Catalyst used for reaction for preparing tetrahydronaphthalene through naphthalene hydrogenation and preparation method and application of catalyst

A technology of catalyst and tetralin, which is applied in the field of catalyst and its preparation for the reaction of hydrogenation of naphthalene to prepare tetralin, can solve the problem of poor selectivity of tetralin in conversion rate of naphthalene, complex processing of tetralin, and the purity of crude naphthalene Low-level problems, to achieve the effect of good activity and stability, convenient operation, and expand the range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

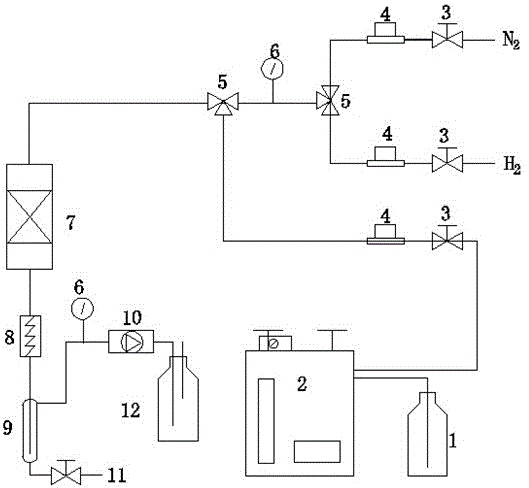

Image

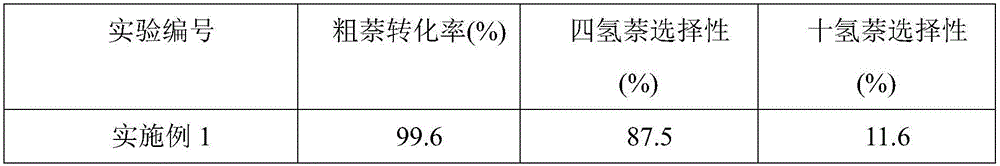

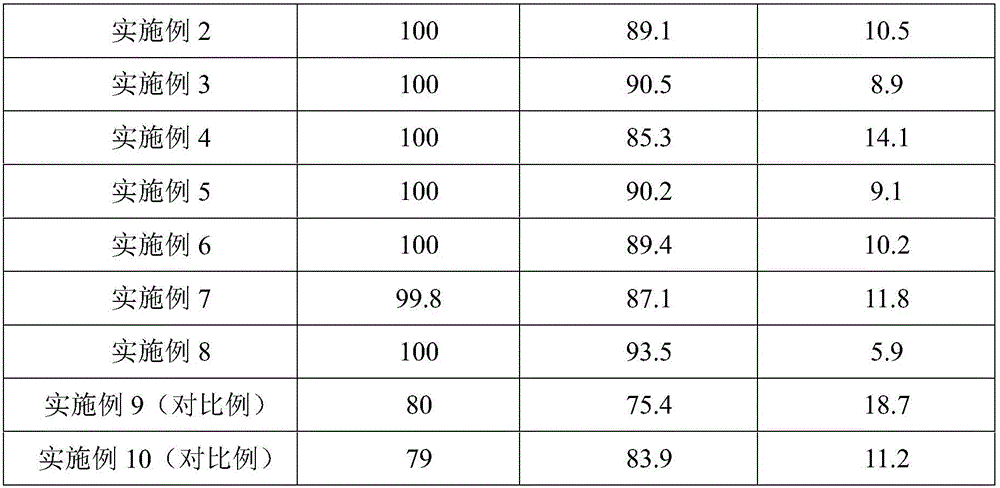

Examples

Embodiment 1

[0034] (1) Preparation of catalyst: 4g of ammonium phosphate is loaded on 100g of γ-Al by equal volume impregnation 2 o 3 , dried at 110°C and then calcined at 350°C for 2 hours to obtain a phosphorus-containing carrier. Load 22.8g of nickel nitrate hexahydrate on the phosphorus-containing carrier gold by equal volume impregnation method, dry at 110°C and then roast at 550°C for 4 hours to obtain the original catalyst; then use equal volume impregnation method to add 30.5g Ammonium molybdate was loaded on the original catalyst, dried at 110°C and then calcined at 550°C for 4 hours to obtain a powder catalyst. The powdered catalyst is pressed into tablets, crushed and screened to obtain a granular catalyst with a particle size of 1-2mm for future use. The active component content of the catalyst is 17.5%, and the additive content is 0.5%.

[0035] (2) Sulfidation of the catalyst: 10 ml of the granular catalyst was packed in a fixed-bed reactor, and a layer of 2 cm thick quar...

Embodiment 2

[0038](1) Catalyst preparation: load 2g of ammonium tetraborate on 100g of β zeolite by equal volume impregnation, dry at 110°C and then roast at 300°C for 2h to obtain a boron-containing carrier. Load 30.5g of ammonium molybdate tetrahydrate on a boron-containing carrier by equal-volume impregnation, dry at 110°C and then roast at 500°C for 4 hours to obtain the original catalyst; Nickel nitrate in water was supported on the original catalyst, dried at 110°C and then calcined at 550°C for 4 hours to obtain a powder catalyst. The powdered catalyst is pressed into tablets, crushed and screened to obtain a granular catalyst with a particle size of 1-2mm for future use. The active component content of the catalyst is 17.5%, and the additive content is 0.3%.

[0039] (2) Sulfidation of the catalyst: 10 ml of the granular catalyst was packed in a fixed-bed reactor, and a layer of 2 cm thick quartz sand was laid on the upper and lower sides of the granular catalyst. After loading ...

Embodiment 3

[0042] (1) Catalyst preparation: load 4 g of ammonium phosphate on 100 g of mordenite by equal-volume impregnation, dry at 110° C., and then roast at 350° C. for 2 hours to obtain a phosphorus-containing carrier. 22.8g of nickel nitrate hexahydrate and 33.55g of ammonium tungstate were loaded on the phosphorus-containing carrier at the same time by the method of equal volume impregnation, dried at 110°C and then roasted at 550°C for 4 hours to obtain the original catalyst; then impregnated with equal volume The method is to load 30.5g of ammonium molybdate tetrahydrate on the original catalyst, dry it at 110°C and then bake it at 550°C for 4h to obtain a powder catalyst. The powdered catalyst is pressed into tablets, crushed and screened to obtain a granular catalyst with a particle size of 1-2mm for future use. The active component content of the catalyst is 30.8%, and the additive content is 0.4%.

[0043] (2) Sulfidation of the catalyst: 10 ml of the granular catalyst was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com