Nitride light emitting diode and manufacturing method thereof

A technology of light-emitting diodes and nitrides, applied in chemical instruments and methods, from chemically reactive gases, crystal growth, etc., can solve the problems of reducing the carrier capture ability, reducing the radiation recombination efficiency, and reducing the injection efficiency. Uniform heat source distribution and luminous intensity, reducing Auger recombination and improving recombination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

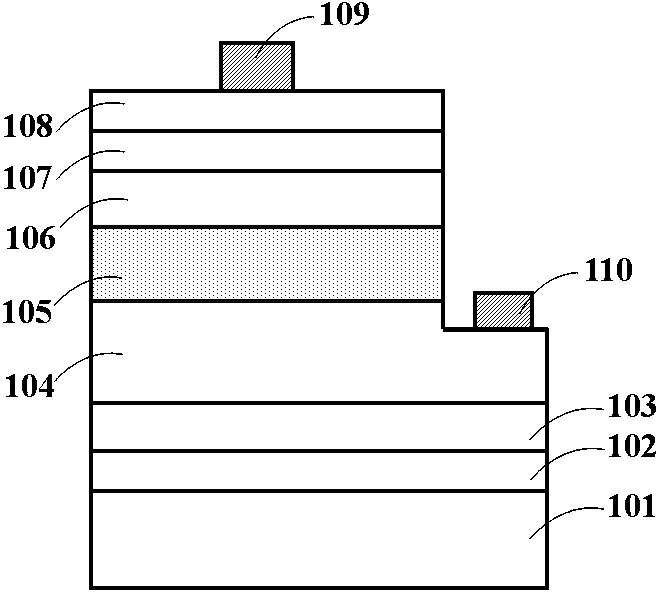

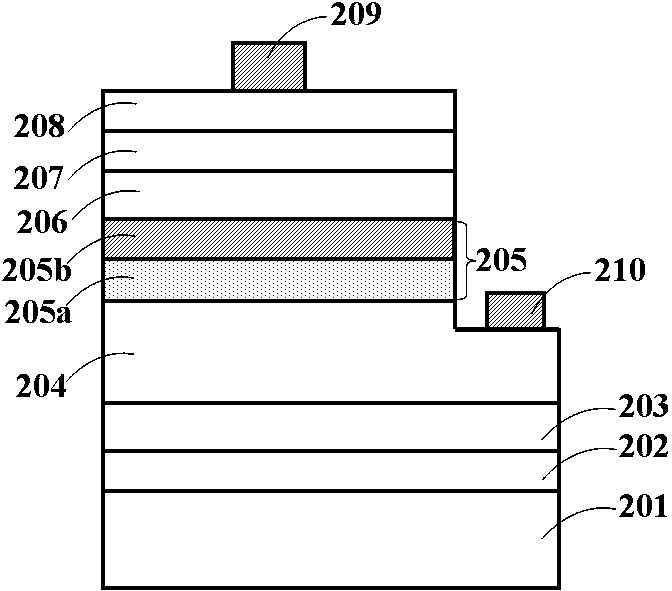

[0038] Such as figure 2 As shown, the nitride light-emitting diode includes: a sapphire substrate 201, a low-temperature buffer layer 202, an undoped GaN layer 203, an n-type GaN layer 204, an active region 205, a p-type electron blocking layer 206, and a p-type GaN layer 207 , p-type highly doped GaN contact layer 208 , p-electrode 209 and n-electrode 210 . The following describes in detail in conjunction with the preparation method.

[0039] First grow a low-temperature buffer layer 202 on a sapphire substrate 201, then grow a non-doped GaN layer 203 with a thickness of 1 μm, and then form a Si-doped layer 203 with a Si doping concentration of 1.5×10 on the non-doped GaN layer 203. 19 cm -3 The n-type GaN layer 204, followed by growing the multi-quantum well active region 205, and then growing the p-type Al 0.15 Ga 0.85 The N layer is used as the p-type electron blocking layer 206, and the Mg doping concentration is 5×10 19 cm -3 After the epitaxial growth of the p-ty...

Embodiment 2

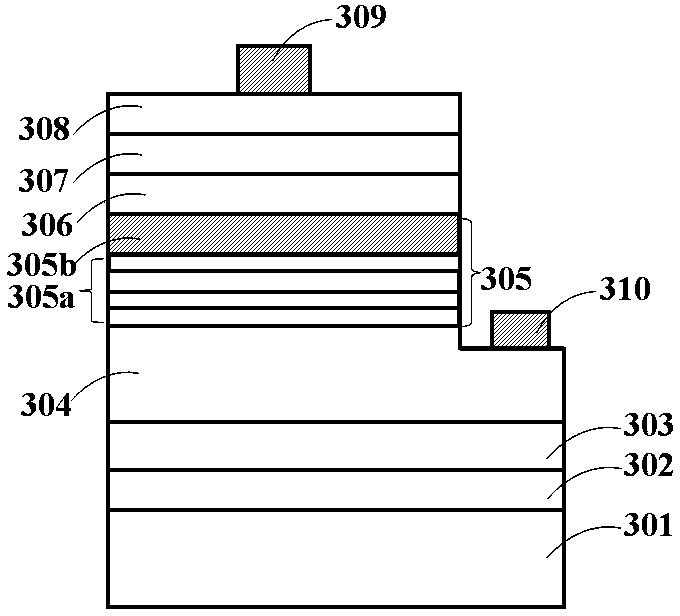

[0042] The difference between this embodiment and embodiment 1 is: the front M of the active region is opposite to the Al 0.10 In 0.16 Ga 0.74 Al and In compositions in N / GaN quantum wells are graded. Such as image 3 As shown, a nitride light-emitting diode includes: a sapphire substrate 301, a low-temperature buffer layer 302, an undoped GaN layer 303, an n-type GaN layer 304, an active region 305, a p-type electron blocking layer 306, and a p-type GaN layer 307 , p-type highly doped GaN contact layer 308 , p-electrode 309 and n-electrode 310 . Among them, 4 cycles of Al x In 1-x-y Ga y The values of Al composition x in N / GaN multiple quantum well 305a are 0.025, 0.05, 0.075 and 0.1 from bottom to top, and correspondingly, the values of In composition 1-x-y are 0.04, 0.08, 0.12 and 0.16 from bottom to top .

Embodiment 3

[0044] Such as Figure 4 As shown, compared with the previous embodiment, the difference is that the quantum well energy band design of this embodiment is different, Al x In 1-x-y Ga y N-well bandgap width ( E g ) minimum value is larger than the bandgap width of the InGaN well. Specifically, Al x In 1-x-y Ga y The bandgap width of the N well is 2.9~3.4eV, and the bandgap width of the InGaN well is 2.3~2.8eV. Thanks Al x In 1-x-y Ga y N-well bandgap width ( E g ) > Bandgap width of InGaN well ( E g ), avoiding that the light generated by the epitaxially grown InGaN well is first epitaxially grown Al x In 1-x-y Ga y The efficiency is reduced due to the absorption of the N well; in addition, the shallower Al x In 1-x-y Ga y The blocking effect of the N well on the return electrons will be better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com