Full-automatic unloaded brick packer

A fully automatic, baler technology, applied in the directions of packaging, transportation and packaging, the type of packaging items, etc., to achieve the effect of low failure rate, easy operation and easy learning, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can understand.

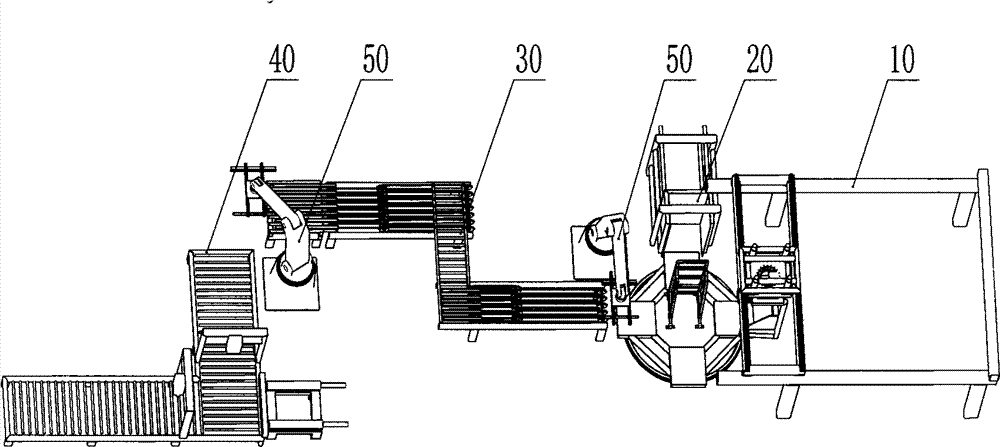

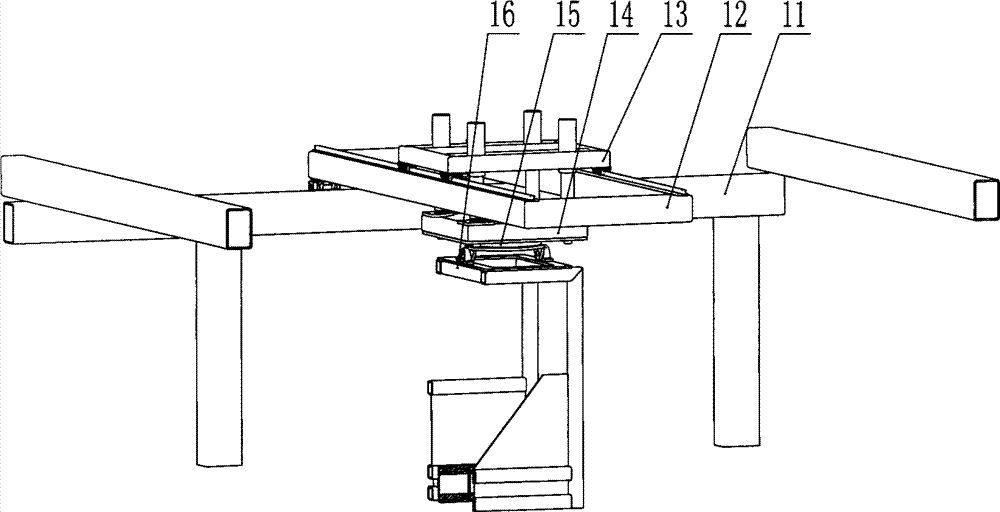

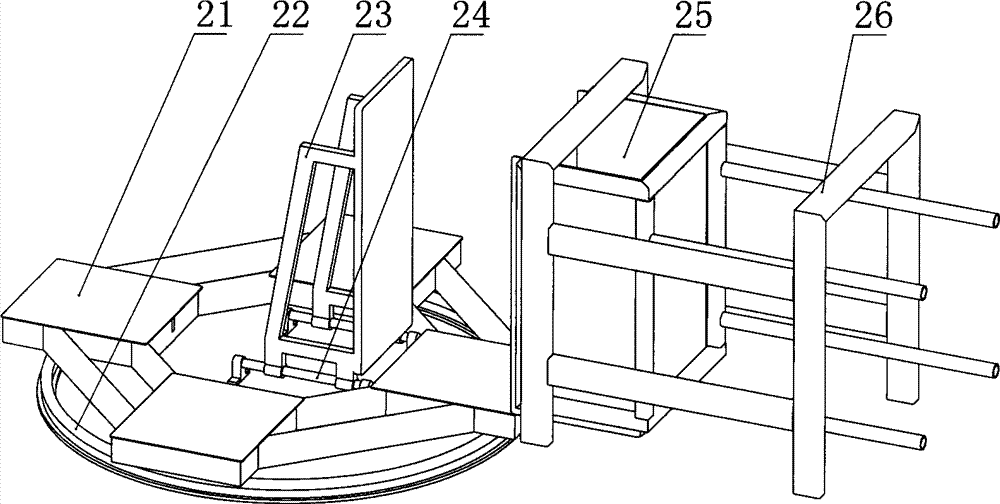

[0033] The fully automatic brick unloading baler provided by the invention has a structure such as figure 1 As shown, it consists of a depalletizer 10, a stacker 20, a robot 50, a marshalling machine 30, another robot 50, and a packing machine 40, which are connected end to end in sequence. The working process is: the depalletizer 10 spans the kiln Car, unload the burnt bricks one by one from the kiln car, and put them on the stacker 20 for shaping. One of the robots 50 removes the bricks one by one from the stack of bricks that have been shaped by the stacker 20. Take off the layers and put them on the marshalling machine 30. The marshalling machine 30 first closes the horizontal seams between bricks and tightens the vertical strips, and then divides the bricks into specified strips ac...

Embodiment 2

[0040] The fully automatic brick unloading baler differs from Embodiment 1 in that: the placement of the marshalling machine 30 can be vertical or parallel to the kiln car track according to the actual situation on site; According to the actual situation on site, it can be vertical or parallel to the kiln car track.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com