Bottom plate rock roadway layer penetrating drilling hydraulic slag discharging efficient cleaning system and method

A technology of layer-through drilling and rock roadway, which is applied in the field of high-efficiency hydraulic slag removal system for layer-through-layer drilling of floor rock roadway, which can solve the problems of affecting drilling construction and sealing drainage operations, and unable to deal with coal slime and gas overflow in time. Limit accidents and other issues to achieve the effect of improving operating efficiency, avoiding gas overrun, and ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

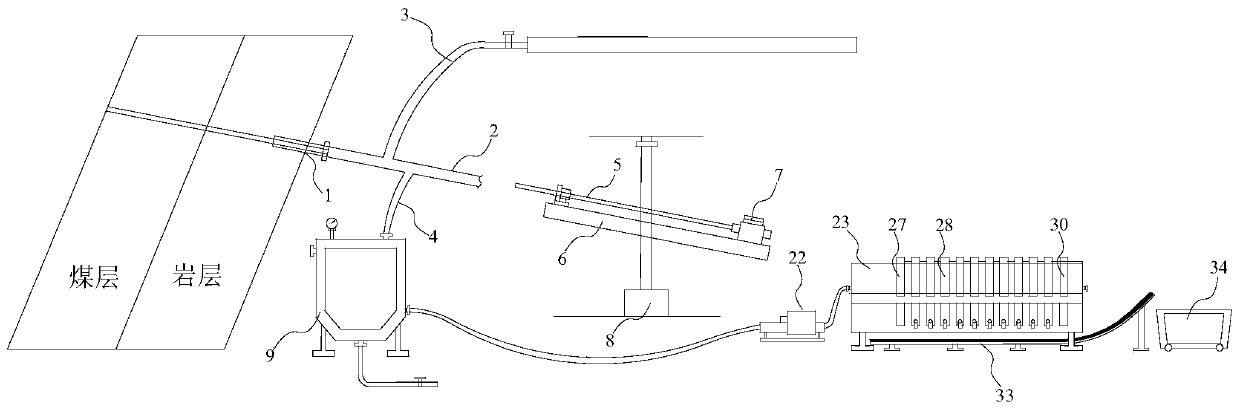

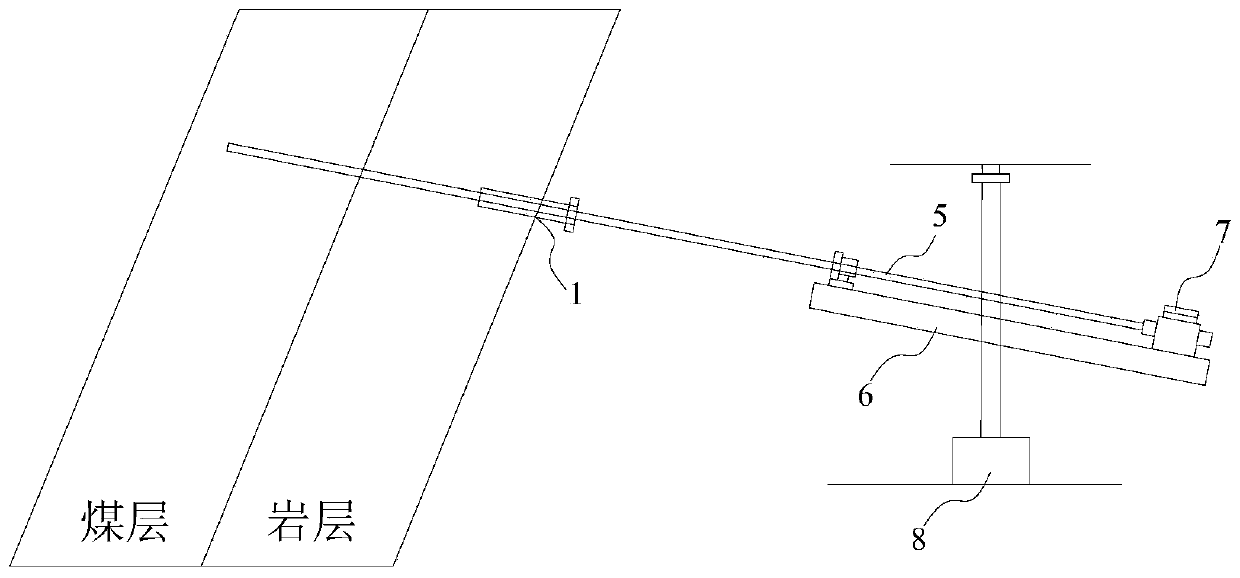

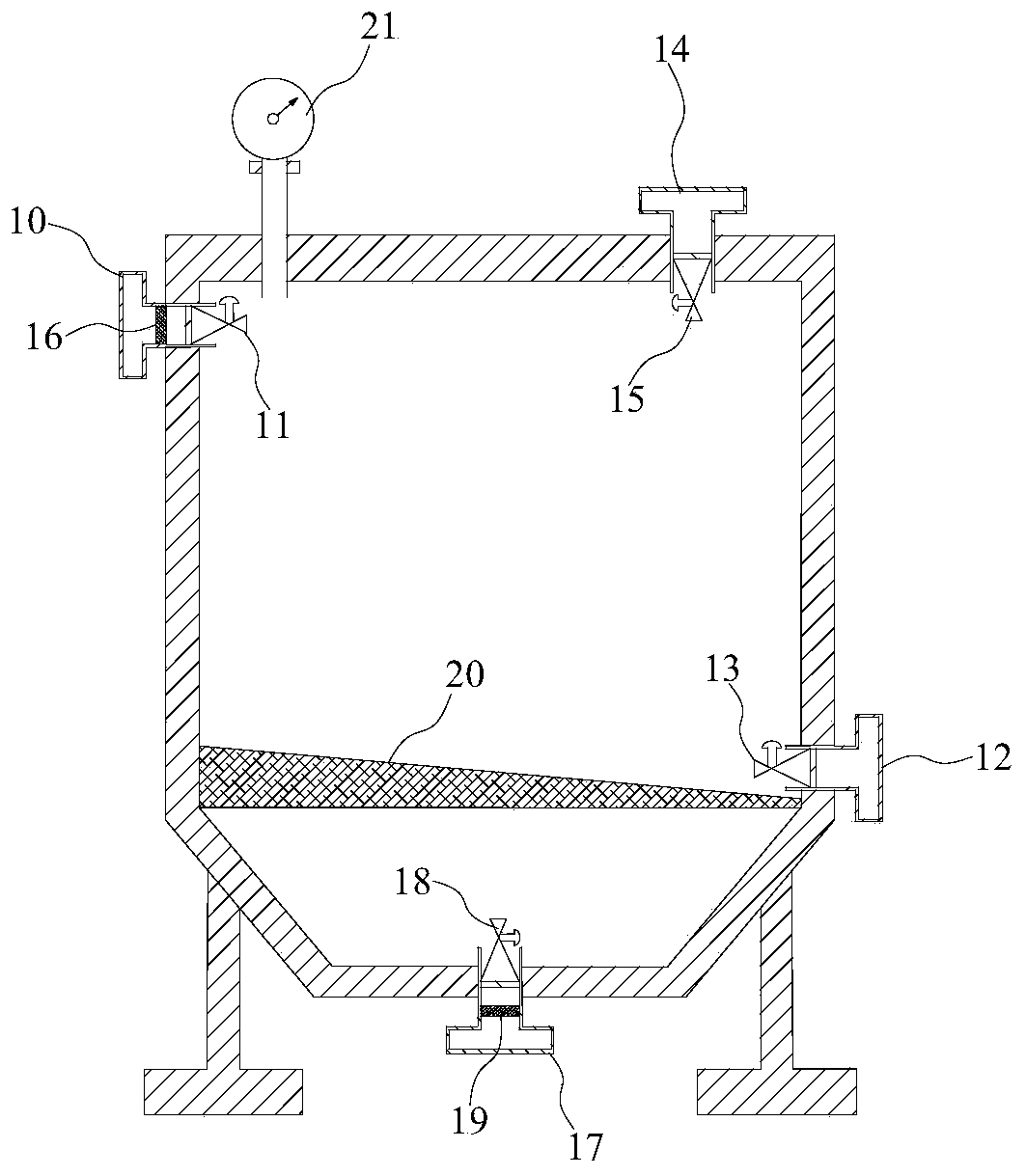

[0032] combine Figure 1 to Figure 4 As shown, the specific implementation of the system and method for hydraulic slag removal and high-efficiency cleaning of floor rock roadway through layer drilling provided by the present invention is as follows.

[0033] For soft and low-permeability outburst coal seams, the drilling hydraulic coal flushing pressure relief and anti-permeability pre-pumping technology is used to drill upward through the layer in the roadway where the coal seam floor is rocky. Hole wall - flush out a large amount of coal - increase the diameter of the borehole to extract gas. During the hydraulic coal flushing process, the drill hole will discharge a large amount of coal-gas-water mixture. In order to improve the treatment of coal-gas-water mixture High efficiency, providing a high-efficiency cleaning system for hydraulic slag removal of floor rock roadway through-layer drilling.

[0034] A high-efficiency hydraulic slag discharge cleaning system for floor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com