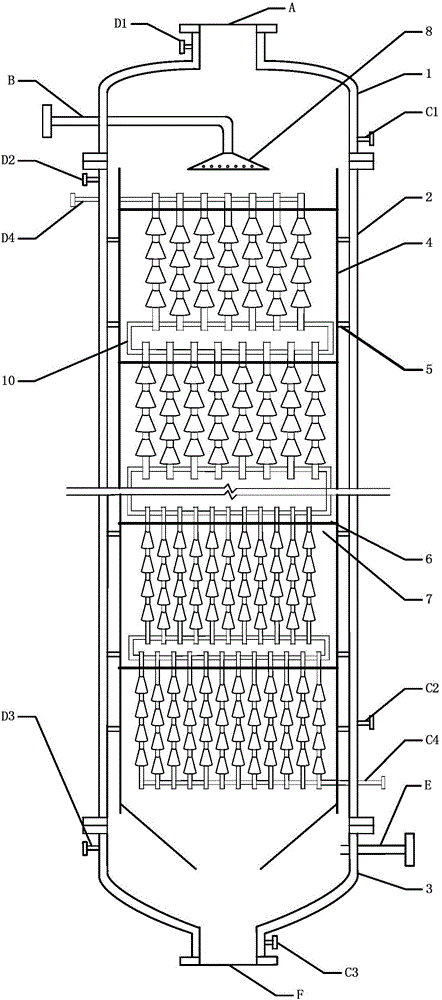

Multilayer falling pipe type falling film devolatilization reactor

A reactor and drop-tube technology, which is applied in the field of multi-layer drop-tube falling film devolatilization reactor, can solve the problems of simplicity and low heat transfer efficiency, and achieve high flow rate, large specific surface area and less internal dead zone. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

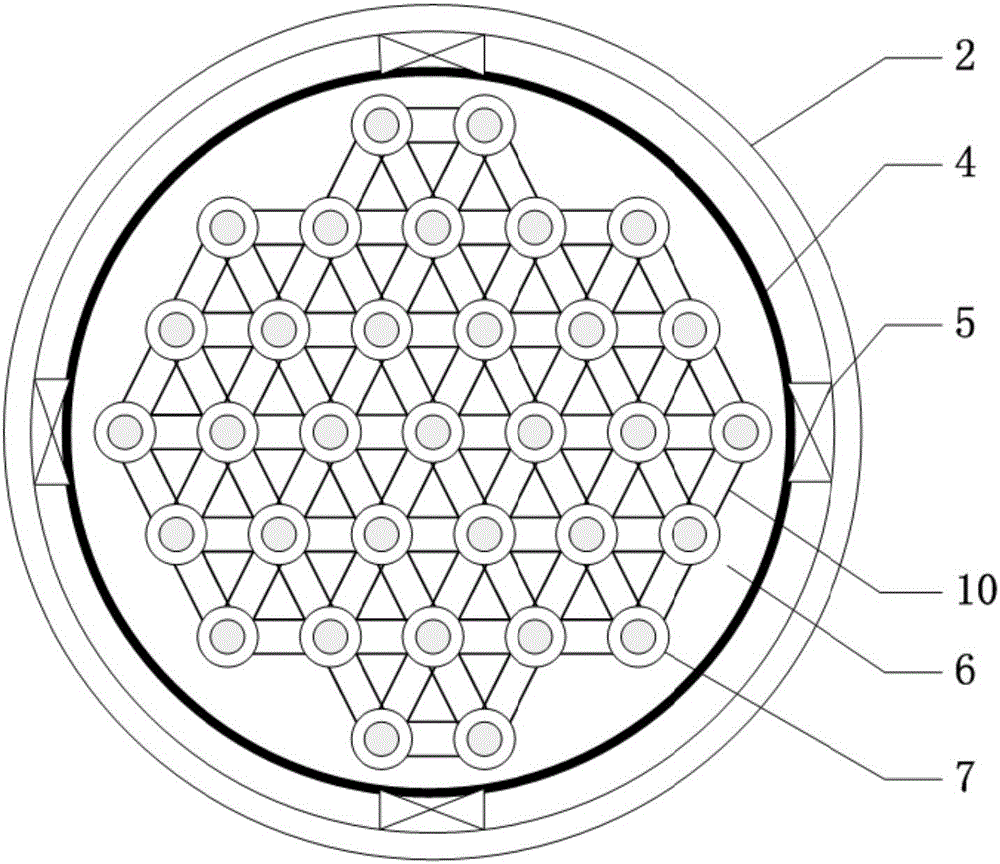

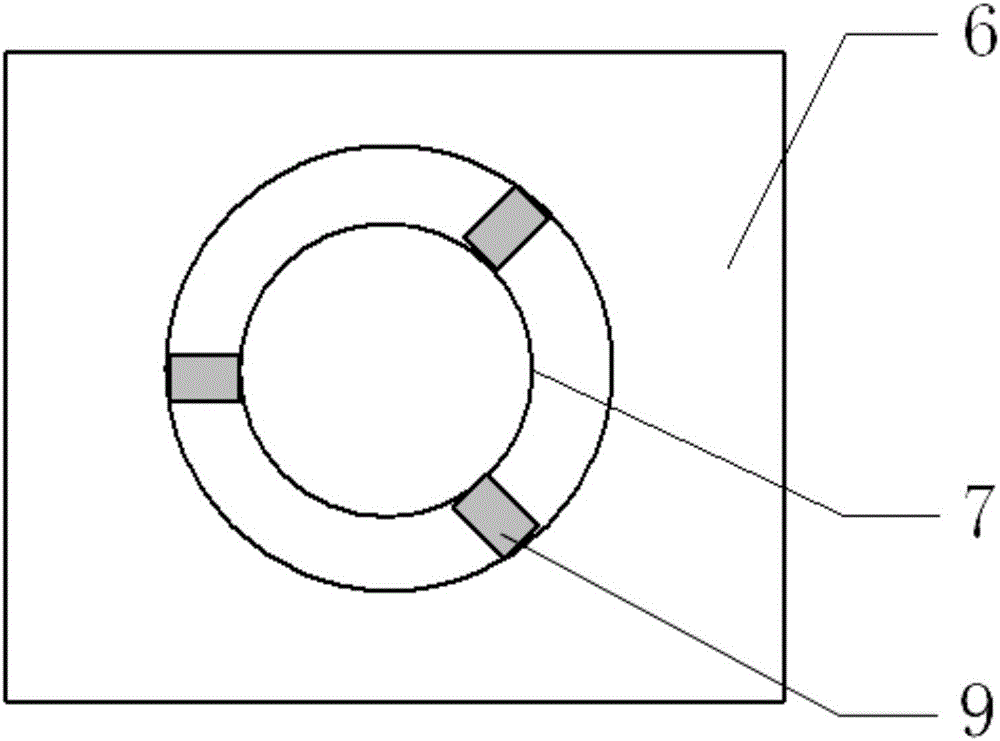

[0032] Embodiment 1: PET final polycondensation process.

[0033] The structure and principle of the reactor are as described above, and the structural parameters of some reactors are as follows: the number of openings is 10-100, the width of the leakage channel is 2-15mm, the vertical distance between two adjacent umbrella skirts is 20-100mm, and the falling film The taper of the umbrella skirt on the drop tube is from 2:1 to 1:5, the bottom diameter of the umbrella skirt is 20-100mm, and the number of layers is 10-30.

Embodiment 2

[0034] Example 2: Polymer devolatilization process.

[0035] The structure and principle of the reactor are as described above, and some structural parameters and operating parameters of the reactor are as follows: melt viscosity 10-100Pa·s, small molecule volatile content 2-5%, number of openings 10-100, leakage channel width 2 -10mm, the vertical distance between two adjacent umbrella skirts is 20-100mm, the taper of the umbrella skirt on the falling film drop tube is 2:1-1:5, and the bottom diameter of the umbrella skirt is 20- 50mm, the number of layers is 10-30; compared with the smooth drop tube devolatilizer under the same structural parameters, the volatilization removal efficiency is increased by 10-30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com