Industrial preparation method of carbon tetrachloride transferring to methyl chloride and its fixed bed reactor

A technology of fixed bed reactor and carbon tetrachloride, which is applied in chemical instruments and methods, preparation of halogenated hydrocarbons, organic chemistry, etc., can solve the problem that carbon tetrachloride is not found to be converted into methylene chloride, etc., and achieve energy saving , Improve the effect of reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

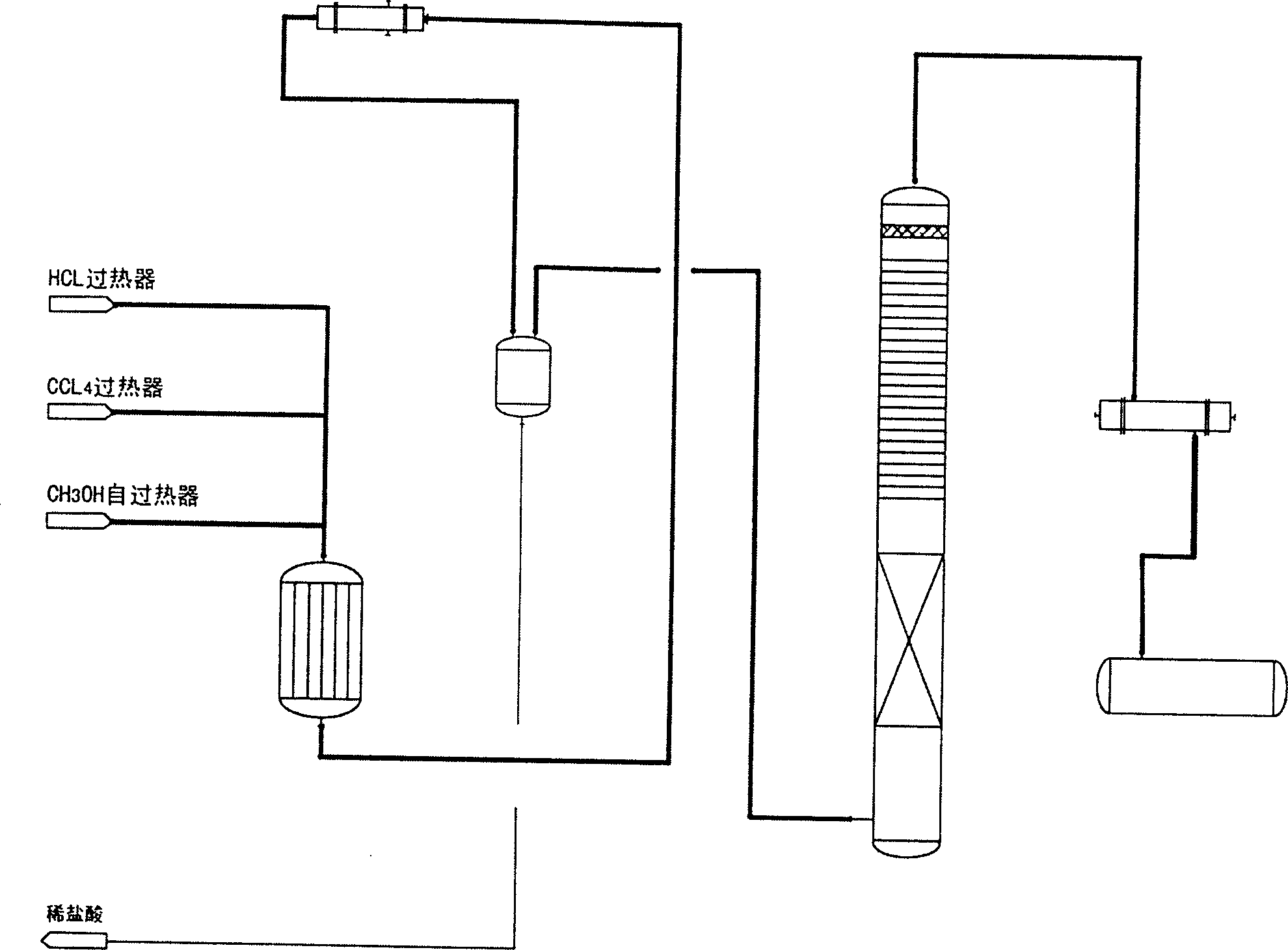

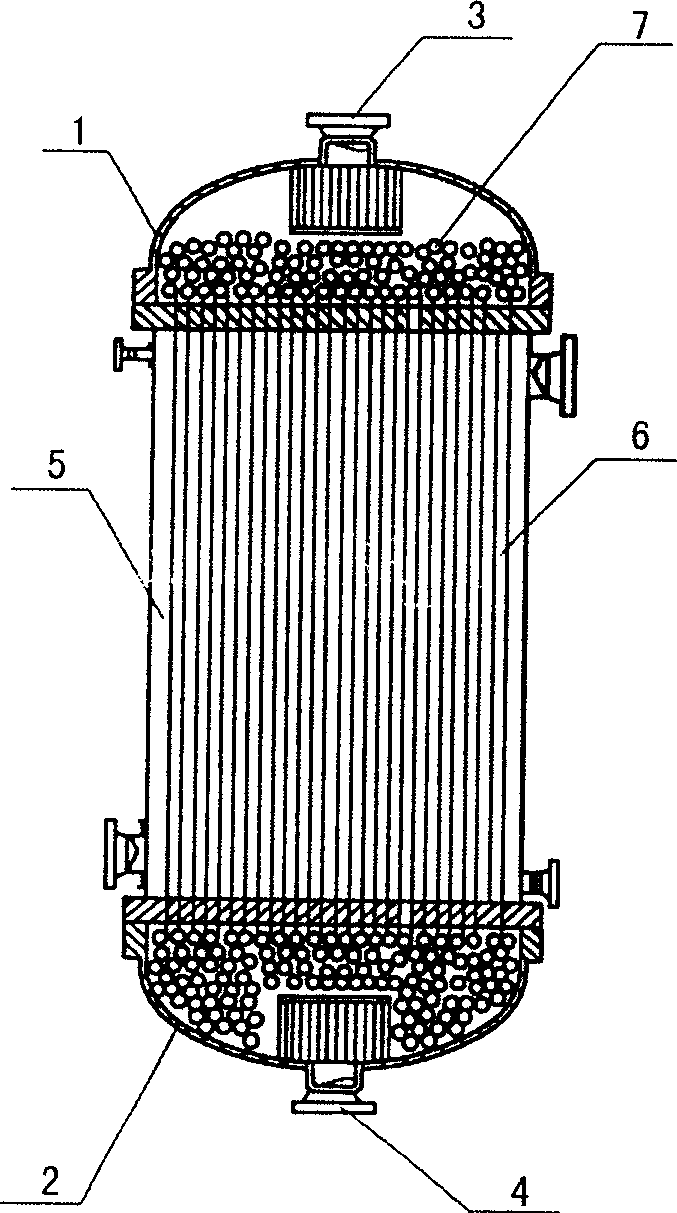

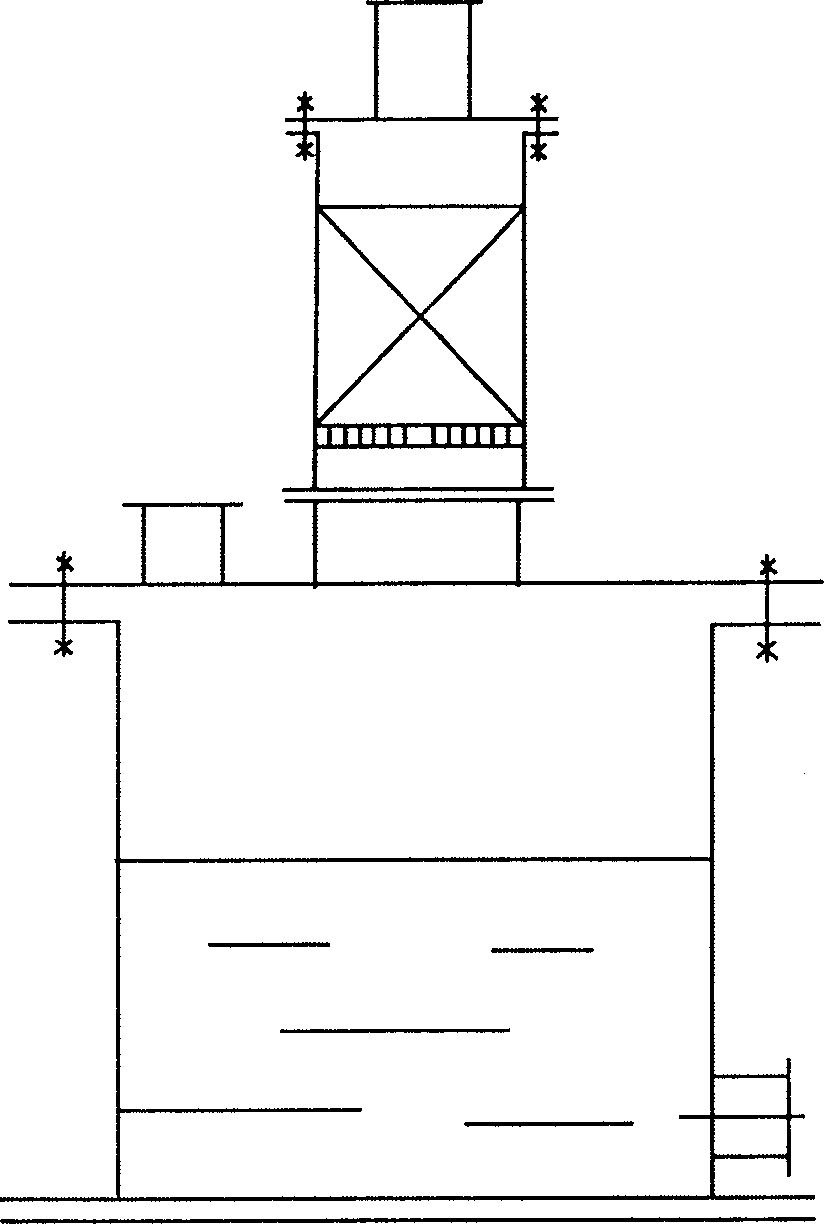

[0012] according to figure 1 , the raw material methanol is sent from the methanol storage tank to the methanol evaporator by the methanol pump, and is vaporized with steam. The vaporized methanol is preheated to 150°C in the preheater, and then superheated to 150°C by the methanol superheater with heat transfer fluid. -240°C. The raw material carbon tetrachloride is sent to the carbon tetrachloride evaporator from the carbon tetrachloride daily storage tank, and is vaporized with steam. -240°C. Hydrogen chloride gas from the outside world is superheated to 150-240 ° C with heat transfer fluid in the hydrogen chloride superheater, and then mixed with superheated methanol from the methanol superheater and carbon tetrachloride superheated by the carbon tetrachloride superheater according to the feed volume ratio at the initial stage of the reaction For, methyl alcohol: hydrogen chloride=1: 1-1.4 or methyl alcohol: carbon tetrachloride: water=1: 0.25-0.35: 0.5-1; During normal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com