Preparation method and application of modified charcoal adsorbent based on lanthanum ferrite

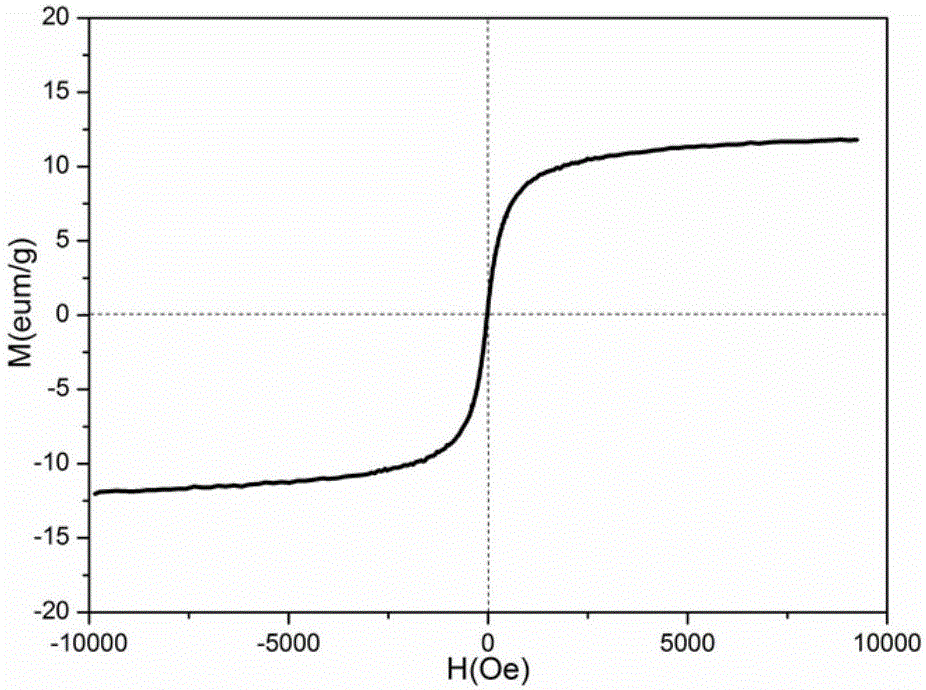

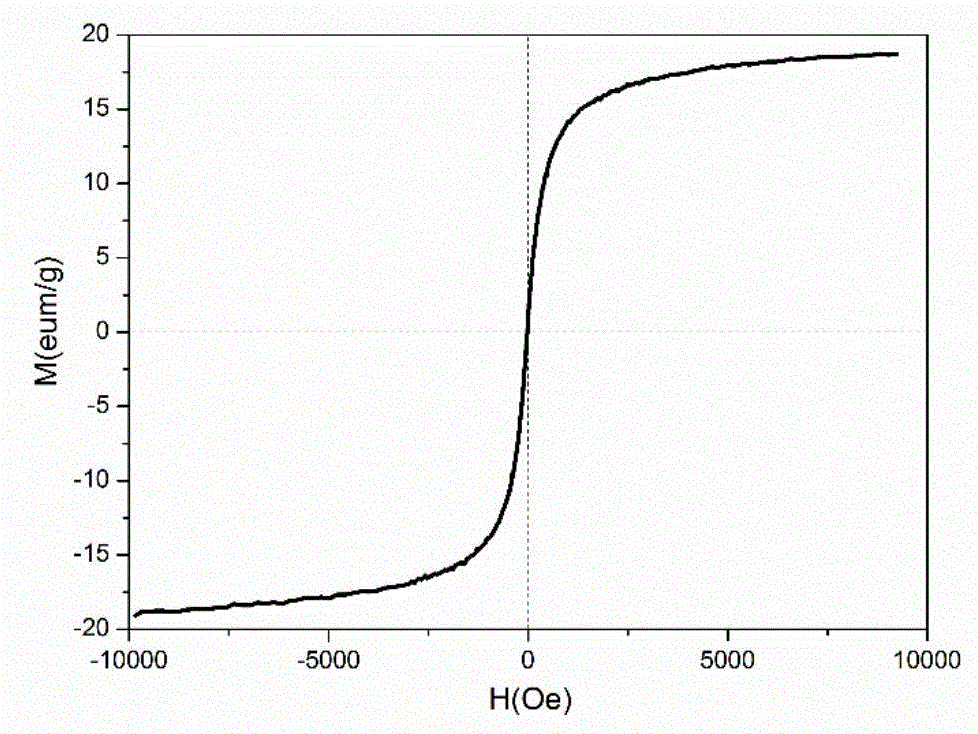

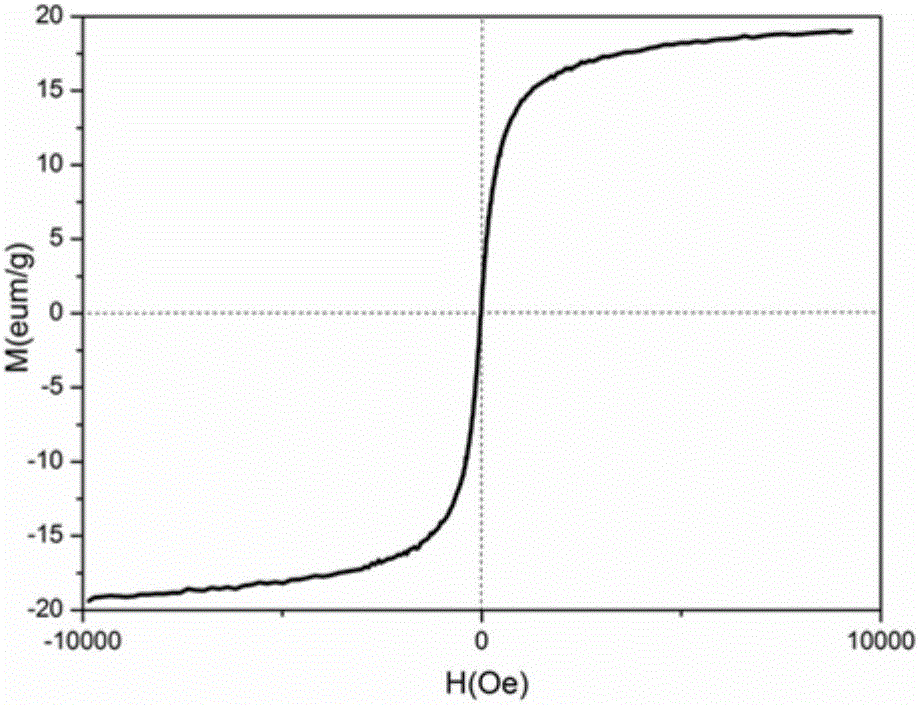

A technology of biochar and lanthanum ferrite, which is applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve the problems of less application of lanthanum ferrite, achieve fast response time, easy recycling, magnetic stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] S1. Preparation of biochar: put agricultural waste into a muffle furnace, pyrolyze it at 400°C for 6 hours, then cool it and pass it through a 10-mesh sieve to obtain biochar;

[0033] S2. Modification treatment: after constant volume of lanthanum nitrate hexahydrate, the molar concentration is 1mol / L, after constant volume of ferric nitrate nonahydrate, the molar concentration is 1mol / L, and the lanthanum nitrate solution and ferric nitrate solution are mixed in a three-necked flask for the first stirring , to obtain a mixed solution, wherein the molar concentration ratio of lanthanum nitrate solution and ferric nitrate solution is 1: 0.1, the stirring speed for the first time is 50 rpm, and the stirring time for the first time is 1 min; then add biochar to the mixed solution, wherein the biological The ratio of charcoal to the mixed solution is 1g:5mL, and the second stirring is carried out, the stirring speed of the second stirring is 50 rpm, and the stirring time is ...

Embodiment 2

[0036] S1. Preparation of biochar: put agricultural waste into a muffle furnace, pyrolyze it at 600°C for 7 hours, then cool it and pass it through a 50-mesh sieve to obtain biochar;

[0037] S2. Modification treatment: after constant volume of lanthanum nitrate hexahydrate, the molar concentration is 1mol / L, after constant volume of ferric nitrate nonahydrate, the molar concentration is 1mol / L, and the lanthanum nitrate solution and ferric nitrate solution are mixed in a three-necked flask for the first stirring , to obtain a mixed solution, wherein the molar concentration ratio of lanthanum nitrate solution and iron nitrate solution is 1: 1, the stirring speed for the first time is 150rpm, and the stirring time for the first time is 15min; The ratio with the mixed solution is 1g:25mL, stir for the second time, the stirring speed of the second stirring is 200rpm, and the stirring time is 30min; the ammoniacal liquor added is stirred for the third time to allow it to fully reac...

Embodiment 3

[0040] S1. Preparation of biochar: put agricultural waste into a muffle furnace, pyrolyze it at 700°C for 8 hours, then cool it and pass it through a 100-mesh sieve to obtain biochar;

[0041] S2. Modification treatment: after constant volume of lanthanum nitrate hexahydrate, the molar concentration is 1mol / L, after constant volume of ferric nitrate nonahydrate, the molar concentration is 1mol / L, and the lanthanum nitrate solution and ferric nitrate solution are mixed in a three-necked flask for the first stirring , to obtain a mixed solution, wherein the molar concentration ratio of lanthanum nitrate solution and ferric nitrate solution is 1: 10, the first stirring speed is 200rpm, and the first stirring time is 1h; then add biochar to the mixed solution, wherein biochar The ratio with the mixed solution is 1g: 30mL, stir for the second time, the stirring speed of the second stirring is 300rpm, and the stirring time is 1h; the ammoniacal liquor added is stirred for the third t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com