Method for preparing cyclohexanol by hydrating cyclohexene

A technology of cyclohexene hydration and cyclohexanol, which is applied in the preparation of hydroxyl addition, chemical instruments and methods, molecular sieve catalysts, etc., can solve the problems of fast deactivation, slow reaction rate of catalysts, and low conversion rate, so as to improve conversion High efficiency, diverse preparation methods, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation of embodiment 1 catalyst

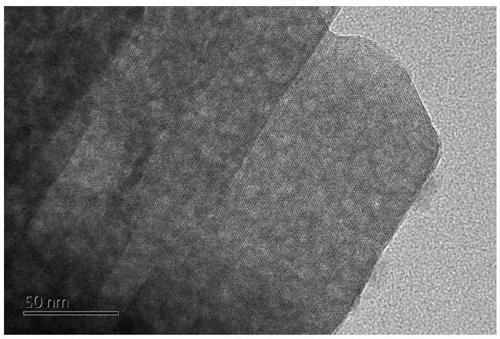

[0046] A ZSM-5 molecular sieve with a silicon-aluminum ratio (Si / Al) of 14.3 was taken, and the molecular sieve was subjected to water vapor treatment at 600°C for 3 hours. Add 100 g of the obtained molecular sieve into 3 L of 0.2 mol / L NaOH solution, stir magnetically at 80 °C for 30 min, then filter and wash until neutral, and dry in an oven at 120 °C for 12 h. The obtained molecular sieve was subjected to ammonium ion exchange to the hydrogen form (exchanged three times with 0.5 mol / L ammonium nitrate aqueous solution, washed with deionized water, dried, and then calcined at 550° C. for 4 hours) to obtain the hydrogen form multi-level porous ZSM-5 molecular sieve , denoted as catalyst A, and its scanning electron microscope image is shown as figure 1 shown.

Embodiment 2

[0047] The preparation of embodiment 2 catalyst

[0048] Taking ZSM-5 molecular sieve with a silicon-aluminum ratio (Si / Al) of 28.4, the same method as in Example 1 was used to obtain a hydrogen-type hierarchical porous ZSM-5 molecular sieve, which was designated as catalyst B.

Embodiment 3

[0049] The preparation of embodiment 3 catalyst

[0050] Take ZSM-5 molecular sieve with a silicon-aluminum ratio (Si / Al) of 50.3, and use the same method as in Example 1 to obtain a hydrogen-type hierarchical porous ZSM-5 molecular sieve, which is designated as catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com