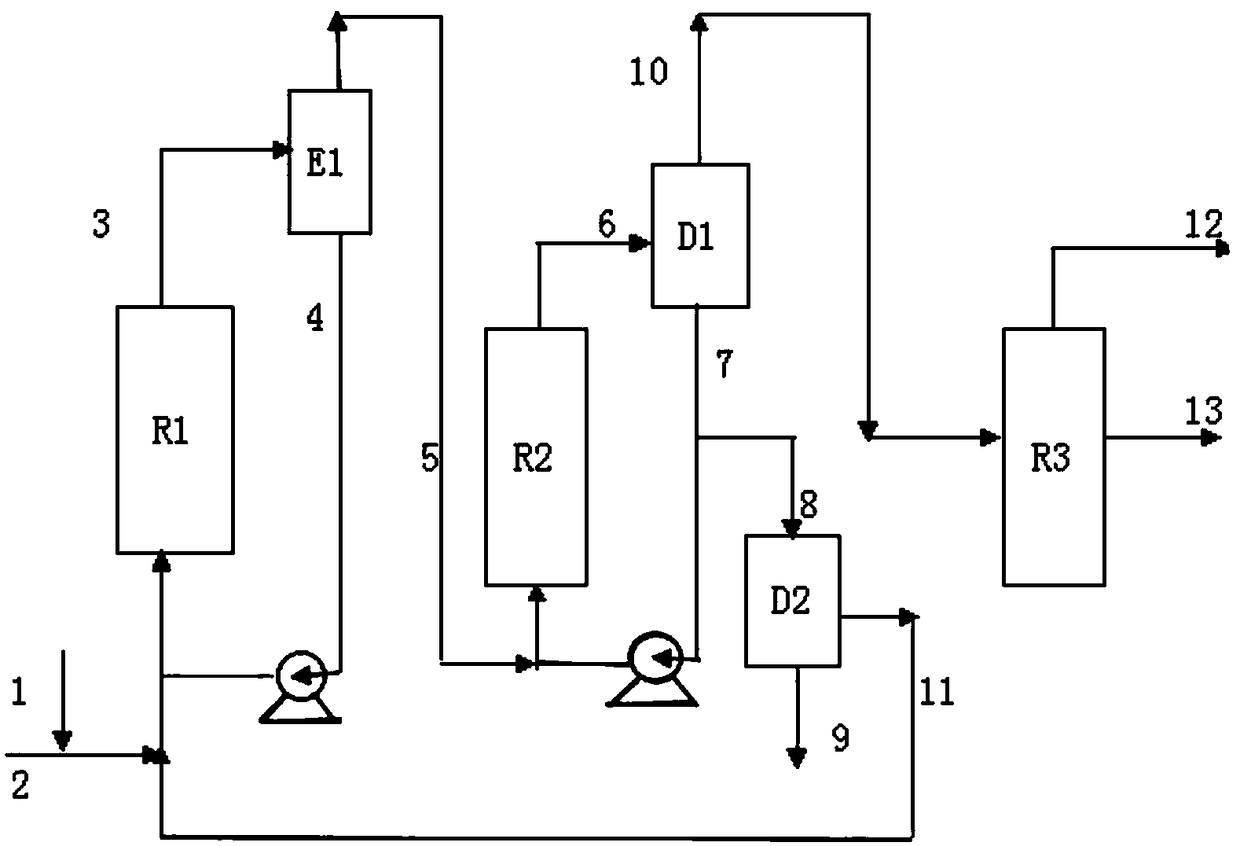

Heavy oil hydrogenation method and hydrogenation system

A heavy oil hydrogenation and heavy oil technology, applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of complex internal components of the reactor, incomplete gas-liquid separation, large gas retention coefficient, etc., and save equipment. effect of investment, avoidance of deposits, reduction of operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

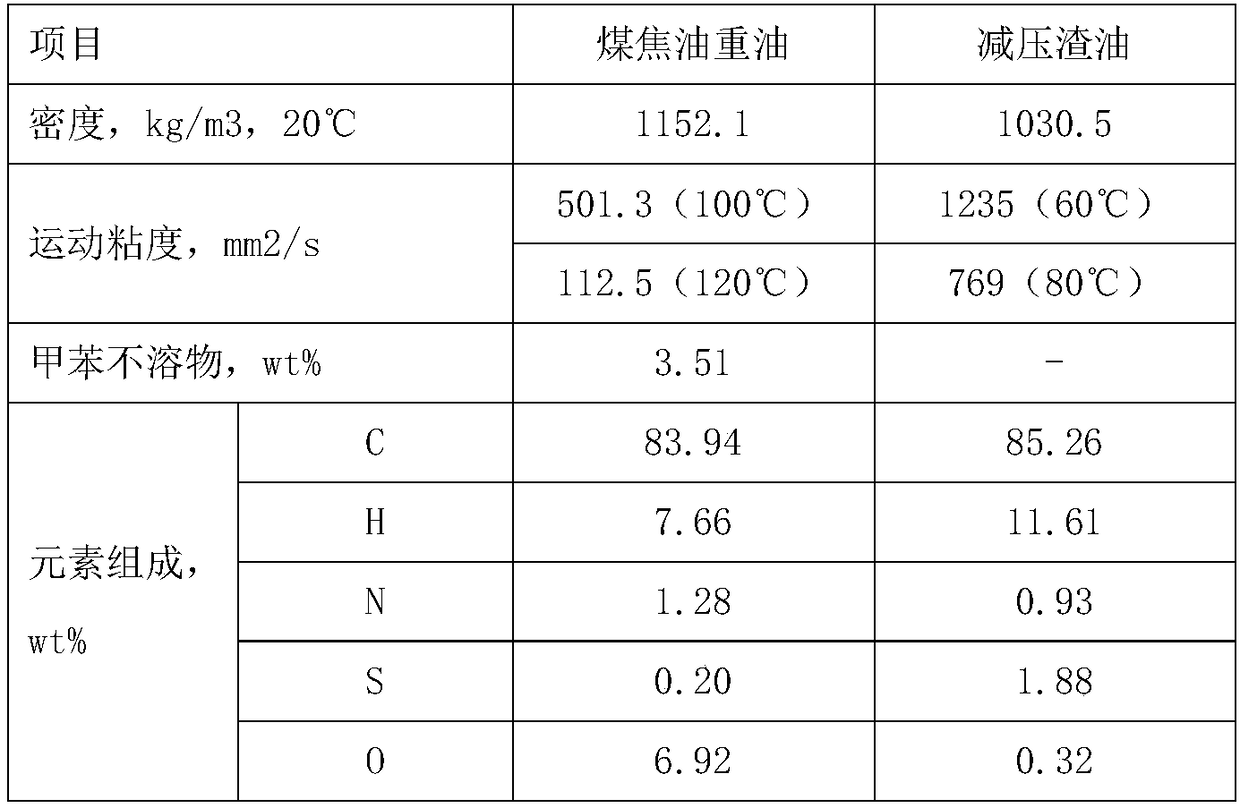

[0080] A kind of coal tar is selected as the heavy oil of this embodiment, and its properties are shown in Table 1.

[0081] The hydrocracking catalyst used in this example is a molybdenum-nickel-iron composite hydrogenation catalyst, the catalyst used includes highly active metal components molybdenum, nickel and low active metal component iron, wherein highly active metal molybdenum, nickel and low active metal components The weight ratio of metal iron is 1:2:500, the water content of the catalyst is less than 0.5wt%, and the particle diameter is less than 1 μm powdery particles. The iron content of the catalyst is 53wt%, and the addition amount of the catalyst is 1% of the weight ratio of the total amount of metal in the active component to the material undergoing hydrocracking. The hydrorefining catalyst carrier used in this example is γ-Al 2 o 3 , the active metal component is tungsten, molybdenum, nickel, by weight of oxide, the active metal component WO 3 Content is ...

Embodiment 2

[0086] A kind of vacuum residue is selected as the heavy oil of this embodiment, and its properties are as shown in Table 1

[0087] The hydrocracking catalyst used in this example is a molybdenum-nickel-iron composite hydrogenation catalyst, and the catalyst used includes highly active metal components molybdenum, nickel and low active metal component iron, wherein high active metal molybdenum, nickel and low active metal The weight ratio of iron is 3:2:500, the water content of the catalyst is less than 0.5wt%, and the particle diameter is less than 1 μm powdery particles. The iron content of the catalyst is 48.6wt%, and the addition amount of the catalyst is 2% of the weight ratio of the total amount of metal in the active component to the material undergoing hydrocracking. The hydrorefining catalyst carrier used in this example is γ-Al 2 o 3 , the active metal component is tungsten, molybdenum, nickel, by weight of oxide, the active metal component WO 3 Content is 13%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com