Preparation technology of cubic boron nitride accumulation abrasive material

A technology of cubic boron nitride and accumulated abrasives, applied in abrasives, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of large usage of liquid-based adhesives, small contact surface between abrasive particles and particles, complicated equipment, etc. , to achieve the effect of improving wettability, improving bonding strength and reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

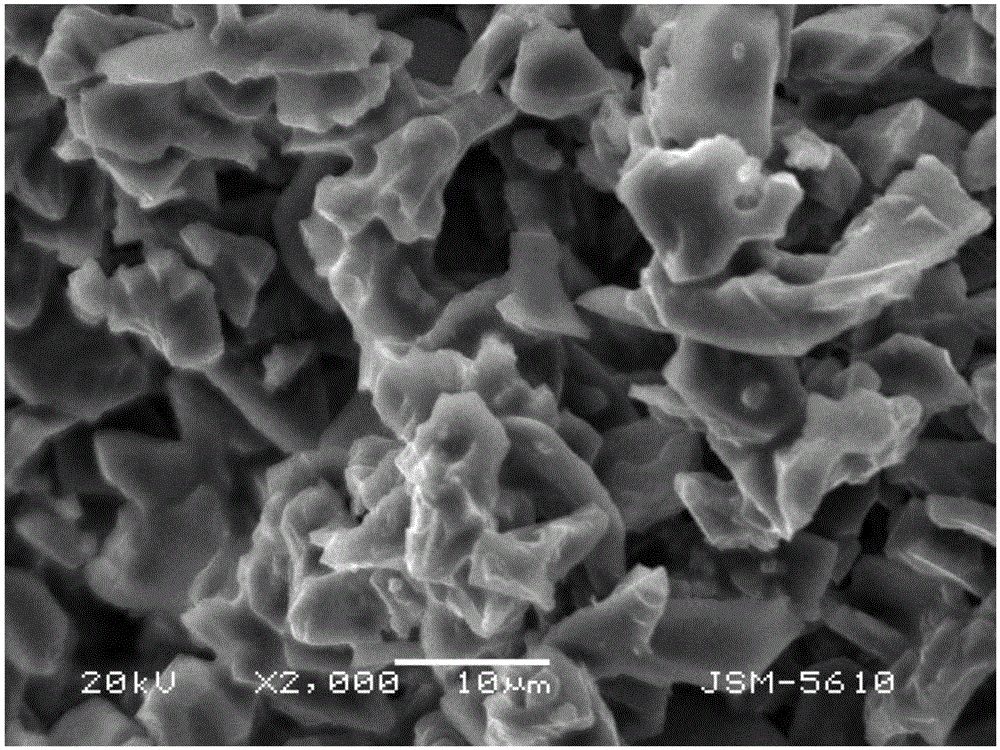

[0035]A kind of preparation technology of CBN accumulation abrasive, concrete steps are:

[0036] Weigh industrial-grade titanium dioxide sol (solid phase content 10wt%), commercially available industrial-grade water glass solution (modulus 2.8) and boric acid (chemically pure) at a mass ratio of 25:70:5, and weigh the water glass Add titanium dioxide sol to the solution, stir for 1 hour at a speed of 2000 rpm, then add weighed boric acid, stir for 1 hour at a speed of 2000 rpm, and then pour the mixed liquid into a closed container to wait Used to obtain the binder of CBN stacked abrasives.

[0037] (2) Weigh the CBN abrasive (grain size W5), the adhesive obtained in step (1) and yellow dextrin powder according to the mass ratio of 77:20:3, and pour the weighed various raw materials into the corundum ball mill altar, The diameter of the ball milling altar is 400mm, and plastic balls are added according to the ratio of ball to material mass ratio of 0.8:1, among which plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com