Method for roasting vanadium-containing material by using chain grate machine and rotary kiln

A technology of chain grate machine and rotary kiln is applied in the field of roasting vanadium-containing materials by using chain grate machine and rotary kiln.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

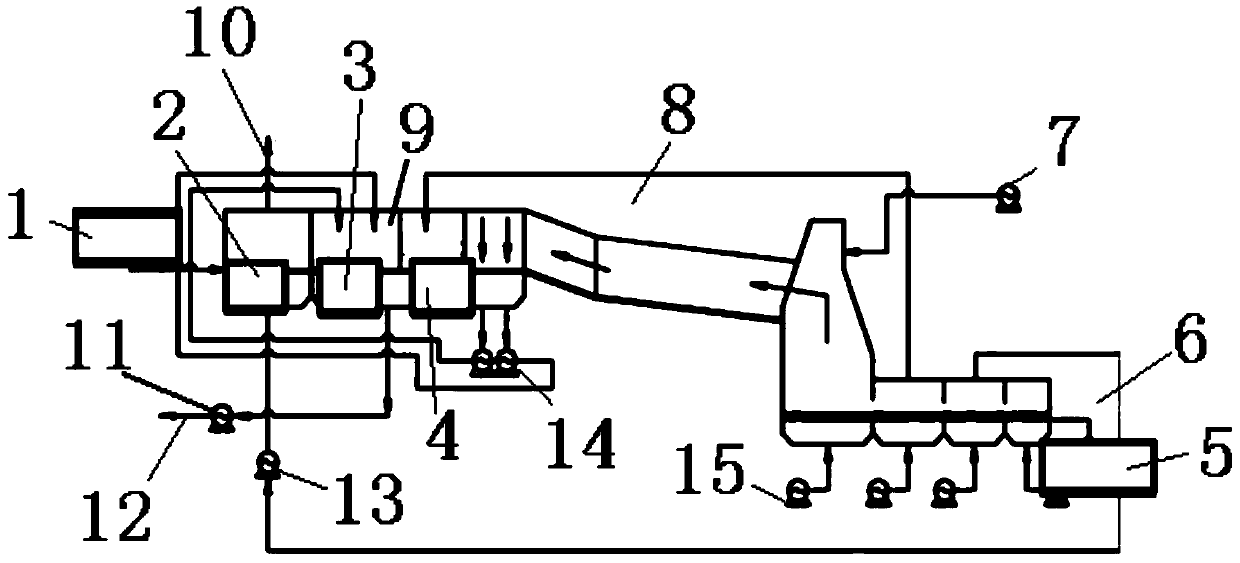

Image

Examples

Embodiment

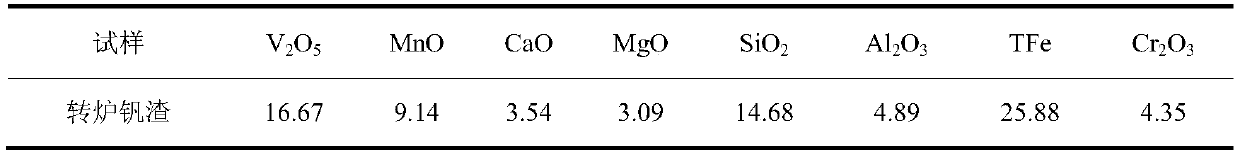

[0030] The present invention will be further described below in conjunction with embodiment. Among them, the main components of each element in the vanadium slag are shown in Table 1.

[0031] Table 1 Converter vanadium slag chemical composition (%)

[0032]

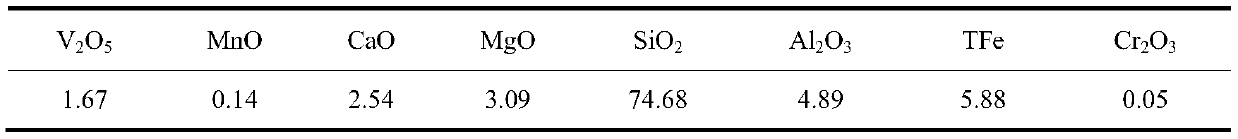

Embodiment 1

[0033] Embodiment one: Utilize the present invention and the method for extracting vanadium by sodium roasting to process converter vanadium slag in table 1

[0034]Take 1000g of converter vanadium slag powder and 220.87g of anhydrous sodium carbonate and lubricate them in a lubricating mill for 30 minutes to obtain a mixture. Put the mixture in a mixer, mechanically moisten and activate it for 30 minutes, and spray water to obtain a wet mixture with a moisture content of about 6%. The mixture is placed in a granulator to prepare a cylindrical material with a particle size of 5-10 mm. After the powder is removed by the roller sieve, the cylindrical material is evenly spread in the grate machine with a roller sieve machine, the thickness is 100mm, the temperature of entering the blast zone 2 is 200°C, and the residence time in the blast zone 2 is 20min; The initial temperature in the heating zone after the exhaust zone 3 is 650°C, and the residence time is 20 minutes; the init...

Embodiment 2

[0035] Embodiment two: Utilize the present invention and the method for extracting vanadium by sodium roasting to process converter vanadium slag in table 1

[0036] Take 1000g of converter vanadium slag powder and 307.75g of sodium bicarbonate and lubricate them in a lubricating mill for 60 minutes to obtain a mixture. Put the mixed material in a mixer, mechanically moisten and activate it for 60 minutes, and spray water to obtain a wet mixed material with a moisture content of about 8%. The mixture is placed in a granulator to prepare a cylindrical material with a particle size of 5-15mm. After the powder is removed by roller sieving, the cylindrical material is evenly spread in the grate machine with a roller sieve machine, with a thickness of 100mm. The temperature of entering the blast zone 2 is 300°C, and the residence time in the blast zone 2 is 20min; The initial temperature in the heating zone after the draft zone 3 is 650°C, and the time in the preheating zone 4 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com