Inorganic adhesive for bamboo-wood structures and preparation method thereof

A structural, inorganic adhesive technology, applied in inorganic adhesives, adhesives, non-polymer adhesive additives, etc., can solve problems such as failure to achieve good bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

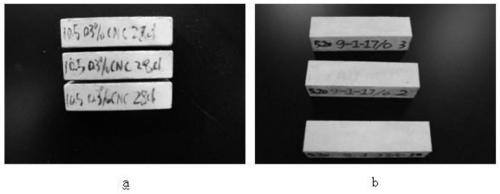

[0038] Embodiment 1 A kind of inorganic glue for bamboo and wood structure

[0039] Its components include: magnesium oxide, magnesium sulfate heptahydrate, silica fume, silica sol, lithium silicate, sodium silicate, citric acid, water.

[0040] The mass ratio of the above components is: magnesium oxide: magnesium sulfate heptahydrate: silica fume: silica sol: lithium silicate: sodium silicate: citric acid: water = 1: 0.42, 0.05, 0.01, 0.005, 0.01, 0.01, 0.39 .

[0041] Magnesium Oxide: Light-burned magnesia, activity 75.

[0042] Magnesium sulfate heptahydrate: industrial grade, effective content 95%.

[0043] Silica fume: Amorphous SiO 2 Content 95%, particle size 100-300nm.

[0044] Silica sol: particle size 10-20nm, liquid, concentration 30%.

[0045] Lithium silicate: solid, modulus 2.0, dissolved in water in advance.

[0046] Sodium silicate: liquid, modulus 2.3.

[0047] Citric acid: 98% purity, powder.

[0048] Water: clean tap water.

[0049] The preparation ...

Embodiment 2

[0062] Embodiment 2 A kind of inorganic glue for bamboo and wood structure

[0063] Its components: magnesium oxide, magnesium sulfate heptahydrate, silica fume, silica sol, lithium silicate, sodium silicate, citric acid, water.

[0064] The mass ratio of the above components is: magnesium oxide: magnesium sulfate heptahydrate: silica fume: silica sol: lithium silicate: sodium silicate: citric acid: water = 1: 0.39, 0.03, 0.005, 0.005, 0.01, 0.005, 0.56 .

[0065] Magnesium Oxide: Light-burned magnesia, active 56.

[0066] Magnesium sulfate heptahydrate: industrial grade, effective content 90%.

[0067] Silica fume: amorphous SiO2 content 92%, particle size 100-300nm.

[0068] Silica sol: particle size 15-25nm, liquid, concentration 30%.

[0069] Lithium silicate: solid, modulus 1.5, dissolved in water in advance.

[0070] Sodium silicate: solid, modulus 1.5, dissolved in water in advance.

[0071] Citric acid: 96% purity, powder.

[0072] Water: clean tap water.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

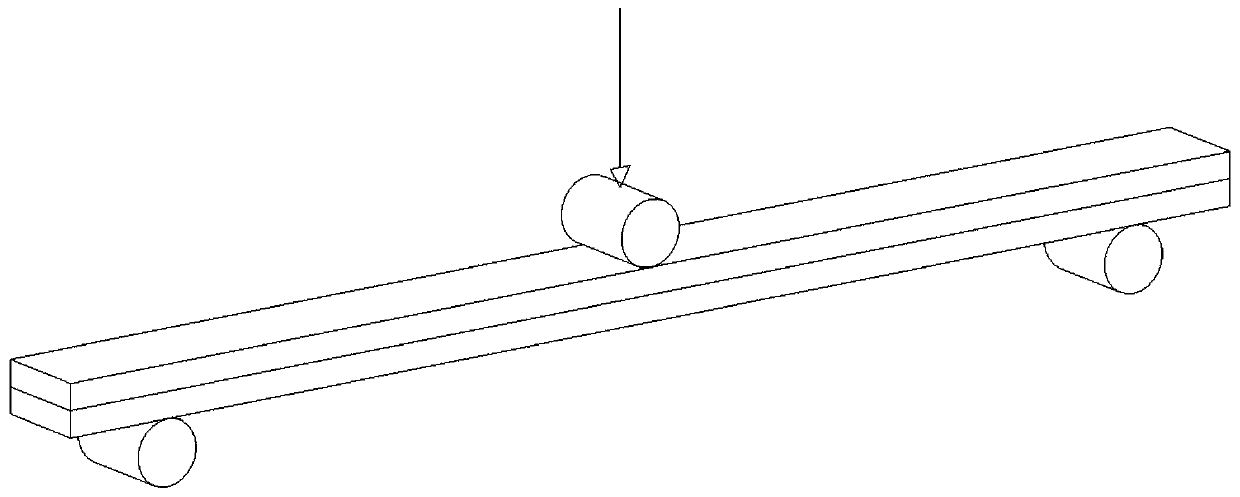

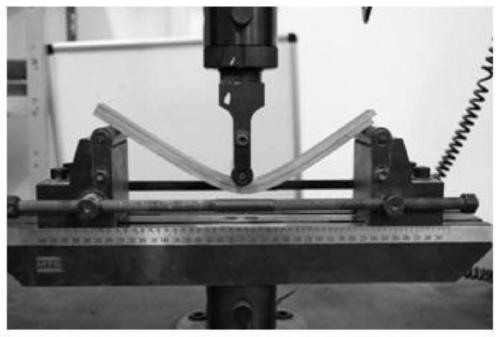

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com