Photocatalytic oxidation reaction- membrane separation method for processing antibiotic industry waste water

A technology of photocatalytic oxidation and catalytic oxidation, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, light water/sewage treatment, etc. It can solve the problems of high cost, unstable treatment effect, and difficulty in meeting industry discharge standards. , to achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

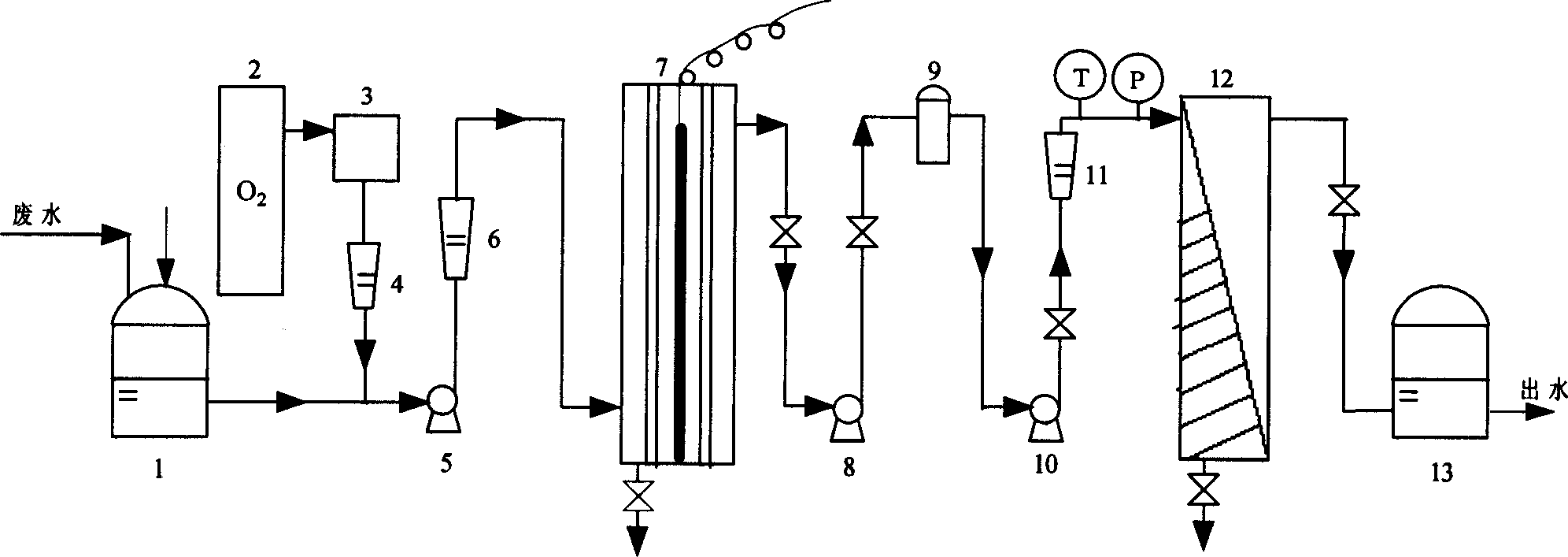

[0013] 15L of antibiotic pharmaceutical wastewater enters the pretreatment tank 1, the temperature of the wastewater is 25°C, the chroma is 320 times (yellow brown), and the content of suspended solids is 850mg / L. After stirring for 10 minutes at ℃, let it stand for precipitation, and take the supernatant of the treated wastewater, COD Cr From 3100mg / L to 550mg / L, the removal rate of organic matter is 82%. Then use coarse filtration (pore size 30μm) to remove fine impurities in the water, and adjust the pH of the wastewater solution to 9.0 with NaOH solution.

[0014] 5L of pretreated waste water is injected into the photocatalytic oxidation reactor 7 through the gas-liquid mixing pump 5, and the water enters from the lower part of the reactor where the ultraviolet lamp is placed, and the particle catalyst TiO 2 Loaded on a glass carrier, the glass carrier is fixed in the reactor, and the coated titanium dioxide has an area of 0.182m 2 , using oxygen generator 2 and ozone g...

Embodiment example 2

[0017] The method of this implementation case is the same as that of implementation case 1, and the effects of different flocculants and coagulant aids in treating wastewater are specifically investigated.

[0018] 15L of antibiotic pharmaceutical wastewater enters the pretreatment tank 1, the temperature of the wastewater is 25°C, the chroma is 320 times (yellow brown), and the content of suspended solids is 850mg / L. Add 6750mg of polyferric chloride as a flocculant and 225mg of activated silicic acid as a coagulant. After stirring for 10 minutes at ℃, let it stand for precipitation, and take the supernatant of the treated wastewater, COD Cr From 3100mg / L to 750mg / L, the removal rate of organic matter is 75%, then use coarse filtration (pore size 30μm) to remove fine impurities in the water, and adjust the pH of the wastewater solution to 9.0 with NaOH solution.

Embodiment example 3

[0020] The method of this implementation case is the same as that of implementation case 1, and the effects of different membranes for wastewater treatment are specifically investigated.

[0021] COD of wastewater treated by photocatalytic oxidizer Cr The wastewater is 88mg / L and the conductivity is 3120μs / cm. The wastewater enters the membrane separator. The membrane is a polyamide reverse osmosis membrane. The wastewater flow rate is 5L / min. It enters the membrane separator through the booster pump 8, the coarse filter 9 and the high pressure pump 10. 12. Membrane flux 30L / m 2 h, at 27°C and 1.0MPa, after separation for 1h, the COD of the permeate was measured Cr The removal rate of organic matter is 8mg / L, the removal rate of organic matter is 91%; the conductivity is 62μs / cm, the desalination rate is 98%, and the permeate can be recycled completely.

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com