Preparation method of lactate

A lactic acid ester and lactic acid technology, which is applied in the field of coupling technology using a membrane process to integrate lactic acid esterification reaction, to achieve the effects of reducing content, increasing conversion rate, and reducing mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

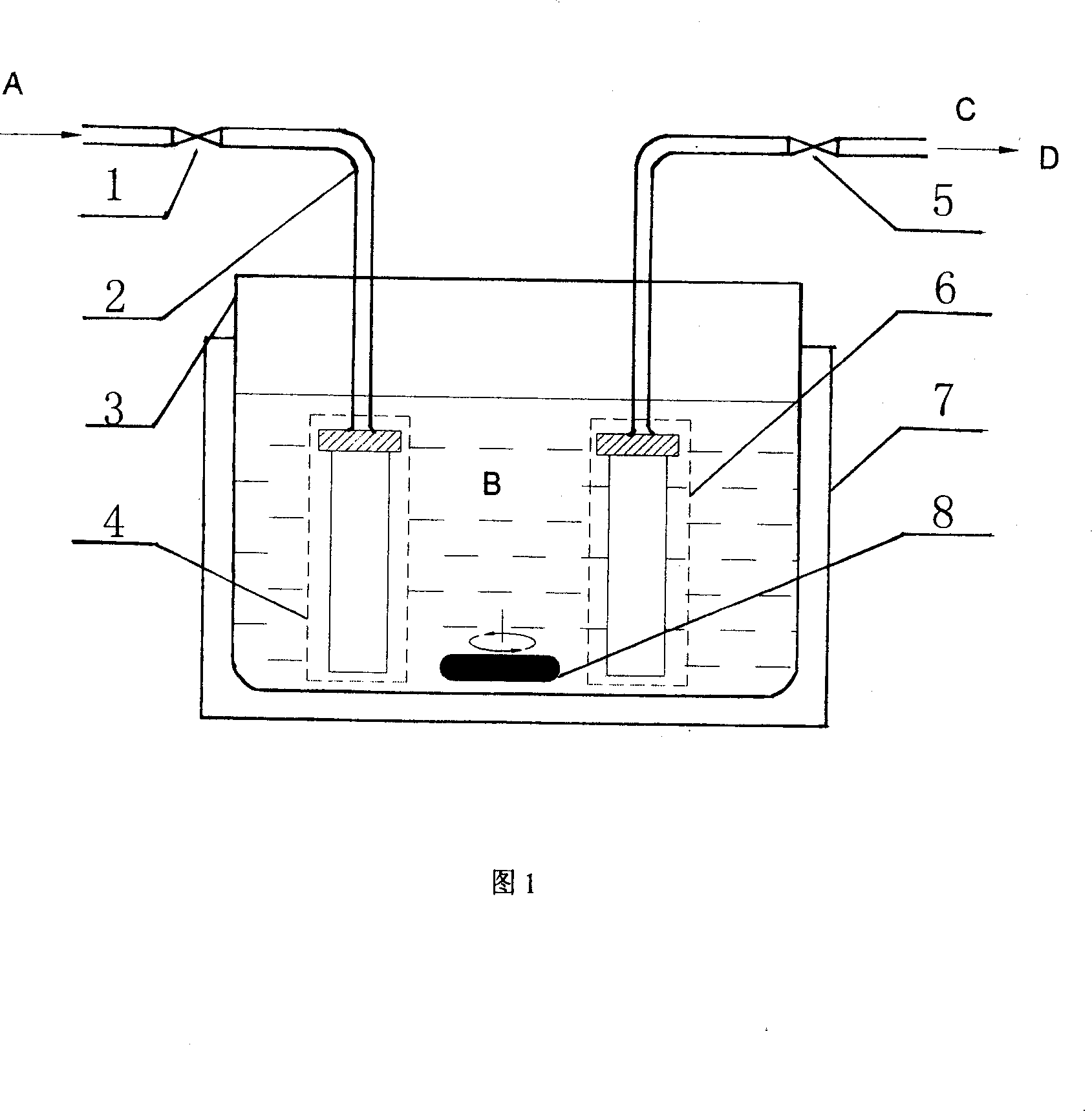

[0021] Connect the membrane, components and related equipment as shown in Figure 1. The porous membrane used is a single-tube alumina ceramic membrane with a pore size of 20nm; the dense membrane used is a NaY single-tube molecular sieve permeable membrane. Add 350 grams of 99% methanol, 10 grams of FeCl to a 2000 ml reactor 3 , turn on the magnetic stirrer to stir, and use a water bath to heat through the jacket to 65 °C and then keep the temperature constant; start the circulating water vacuum pump to vacuum the submerged pervaporation device, slowly open the regulating valve 4, the gauge pressure of the vacuum pump is 30kPa; open the regulating valve 1, The operating pressure is 600kPa, so that 80% lactic acid permeates the ceramic membrane 4 at a flow rate of 10 grams per minute (the equivalent permeation flow rate is 100L·m -2 h -1 ); after completion of the reaction, accumulatively add 1125 grams of lactic acid, and pervaporate 394 grams of water passing through the mol...

Embodiment 2

[0023] Connect the membrane, components and related equipment as shown in Figure 1. The porous membrane used is a multi-channel zirconia ceramic membrane with a pore size of 200nm; the dense membrane used is a NaA single-tube molecular sieve permeable membrane. Add 700 grams of 95% ethanol, 9 grams of AlCl in a 2000 ml reaction kettle 3 , turn on the magnetic stirrer to stir, and use a water bath to heat through the jacket to 75°C and then keep the temperature constant; start the circulating water vacuum pump to vacuum the submerged pervaporation device, slowly open the regulating valve 4, the gauge pressure of the vacuum pump is 15kPa; open the regulating valve 1, The operating pressure is 300kPa, so that 80% lactic acid permeates the ceramic membrane 4 at a flow rate of 80 grams per minute (equivalent permeation flow rate 4500L·m -2 h -1 ); after completion of the reaction, accumulatively add 1125 grams of lactic acid, and pervaporate 400 grams of water passing through the ...

Embodiment 3

[0025] Connect the porous membrane, components and related equipment as shown in Figure 1. The dense membrane adopts an external circulation pervaporation dehydration device. The porous membrane used is a flat alumina ceramic membrane with a pore size of 500nm; the dense membrane used is a macromolecule Permeable membrane. Add 800 grams of 99% n-propanol and 20 grams of cation exchange resin into a 2000 ml reaction kettle, turn on the magnetic stirrer to stir, and use a water bath to heat to 70°C through the jacket and then keep the temperature; start the circulating water vacuum pump to circulate pervaporation The device is vacuumed, and the regulating valve 4 is slowly opened, and the gauge pressure of the vacuum pump is 10kPa; the regulating valve 1 is opened, and the operating pressure is 50kPa, so that 80% lactic acid permeates the ceramic membrane 4 at a flow rate of 40 grams per minute (equivalent permeation flow rate 2000L· m -2 h -1 ); after completion of the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com