Multistage screening and sorting device for construction waste

A construction waste and sorting device technology, which is applied in construction waste recycling, filtering, magnetic separation, etc., can solve problems affecting the efficiency of waste sorting, unfavorable dust safety treatment, unfavorable dust collection effect, etc., and achieve continuous work intensity improvement , Reduce cleaning operations and improve screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

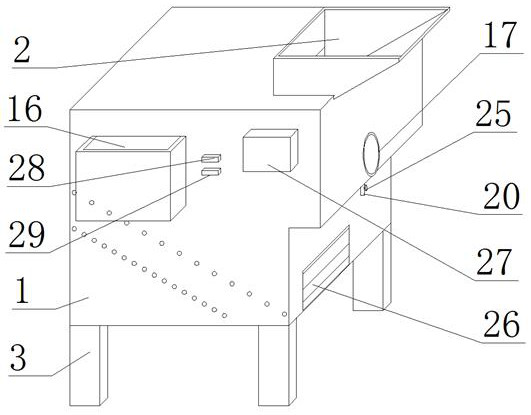

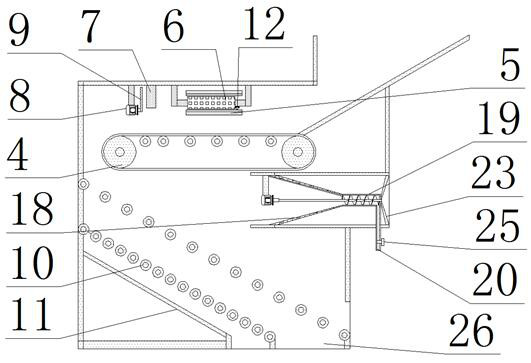

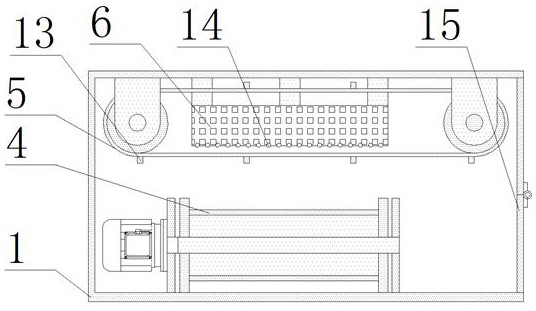

Embodiment 1

[0023] see figure 2 , a multi-stage screening and sorting device for construction waste, comprising a box 1, a hopper 2 and legs 3, the hopper 2 is welded on the top of the box 1, and the legs 3 are welded on the bottom of the box 1, The inboard of described casing 1 is equipped with conveyer one 4, and the top of described conveyer one 4 is provided with conveyer two 5, and the inboard of described conveyer two 5 is equipped with electromagnet 6, and the inboard of described casing 1 A metal detector 7 is installed through bolts, a motor-8 is installed on one side of the metal detector 7, a guide rod 9 is installed on the motor-8, and a roller 10 is installed on the bottom of the conveyor-4, so The bottom of the drum 10 is welded with a slant plate 11, one side of the electromagnet 6 is equipped with a push switch 12 through a bolt, the outer side of the conveyor two 5 is bonded with a baffle plate 13, the bottom of the electromagnet 6 Balls 14 are installed, one side of th...

Embodiment 2

[0025] See figure 2 The difference from Embodiment 1 is that the switch one 28 is connected with the intelligent controller 27, the push switch 12, the metal detector 7 and the conveyor one 4 through wires, and the switch two 29 is connected with the motor two 21 through wires , the push switch 12 is connected with the conveyor two 5 through wires, the metal detector 7 is connected with the intelligent controller 27 through the wires, the intelligent controller 27 is connected with the motor one 8 through the wires, and the guide rod 9 is welded On the output shaft of motor one 8, metal detector 7 can be used to detect copper and aluminum metal, and motor one 8 can be started by intelligent controller 27, so that motor one 8 rotates forward or reversely, so that copper, aluminum metal can be transferred through guide rod 9 Aluminum metal is pushed out from both sides of conveyor one 4 to ensure the recovery of copper and aluminum metal.

Embodiment 3

[0027] See Figure 4The difference from Embodiment 2 is that the top end of the outlet pipe 20 communicates with the sleeve 19, and the bottom end of the outlet pipe 20 passes through the sleeve 19, the air duct 17 and the box body 1 in turn and extends to the box The bottom of the body 1, one end of the spiral plate 22 is installed on the output shaft of the second motor 21 through the transmission shaft, the sleeve 19 is sleeved on the outer side of the spiral plate 22, and the outer side of the scraper 24 is stuck on the On the inner wall of the filter cartridge 18, the other end of the spiral plate 22 passes through the outer wall of the sleeve 19 and is welded to the center of the fan blade 23, and the second end of the motor 21 drives the spiral plate 22 to rotate, so that one end of the spiral plate 22 drives the fan. The blades 23 rotate to generate suction, suck the dust into the air cylinder 17, and be filtered out by the filter cylinder 18. At the same time, the spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com