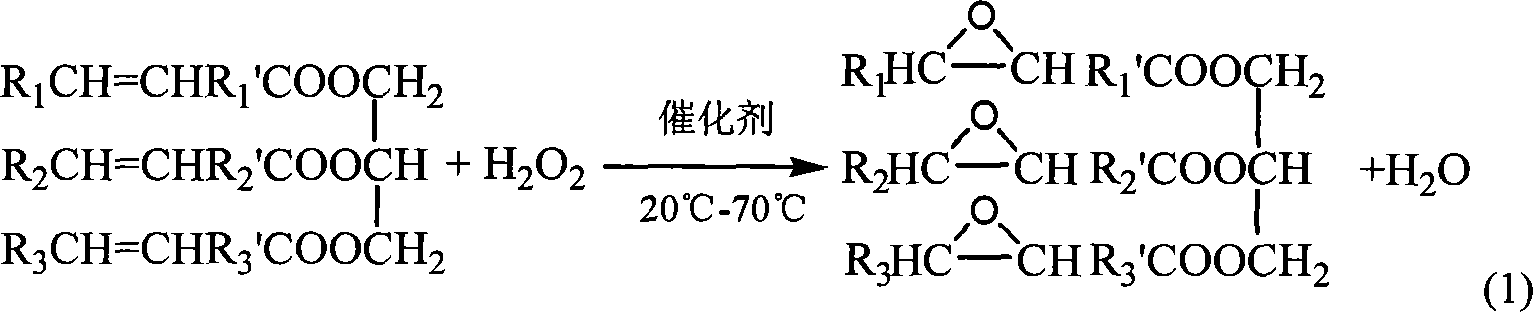

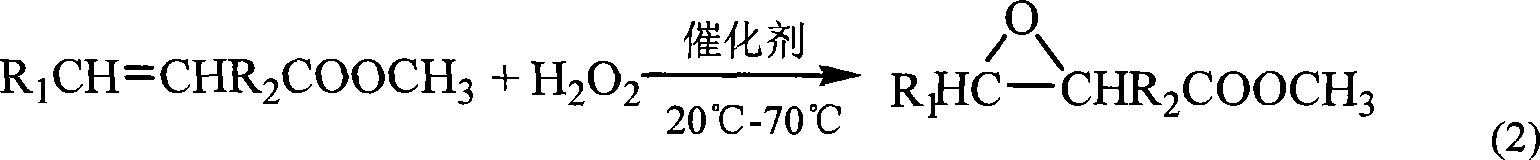

Method for preparing epoxidized soybean oil or epoxy fatty acid methyl(ethyl) ester by heteropolyacid liquid phase catalysis

A technology of epoxidized soybean oil and epoxidized fatty acid, which is applied in the direction of organic chemistry, can solve the problems of reduced catalytic activity, difficult wastewater treatment, equipment corrosion, etc., and achieves the effects of simple operation, avoiding difficult recovery, and low corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the reactor, add a certain amount of iodine and the value is 130gI 2 / 100g of soybean oil, the acid value is less than 0.5mgKOH / g, add phosphotungstic heteropoly salt catalyst according to 5%-8% of the weight of raw soybean oil, stir vigorously and heat up to 50°C-60°C; maintain this temperature, drop Add hydrogen peroxide solution (concentration: 35%) equal to the weight of the raw material soybean oil, drop it in 2h-3h, and stop after 3h-5h of reaction. After resting, the water layer is separated, and the oil layer is distilled under reduced pressure, and the temperature is controlled below 110°C. The epoxy value of the product is 5.6%, and the conversion rate is greater than 99%.

Embodiment 2

[0026] In the reactor, add a certain amount of iodine and the value is 130gI 2 / 100g soybean oil, the acid value is less than 0.5mgKOH / g, add peroxyphosphotungstic heteropoly salt catalyst according to 1%-2% of the weight of raw soybean oil, stir vigorously and heat up to 20°C-40°C; maintain the temperature , dropwise the hydrogen peroxide solution (concentration is 50%) of raw material soybean oil weight equivalence, 2h-3h dropwise, stop after reaction 3h-5h. After standing still, the water layer was separated, and the oil layer was distilled under reduced pressure, and the temperature was controlled below 110°C. The epoxy value of the product was 5.9%, and the conversion rate was greater than 99%.

Embodiment 3

[0028] In the reactor, add a certain amount of iodine and the value is 108gI 2 Soybean oil methyl oleate / 100g, the acid value is less than 2mg KOH / g, according to the 1%-2% of raw material soybean oil methyl oleate weight, add peroxophosphotungstic heteropoly salt catalyst, vigorously stir and heat up to 20 ℃-40 ℃; add dropwise a hydrogen peroxide solution (concentration: 27.5%) of 60% by weight of the raw material soybean oil methyl oleate, drop it in 1h-2h, and stop after 2h-4h of reaction. After resting, the water layer is separated, and the oil layer is distilled under reduced pressure, and the temperature is controlled below 110°C. The epoxy value of the product is 4.2%, and the conversion rate is greater than 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com