Full temperature range-pressure swing adsorption (FTrPSA) separation method for reaction cycle gas in direct oxidation of ethylene to ethylene oxide

A technology of ethylene oxide and separation method, applied in the field of FTrPSA separation, can solve the problems of impurity accumulation, waste, unstable cycle ratio, etc., and achieve the effects of low energy consumption and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

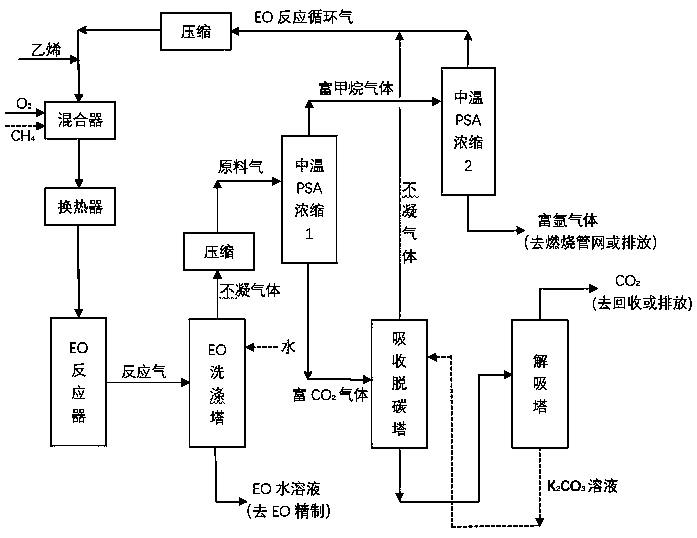

[0032] A kind of FTrPSA separation method of reaction circulation gas in ethylene method system ethylene oxide, comprises the steps:

[0033] (1) Medium-temperature PSA enrichment 1 (PSA1), the non-condensable gas from the top of the ethylene oxide (EO) scrubber is used as the raw material gas,

[0034] Its components are ethylene 20.2% (volume ratio, the same below), oxygen 6.0%, methane 49.4%, argon 10.4%, carbon dioxide 12.0%, and the rest 1.0%, mainly including water, nitrogen, ethylene glycol, carbon monoxide etc., the temperature is 80°C, the pressure is 1.7MPa, the gas flow rate is 10,000 standard cubic meters per hour, and it directly enters the medium temperature 5-tower series pressure swing adsorption concentration system with an operating temperature of 80°C and an operating pressure of 1.7MPa. A variety of adsorbent combinations filled with activated alumina, silica gel, activated carbon, and molecular sieves are used. The control system composed of regulating val...

Embodiment 2

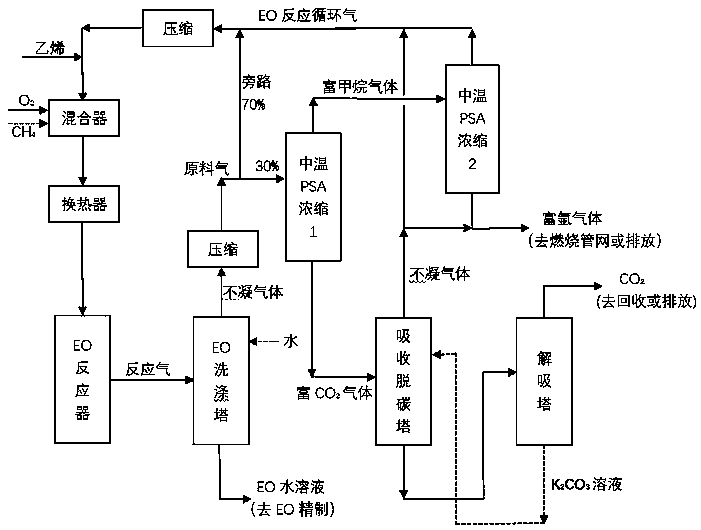

[0038] Based on Example 1, such as figure 2 As shown, in step (1), the non-condensable gas from the top of the ethylene oxide (EO) scrubber is used as the raw material gas, and 60~70% of it can be bypassed by PSA1 as the EO reaction cycle gas and directly enter the cycle The gas compressor is recycled, and 30~40% of it directly enters the PSA1 and PSA2 systems for processing. Correspondingly, the 5-tower operation is automatically switched to the 4-tower operation control system, and the PSA operation mode of the two processes is switched from PSA5-1-2V to PSA4-1-2V meets the requirement of 30~40% operating flexibility of the PSA unit, and can adjust the ratio of the direct reaction cycle gas volume through the PSA1 bypass to the indirect reaction cycle gas volume processed by the PSA1 system to maintain the EO reactor. The effective composition of the working concentration and stable and complete operation.

Embodiment 3

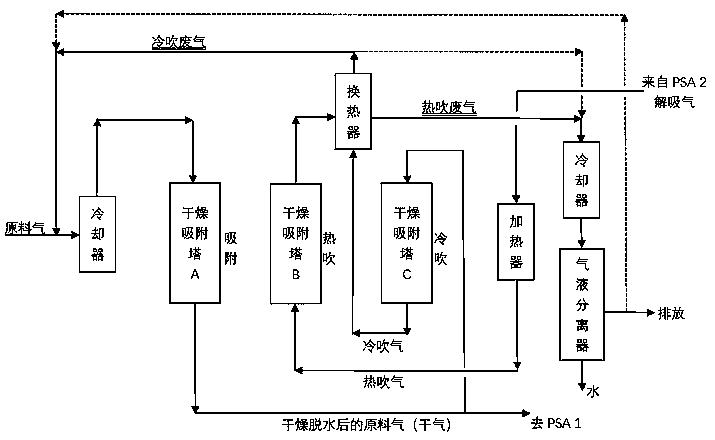

[0040] Based on Example 1, such as image 3 As shown, the non-condensable gas from the top of the ethylene oxide (EO) scrubber described in step (1) is used as the raw material gas, and first enters the temperature swing adsorption (TSA) system composed of three adsorption towers in series for drying and dehydration , among which, one of the three towers is adsorption, one tower is hot blowing, and the other is cold blowing. Each adsorption tower is filled with various adsorbent combinations of activated alumina, silica gel, and molecular sieve. The adsorption temperature is 76~80°C, and the regeneration temperature is 200 ~220°C, the argon-rich non-adsorbed phase gas from the PSA2 system is used as the regeneration carrier gas, and the generated regeneration waste gas is used as the fuel gas and directly enters the fuel gas pipeline network. The inlet and outlet pipes of each adsorption tower in the drying system are connected with heaters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com