Rear-arch-free flow smoothening device for garbage incinerator

A waste incinerator and incinerator technology, which is applied in the field of downstream equipment without back arches, can solve the problems of insufficient consideration of radiation and convective heat transfer, poor flame fullness, lack of experience, etc., and achieve simple and easy technical means and reduce combustion The effect of temperature and prolonged exercise time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

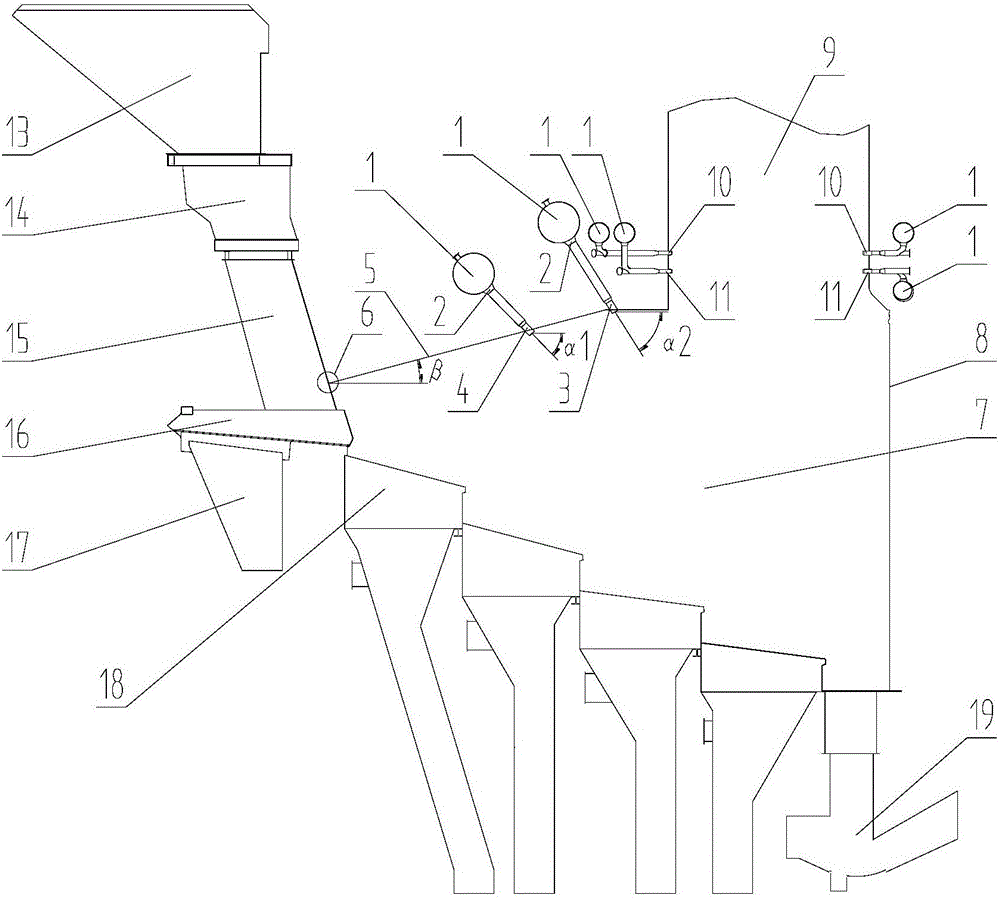

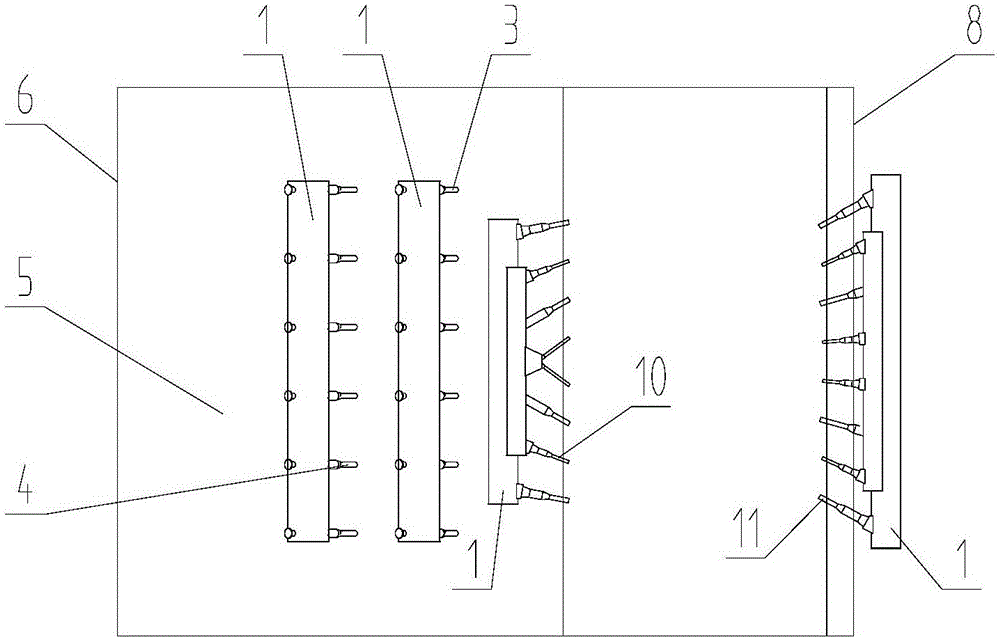

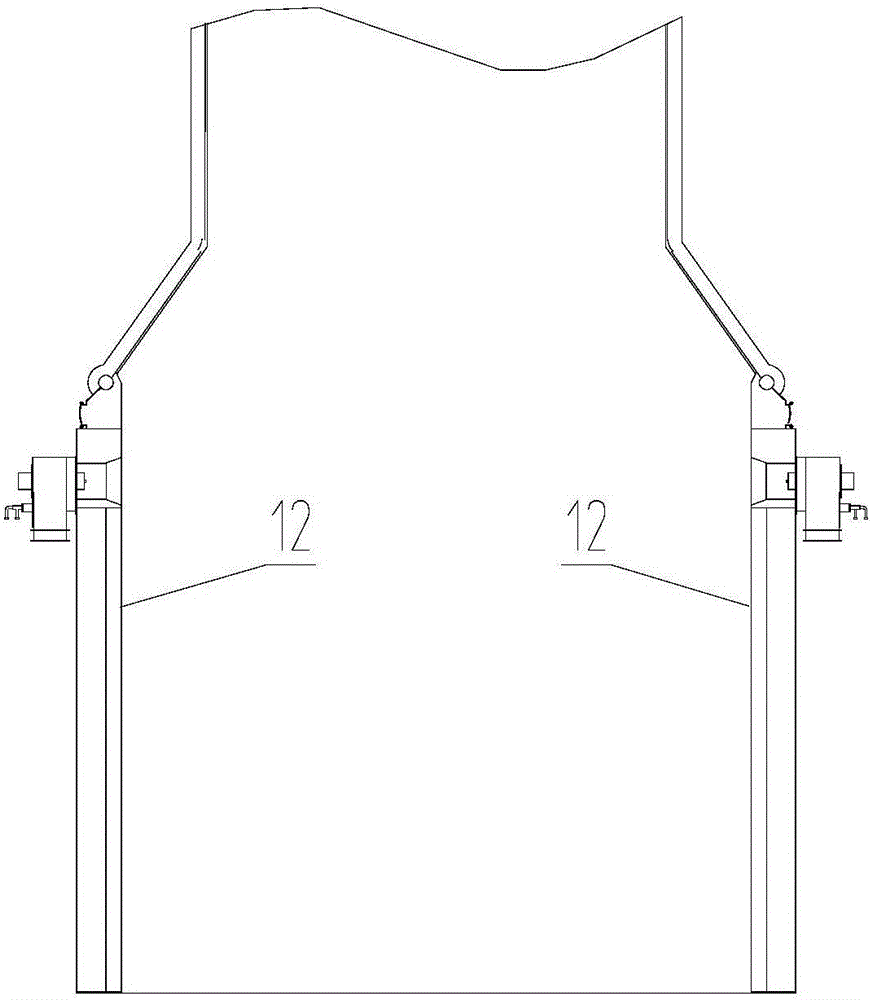

[0026] Such as figure 1 Shown, in the existing basic incinerator side walls 12, garbage feed hopper 13, feed baffle 14, water-cooled chute 15, pusher 16, ash hopper 17, fire grate 18, slag machine 19 foundations On, the present invention has flue 9 especially, and there is furnace 7 below flue 9, and one side of furnace 7 is rear wall 8, and there are front supply 5 and front supply lower header 6 in furnace 7, and described front supply 9 The upper water wall fin is provided with at least one upper layer secondary air nozzle 3 and the throat upper layer secondary air nozzle 10, and at least one lower layer secondary air nozzle 4, and the throat lower layer secondary air nozzle 11 each layer two The air inlets of the secondary air nozzles are respectively connected with the secondary air pipes (1), and secondary air doors (2) are arranged at the joints between the air nozzles of each layer described above and the secondary air pipes (1).

Embodiment 2

[0028] Same as Example 1, except that the vertical distance between the horizontal section of the upper secondary air nozzle 3 and the lower header 6 of the front arch is 1.6m to 1.8m, and the horizontal section of the secondary air nozzle 4 of the lower layer is located at 6 The vertical distance is 1.0m ~ 1.3m.

Embodiment 3

[0030] Same as Embodiment 1, except that there are two layers of secondary air nozzles on the upper and lower layers of the front arch, each layer has 6 nozzles, which are respectively arranged at intervals on the front arch, and there are 12 secondary air nozzles in total in the two layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com