Coal hydrogenation catalytic gasification method and device

A technology of hydrogenation catalysis and catalytic gasification, applied in the field of coal gasification, can solve the problems of complex process and low content, achieve high economic value and improve the effect of formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

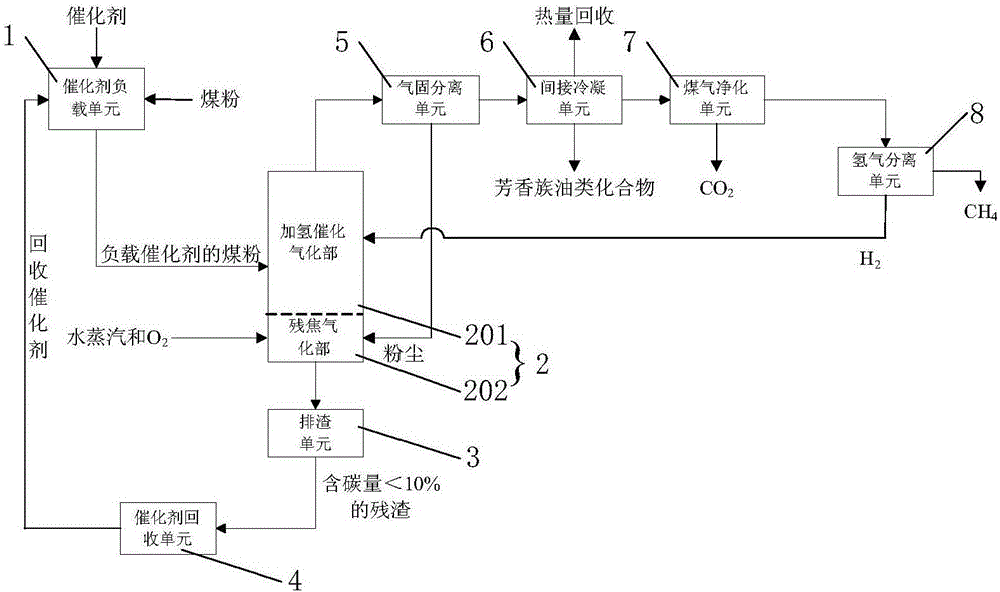

[0086] This embodiment provides a coal hydrogenation catalytic gasification method, the method comprises the following steps:

[0087] S1: Anthracite powder with a particle size of 6mm or less and a water content of <5% is dry mixed with a catalyst in the catalyst loading unit 1 to generate anthracite powder loaded with Fe salt, and the catalyst is Fe salt.

[0088] S2: The catalyst-loaded anthracite powder enters the hydrogenation catalytic gasification part 201, and under the action of the catalyst, the catalyst-loaded anthracite powder and the H present in the hydrogenation catalytic gasification part 202 2 Hydrocatalytic gasification reaction occurs to generate CH 4 , catalyst-rich coke and aromatic oil compounds, and the CO present in the hydrogen catalytic gasification unit 202 2 with H 2 The reaction produces CH 4 , wherein the operating pressure of the hydrocatalytic gasification reaction is 0.5 MPa, and the reaction temperature of the hydrocatalytic gasification re...

Embodiment 2

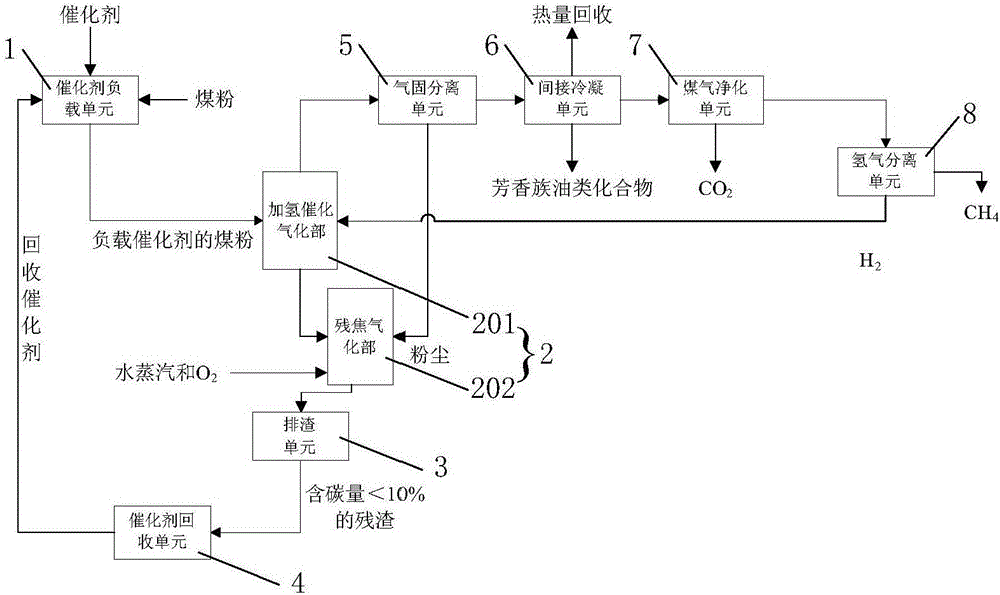

[0095] This embodiment provides a coal hydrogenation catalytic gasification method, the method comprises the following steps:

[0096] S1: Sub-bituminous coal powder with a particle size of 6mm or less and a water content of <5% and the catalyst are impregnated and partially dry-mixed in the catalyst loading unit 1 to generate sub-bituminous coal powder loaded with the catalyst. The catalyst is a mixture of Co salt and Ni salt. mixture.

[0097] S2: The sub-bituminous coal powder of the catalyst-loaded mixture enters the hydrocatalytic gasification part 201, and under the action of the catalyst, the catalyst-loaded sub-bituminous coal powder and the H present in the hydrogen catalytic gasification part 202 2 Hydrocatalytic gasification reaction occurs to generate CH 4 , catalyst-rich coke and aromatic oil compounds, and the CO present in the hydrogen catalytic gasification unit 202 2 with H 2 The reaction produces CH 4 , wherein the operating pressure of the hydrocatalytic...

Embodiment 3

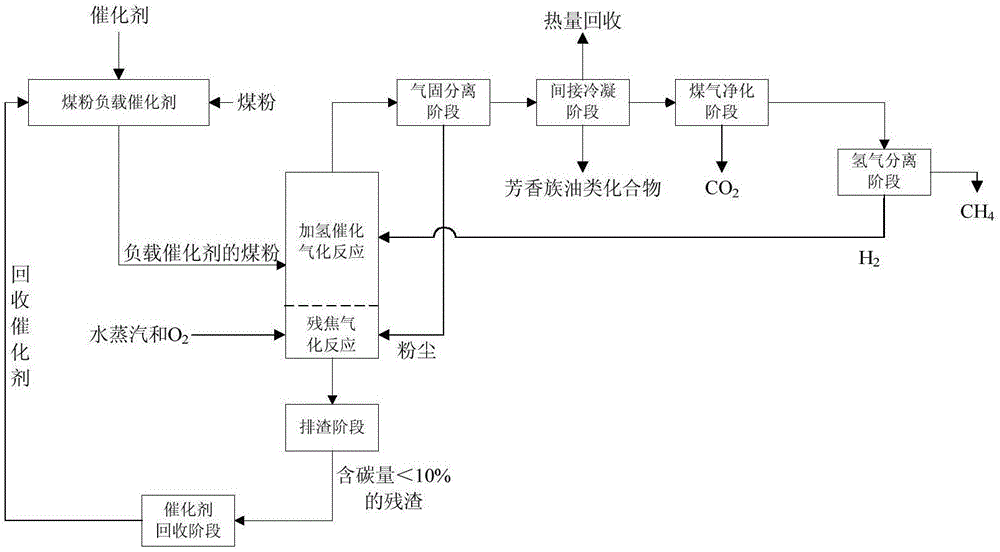

[0104] This embodiment provides a coal hydrogenation catalytic gasification method, the method comprises the following steps:

[0105] S1: The pulverized coal mixture with a particle size of 6mm or less and a water content of <5% and the catalyst are impregnated and partially dry mixed in the catalyst loading unit 1 to generate a pulverized coal mixture loaded with the catalyst. The pulverized coal mixture is sub-bituminous coal powder and volatile coal powder. The mass percentage of bituminous coal powder is higher than 30%. The catalyst is a composite catalyst. The main catalyst of the composite catalyst is Fe salt, and the promoter is Mg salt. The quality of Fe salt accounts for 3% of the mass of coal powder, and the Mg salt The mass accounts for 0.2% of the mass of pulverized coal.

[0106] S2: The catalyst-loaded pulverized coal mixture enters the hydrogenation catalytic gasification part 201, and under the action of the catalyst, the catalyst-loaded coal powder mixture a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com