Catalyst for preparing arene from synthesis gas through one-step conversion and preparation method of catalyst

A technology for synthesis gas and catalyst, which is applied to the catalyst for one-step conversion of synthesis gas to aromatic hydrocarbons and the field of preparation thereof, can solve the problems of complex reactor process, difficulty in maintaining life, lack of competitiveness, etc., and achieves improved conversion efficiency, low cost, and stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

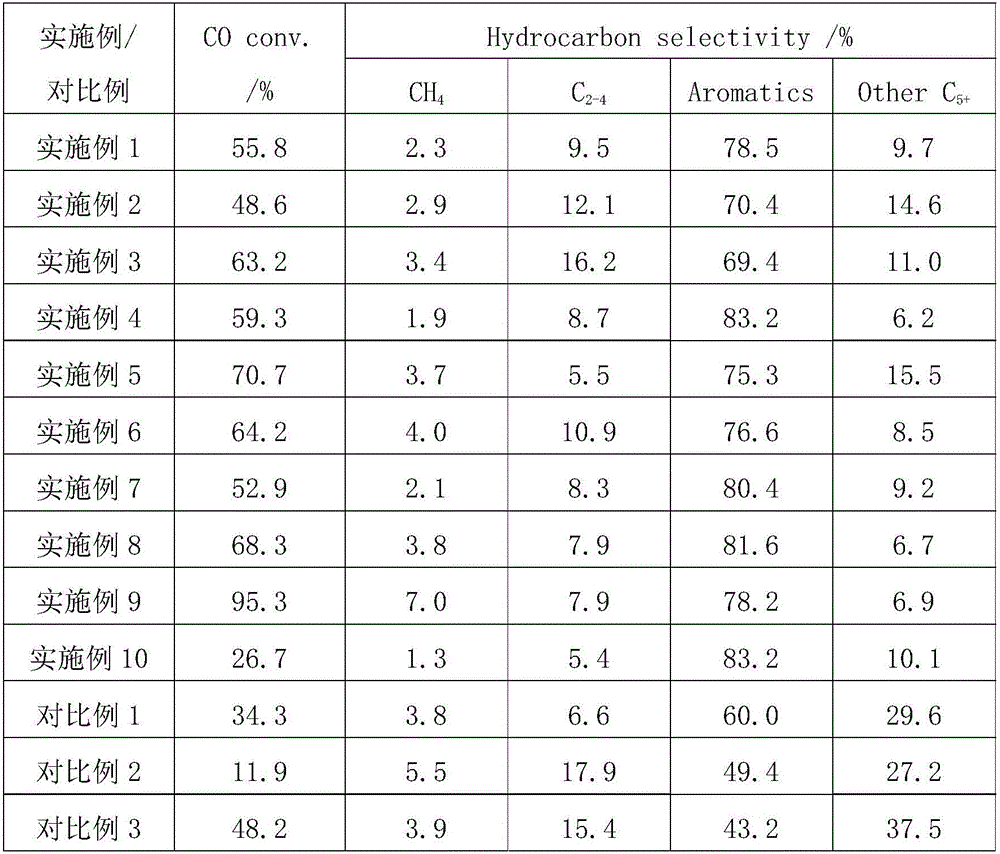

Examples

Embodiment 1

[0033] Weigh 1.34g KNO 3 , add 60ml of deionized water and stir for 5h to form a solution, then weigh 5.0g of hierarchical zeolite molecular sieve H-ZSM-11 and add it to the above solution, and stir at room temperature for 6h. After suction filtration and washing, the resulting filter cake was moved to a vacuum drying oven and dried at 70° C. for 24 hours. The dried solid powder was mixed with 6.25g BaZrO 3 The perovskite was mixed, and after being ground, the sample was moved to a muffle furnace, and the temperature was raised to 500°C at a rate of 2°C / min for 10 hours of roasting. The calcined samples were placed in a tube furnace, fed with hydrogen gas at a rate of 2 °C / min to 400 °C for reduction, and the reduction time was 10 h. The reduced solid sample was pressed into tablets to obtain the catalyst.

[0034] The catalytic reaction is carried out in a fixed-bed high-pressure microreactor, and the H in the syngas 2 The volume ratio to CO is 2, the reaction pressure is...

Embodiment 2

[0036] Weigh 2.29g Mg(NO 3 ) 2, add 50ml of deionized water and stir for 5h to form a solution, then weigh 5.0g of hierarchical zeolite molecular sieve H-ZSM-5 and add to the above solution, and stir at room temperature for 6h. After suction filtration and washing, the resulting filter cake was moved to a vacuum drying oven and dried at 70° C. for 24 hours. The dried solid powder was mixed with 5.0g BaZrO 3 The perovskite was mixed, and after being ground, the sample was moved to a muffle furnace, and the temperature was raised to 500°C at a rate of 2°C / min for 10 hours of roasting. The calcined samples were placed in a tube furnace, fed with hydrogen gas at a rate of 2 °C / min to 450 °C for reduction, and the reduction time was 10 h. The reduced solid sample was pressed into tablets to obtain the catalyst.

[0037] The catalytic reaction was carried out in a fixed-bed high-pressure microreactor. The reaction conditions and product analysis were the same as in Example 1. Th...

Embodiment 3

[0039] Weigh 0.51g Mn(CH 3 COO) 2 , add 50ml of absolute ethanol and stir for 5h to form a solution, then weigh 5.0g of hierarchical zeolite molecular sieve H-X and add it to the above solution, and stir at room temperature for 6h. After suction filtration and washing, the resulting filter cake was moved to a vacuum drying oven and dried at 70° C. for 24 hours. The dried solid powder was mixed with 5.0g CaZrO 3 The perovskite was mixed, and after being ground, the sample was moved to a muffle furnace, and the temperature was raised to 500°C at a rate of 2°C / min for 10 hours of roasting. The calcined samples were placed in a tube furnace, fed with hydrogen gas at a rate of 2 °C / min to 450 °C for reduction, and the reduction time was 10 h. The reduced solid sample was pressed into tablets to obtain the catalyst.

[0040] The catalytic reaction was carried out in a fixed-bed high-pressure microreactor. The reaction conditions and product analysis were the same as in Example 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com