Highly effective slurry phase bed reactor

A reactor and slurry bed technology, applied in the field of slurry bed reactors, can solve the problems of abnormal operation of the reactor and easy occurrence of bias flow, etc., and achieve the effects of large reaction activity, difficult bias flow, and smooth operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

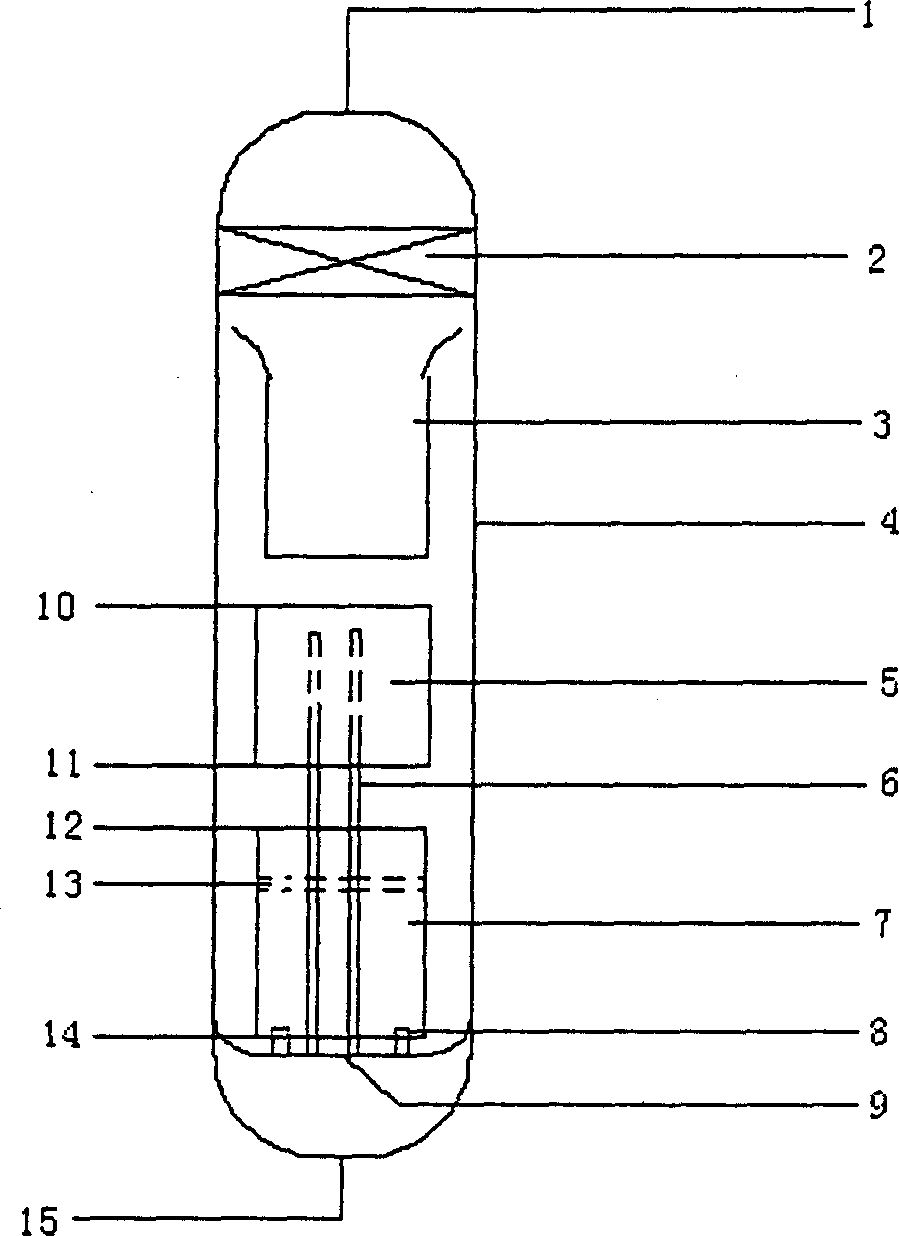

[0017] The high-efficiency slurry bed reactor of the present invention consists of a solid-liquid separator 2, a variable-diameter inner sleeve 3, a reactor outer sleeve 4, a heat exchanger 5 with internal components, a gas riser 6 with nozzles, and a heating and gas distribution function. The inner sleeve 7, the anti-clogging nozzle 8, the nozzle installation plate 9 of the head type structure and the secondary distribution plate 13 are formed. In this reactor, the internal components for realizing the internal circulation of the slurry are arranged, including the inner sleeve with variable diameter 3, which has The inner sleeve 7 for heating and gas distribution, the nozzle mounting plate 9 of the head type structure, the gas riser 6 for uniformly distributing the gas along the axial direction of the reactor, the secondary gas distribution plate 13 for realizing the secondary distribution of the gas, and the solid The liquid separator 2 constitutes. The anti-blocking nozzle ...

Embodiment approach 2

[0020] In the high-efficiency slurry bed reactor of the present invention, the outlet of the anti-clogging nozzle 8 has a spherical body to prevent the backflow of the slurry, and its diameter is 1.2 times that of the nozzle throat. The nozzle installation plate 9 of the head type structure is tangent to the inner wall of the reactor, and forms a smooth slurry return channel with the inner wall of the reactor. The inner sleeve 7 with heating and gas distribution functions is made of coiled tubes, and the distance between the coiled tubes changes from zero to the diameter of the coiled tubes from bottom to top. The barrel diameters of the variable diameter inner sleeve 3, the heat exchanger 5 with internal components and the inner sleeve 7 with heating and gas distribution functions change from 0.5 times the reactor diameter to 0.9 times the reactor diameter from bottom to top along the reactor. Gas riser 6 is installed in the inside of the reactor and directly links to each ot...

Embodiment approach 3

[0023] In the high-efficiency slurry bed reactor of the present invention, the outlet of the anti-clogging nozzle 8 has a spherical body to prevent the backflow of the slurry, and its diameter is 1.3 times that of the nozzle throat. The nozzle installation plate 9 of the head type structure is tangent to the inner wall of the reactor, and forms a smooth slurry return channel with the inner wall of the reactor. The inner sleeve 7 with heating and gas distribution functions is made of coiled tubes, and the distance between the coiled tubes changes from zero to the diameter of the coiled tubes from bottom to top. The barrel diameters of the variable diameter inner sleeve 3, the heat exchanger 5 with internal components and the inner sleeve 7 with heating and gas distribution functions change from 0.6 times the reactor diameter to 1 times the reactor diameter from bottom to top along the reactor. Gas riser 6 is installed in the inside of the reactor and directly links to each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com