Method for preparing nano-crystal lithium-titanium composite oxide

A lithium-titanium composite and oxide technology, which is applied in the fields of titanium compounds, nanostructure manufacturing, chemical instruments and methods, etc., can solve the problems of complex cost process, industrialized amplification of material agglomeration, etc., and achieves abundant reserves, regular morphology, The obvious effect of the platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

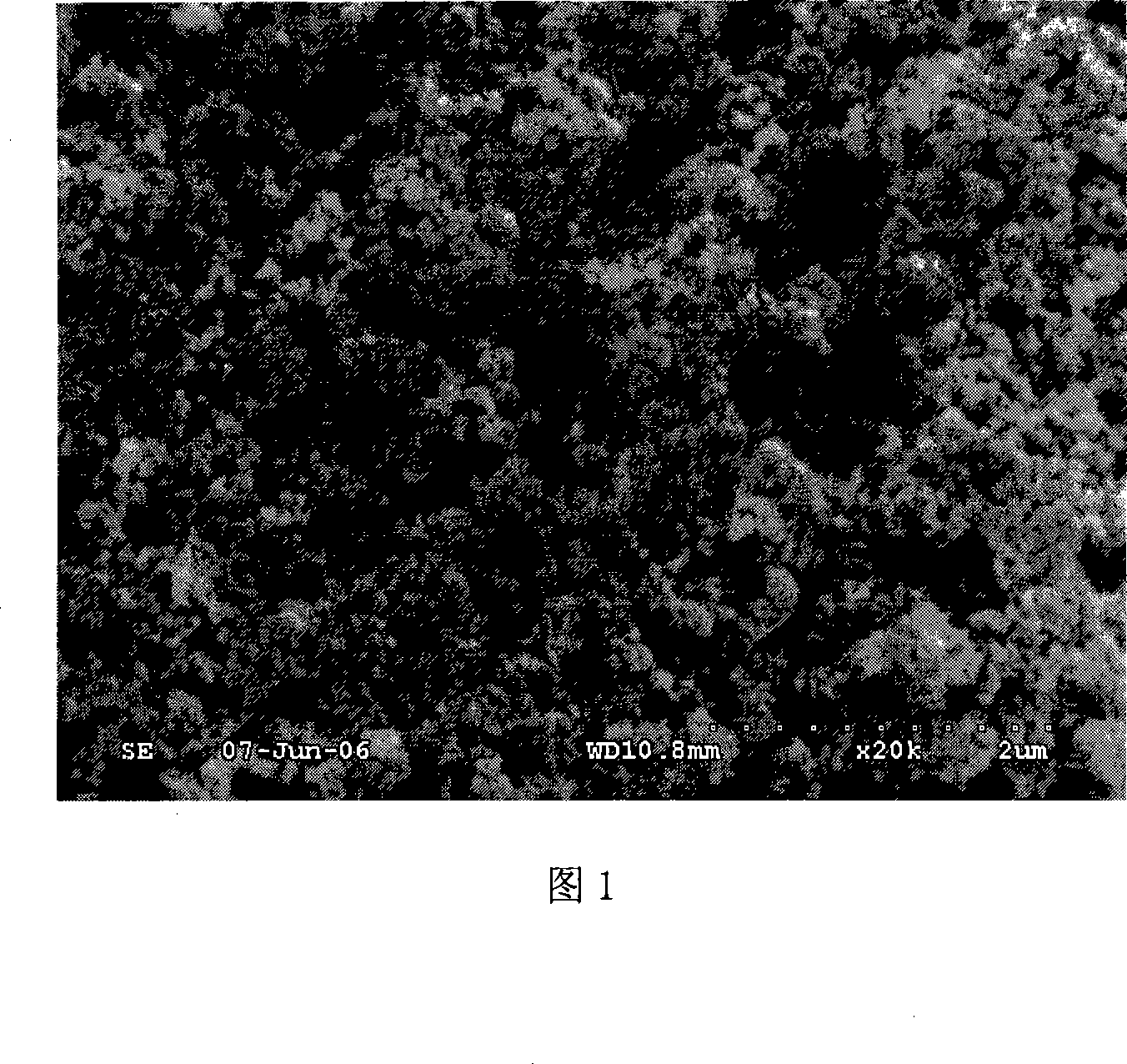

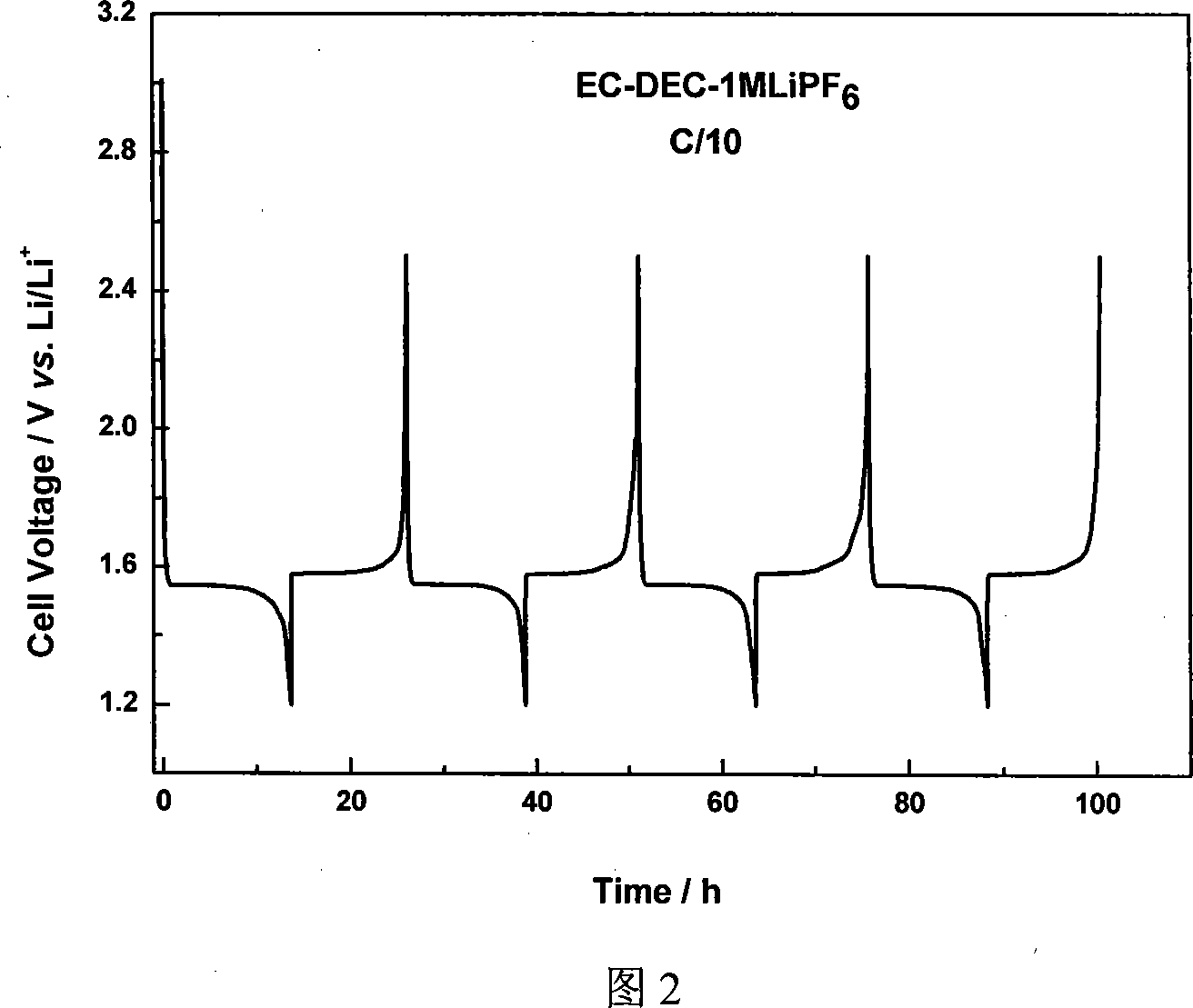

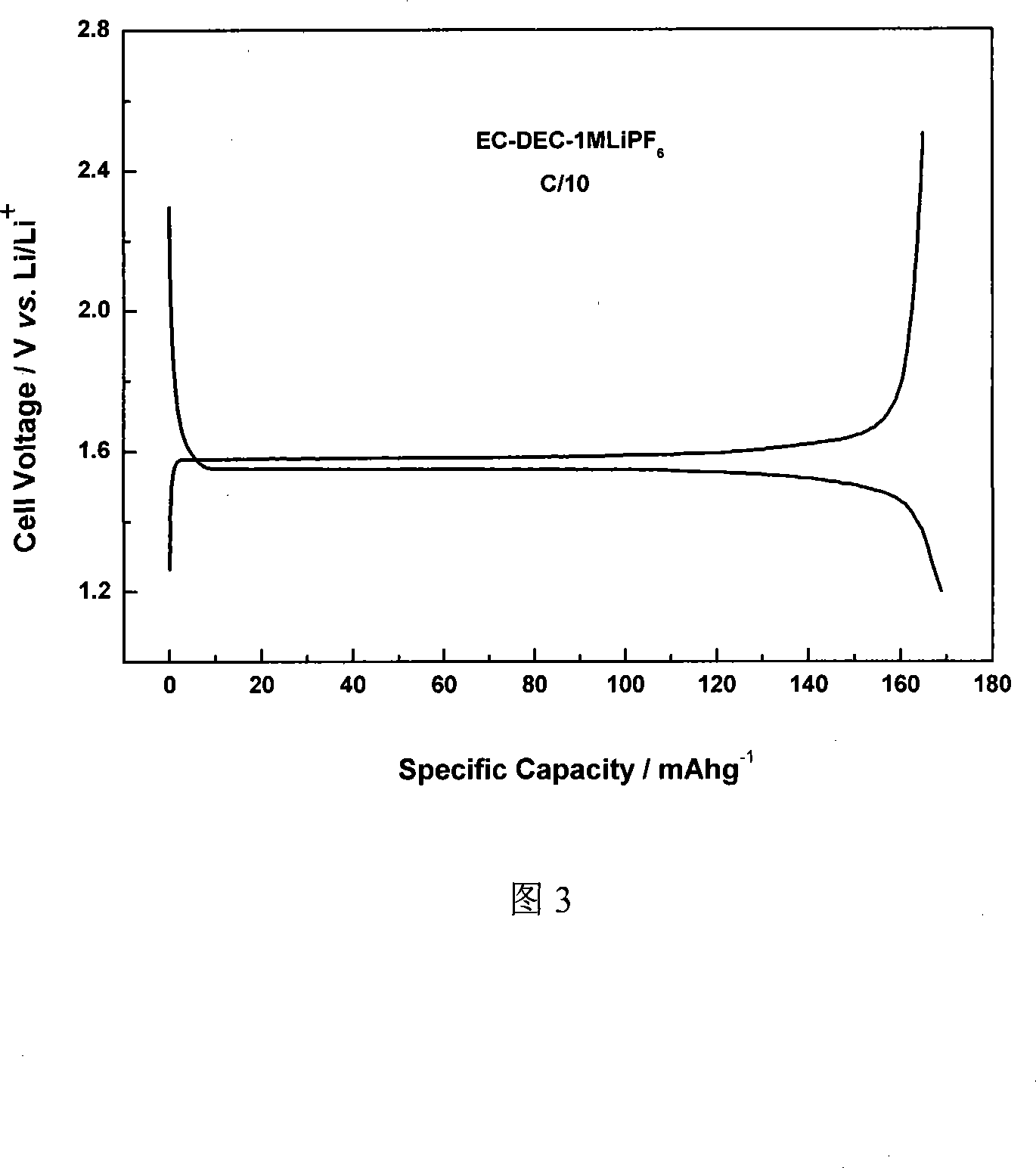

[0020] Example 1: Dissolve 5g of titanium powder in 30ml of 30% hydrogen peroxide solution at a temperature of 0-5°C, add 3.6g of lithium hydroxide monohydrate as an aqueous solution, and add a certain amount of activated carbon powder , stir well. After adding 5% ammonia water, it was transferred to a water bath at 50° C. and stirred thoroughly for 30 minutes, and the mixture was placed in an oven and dried directly to obtain a precursor. After the precursor was heat-treated at 300°C for 4 hours, it was heated to 800°C for 24 hours and then cooled and ground to obtain a nanocrystalline lithium-titanium composite oxide with a spinel structure, Li 4 Ti 5 o 12 The content is more than 99%. The average grain size of the lithium-titanium composite oxide is about 20nm, and the specific surface area is 70m 2 / g, under 0.1C charge and discharge conditions, its reversible lithium intercalation capacity is 165mAh / g, under 100C charge and discharge conditions, the capacity retention...

Embodiment 2

[0021] Embodiment 2: under the temperature environment of 3~8 ℃, 16g TiOSO 4 Dissolve in 50ml of 30% hydrogen peroxide solution, add 5.3g of lithium acetate as an aqueous solution, add a certain amount of starch, and stir thoroughly. After adding 5% ammonia water until the solution is alkaline, transfer it to a water bath at 100°C for a full reaction for 60 minutes, and place it in an oven to dry directly to obtain a precursor. The precursor was heat-treated at 200°C for 4 hours, heated to 900°C for 20 hours, cooled and ground to obtain a nanocrystalline lithium-titanium composite oxide with a spinel structure, Li 4 Ti 5 o 12 Content 92%. The average grain size of the nanocrystalline lithium-titanium composite oxide is about 50nm, and the specific surface area is 45m 2 / g, under 0.1C charge and discharge conditions, its reversible lithium intercalation capacity is 160mAh / g, and the capacity retention rate under 100C charge and discharge conditions is 62%.

Embodiment 3

[0022] Example 3: 10g TiO(OH) 2 Mix with 50ml of 30% hydrogen peroxide solution, add 6g of lithium nitrate as an aqueous solution, add a certain amount of polypropylene glycol, and stir well. After adding 5% ammonia water until the solution is alkaline, transfer it to a water bath at 100°C for a full reaction for 60 minutes, and place it in an oven to dry directly to obtain a precursor. The precursor was heat-treated at 400°C for 2 hours, heated to 1000°C for 20 hours, cooled and ground to obtain a nanocrystalline lithium-titanium composite oxide with a spinel structure, Li 4 Ti 5 o 12 Content 96%. The average grain size of the nanocrystalline lithium-titanium composite oxide is about 90nm, and the specific surface area is 30m 2 / g, under 0.1C charge and discharge conditions, its reversible lithium intercalation capacity is 165mAh / g, and the capacity retention rate under 100C charge and discharge conditions is 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com