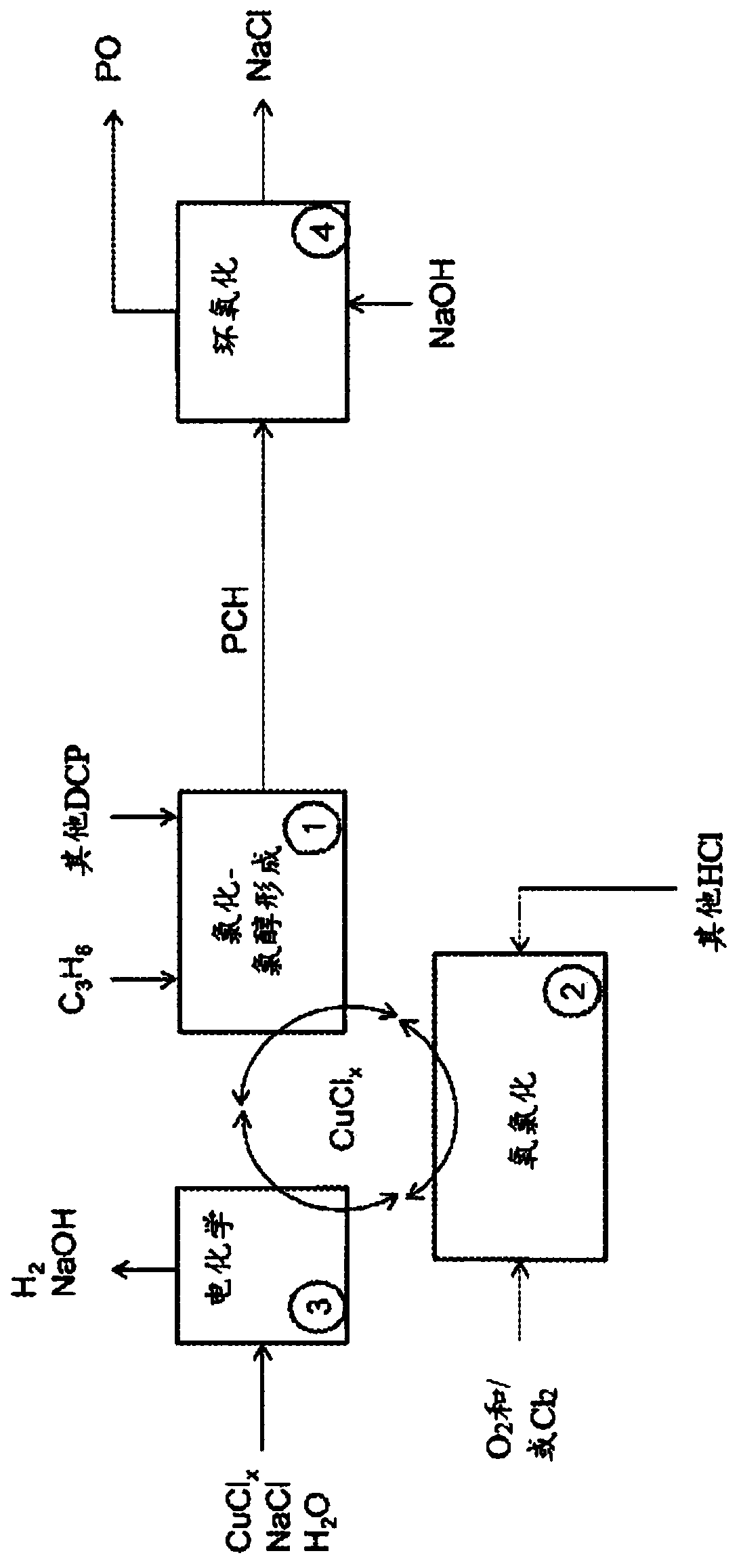

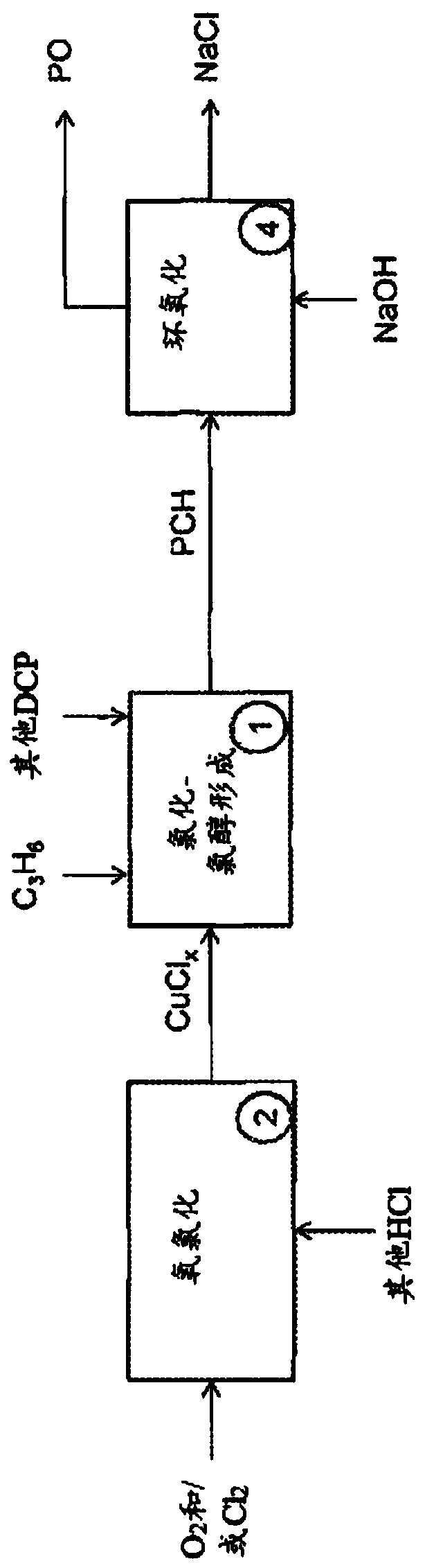

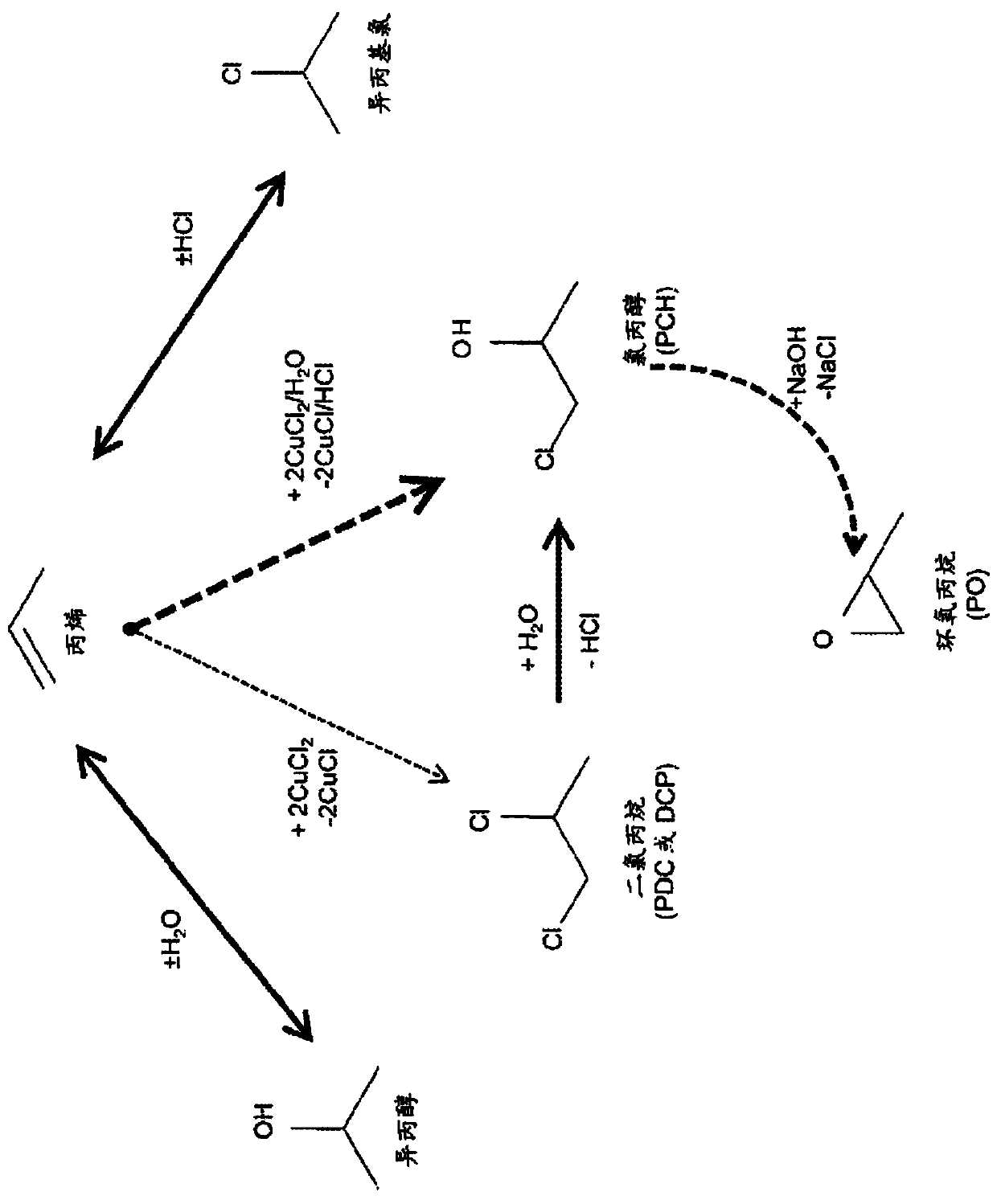

Methods and systems to form propylene chlorohydrin and propylene oxide

InactiveCN110753679AOrganic compound preparationPreparation by OH and halogen introductionDichloropropanePropanol

There are provided methods and systems to form propylene chlorohydrin by hydrolysis of 1,2-dichloropropane and to further form propylene oxide from propylene chlorohydrin.

Owner:CALERA CORP

Method for synthesizing chlorohydrin by using hydrochloric acid and ethylene oxide

ActiveCN101811935ASimple processHigh purityPreparation by OH and halogen introductionEthylene oxideReaction temperature

The invention discloses a method for synthesizing chlorohydrin by the reaction of 30 to 36 wt% industrial hydrochloric acid and ethylene oxide. The molecular ratio of the ethylene oxide to the chlorine hydride is kept between 1.01 and 1.05; in the method, a self-prepared supported catalyst is used, so that the side reactions are effectively inhibited and the conversion rate is improved; and a fixed bed reactor is used, the reaction temperature is controlled to between 30 and 60 DEG C, and the 47 to 53 wt% aqueous solution of chlorohydrin can be finally obtained. The method has the advantages of simplifying the production process and lowering production cost.

Owner:锦西化工研究院有限公司

Method for preparing chlorohydrins and method for preparing epichlorohydrin using chlorohydrins prepared thereby

ActiveUS20130096327A1High selectivityOrganic compound preparationPreparation by halogen introductionUnit operationAliphatic hydrocarbon

A method of preparing chlorohydrins and a method of preparing epichlorohydrin by using chlorohydrins prepared using the method are provided. The method of preparing chlorohydrins by reacting polyhydroxy aliphatic hydrocarbon with a chlorination agent in the presence of a catalyst includes at least one combination of a series of unit operations including a first reaction step, a water removal step, and a second reaction step, in that respective order, wherein the method further includes purifying chlorohydrins from a reaction mixture discharged from a final reaction step of the plurality of reaction steps. The method of preparing epichlorohydrin includes reacting chlorohydrins prepared using the method of preparing chlorohydrins, with an alkaline agent.

Owner:LOTTE FINE CHEM CO LTD

Popular searches

Carbonyl compound preparation Halogenated hydrocarbon preparation Steroids Carboxylic compound preparation Sugar derivatives preparation Nature of treatment water Water/sewage treatment apparatus Hypochlorite Carbonyl compound preparation by condensation Photosensitive materials for photomechanical apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com