Catalytic permeable membrane reactor for producing hydrogen from ammonia-containing tail gas in MOCVDprocess as well as preparation method and application of the catalytic permeable membrane reactor

A membrane reactor and permeability technology, applied in the field of hydrogen production, can solve the problems of high energy consumption, increase load and cost, inhibit decomposition, etc., and achieve the effects of significant economic benefits, reduction of load and cost, and reduction of exhaust gas emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

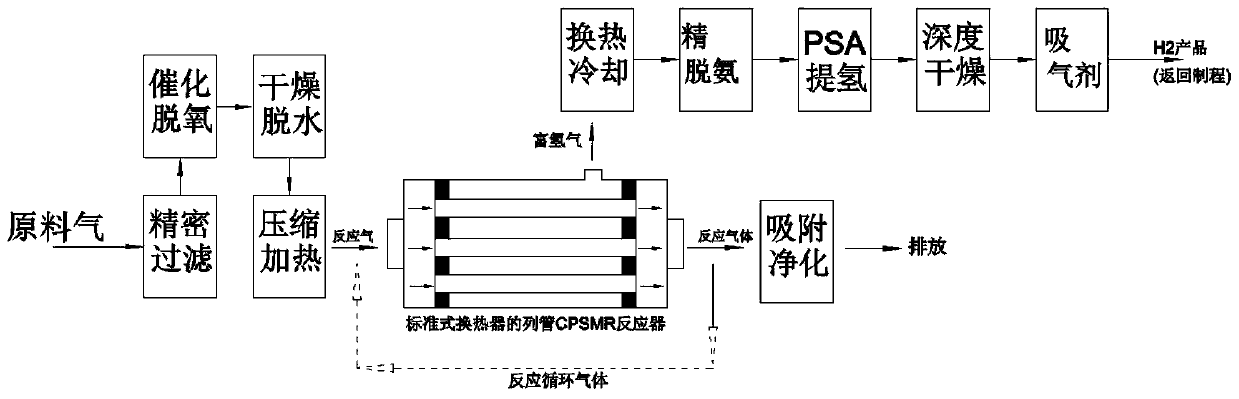

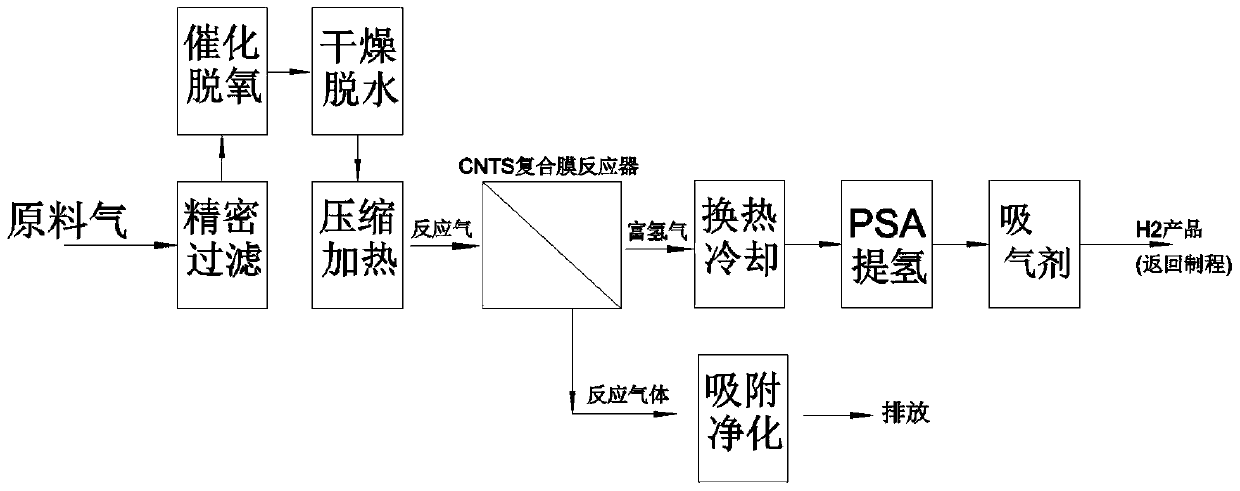

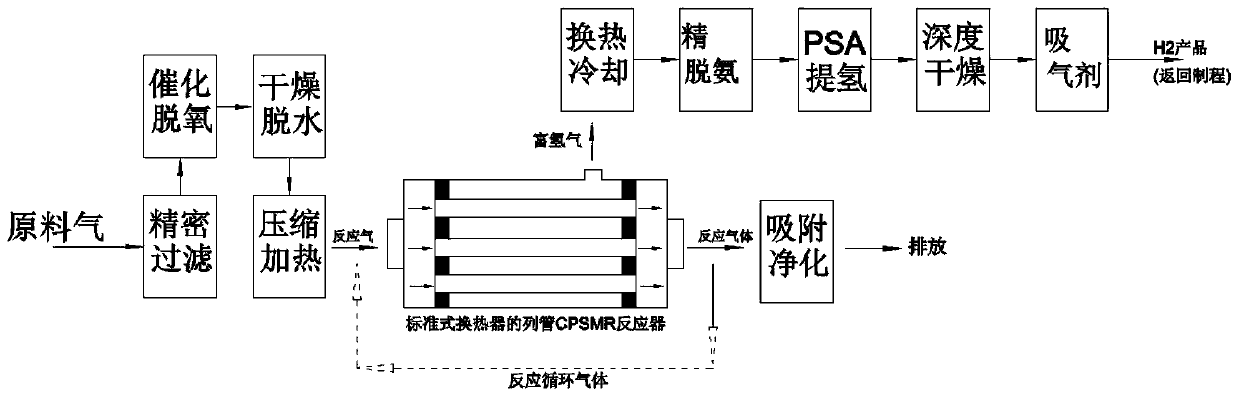

[0055] Such as figure 1 Shown, a kind of catalytic permeable membrane reactor and application of MOCVD process process containing ammonia tail gas hydrogen production, this membrane reactor is made of metal palladium dispersed in porous gamma- Aluminum oxide (γ-Al 2 o 3 ) The ceramic round tube is the support body, containing 15-20% of the active component cobalt and 14-16% of the molybdenum, 4-6% of the lanthanum-containing catalytic component and 3-5% of the promoter potassium embedded in the pretreated carbon Nanotubes (CNTs) and coated on the inner wall of alumina ceramic tubes are inorganic carbon nanofilms with a film thickness of 50nm and a film pore size of 0.30-0.60nm, including stainless steel connectors, cermet seals and heads , the reactor inlet and outlet, and the carbon steel jacket, forming a standard heat exchanger with catalytic activity and separation selectivity at the same time. ), carry out the catalytic thermal cracking hydrogen production reaction of ...

Embodiment 2

[0059]On the basis of Example 1, containing active component cobalt 15~20% and molybdenum 14~16%, containing promoter component lanthanum 460% and containing accelerator potassium 3~5% are embedded in pretreated carbon nanotube ( CNTs) and coated on γ-alumina (γ-Al 2 o 3 ) The film thickness of the inner wall of the ceramic circular tube is 50nm, and the film pore diameter is 0.30~0.60nm The inorganic CNTs film that constitutes, is to pass through the alcohol thermal melting-roasting method, first will appropriate amount of said pretreated multilayer carbon nanotubes (CNTs), added to an appropriate amount of absolute ethanol solution, after heating and stirring to form a slurry, heating a certain concentration of cobalt-molybdenum bimetallic catalyst to prepare the precursor as cobalt nitrate (Co(NO 3 ) 2 ) and molybdenum nitrate (Mo(NO 3 ) 3 ) mixed solution, the cocatalyst precursor is lanthanum nitrate (La(NO 3 ) 3 ) and potassium nitrate (KNO 3 ) mixed solution, and...

Embodiment 3

[0061] On the basis of Examples 1 and 2, the pretreated CNTs in the inorganic CNTs membrane reactor is to add an appropriate amount of 10-30% mass concentration of nitric acid and 50-70% mass concentration of a commercially available 10-20nm CNTs carrier. In a mixed solution of nitric acid with a high concentration, heat and stir, and azeotropically reflux for 4 to 8 hours, cool to ambient temperature, vacuum filter, wash with deionized water two to three times until neutral, and dry the obtained filter cake at 120°C for 1 to 8 hours. After 2 hours, it was ground into 10nm powder, and after calcination under nitrogen flow and 630-660° C. for 4-5 hours, the pretreated CNTs formed after cooling were cooled to ambient temperature and calcined.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com