Novel solar photovoltaic conversion coating

A technology of photoelectric conversion and solar energy, applied in anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of poor weather resistance, poor mechanical properties, low photoelectric conversion rate, etc., and achieve good aging performance, low production cost, photoelectricity High conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

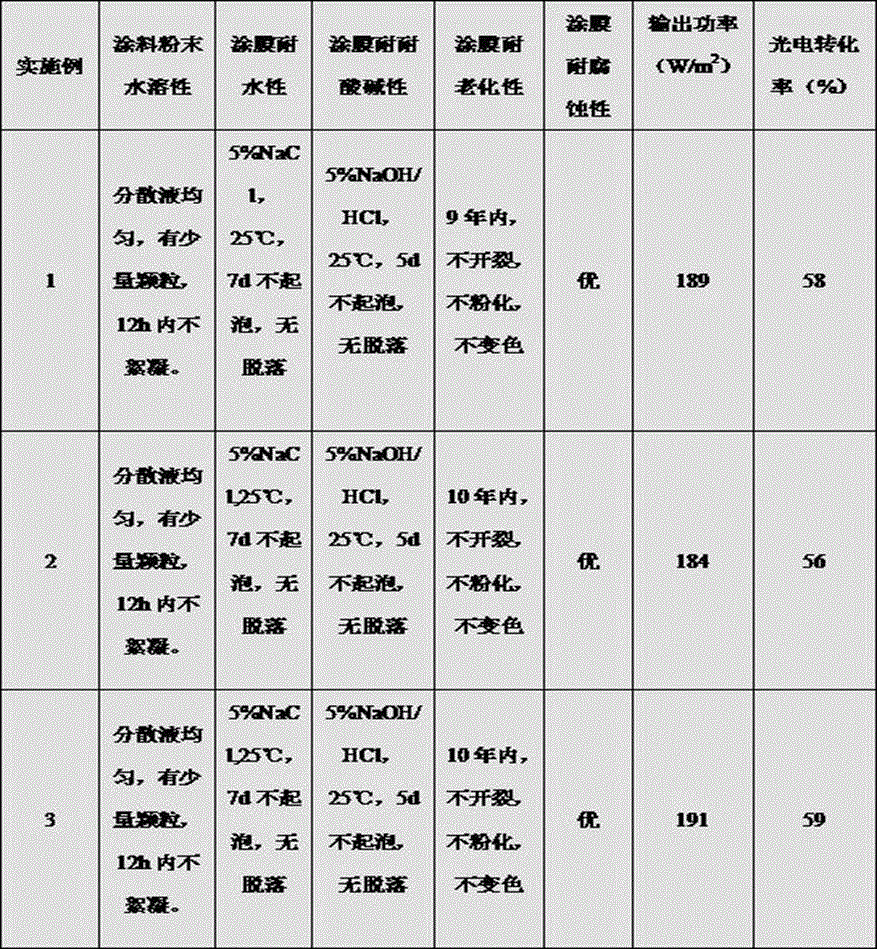

Examples

preparation example Construction

[0035] The preparation method of the novel solar photoelectric conversion coating comprises the following steps:

[0036] S1: Mix and grind matrix resin, graphite, pigments and fillers, gallium arsenide, cerium oxide, lanthanum oxide, titanium oxide, aluminum oxide, and zinc oxide, so that the particle size of the mixed pulverized product is 2-8 μm;

[0037] S2: Put the mixed pulverized product, glycerin, additive, curing agent, degassing agent, dispersant, wetting agent, emulsifier, preservative, and antioxidant prepared in step S1 into a microwave reactor, Process at a power of 100-300W, a temperature of 45-65°C, and a stirring speed of 100-200r / min for 10-20 minutes, then put it in a homogenizer for dispersion treatment, and obtain a paint emulsion;

[0038] The preparation method of the addition agent described in step S2 comprises the following steps:

[0039] S21: Mix the generating agent, coupling agent, compatibilizer, stabilizer, and bridging agent and heat up to 110...

Embodiment 1

[0044] A new type of solar photoelectric conversion coating, including the following raw materials in units of weight: 80 parts of matrix resin, 45 parts of graphite, 30 parts of pigments and fillers, 45 parts of gallium arsenide, 8 parts of cerium oxide, 8 parts of lanthanum oxide, 6 parts of titanium oxide 1 part, 6 parts of aluminum oxide, 5 parts of zinc oxide, 80 parts of glycerol, 15 parts of additive, 8 parts of curing agent, 2 parts of degasser, 1.5 parts of dispersant, 0.9 part of wetting agent, 0.8 part of emulsifier , 0.4 parts of preservatives, 0.3 parts of antioxidants;

[0045] The matrix resin is polyester resin; the pigment and filler are metal pigments and extender pigments, the metal pigment is silver powder, and the extender pigment is quartz powder;

[0046] The addition agent is made of the following raw materials in parts by weight: 1.5 parts of generator, 3 parts of coupling agent, 1.5 parts of compatibilizer, 1.5 parts of stabilizer, 1.4 parts of bridgi...

Embodiment 2

[0058] A new type of solar photoelectric conversion coating, with weight as the unit, including the following raw materials: 55 parts of matrix resin, 35 parts of graphite, 20 parts of pigment and filler, 30 parts of gallium arsenide, 5 parts of cerium oxide, 5 parts of lanthanum oxide, 4 parts of titanium oxide 1 part, 4 parts of aluminum oxide, 3 parts of zinc oxide, 60 parts of glycerin, 10 parts of additive, 6 parts of curing agent, 1 part of degasser, 1 part of dispersant, 0.5 part of wetting agent, 0.4 part of emulsifier , 0.2 parts of preservatives, 0.2 parts of antioxidants;

[0059] The matrix resin is polyester resin; the pigment and filler are metal pigments and extender pigments, the metal pigment is silver powder, and the extender pigment is quartz powder;

[0060] The addition agent is made of the following raw materials in parts by weight: 2 parts of generating agent, 2 parts of coupling agent, 1 part of compatibilizer, 1 part of stabilizer, 0.8 part of bridging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com