Micro reaction system and method for chlorohydrination of chloropropene

A technology of chloropropene chlorohydrin and chloropropene, which is applied in the field of organic compound synthesis, can solve the problems of decreased reaction yield, increased side reactions of trichloropropane, and high energy consumption in the process, so as to improve selectivity and yield, reduce process Effects of energy consumption and shortened response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

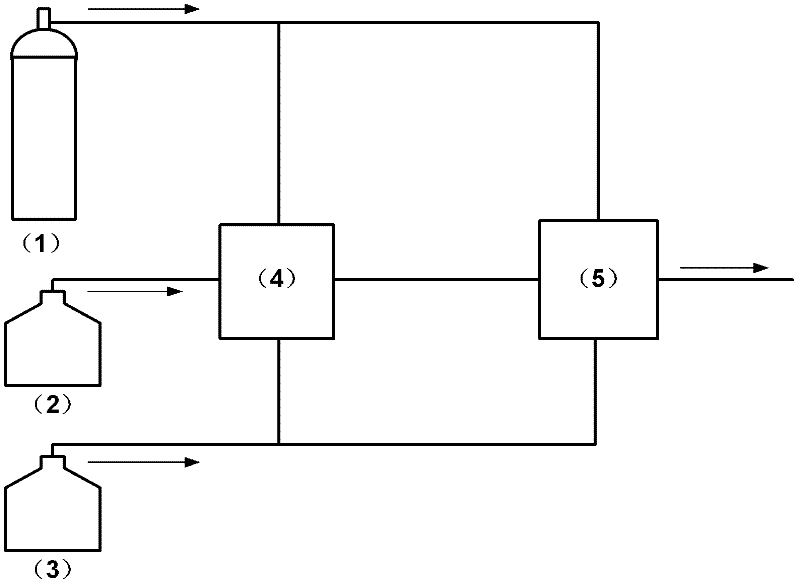

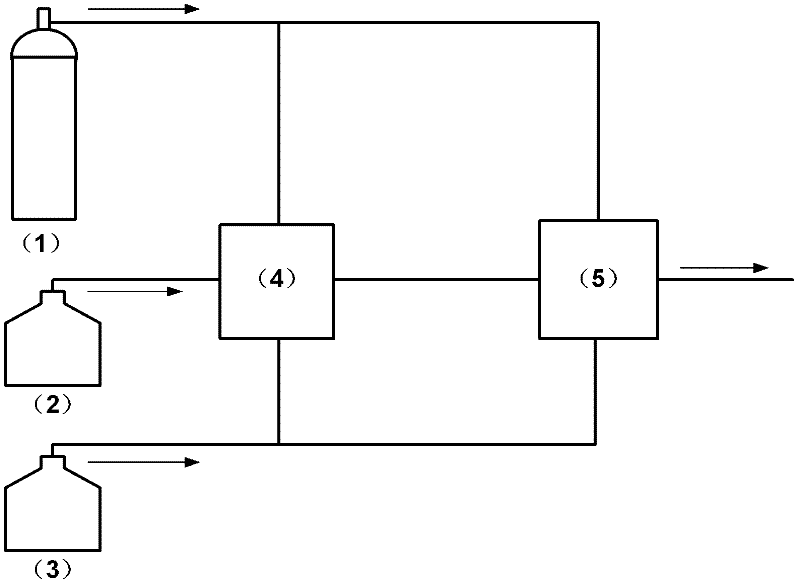

[0025] A method for the chlorohydrination of allyl chloride, the method is carried out according to the following steps:

[0026] a) In the first micro-reactor unit, inject chlorine and water into the first micro-mixing device (chlorine gas mixer) respectively by chlorine cylinder and water liquid addition tank, the flow of the two is respectively 20ml / min and 5ml / min min, to prepare chlorine water, the temperature of dissolving chlorine gas is 20°C, and the pressure is 4 atmospheres. Chlorine water and allyl chloride injected into the allyl chloride filling tank are quickly mixed and reacted in the second micro-mixing device, and the flow rate of allyl chloride is 76 μl / min, and complete the reaction in the subsequent pipeline, the temperature of the pipeline is 20°C.

[0027] b) After the reaction material flows out from the first microreactor unit, it is matured in the pipeline for 10-100 seconds to obtain the reaction product dichloropropanol solution.

[0028] The micro...

Embodiment 2

[0031] A method for the chlorohydrination of allyl chloride, the method is carried out according to the following steps:

[0032] a) In the first microreactor unit, inject chlorine gas and water into the first micro-mixing device (chlorine gas mixer) respectively by the chlorine gas bottle and the water liquid addition tank, and the flow rates of the two are respectively 10ml / min and 5ml / min. min, to prepare chlorine water, the temperature of dissolving chlorine gas is 10°C, and the pressure is 1 atmosphere. Chlorine water and allyl chloride injected into the allyl chloride filling tank are quickly mixed and reacted in the second micro-mixing device, and the flow rate of allyl chloride is 36 μl / min, and complete the reaction in the subsequent pipeline, the temperature of the pipeline is 40°C.

[0033] B) the solution obtained is passed into the second microreactor unit, reacts with the added chlorine and allyl chloride, the flow rate of the two, the dissolution temperature an...

Embodiment 3

[0038] A method for the chlorohydrination of allyl chloride, the method is carried out according to the following steps:

[0039] a) In the first microreactor unit, inject chlorine gas and water into the first micro-mixing device (chlorine gas mixer) respectively by the chlorine cylinder and the water liquid addition tank, and the flow rates of the two are respectively 15ml / min and 5ml / min. min, to prepare chlorine water, the temperature of dissolving chlorine gas is 10°C, and the pressure is 3 atmospheres. Chlorine water and allyl chloride injected into the allyl chloride filling tank are quickly mixed and reacted in the second micro-mixing device, and the flow rate of allyl chloride is 54 μl / min, and complete the reaction in the subsequent pipeline, the temperature of the pipeline is 50°C.

[0040] b) The solution obtained is passed into the second and third microreactor units to react with the added chlorine and allyl chloride, the flow of allyl chloride is 53.5 μl / min, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com