Patents

Literature

34 results about "Butoconazole Nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

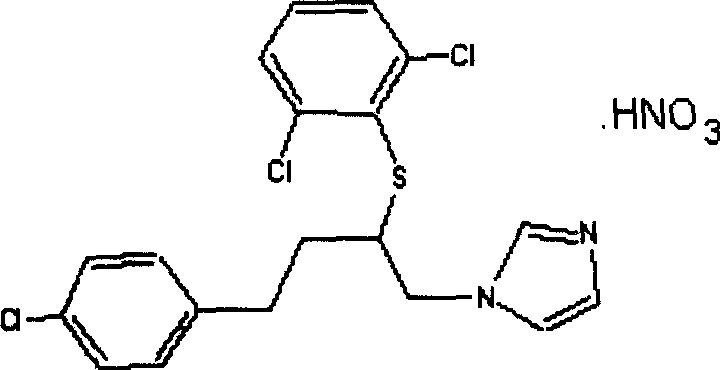

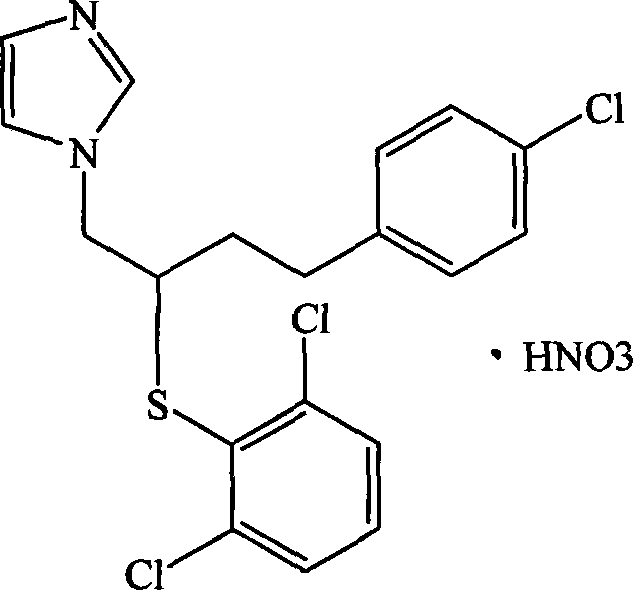

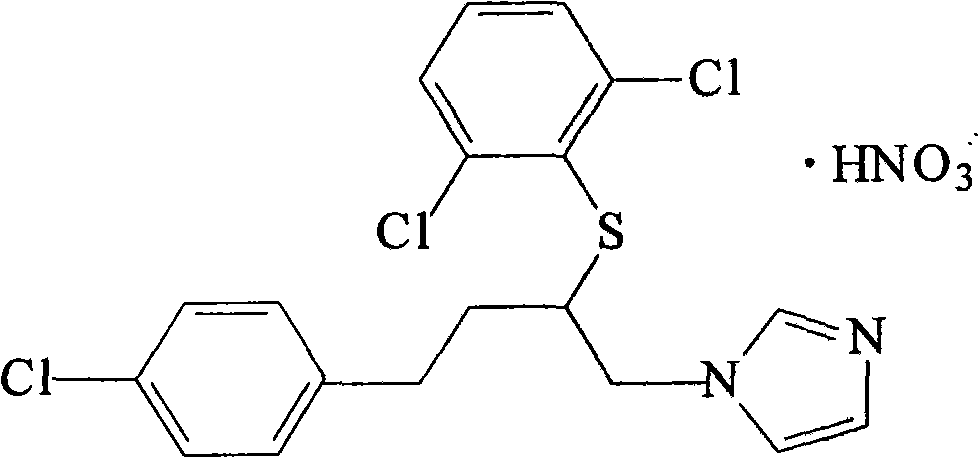

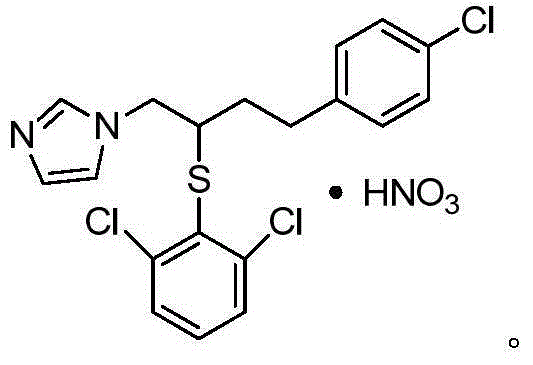

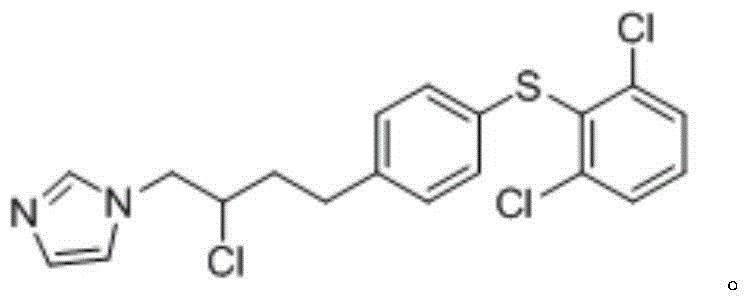

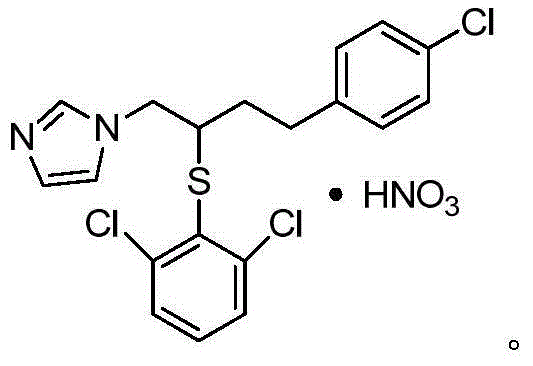

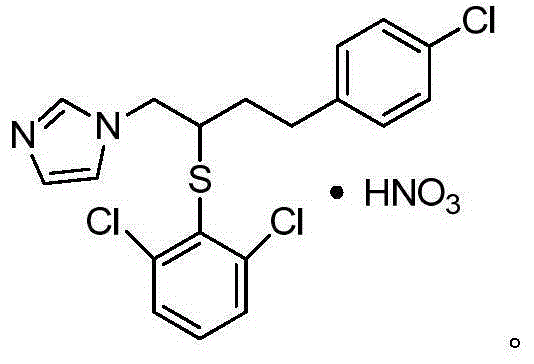

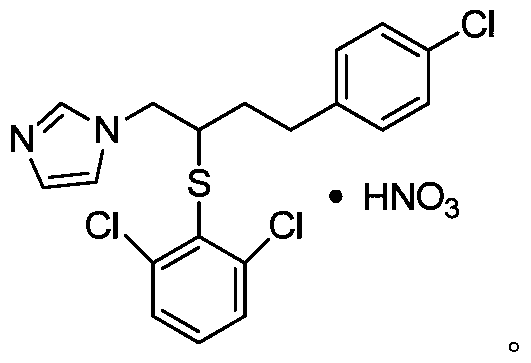

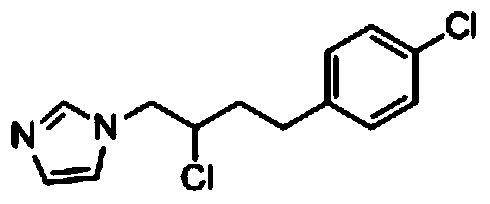

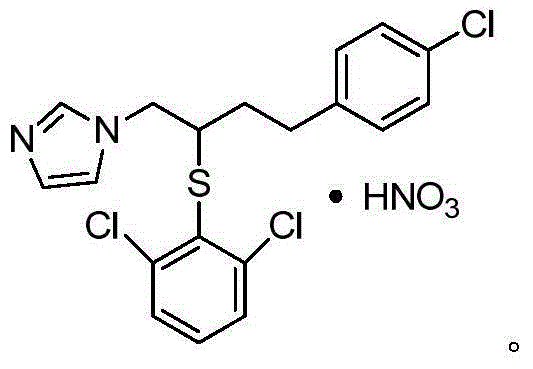

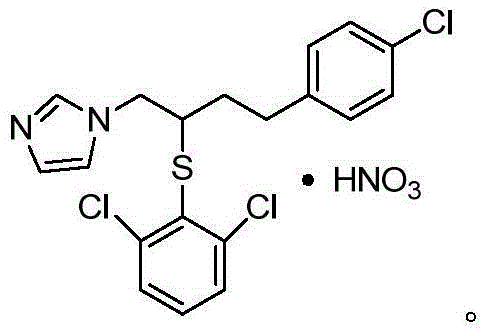

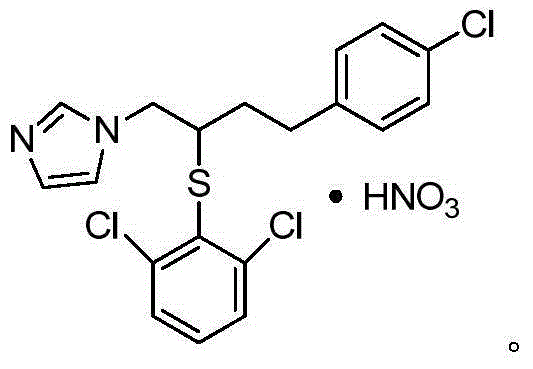

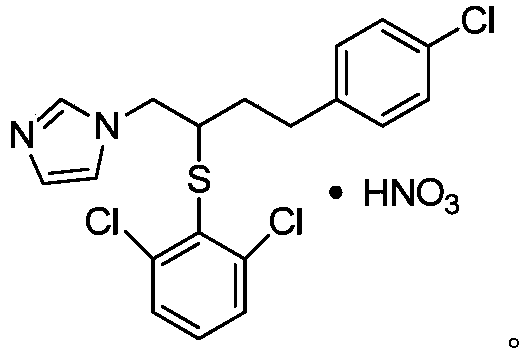

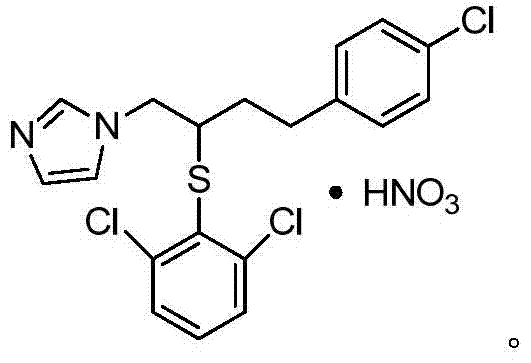

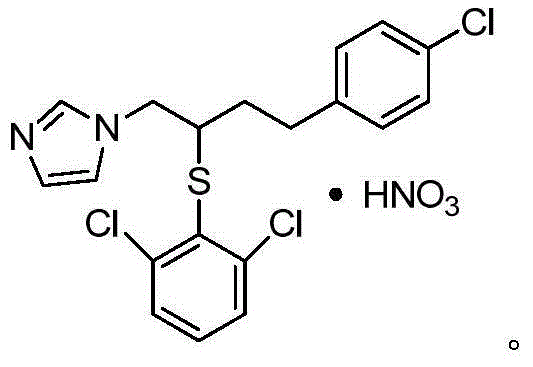

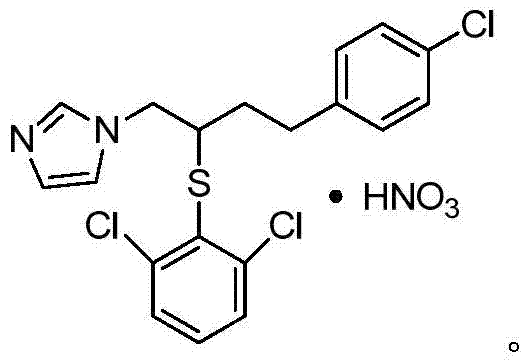

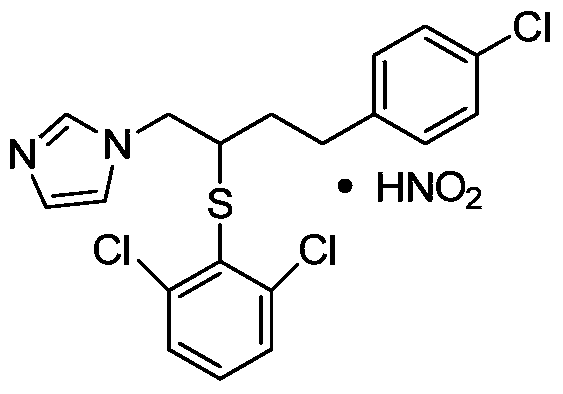

The nitrate salt form of butaconazole, a synthetic imidazole derivative with fungistatic properties. Butoconazole nitrate interferes with steroid biosynthesis by inhibiting the conversion of lanosterol to ergosterol, thereby changing the fungal cell membrane lipid composition. This alters cell permeability and leads to growth inhibition. Butaconazole nitrate is active against many dermatophytes and yeasts. It also contains antibacterial effects against some gram-positive organisms.

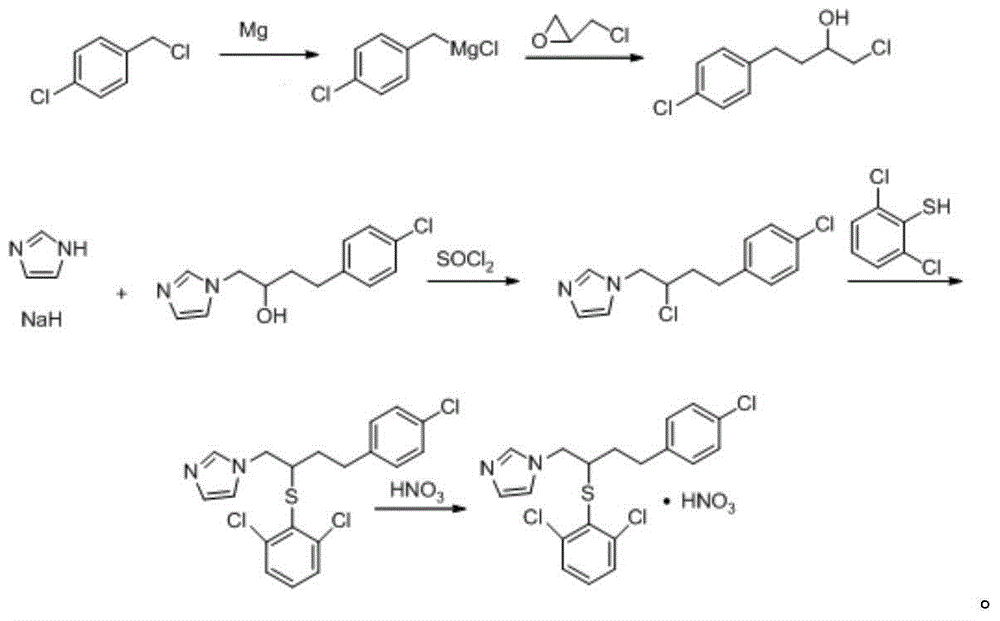

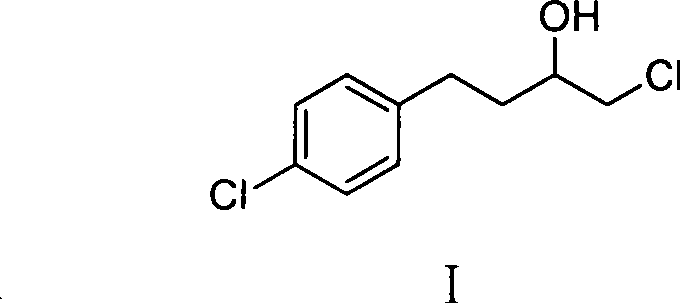

Preparation method of butoconazole nitrate intermediate suitable for industrial production

ActiveCN103880596AHigh yieldReduce bumpsPreparation by OH and halogen introductionMagnesium organic compoundsGrignard reactionEthyl Chloride

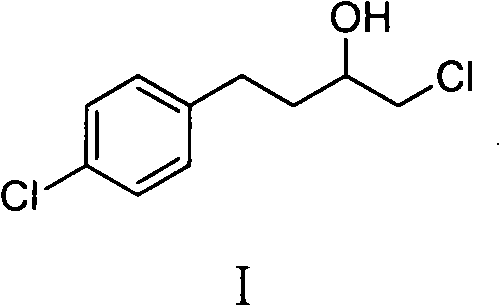

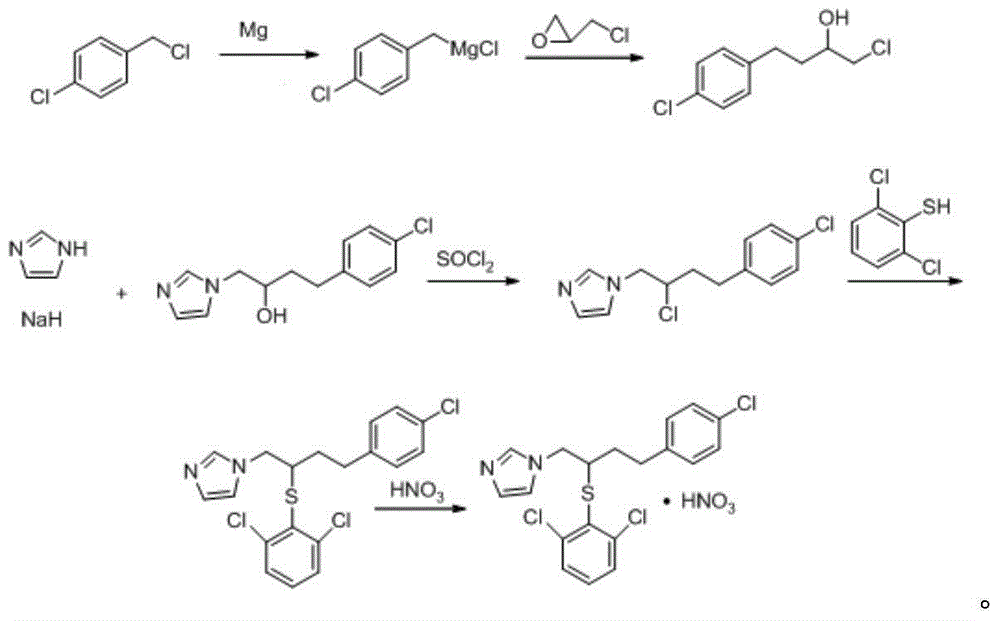

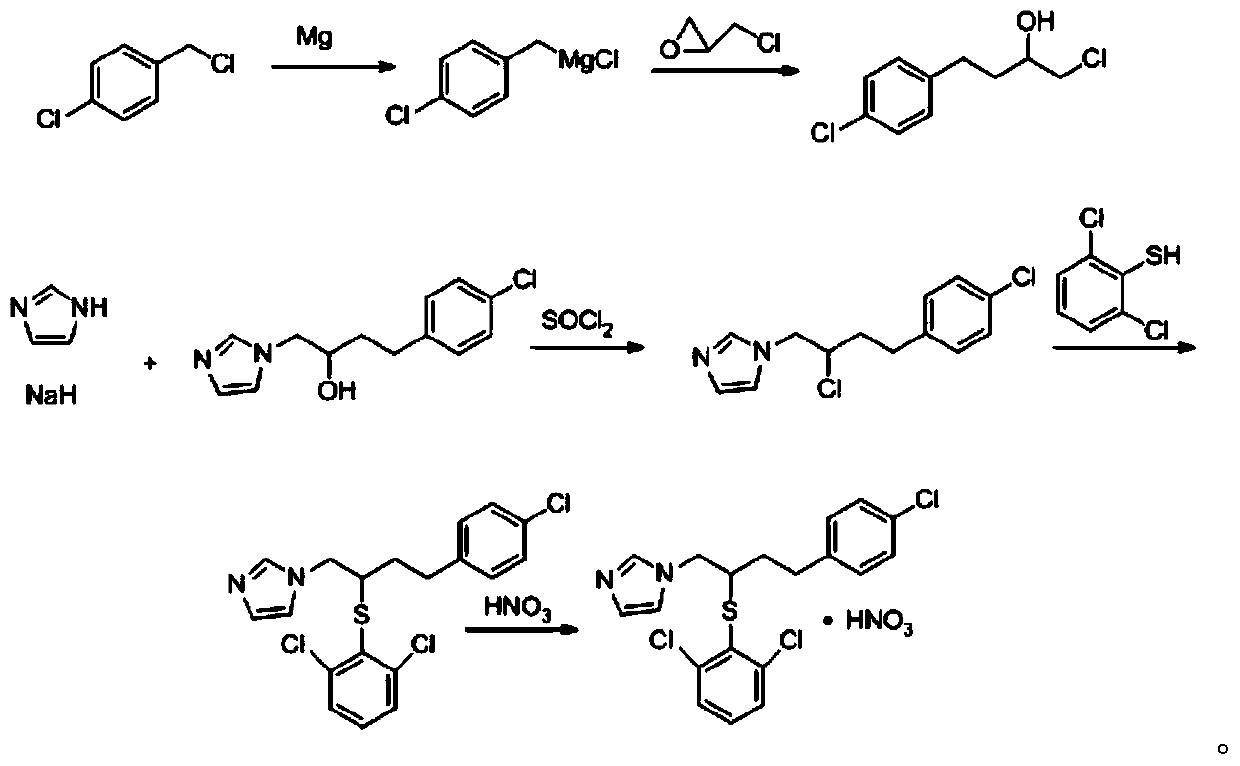

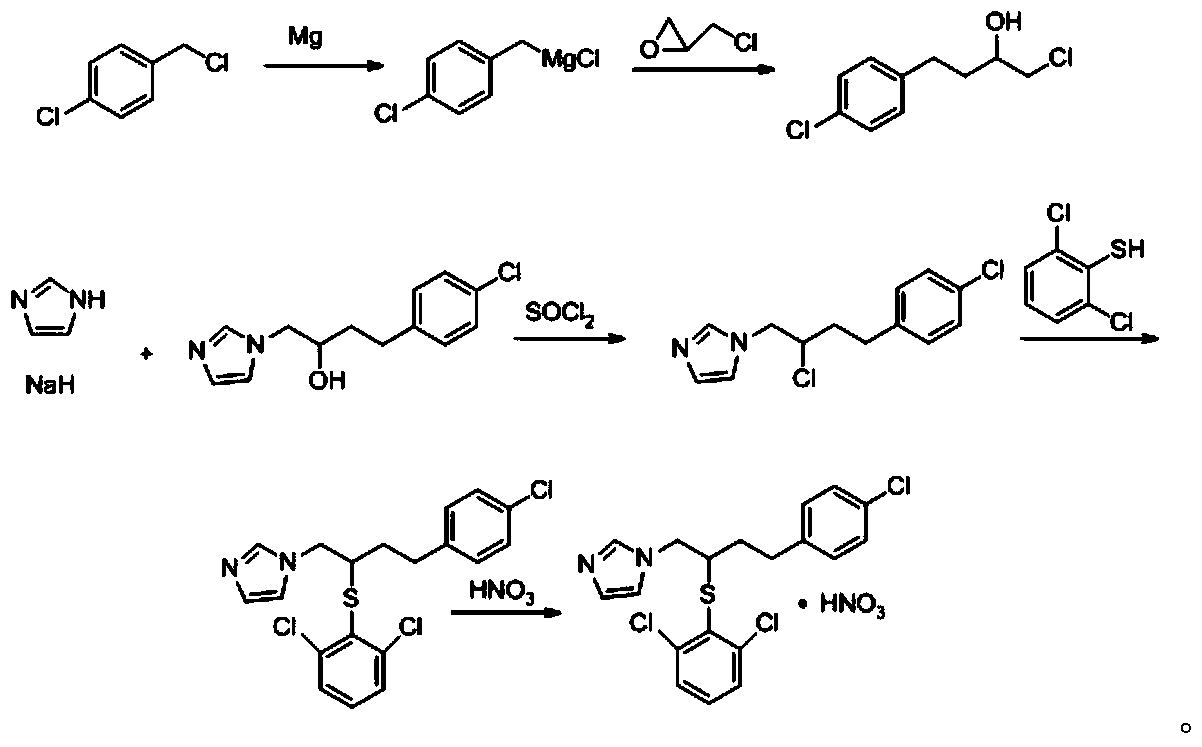

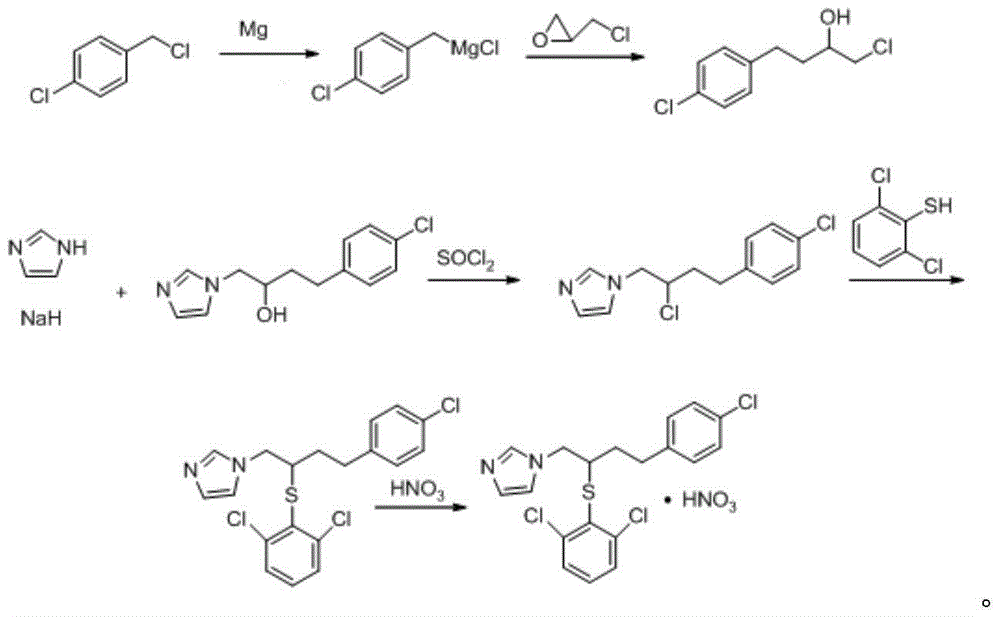

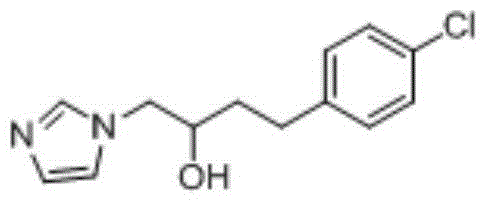

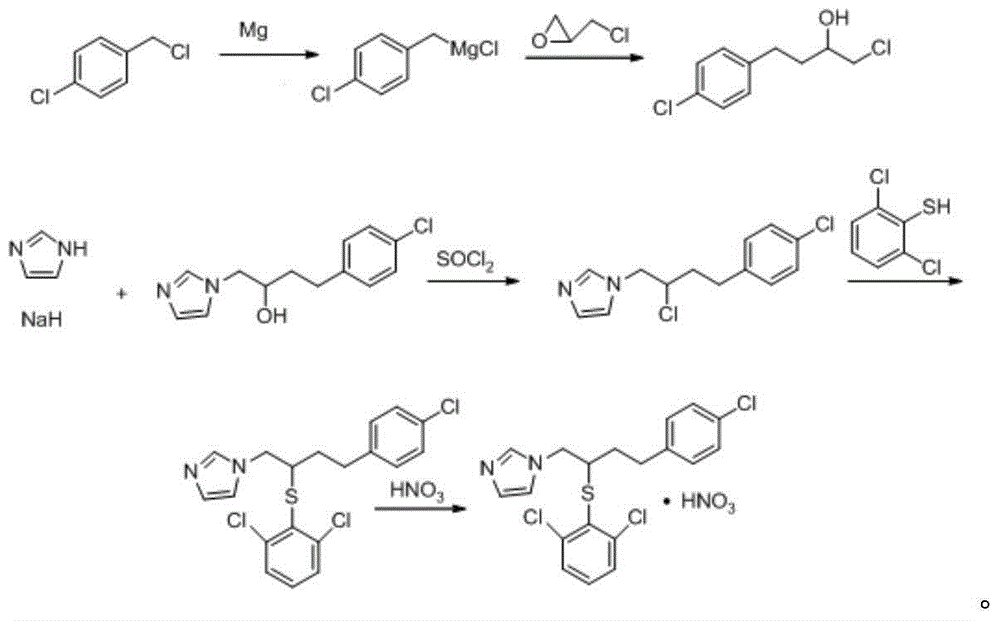

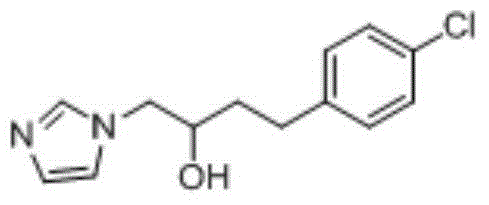

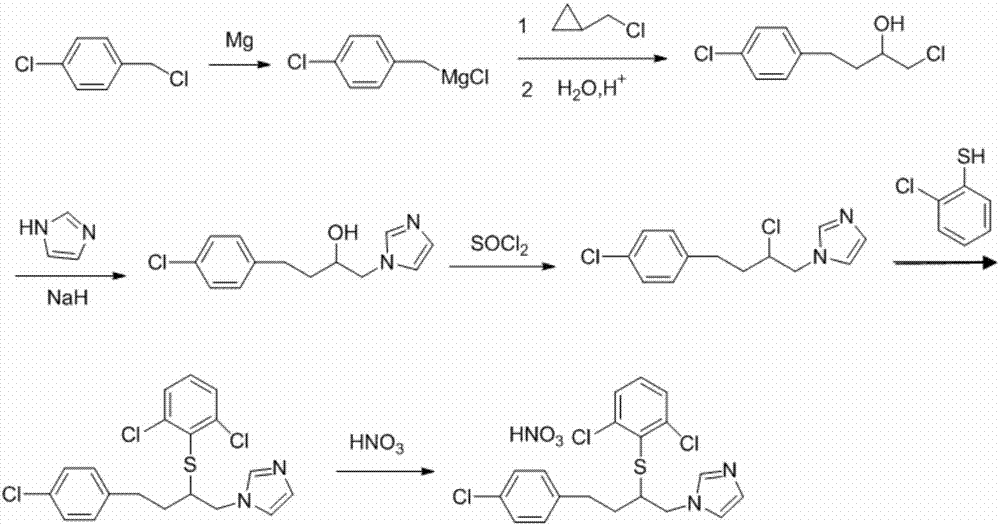

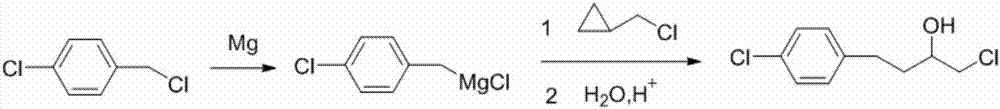

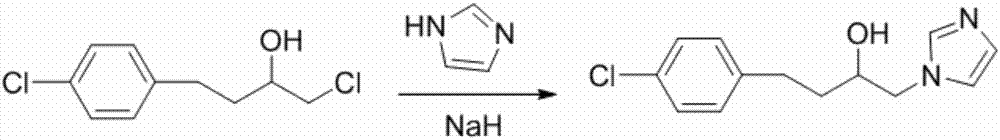

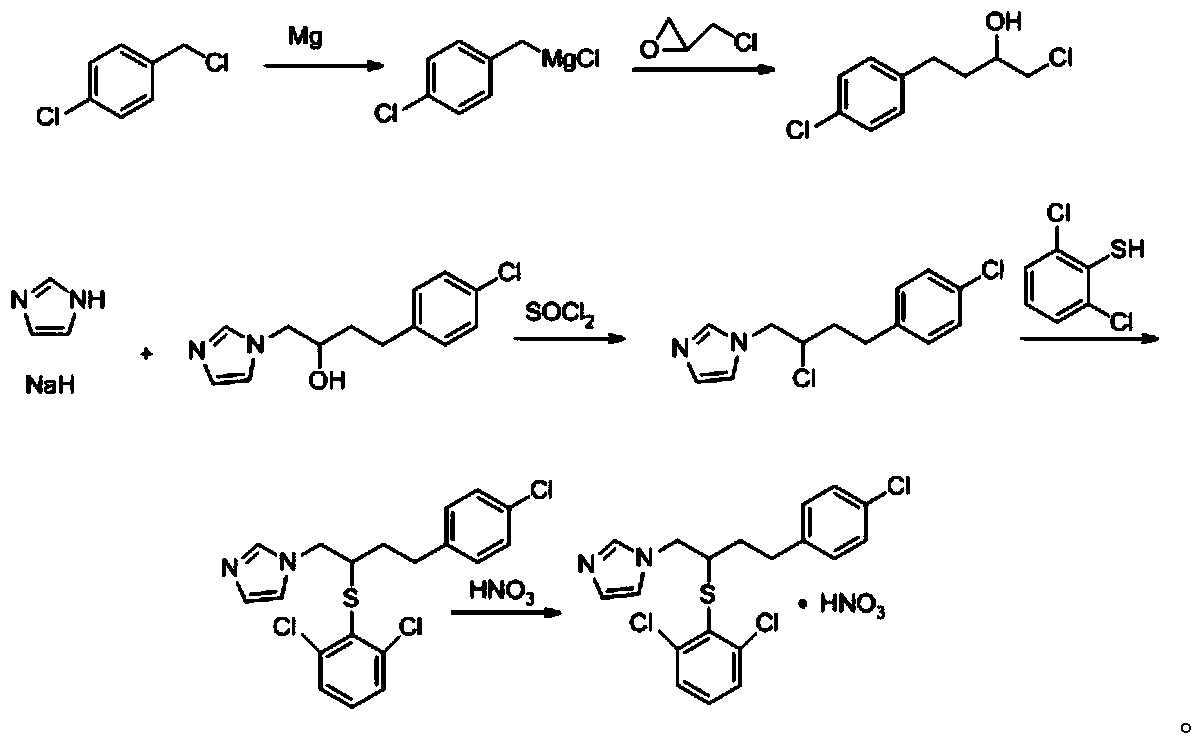

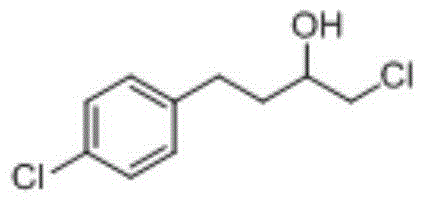

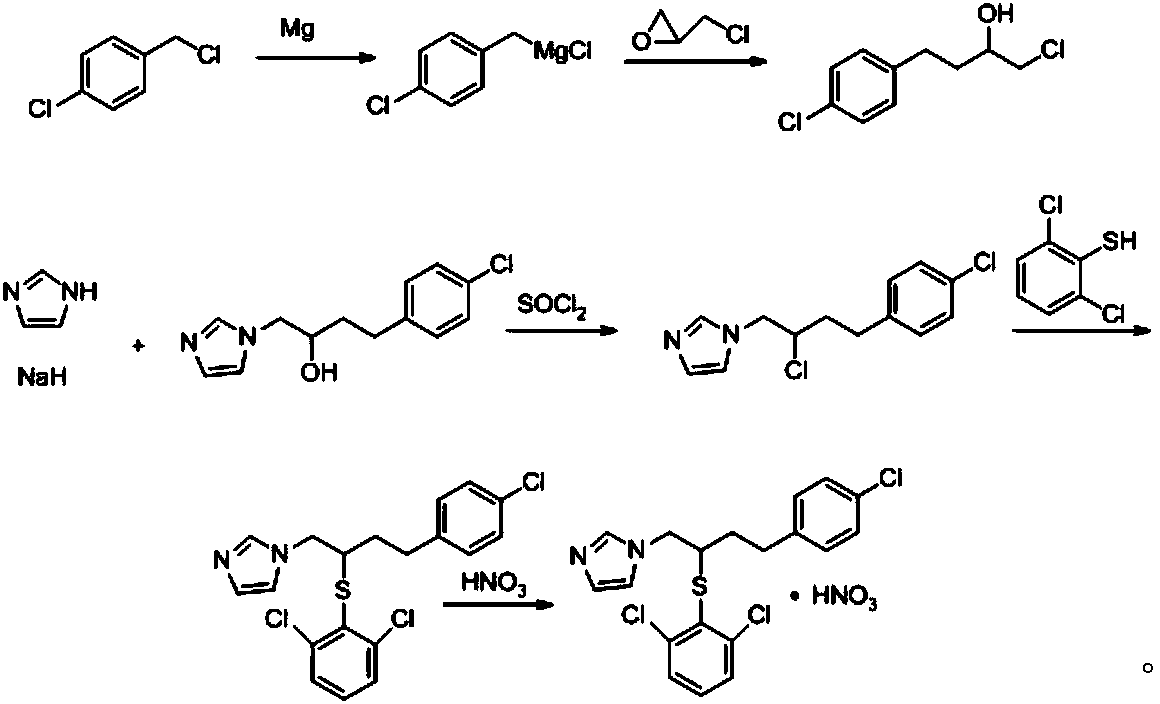

The invention provides a method for industrial production of a butoconazole nitrate intermediate, that is 1-chloro-4-p-chlorophenyl-2-butanol (a compound in formula II). The method of the invention comprises: 1. a Grignard reaction, that is, adopting p-chlorobenzyl chloride as a raw material, and performing a Grignard reaction with magnesium powder in a mixed solvent of methyl tertiary butyl ether and tetrahydrofuran; 2. a condensation reaction, that is, continuing reaction by adding epichlorohydrin to obtain the compound II which is an important intermediate for preparing butoconazole nitrate. According to the method, the raw materials are cheap and easily available, the reaction solvent is safer, and the method is suitable for industrial production.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

Compound prepn for treating women's inflammation

The present invention is compound preparation for treating womení»s inflammation, and belongs to the field of medicine technology. Each 1000 application units of the compound preparation consists of ornidazole 100-1000 g, butoconazole nitrate 10-500 g and policresulen 50-300 g. The compound preparation may be prepared into different forms, including vaginal suppository, vaginal effervescent tablet, vaginal tablet, vaginal gel, etc. The compound preparation has the functions of resisting anaerobic bacteria, resisting protoplasm, resisting mildew and resisting aerobion, and may be used in treating various womení»s infectious diseases, such as bacterial vaginitis, mycotic vaginitis, protozoal vaginitis, non-specific vaginitis, mixed infectious vaginitis, pruritus vulvae, etc.

Owner:山东特瑞林医药科技发展有限公司

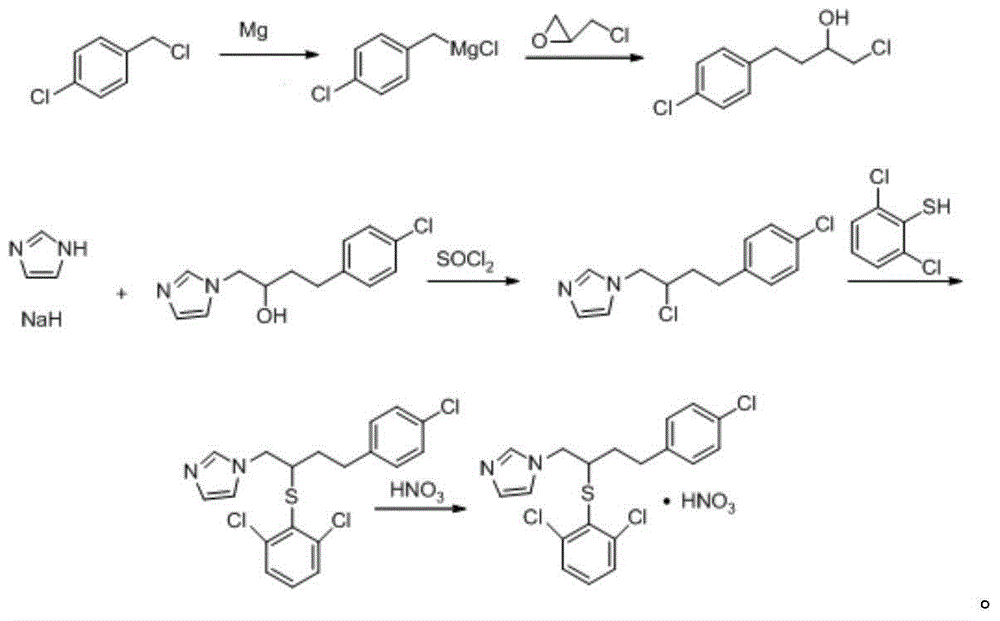

Preparation method of butoconazole

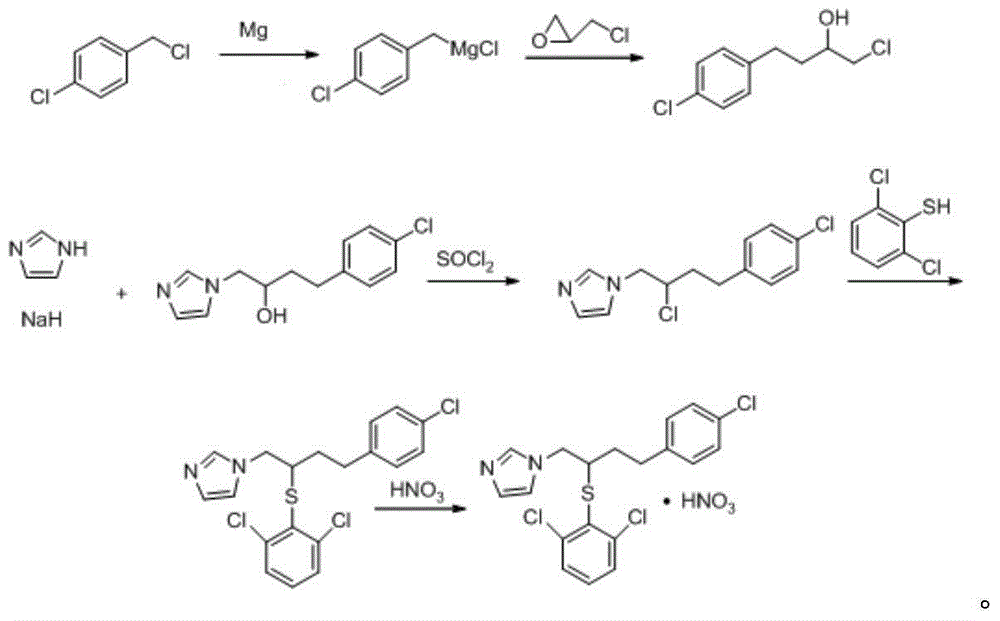

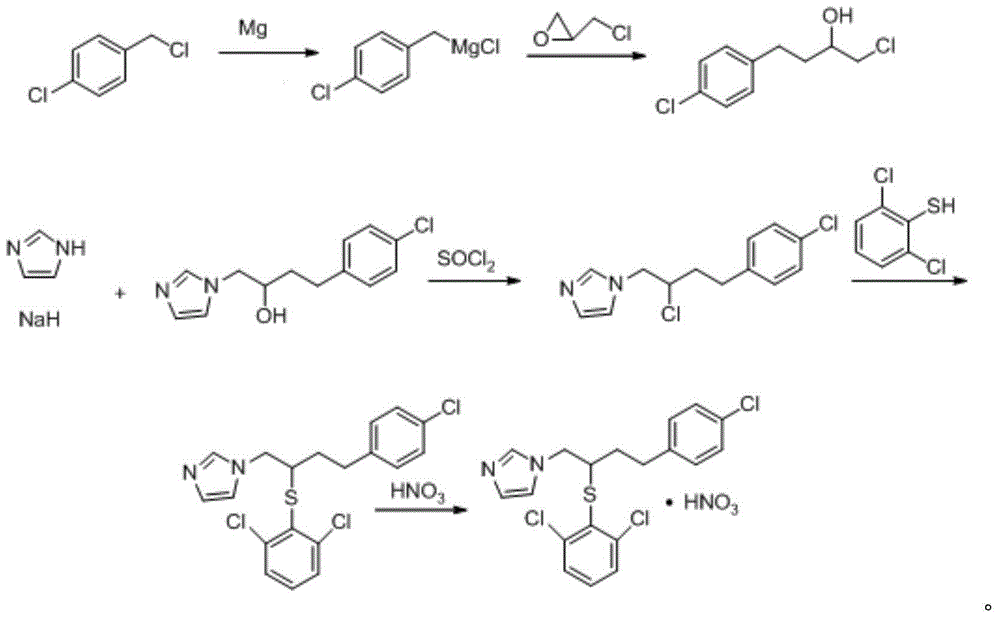

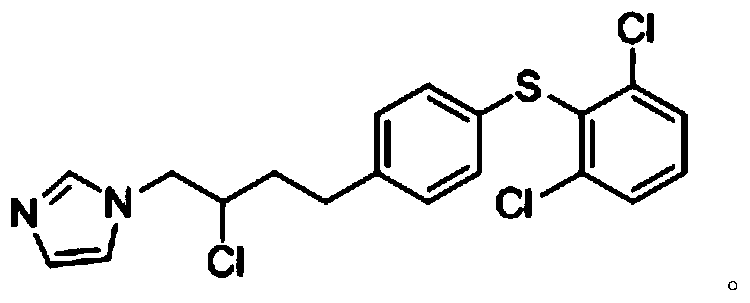

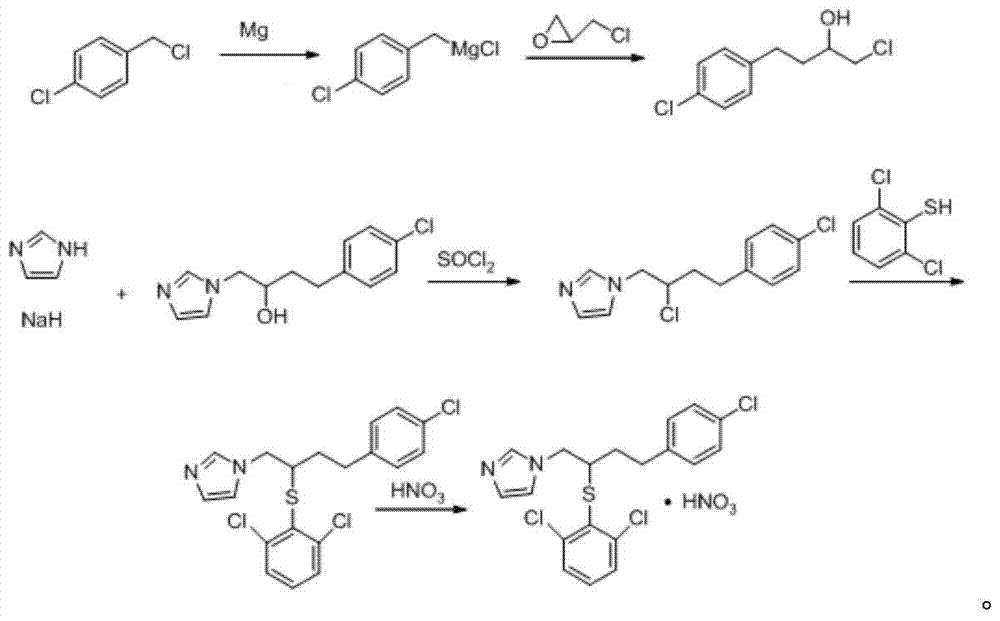

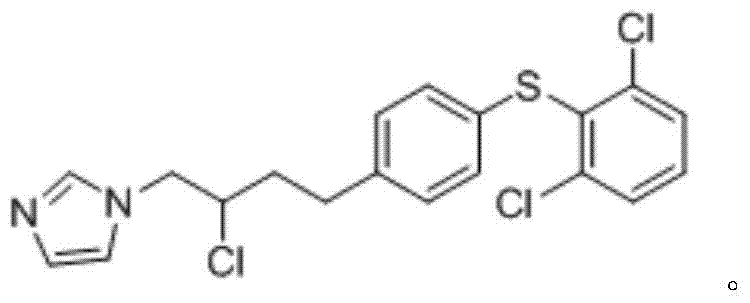

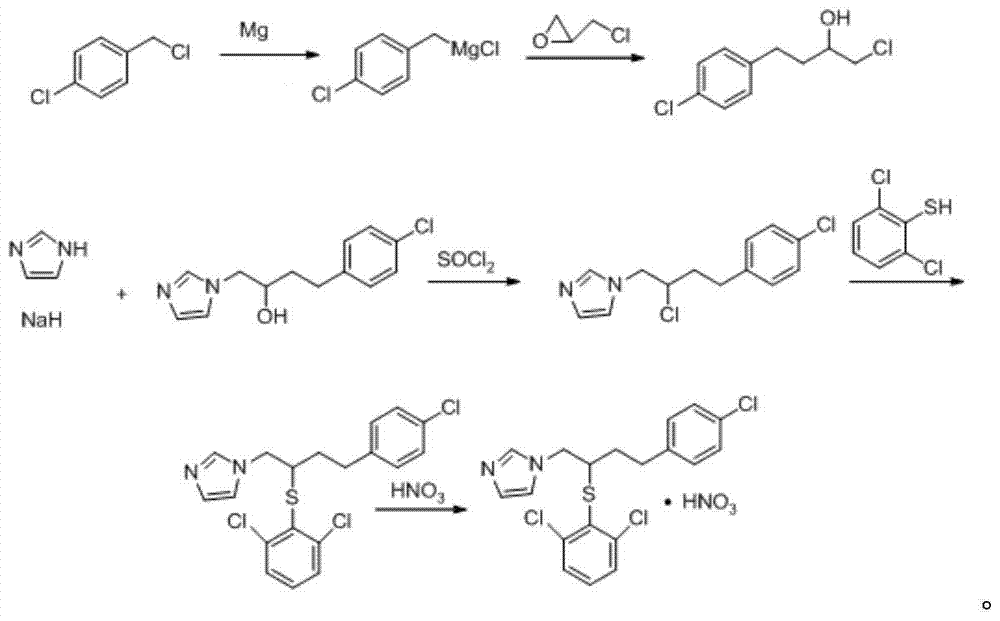

InactiveCN104744371AReduce manufacturing costEfficient infectionOrganic chemistryGrignard reagentButoconazole

The invention relates to a preparation method of butoconazole. The method comprises the following specific steps: converting a raw material p-chlorobenzyl chloride into a Grignard reagent, reacting with chloro epoxypropane to obtain 1-4-chloro-p-chlorophenyl butanol-2, introducing imidazole, converting the hydroxyl into chlorine, introducing 2,6-dichloro thiophenol to obtain butoconazole, and acidifying with nitric acid to obtain butoconazole nitrate. The preparation method of butoconazole is simple in manufacture and low in production cost, and the butoconazole is an antifungal drug highly effective in the infection of Candida albicans and Candida albicans.

Owner:储海燕

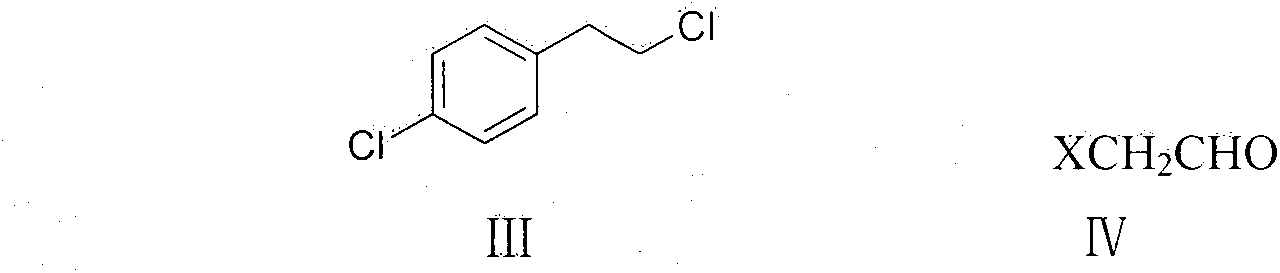

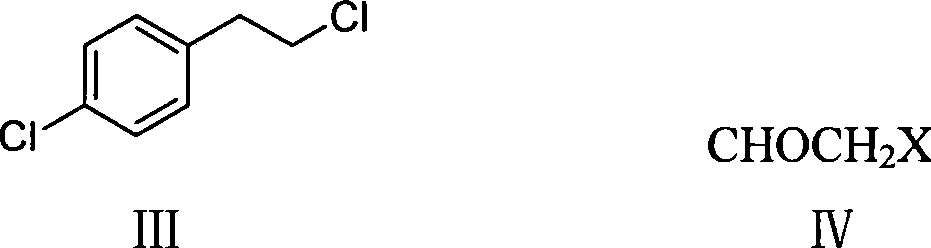

Preparation of butoconazole nitrate intermediate

ActiveCN101328110AThe reaction is easy and controllableEasy to separateOrganic active ingredientsAntimycoticsGrignard reagentButoconazole Nitrate

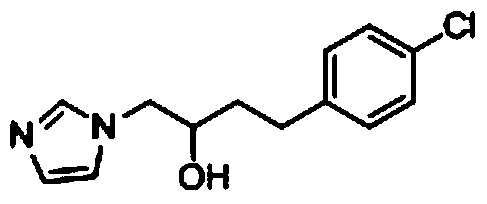

The invention discloses a method for preparing 1-chloro-4-(4-chlorophenyl)-2-tutanol comprising reacting a compound of formula III with magnesium to prepare a grignard reagent at a proper temperature in one or several non protonic solvents, then reacting the grignard reagent with a compound of formula IV. The 1-chloro-4-(4-chlorophenyl)-2-tutanol is an important intermediate for preparing butoconazole nitrate.

Owner:万全万特制药(厦门)有限公司

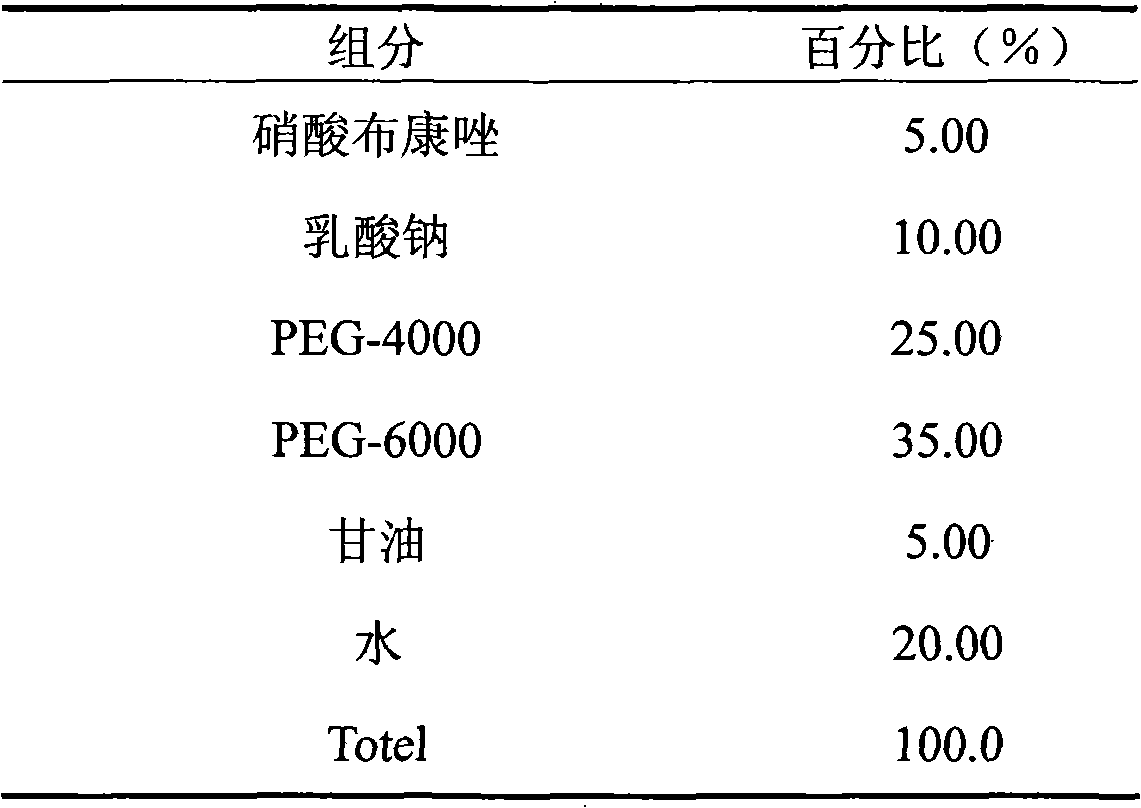

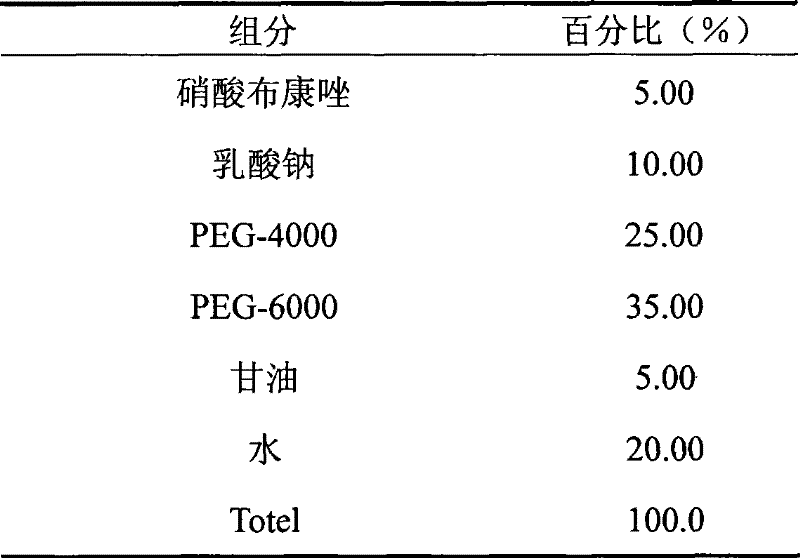

Preparation process of butoconazole nitrate vagina plug and use thereof

InactiveCN101455663ASimple methodImprove stabilityOrganic active ingredientsAntimycoticsCandida vaginitisVaginal Suppository

The invention discloses a preparation method for vaginal suppository having butoconazole nitrate and application therefor. The invention belongs to the field of new technology of drug, relating to a suppository of butoconazole nitrate, pharmaceutical preparation for treating candida vaginitis and preparation method thereof.

Owner:BEIJING HOPE HUGE PHARM SCI

Antibacterial gynecology externally used pharmaceutical combination

ActiveCN101269067AImprove stabilityImprove antibacterial propertiesOrganic active ingredientsAntisepticsPharmacyAdditive ingredient

The invention discloses an external gynecological drug compound which consists of an active ingredient butoconazole nitrate and other drug carriers acceptable in pharmacy. The external gynecological drug compound has the forms of suppositories, vaginal tablets and vaginal effervescent tablets and can be used for treating the fungal infection outside the vagina caused by mycotoruloides.

Owner:万全万特制药(厦门)有限公司

Nitric acid butoconazole cyclodextrin or cyclodextrin derivant clathrate and preparation method as well as application thereof

InactiveCN101181265AGood effectGood water solubilityOrganic active ingredientsAntimycoticsSolubilitySide effect

The invention relates to a butoconazole nitrate cyclodextrin or a cyclodextrin derivative inclusion compound, the preparation method and the usage. The invention uses the cyclodextrin or the cyclodextrin derivative to carry out the inclusion of the butoconazole nitrate, and the weight ratio of the butoconazole nitrate and the cyclodextrin or the cyclodextrin derivative in the inclusion compound is 1: 1 to 300. The inclusion compound can be used in the preparation of transfusion, liquid acupuncture therapy, powder injection, oral liquor, syrup, tablets, pills, capsules, granules, gels, soft capsules, suppositories, aerosols, creams and other various formulations. The water solubility and the stability of the prepared preparations are improved significantly, moreover, the invention has long drug release time, no irritating smell and small side effects, and can be used for mycotic vaginitis and skin fungal infections, and the clinical usage is more safe and effective.

Owner:山东特瑞林医药科技发展有限公司

Butoconazole nitrate suppository used in gynaecology, preparation method and application thereof

InactiveCN101982167AEasy to produceEasy to transportOrganic active ingredientsAntimycoticsGlycerolButoconazole Nitrate

The invention relates to a butoconazole nitrate suppository used in gynaecology, and a preparation method and application thereof. The preparation method has the characteristics of simple process and lower cost and is convenient for medication. The butoconazole nitrate suppository used in gynaecology comprises the following components in parts by weight: 100 parts of butoconazole nitrate, 100-1000 parts of polyoxyl (40) stearate, 100-2000 parts of polyethylene glycol 1000, 1-50 parts of glycerol and 1-100 parts of sodium citrate.

Owner:孙福春

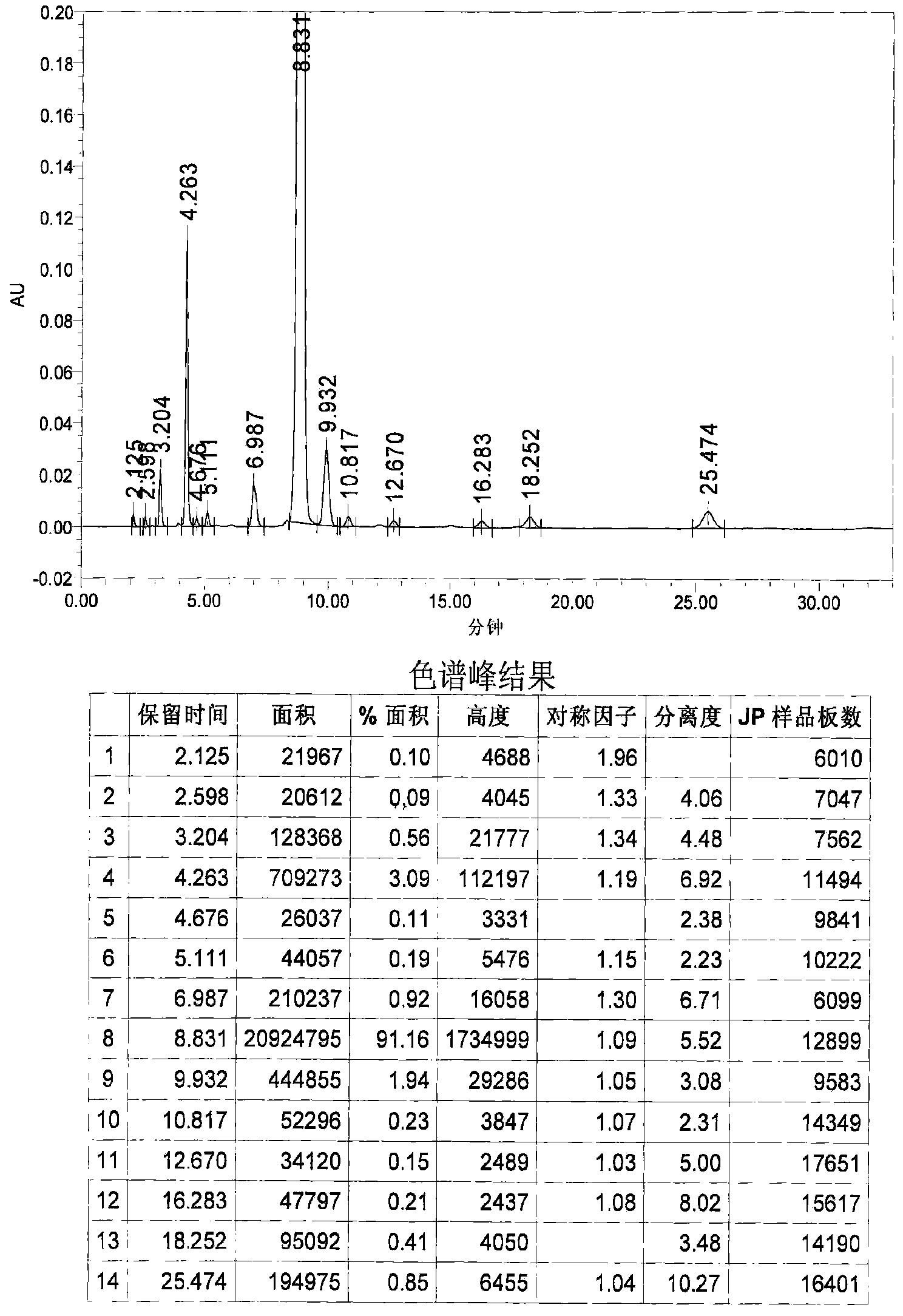

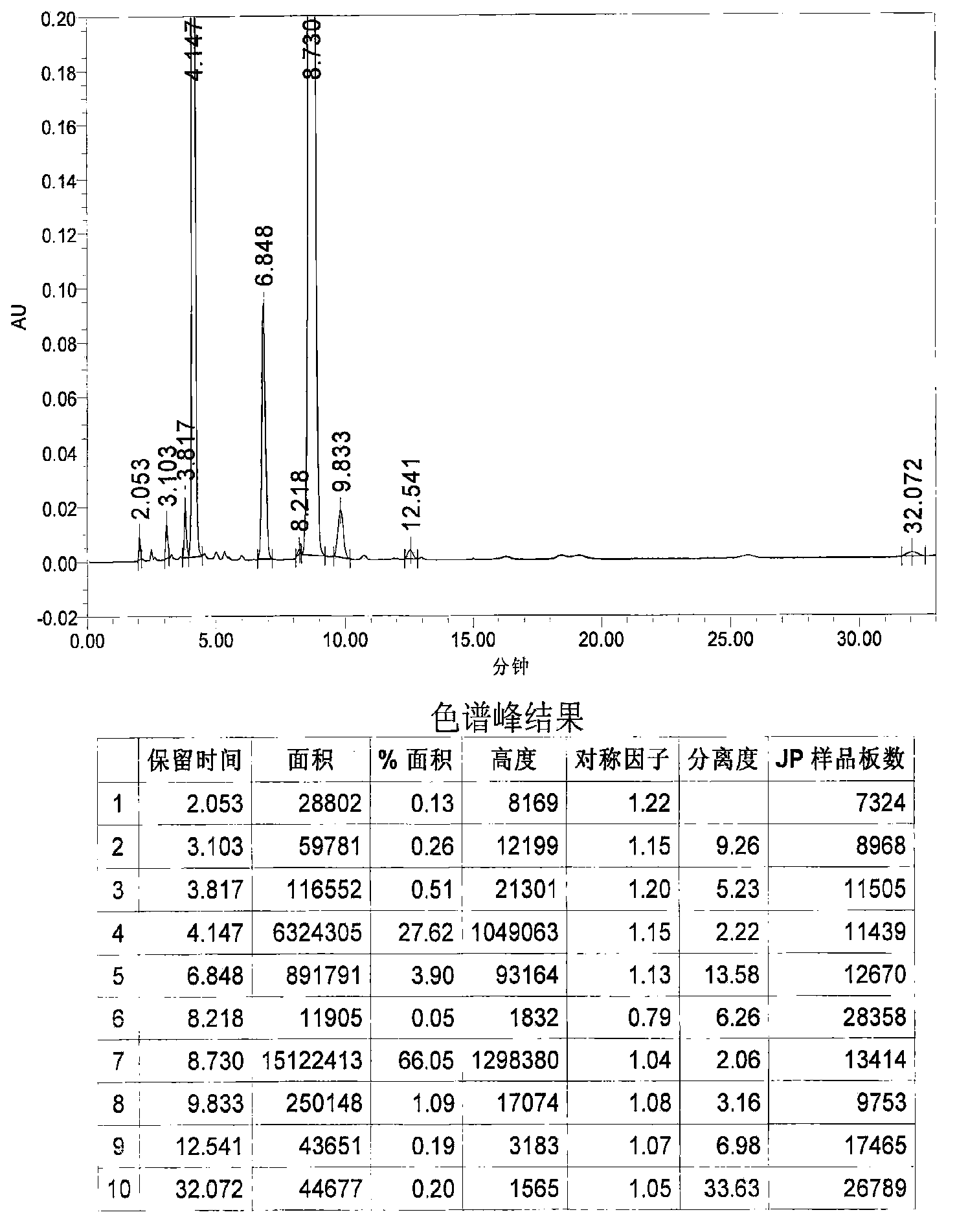

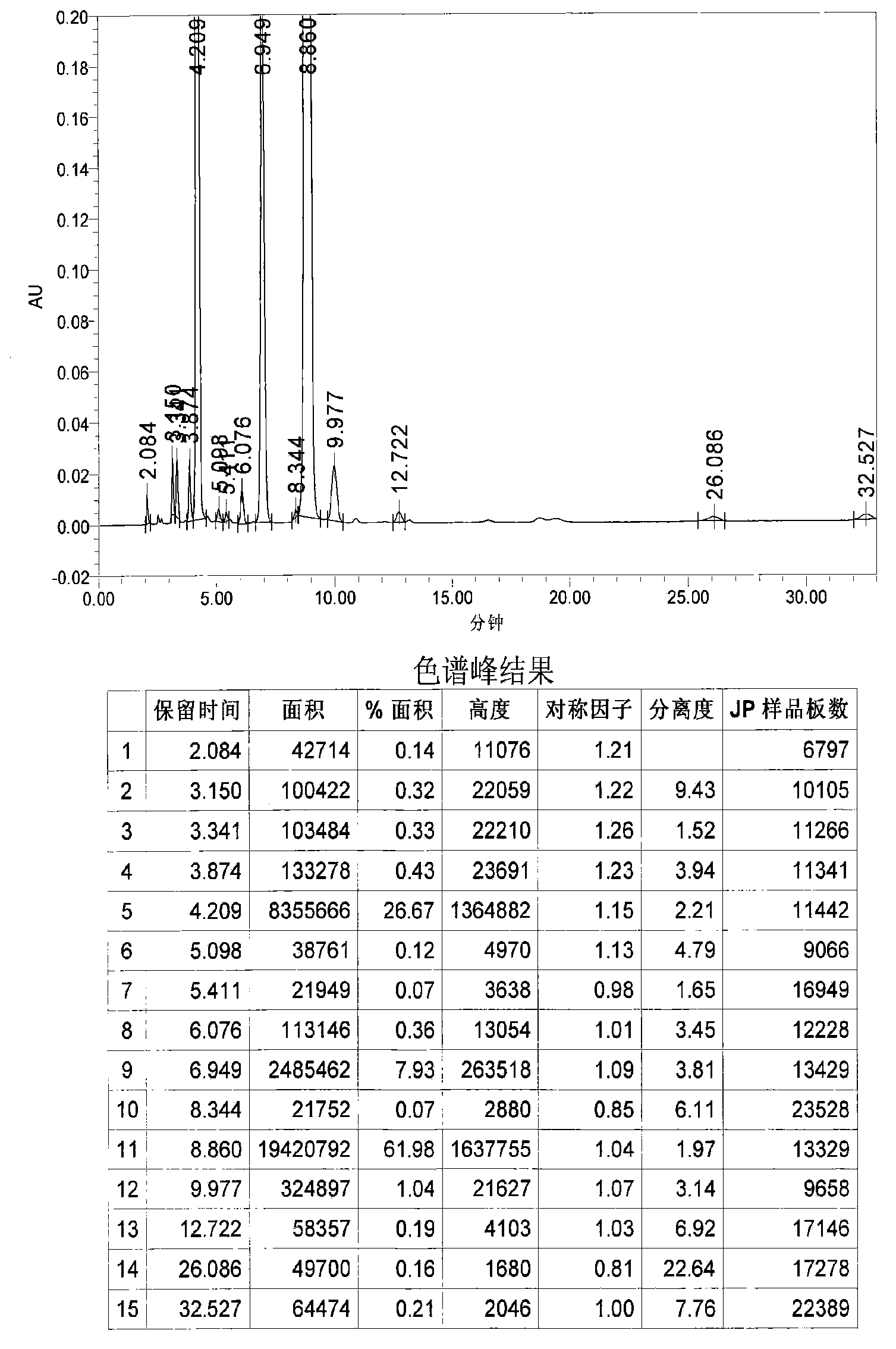

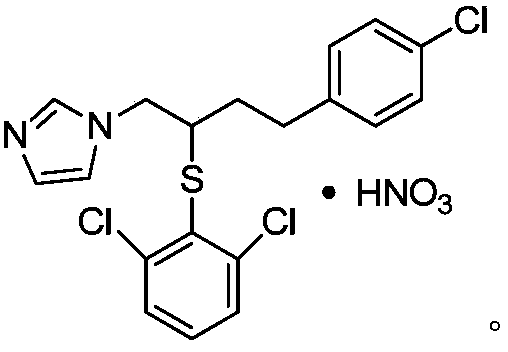

Method for industrially producing butoconazole nitrate

The invention relates to a method for industrially producing butoconazole nitrate. The method comprises the following steps: (1) taking 1-8 parts of 1-(2-chloro-4-(4-chlorphenyl)butyl)-1-hydro-imidazole, 1-8 parts of 2,6-dichlorothiophenol, 1-5 parts of anhydrous potassium carbonate and 30-50 parts of acetone to undergo heating reflux reaction for 4-6 hours, then replenishing 0.1-1 part of anhydrous potassium carbonate, continuously carrying out heating reflux reaction for 5-9 hours, cooling and filtering the reactant and concentrating the filtrate, thus obtaining a concentrate; (2) taking the concentrate obtained in the step (1), adding extract liquor formed by an organic solvent and water, and after full extraction, retaining an organic phase for later use; (3) dropwise adding concentrated nitric acid to the organic phase obtained in the step (2) and carrying out filtration after stopping generating a precipitate; discarding the filtrate and washing and drying a filter cake, thus obtaining butoconazole nitrate. In the method provided by the invention, the conditions and parameters in the synthetic process are comprehensively and preferentially selected, and the impurities which are likely to be introduced in the production process are effectively controlled, thus increasing the production efficiency and the purity and yield of the product. Therefore, the method is more suitable for large-scale industrial production.

Owner:ZHUZHOU QIANJIN PHARMA

Method for industrial process production of butoconazole nitrate

The invention relates to a method for industrial process production of butoconazole nitrate. The method comprises the step that an intermediate product 1-chlorine-4-(4-chlorphenyl)-2-butanol, an intermediate product 1-(2-hydroxy-4-(4-chlorphenyl)butyl)-1 hydrogen-imidazole, an intermediate product 1-(2-chlorine-4-(4-chlorphenyl)butyl)-1 hydrogen-imidazole, a butoconazole nitrate crude product and a butoconazole nitrate finished product are sequentially synthesized. According to the method, conditions and parameters in the synthesizing process are comprehensively optimized, impurities likely to be introduced in the production process are effectively controlled, the production efficiency is improved, the purity and yield of the products are increased, and the method is suitable for industrial production.

Owner:ZHUZHOU QIANJIN PHARMA

Method for industrial production of butoconazole nitrate

ActiveCN105218456AReduce generationEasy to refine and purifyOrganic chemistryButoconazoleDiethyl ether

The invention relates to a method for industrial production of butoconazole nitrate. The method comprises the following steps that firstly, 1-(2-chlorine-4-(4-chlorphenyl)butyl)-1 hydrogen-imidazole is mixed with 2,6-dichoribenzene thiophenol, anhydrous potassium carbonate and acetone, a heating reflux reaction is carried out, anhydrous potassium carbonate is supplemented, the heating reflux reaction is continued, cooling and filtering are carried out, and concentrate is obtained after filter liquor is concentrated; secondly, extract liquor containing diethyl ether and water is added in the concentrate, after sufficient extraction is carried out, a water phase is discarded, and an organic phase is reserved; thirdly, concentrated nitric acid is dripped into the obtained organic phase on ice bath and stirring conditions, and filtering is carried out when sediment stops being generated; the filter liquor is discarded, a filter cake is washed with diethyl ether and acetone in sequence, and the metric acid butoconazole is obtained after the filter cake is dried. According to the method, conditions and parameters in the synthesizing process are comprehensively optimized, impurities likely to be introduced in the production process are effectively controlled, the production efficiency is improved, the purity and yield of products are increased, and the method is more suitable for large-scale industrial production.

Owner:ZHUZHOU QIANJIN PHARMA

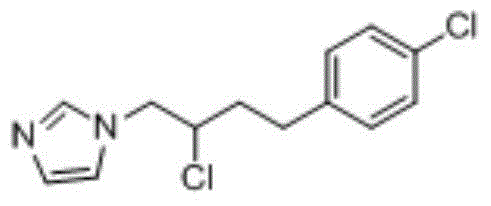

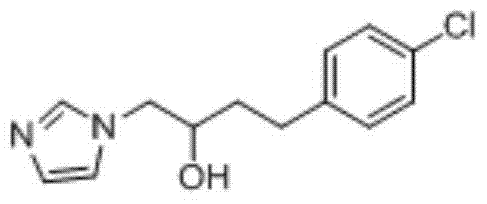

A kind of method of industrialized synthesis butoconazole nitrate intermediate

The invention relates to a method for industrially producing a butoconazole nitrate intermediate 1-(2-hydroxy-4-(4-chlorphenyl)butyl)-1-hydro-imidazole. The method comprises the following steps: (1) taking a sodium hydride DMF (dimethyl formamide) solution, slowly dropwise adding an imidazole DMF solution under the condition of an ice bath and heating and stirring the solutions to react; after cooling, slowly adding 1-chloro-4-(4-chlorphenyl)-2-butanol, heating and stirring the materials to react and cooling to obtain a reaction liquid; and (2) taking the reaction liquid obtained in the step (1), mixing the reaction liquid with ice water under the condition of stirring, filtering the mixture after stopping separating out a precipitate, washing a filter cake and drying and re-crystallizing the filter cake, thus obtaining the butoconazole nitrate intermediate. In the method provided by the invention, the conditions and parameters in the synthetic process are comprehensively and preferentially selected, thus increasing the purity and yield of the product. Therefore, the method is more suitable for large-scale industrial production.

Owner:ZHUZHOU QIANJIN PHARMA

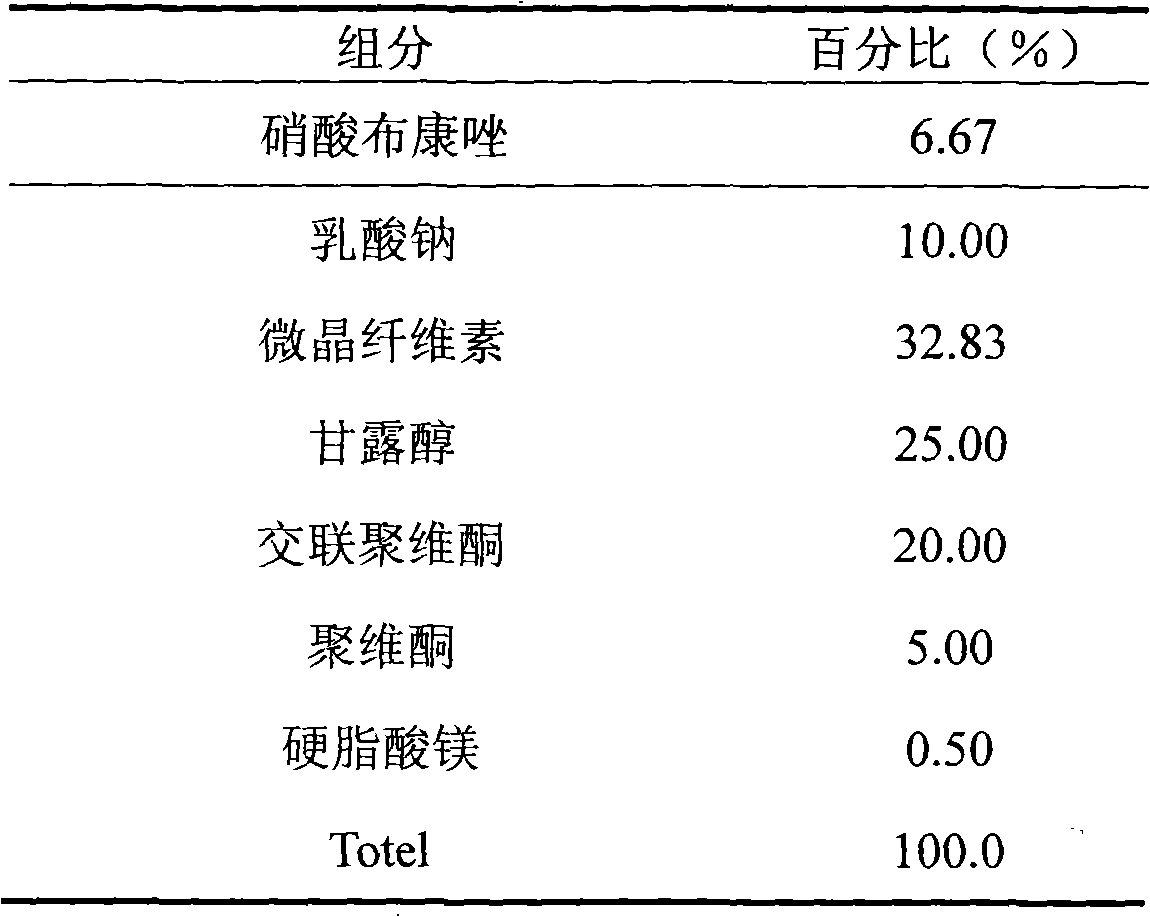

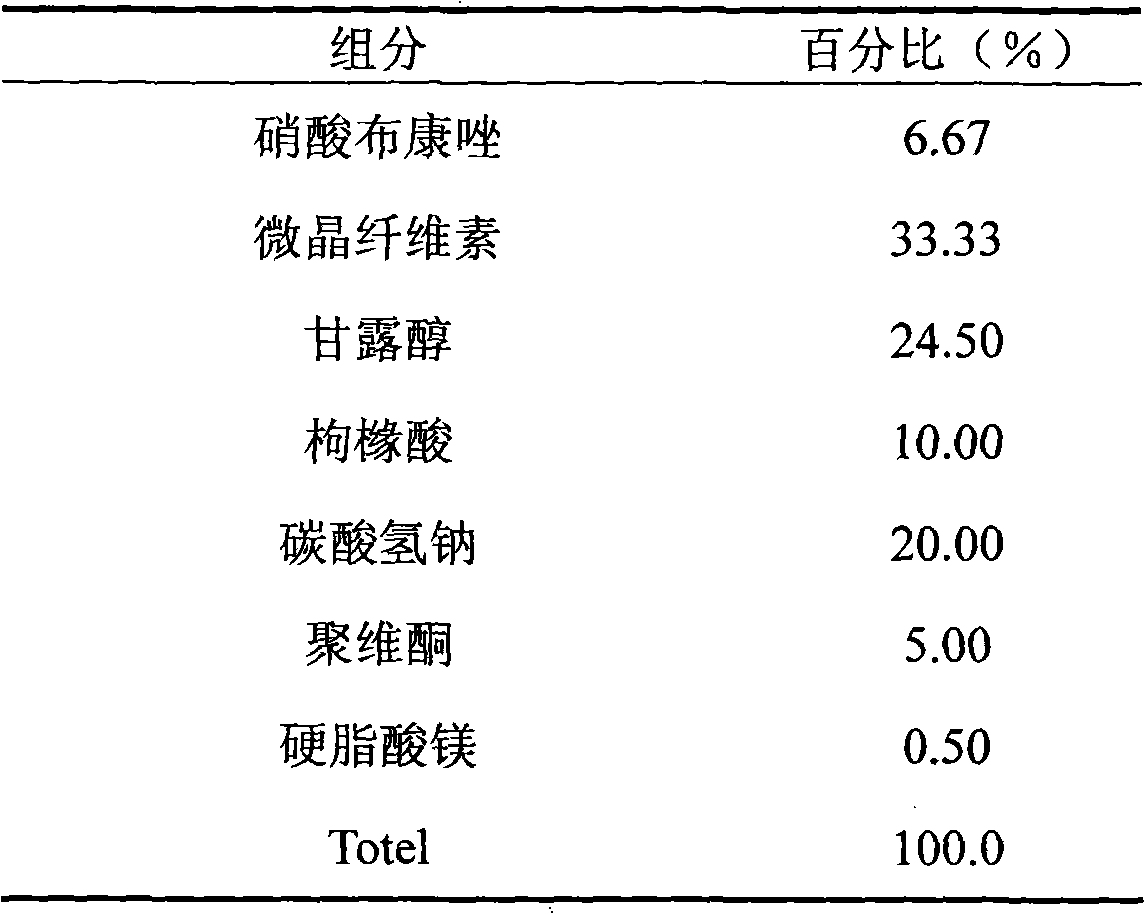

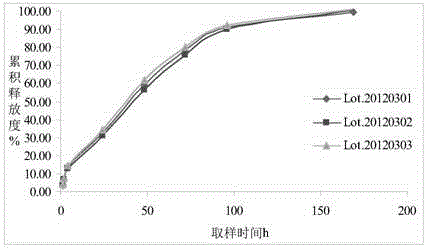

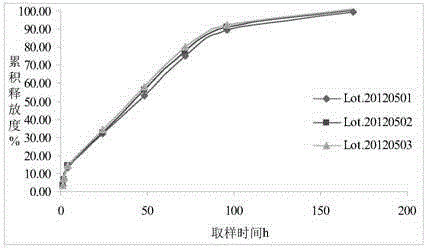

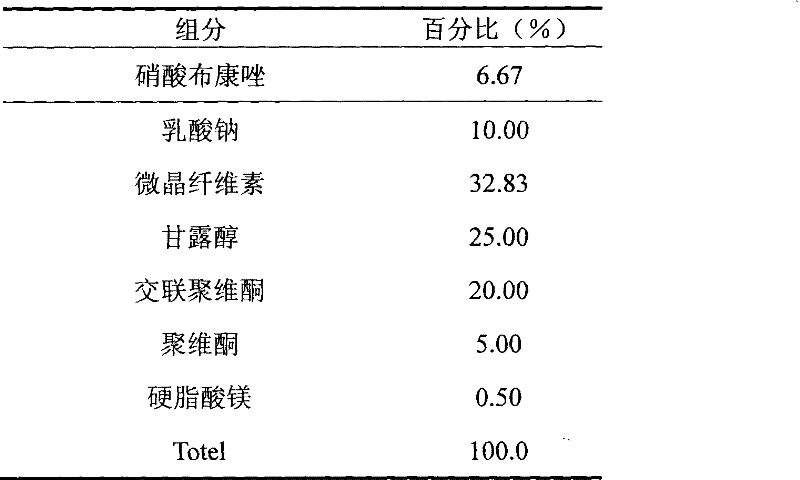

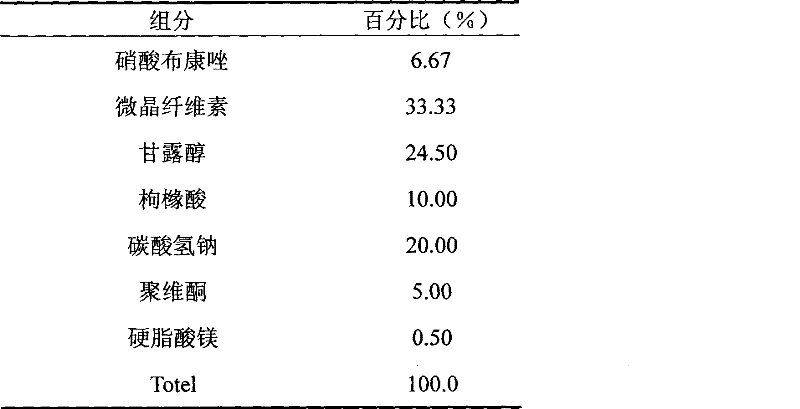

Slow release butoconazole nitrate directly compressed tablet and preparation method thereof

The invention discloses a slow release butoconazole nitrate directly compressed tablet and a preparation method thereof and belongs to the technical field of medicines. The slow release butoconazole nitrate directly compressed tablet comprises a, an active component butoconazole nitrate, b, a single or compound directly compressed slow release material and c, a hydrophilic carrier material. The preparation method comprises blending the butoconazole nitrate and the hydrophilic carrier material, grinding the mixture, sieving the mixture, blending the mixture, the single or compound directly compressed slow release material, any pharmaceutically acceptable diluents and a flow aid, adding a lubricant into the mixture, carrying out mixing and direct tabletting and carrying out coating or not.

Owner:DIHON PHARMA GROUP

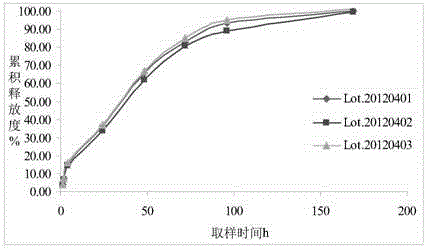

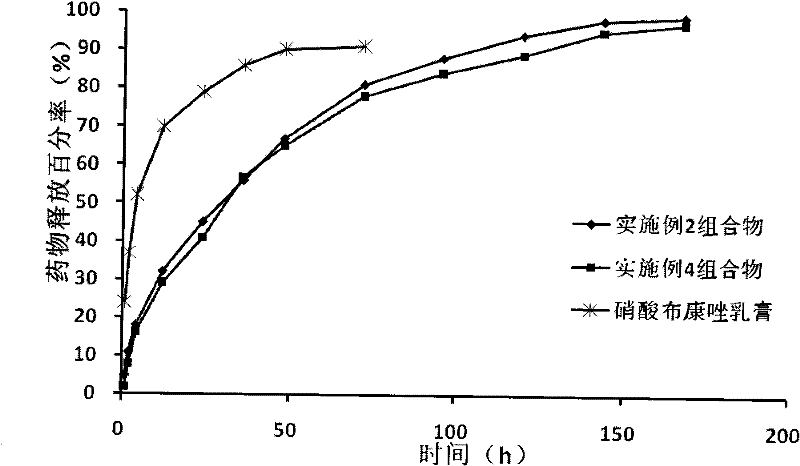

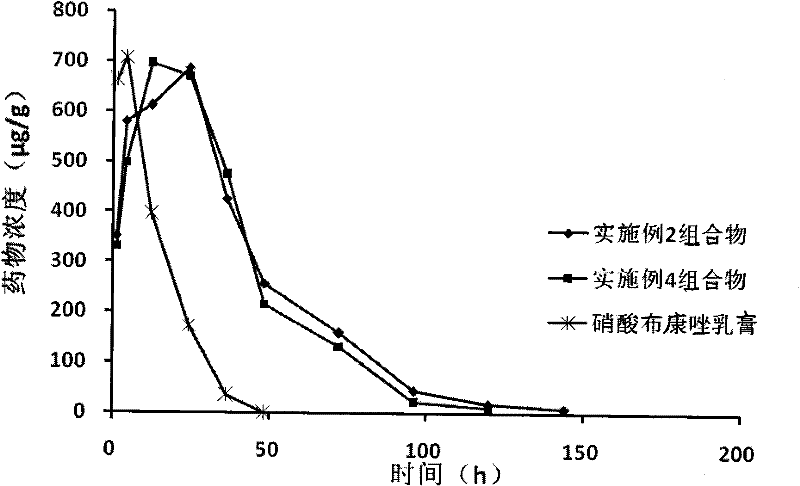

Medicinal composition for vagina

ActiveCN101703504BImprove liquidityEasy to spreadOrganic active ingredientsAntimycoticsButoconazole NitrateHypromellose

The invention relates to a medicinal composition for vagina. The composition comprises butoconazole nitrate, poloxamer, hydroxypropyl methylcellulose, Carbomer and other additives. The composition has the characteristics of good vagina mucosa adhesion and long-acting slow release, and in vivo and in vitro experiment results prove that the composition can continuously release the medicament for more than 72 hours.

Owner:JIANGXI ANGTAI PHARMA

A kind of method of industrialized production butoconazole nitrate intermediate

ActiveCN105198814BThe next steps are smoothThe next steps went smoothlyOrganic chemistryChlorobenzeneButoconazole Nitrate

The invention relates to a method for industrially producing a butoconazole nitrate intermediate 1-(2-chloro-4-(4-chlorphenyl)butyl)-1-hydro-imidazole. The method comprises the following steps: (1) taking 1-(2-hydroxy-4-(4-chlorphenyl)butyl)-1-hydro-imidazole and thionyl chloride as raw materials to undergo heating reflux in dichloromethane, and after full reaction, cooling the reactant, thus obtaining a reaction liquid; and (2) slowly adding cold water and anhydrous sodium carbonate to the reaction liquid obtained in the step (1) in sequence, carrying out suction filtration, discarding the solid, concentrating the liquid and drying the concentrate, thus obtaining the butoconazole nitrate intermediate. In the method provided by the invention, the conditions and parameters in the synthetic process are comprehensively and preferentially selected, thus increasing the purity and yield of the product. Therefore, the method is more suitable for large-scale industrial production.

Owner:ZHUZHOU QIANJIN PHARMA

Antibacterial gynecology externally used pharmaceutical combination

The invention discloses an external gynecological drug compound which consists of an active ingredient butoconazole nitrate and other drug carriers acceptable in pharmacy. The external gynecological drug compound has the forms of suppositories, vaginal tablets and vaginal effervescent tablets and can be used for treating the fungal infection outside the vagina caused by mycotoruloides.

Owner:万全万特制药(厦门)有限公司

Method for industrially producing butoconazole nitrate intermediate

ActiveCN105198814AThe next steps are smoothThe next steps went smoothlyOrganic chemistryFiltrationEthyl Chloride

The invention relates to a method for industrially producing a butoconazole nitrate intermediate 1-(2-chloro-4-(4-chlorphenyl)butyl)-1-hydro-imidazole. The method comprises the following steps: (1) taking 1-(2-hydroxy-4-(4-chlorphenyl)butyl)-1-hydro-imidazole and thionyl chloride as raw materials to undergo heating reflux in dichloromethane, and after full reaction, cooling the reactant, thus obtaining a reaction liquid; and (2) slowly adding cold water and anhydrous sodium carbonate to the reaction liquid obtained in the step (1) in sequence, carrying out suction filtration, discarding the solid, concentrating the liquid and drying the concentrate, thus obtaining the butoconazole nitrate intermediate. In the method provided by the invention, the conditions and parameters in the synthetic process are comprehensively and preferentially selected, thus increasing the purity and yield of the product. Therefore, the method is more suitable for large-scale industrial production.

Owner:ZHUZHOU QIANJIN PHARMA

Method for industrially synthesizing butoconazole nitrate intermediate

The invention relates to a method for industrially producing a butoconazole nitrate intermediate 1-(2-hydroxy-4-(4-chlorphenyl)butyl)-1-hydro-imidazole. The method comprises the following steps: (1) taking a sodium hydride DMF (dimethyl formamide) solution, slowly dropwise adding an imidazole DMF solution under the condition of an ice bath and heating and stirring the solutions to react; after cooling, slowly adding 1-chloro-4-(4-chlorphenyl)-2-butanol, heating and stirring the materials to react and cooling to obtain a reaction liquid; and (2) taking the reaction liquid obtained in the step (1), mixing the reaction liquid with ice water under the condition of stirring, filtering the mixture after stopping separating out a precipitate, washing a filter cake and drying and re-crystallizing the filter cake, thus obtaining the butoconazole nitrate intermediate. In the method provided by the invention, the conditions and parameters in the synthetic process are comprehensively and preferentially selected, thus increasing the purity and yield of the product. Therefore, the method is more suitable for large-scale industrial production.

Owner:ZHUZHOU QIANJIN PHARMA

Method for industrially synthesizing butoconazole nitrate intermediate

The invention relates to a method for industrially synthesizing a butoconazole nitrate intermediate. The method comprises steps as follows: (1), imidazole and sodium hydride are taken as raw materials, are heated and stirred in a DMF (dimethyl formamide) solution and are cooled after sufficient reaction, 1-chlorine-4-(4-chlorphenyl)-2-butanol is slowly dropwise added, the mixture is heated, stirred and cooled after sufficient reaction, and a reaction liquid is obtained; (2), n-hexane and ice water are sequentially added to the reaction liquid obtained in the step (1), sufficiently stirred and filtered after sediment separation stops, a filter cake is washed, centrifugally dried and recrystallized with ethyl acetate and activated carbon, and the butoconazole nitrate intermediate is obtained. According to the provided method, conditions and parameters in the synthesis process are comprehensively and preferentially selected, the purity and yield of products are improved, and the method is more suitable for large-scale industrial production.

Owner:ZHUZHOU QIANJIN PHARMA

Preparation method of butoconazole nitrate

The invention discloses a preparation method of butoconazole nitrate. The preparation method comprises the following steps: with 4-chlorobenzyl chloride as a starting raw material, synthesizing 1-chloro-4-(4-chlorophenyl)-2-butanol, then synthesizing 1-(4-(4-chlorophenyl)-2-hydroxy-butyl) imidazole, then synthesizing 1-(4-(4-chlorophenyl)-2-chloro-butyl) imidazole, adding the 1-(4-(4-chlorophenyl)-2-chloro-butyl) imidazole, 2, 6-dichlorobenzenethiol and potassium carbonate into acetone, heating for refluxing, adding water and ethyl acetate after the completion of a reaction, performing liquid separation, sequentially washing an ethyl acetate phase by using saturated potassium carbonate and saturated salt water, drying by using anhydrous magnesium sulfate, removing magnesium sulfate, dropwise adding nitric acid with the concentration of 65% in an ice bath until no precipitate is produced, filtering for collecting solid, and recrystallizing by using absolute ethanol to obtain white crystals, namely the butoconazole nitrate. By the preparation method of the butoconazole nitrate, the process is simple, the yield is high, the cost is low, and the purity of the obtained product is high.

Owner:JIANGXI YONGTONG TECH

A kind of method of industrialized production butoconazole nitrate

The invention relates to a method for producing butoconazole nitrate. The method comprises the following steps: (1) taking 1-(2-chloro-4-(4-chlorphenyl)butyl)-1-hydro-imidazole, 2,6-dichlorothiophenol and anhydrous potassium carbonate as raw materials to undergo heating reflux in acetone, after full reaction, cooling and filtering the reactant and concentrating the filtrate, thus obtaining a concentrate; (2) taking the concentrate obtained in the step (1) and adding extract liquor which comprises diethyl ether and water in a weight ratio of (2-3) to (1-2); after full extraction, discarding a water phase and retaining an organic phase for later use; (3) dropwise adding concentrated nitric acid to the organic phase obtained in the step (2) and carrying out filtration after stopping generating a precipitate; discarding the filtrate and washing and drying a filter cake, thus obtaining butoconazole nitrate. In the method provided by the invention, the conditions and parameters in the synthetic process are comprehensively and preferentially selected, and the impurities which are likely to be introduced in the production process are effectively controlled, thus increasing the production efficiency and the purity and yield of the product. Therefore, the method is more suitable for large-scale industrial production.

Owner:ZHUZHOU QIANJIN PHARMA

A kind of method of industrialized production butoconazole nitrate

Owner:ZHUZHOU QIANJIN PHARMA

Method for industrially producing butoconazole nitrate intermediate

InactiveCN105198708AProcess stabilityHigh yieldOrganic compound preparationHydroxy compound preparationGrignard reagentEthyl Chloride

Owner:ZHUZHOU QIANJIN PHARMA

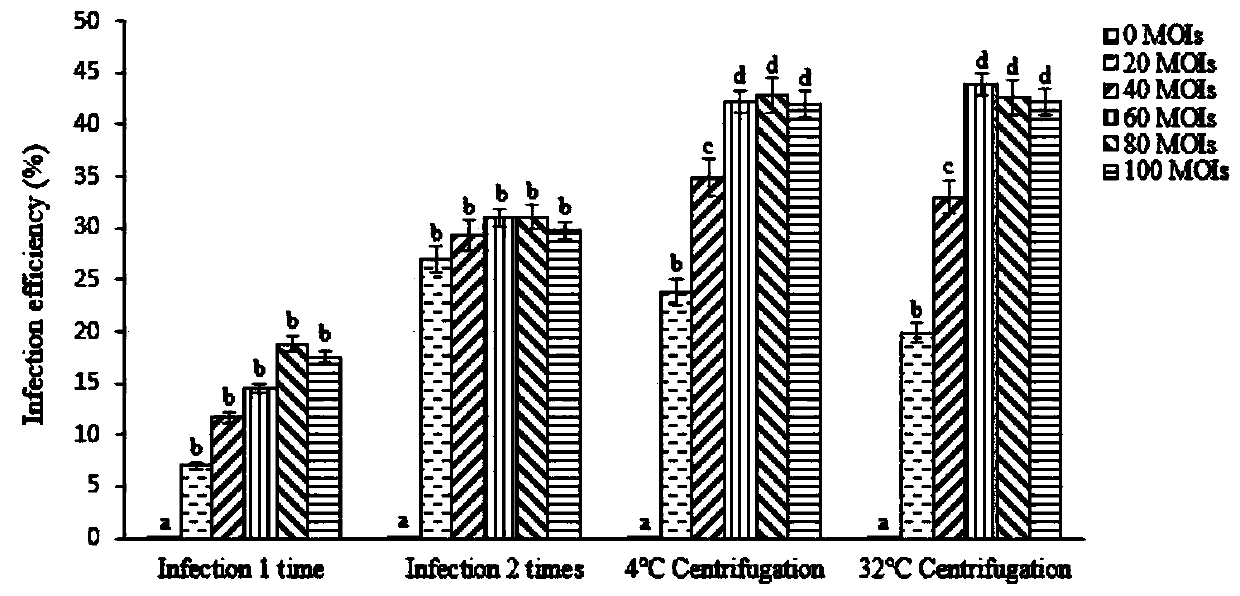

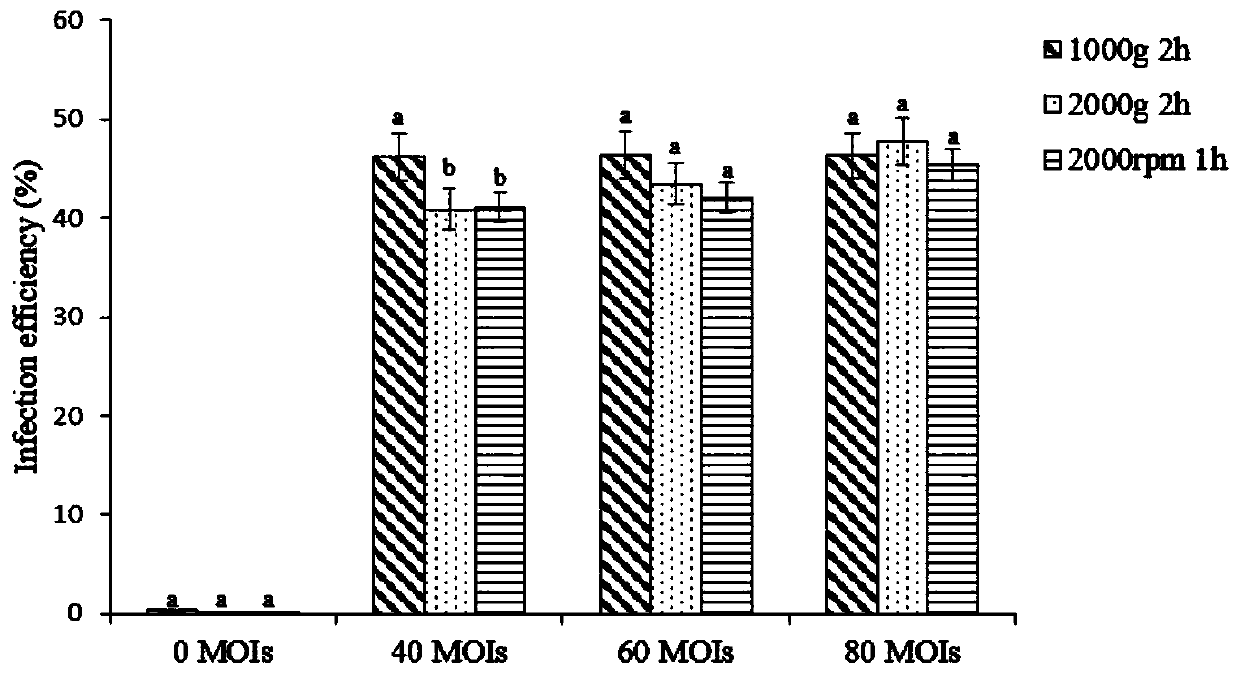

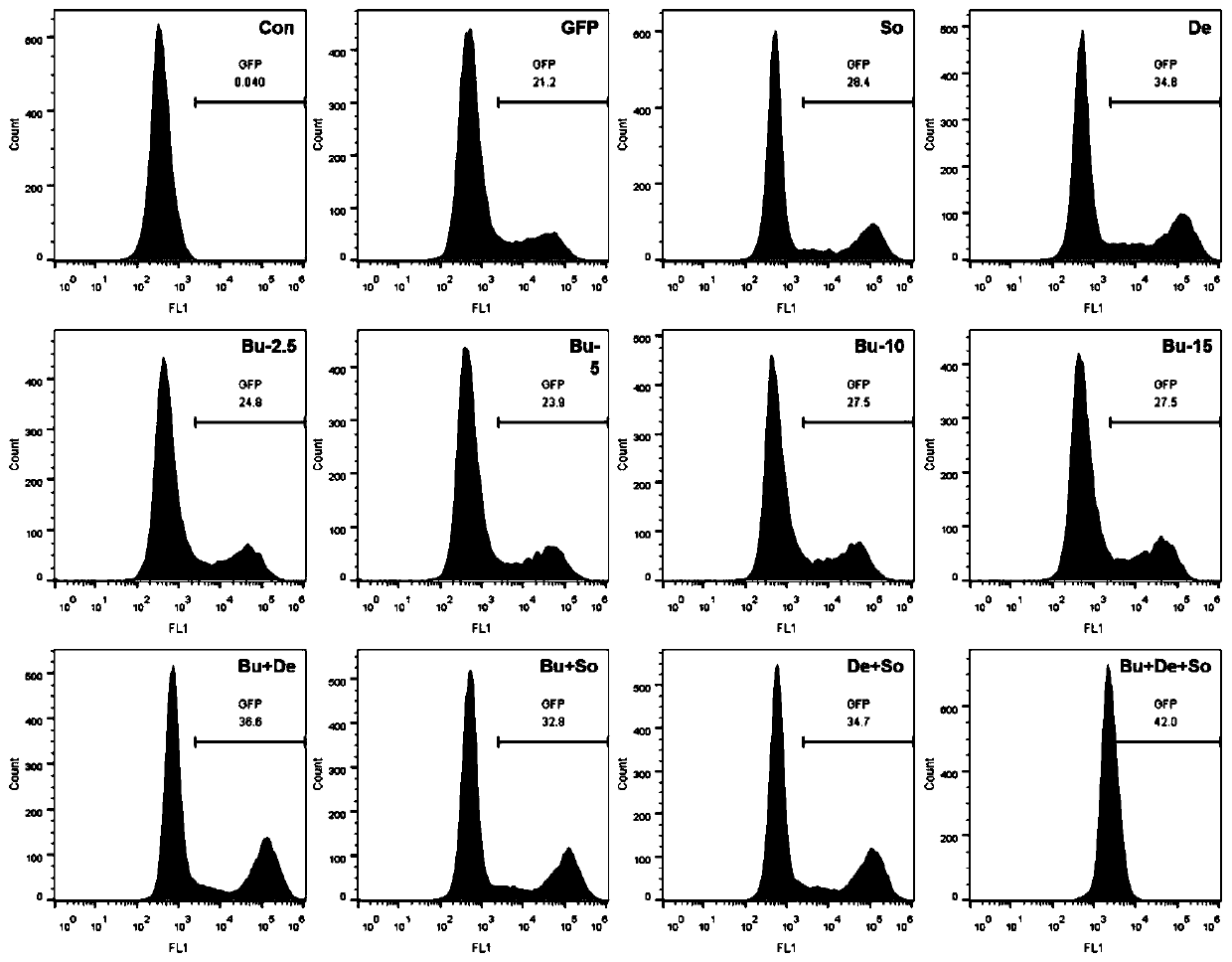

Reagent for cell infection by viruses and application of reagent

ActiveCN110218742AProliferative capacity is not affectedUnaffected lethalityGenetically modified cellsBlood/immune system cellsButoconazole NitrateT cell

The invention discloses a reagent for cell infection by viruses and application of the reagent, and belongs to the technical field of gene engineering. The reagent for cell infection by the viruses comprises two or three of dinconazole nitrate, decitabine and sodium butyrate. By utilizing the reagent, the efficiency of infecting passage T cells by the lentiviruses can reach 80% or above, and is far higher than that of existing methods. Meanwhile, a carrier of CAR-T is adopted, the proliferation capability of CAR-T cells obtained by means of the technology is not influenced, and the killing capability on tumors with specificity is not influenced either.

Owner:北京华奥玄德生物医药科技有限公司

Preparation of butoconazole nitrate intermediate

ActiveCN101328110BThe reaction is easy and controllableEasy to separateOrganic active ingredientsAntimycoticsGrignard reagentButoconazole Nitrate

The invention discloses a method for preparing 1-chloro-4-(4-chlorophenyl)-2-tutanol comprising reacting a compound of formula III with magnesium to prepare a grignard reagent at a proper temperature in one or several non protonic solvents, then reacting the grignard reagent with a compound of formula IV. The 1-chloro-4-(4-chlorophenyl)-2-tutanol is an important intermediate for preparing butoconazole nitrate.

Owner:万全万特制药(厦门)有限公司

A kind of preparation method of the butoconazole nitrate intermediate suitable for industrialized production

ActiveCN103880596BLow costImprove securityPreparation by OH and halogen introductionMagnesium organic compoundsSec-ButanolButoconazole Nitrate

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

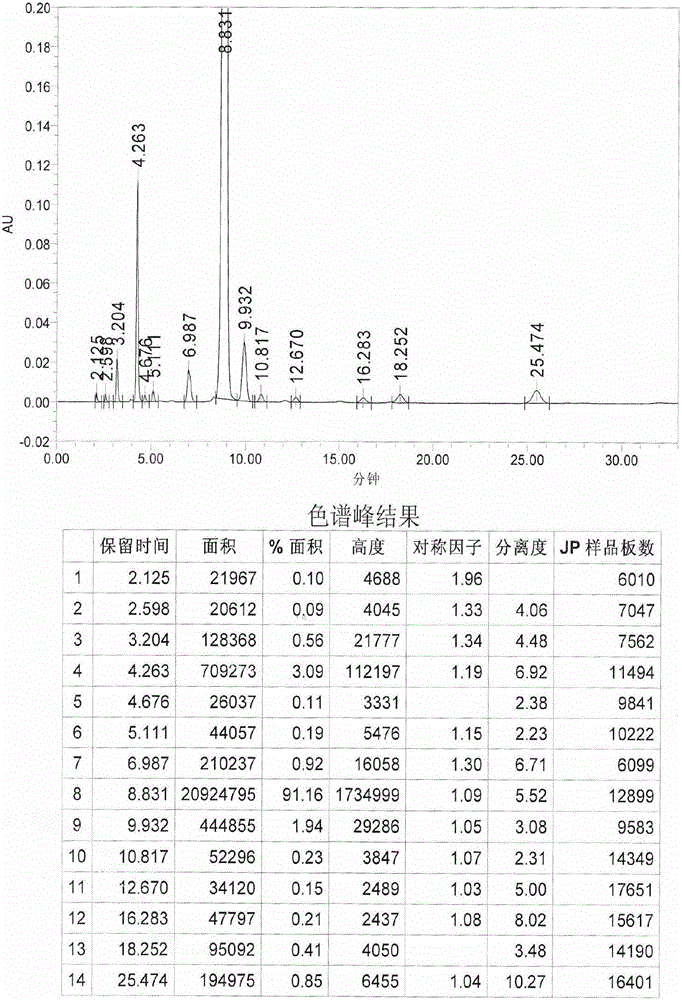

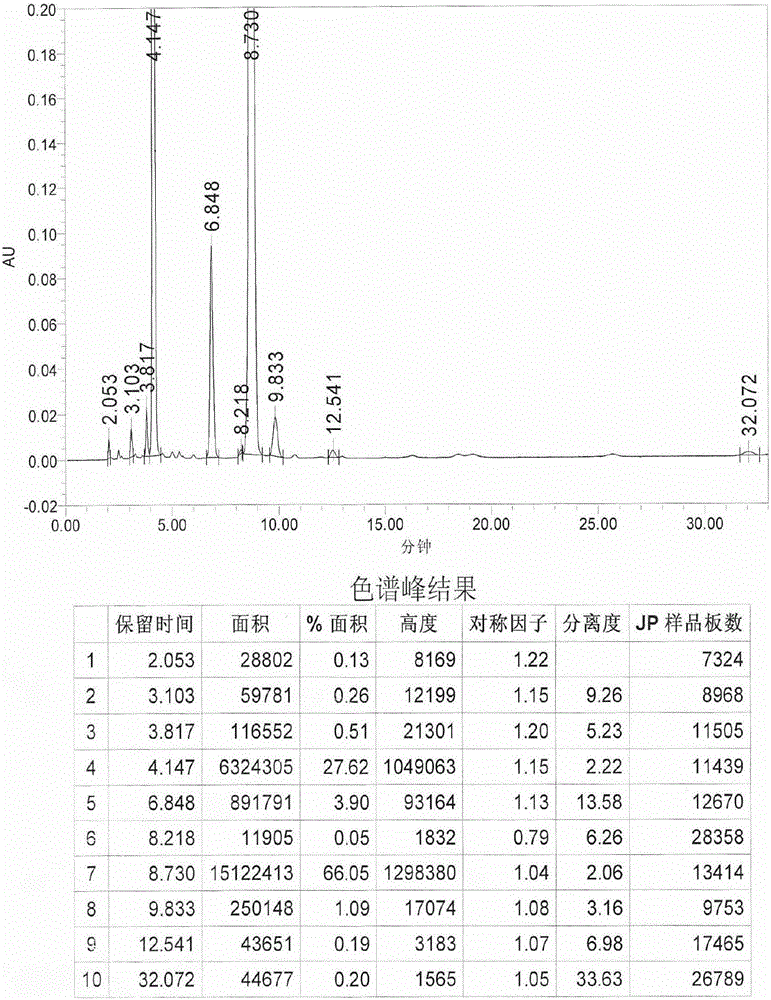

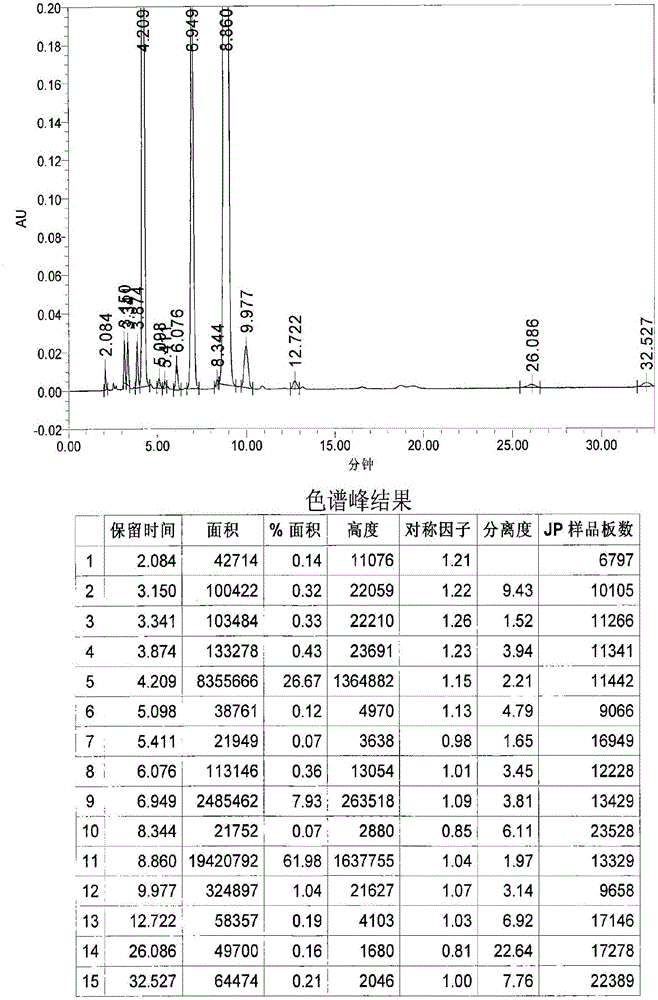

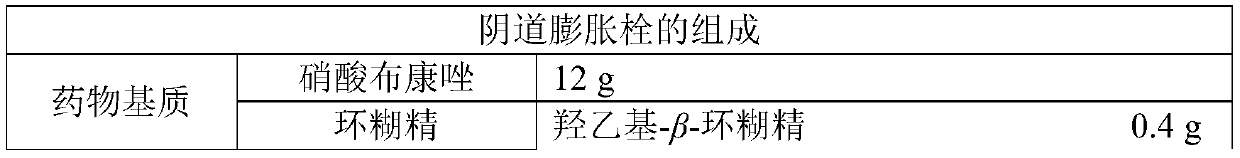

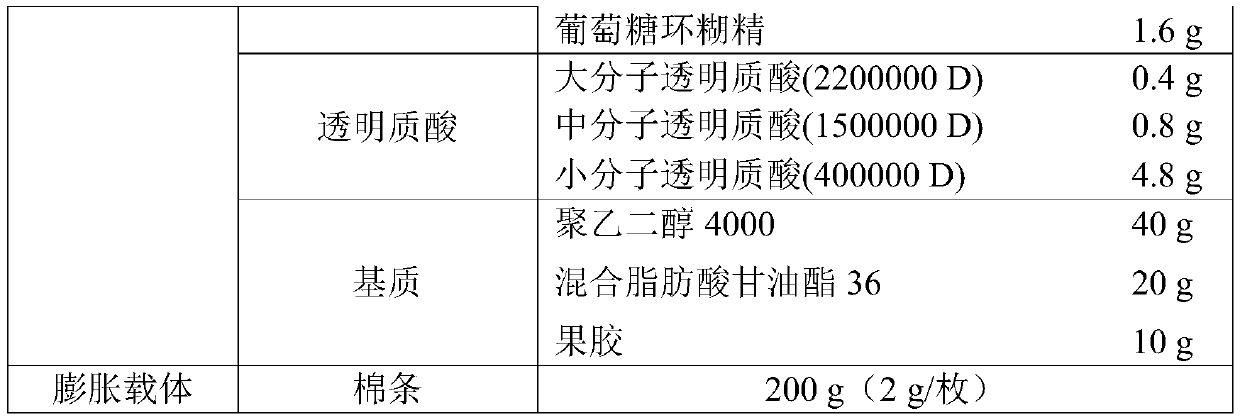

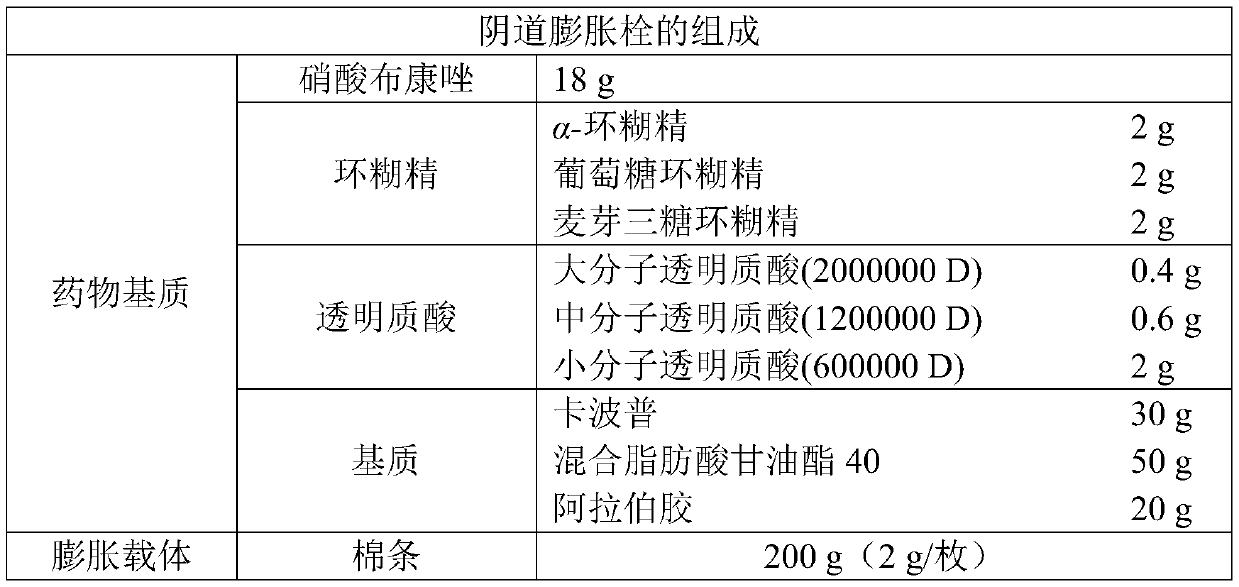

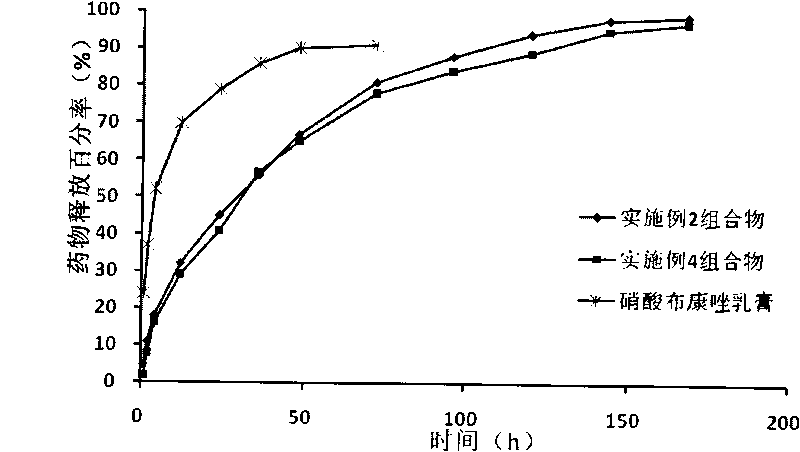

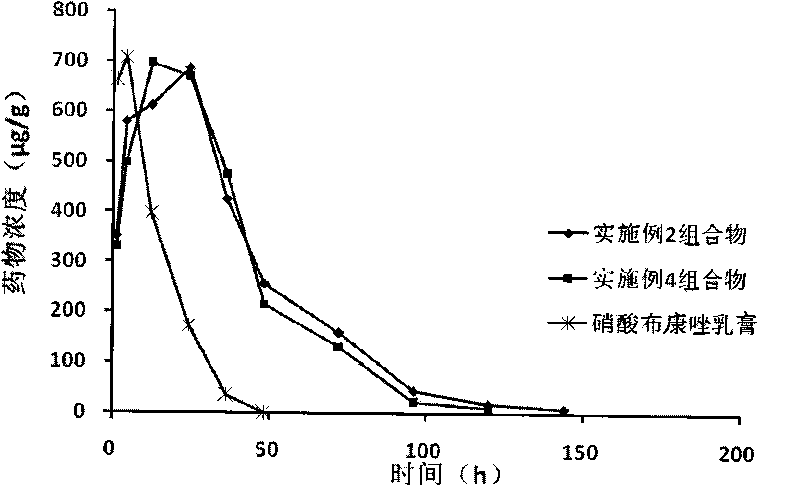

Butoconazole nitrate vaginal expansion suppository and preparation method and application thereof

ActiveCN110623915AEliminate rednessEffective againstAntimycoticsSuppositories deliveryBiotechnologyButoconazole Nitrate

The invention provides a butoconazole nitrate vaginal expansion suppository. The vaginal expansion suppository comprises an expansion carrier and a drug matrix coating the surface of the expansion carrier; and the drug matrix comprises butoconazole nitrate and a matrix. According to the invention, the active components are matched with each other and have a synergistic effect, so that the self-healing capability of vagina is enhanced, and the growth and propagation of pathogenic bacteria are effectively controlled; the medicine effect can also be exerted to the greatest extent, and the bioavailability is improved; and the drug release speed is effectively controlled, the drug dispersion uniformity is improved, the time of the drug acting on an affected part is prolonged, and vaginitis canbe effectively treated.

Owner:HARBIN OT PHARMA +1

Medicinal composition for vagina

ActiveCN101703504AGood biomucoadhesionGood slow releaseOrganic active ingredientsAntimycoticsButoconazole NitrateHypromellose

The invention relates to a medicinal composition for vagina. The composition comprises butoconazole nitrate, poloxamer, hydroxypropyl methylcellulose, Carbomer and other additives. The composition has the characteristics of good vagina mucosa adhesion and long-acting slow release, and in vivo and in vitro experiment results prove that the composition can continuously release the medicament for more than 72 hours.

Owner:JIANGXI ANGTAI PHARMA

A kind of method of industrialized synthesis butoconazole nitrate intermediate

The invention relates to a method for industrially synthesizing a butoconazole nitrate intermediate. The method comprises steps as follows: (1), imidazole and sodium hydride are taken as raw materials, are heated and stirred in a DMF (dimethyl formamide) solution and are cooled after sufficient reaction, 1-chlorine-4-(4-chlorphenyl)-2-butanol is slowly dropwise added, the mixture is heated, stirred and cooled after sufficient reaction, and a reaction liquid is obtained; (2), n-hexane and ice water are sequentially added to the reaction liquid obtained in the step (1), sufficiently stirred and filtered after sediment separation stops, a filter cake is washed, centrifugally dried and recrystallized with ethyl acetate and activated carbon, and the butoconazole nitrate intermediate is obtained. According to the provided method, conditions and parameters in the synthesis process are comprehensively and preferentially selected, the purity and yield of products are improved, and the method is more suitable for large-scale industrial production.

Owner:ZHUZHOU QIANJIN PHARMA

A kind of method of industrialized production butoconazole nitrate

The invention relates to a method for industrial production of butoconazole nitrate. The method comprises the following steps that firstly, 1-(2-chlorine-4-(4-chlorphenyl)butyl)-1 hydrogen-imidazole is mixed with 2,6-dichoribenzene thiophenol, anhydrous potassium carbonate and acetone, a heating reflux reaction is carried out, anhydrous potassium carbonate is supplemented, the heating reflux reaction is continued, cooling and filtering are carried out, and concentrate is obtained after filter liquor is concentrated; secondly, extract liquor containing diethyl ether and water is added in the concentrate, after sufficient extraction is carried out, a water phase is discarded, and an organic phase is reserved; thirdly, concentrated nitric acid is dripped into the obtained organic phase on ice bath and stirring conditions, and filtering is carried out when sediment stops being generated; the filter liquor is discarded, a filter cake is washed with diethyl ether and acetone in sequence, and the metric acid butoconazole is obtained after the filter cake is dried. According to the method, conditions and parameters in the synthesizing process are comprehensively optimized, impurities likely to be introduced in the production process are effectively controlled, the production efficiency is improved, the purity and yield of products are increased, and the method is more suitable for large-scale industrial production.

Owner:ZHUZHOU QIANJIN PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com