Fluidized-bed reactor for oxidizing carbon black through ozone

A technology of fluidized bed reactor and carbon black oxidation, which is applied in chemical instruments and methods, chemical/physical processes, fibrous fillers, etc., can solve the problems of complex processing of gas distributors, and eliminate the phenomenon of channeling and throttling , the residence time distribution is uniform, the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

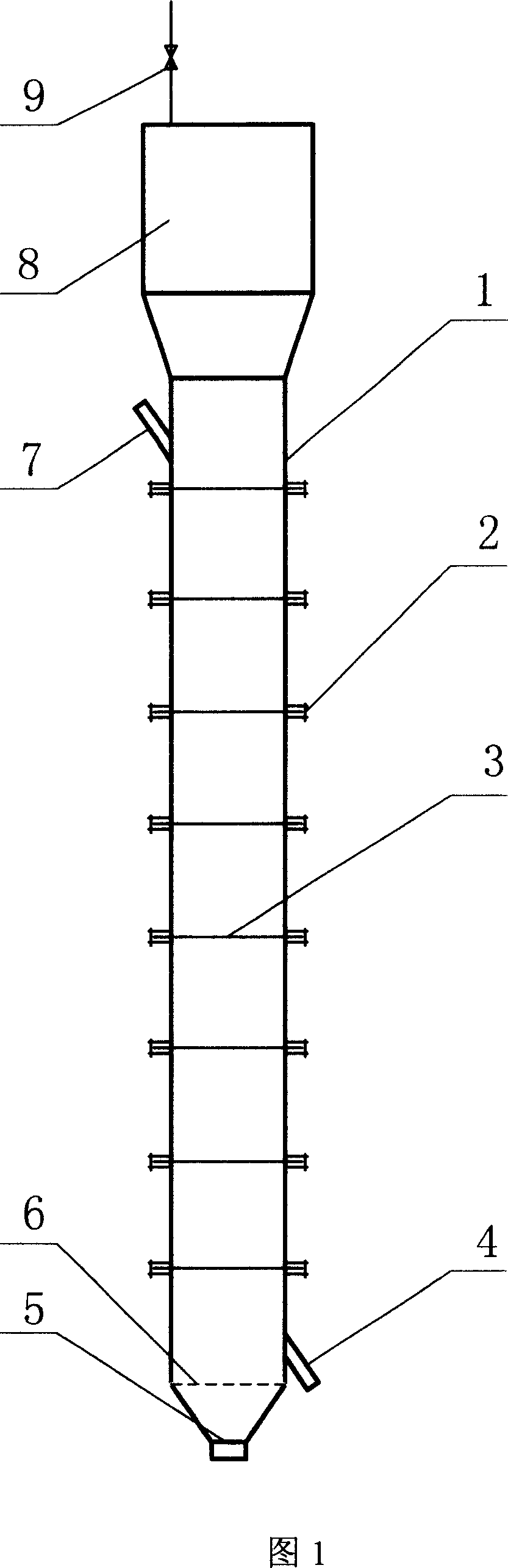

[0036] See Figure 1. The lower part of the fluidized bed reactor main body 1 is shaped like a truncated cone, and the upper part is provided with a carbon black discharge opening 4, and the carbon black feed opening is opened below the expansion section; There is a gas inlet 5 at the bottom; a carbon black feed port 7 is opened on the upper part of the fluidized bed reactor main body 1, and a gas outlet 9 is opened at the top; a baffle with a gap is installed inside the fluidized bed reactor main body 1 plate 3, a gas distribution plate 6 is installed below the carbon black discharge port 4.

[0037] The height of the reactor is 1500mm, the inner diameter is 100mm, and the fluidized bed contains multi-layer internal baffles. The distance between the baffles is 100mm. The baffles are fixed by flange 2, and the fluidization gas velocity is 1.6m 3 / h,O 3 Produced by an air-sourced ozone generator with an output of 20 g / h, the carbon black material is furnace carbon black N220 p...

Embodiment 2

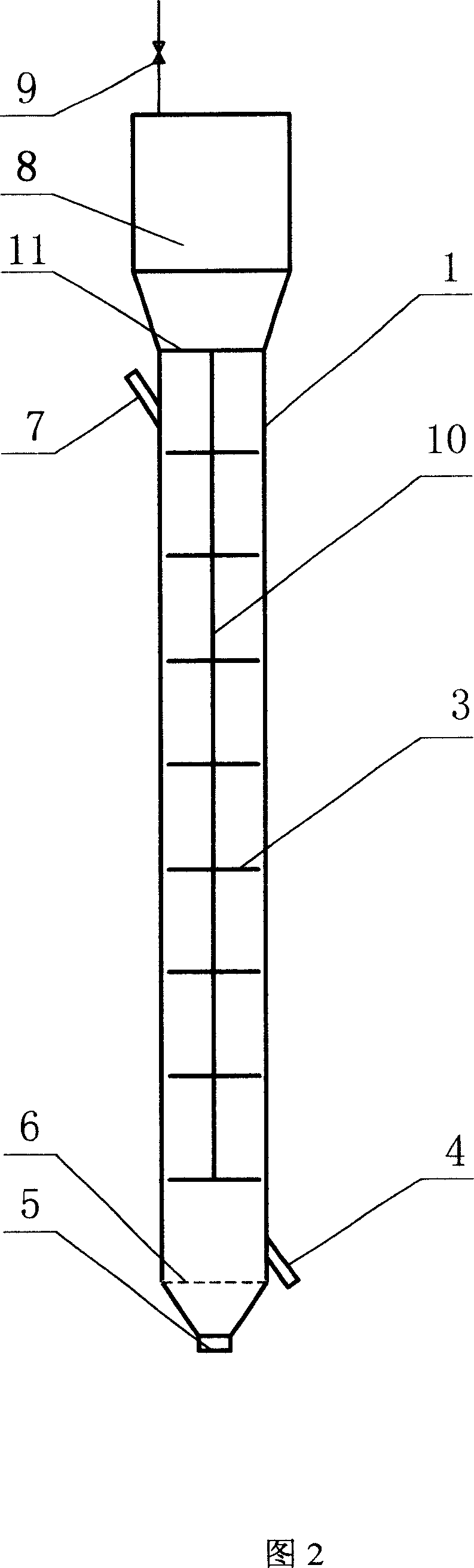

[0041]Please refer to Fig. 2, the structure is the same as that of Embodiment 1, but the baffle plate 3 is fixed at the center. The baffle plate 3 is fixed on a column 10 in the main body of the fluidized bed reactor, and the column 10 is fixed on a fixing frame 11, and the fixing frame 11 is fixed on the main body of the fluidized bed reactor.

[0042] Reactor height 1500mm, inner diameter 100mm, fluidized bed with multi-layer internal baffles, baffle spacing 30mm, fluidization gas velocity 2.5m 3 / h,O 3 Produced by the ozone generator of the air source, the output is 20g / h, and the carbon black adopts the furnace carbon black N219 produced for Tianjin Dolphin Carbon Black Factory. Experiments have found that the superfine carbon black is evenly fluidized, the phenomenon of throttling and channeling disappears, the pressure drop of the bed is stable, and the lower part of the bed can continuously and stably flow and discharge. When the average residence time is 100min, the ...

Embodiment 3

[0046] Please refer to Fig. 2, the structure is as in embodiment 2. The height of the reactor is 1500mm, the inner diameter is 100mm, and it is carried out in a fluidized bed with multi-layer internal component baffles. The distance between the baffles is 200mm. 3 / h,O 3 Produced by the ozone generator of the air source, the output is 25g / h, and the carbon black adopts the furnace carbon black N234 produced by Tianjin Dolphin Carbon Black Factory. Experiments have found that the superfine carbon black is evenly fluidized, the phenomenon of throttling and channeling disappears, the pressure drop of the bed is stable, and the lower part of the bed can continuously and stably flow and discharge. The average residence time of carbon black in the fluidized bed is controlled by the fluidization gas velocity and the amount of carbon black held in the fluidized bed. The changes of the main technical parameters pH value and volatile matter under different residence times are shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com