Method for preparing aldehyde or hemiacetal by alcohol dehydrogenation

A hemiacetal and dehydrogenation technology, applied in the field of chemical production, can solve the problems of increasing the production cost of glyphosate, the odor of paraformaldehyde, and the complicated process, so as to control the production cost of the process, and solve the problem of low conversion rate and selectivity. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

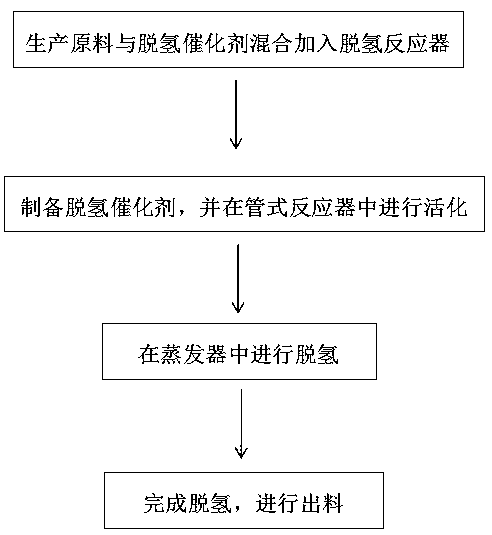

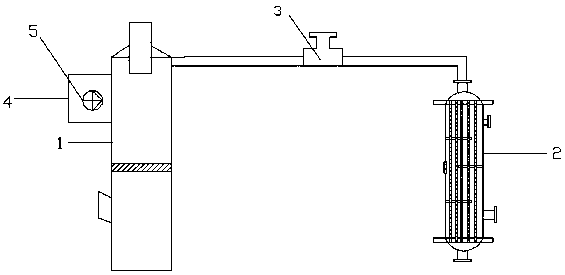

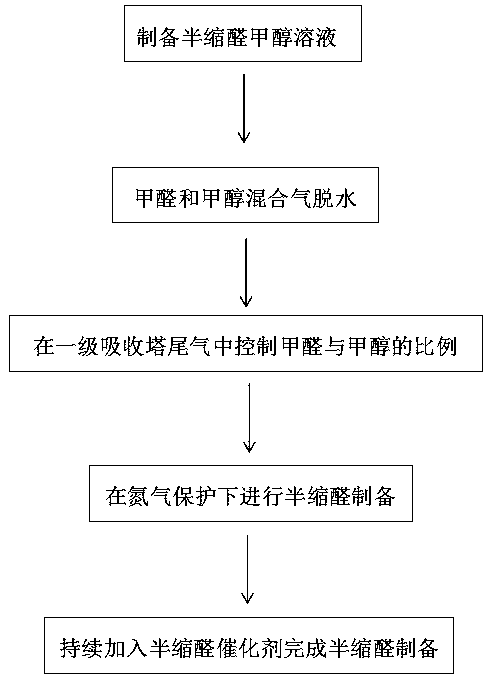

[0038] see Figure 1-4 , the present invention provides the following technical solutions:

[0039] A kind of method utilizing alcohol dehydrogenation to prepare aldehyde, this method comprises the following steps:

[0040] A, the mixture of production raw material n-butanol, isobutanol, sec-butanol, tert-butanol, alkenol and dehydrogenation catalyst are added in the dehydrogenation reactor in a weight ratio of 7:1;

[0041] B. Preparation of a dehydrogenation catalyst for the dehydrogenation of 3-methanol piperidine (3-MPIP) in a tubular reactor with an inner diameter of 26 mm by impregnating a ZrO extrudate with a Pd(NO3)2 solution To obtain the activity of 3-methanolpyridine (3-PIC), first take 50ml of catalyst material, and activate it in 20% volume hydrogen at 80°C in N2 atmosphere for 4 hours, and then activate it in pure hydrogen at 200°C for 3 hours;

[0042] C. Start metering 3-MPIP, feed 30-120ml / h production raw materials into the evaporator, and completely gasify...

Embodiment 2

[0055] see Figure 1-4 , the present invention provides the following technical solutions:

[0056] A kind of method utilizing alcohol dehydrogenation to prepare aldehyde, this method comprises the following steps:

[0057] A, the mixture of production raw material n-butanol, isobutanol, sec-butanol, tert-butanol, alkenol and dehydrogenation catalyst are added in the dehydrogenation reactor in a weight ratio of 7:1;

[0058] B. Preparation of a dehydrogenation catalyst for the dehydrogenation of 3-methanol piperidine (3-MPIP) in a tubular reactor with an internal diameter of 1.3 m by impregnating a ZrO extrudate with a Pd(NO3)2 solution For the activity of hydrogen into 3-methanolpyridine (3-PIC), first take 50ml of catalyst material, and activate it in 20% volume hydrogen at 80°C in N2 atmosphere for 6 hours, and then activate it in pure hydrogen at 200°C for 4 hours;

[0059] C. Start metering 3-MPIP, feed 30-120ml / h raw material into the evaporator, and completely vaporiz...

Embodiment 3

[0072] see Figure 1-4 , the present invention provides the following technical solutions:

[0073] A kind of method utilizing alcohol dehydrogenation to prepare aldehyde, this method comprises the following steps:

[0074] A, the mixture of production raw material n-butanol, isobutanol, sec-butanol, tert-butanol, alkenol and dehydrogenation catalyst are added in the dehydrogenation reactor in a weight ratio of 7:1;

[0075] B. Preparation of a dehydrogenation catalyst for 3-methanolpiperidine (3 -MPIP) dehydrogenation into 3-methanolpyridine (3-PIC) activity, first take 50ml of catalyst material, and activate T1 hour in 20% volume hydrogen at 80°C in N2 atmosphere, then activate T2 in pure hydrogen at 200°C Hours; the inner diameter of the tubular reactor is positively correlated with the activation time; in order to improve the production efficiency, the activation time T1 (in hours) at 80°C in 20% volume hydrogen in N2 atmosphere, the activation time in pure hydrogen at 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com