Patents

Literature

43results about How to "Yield advantage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for treating waste tire

InactiveCN101544781AFully lysedAdd processing programPigmenting treatmentPlastic recyclingLiquid hydrocarbonsEngineering

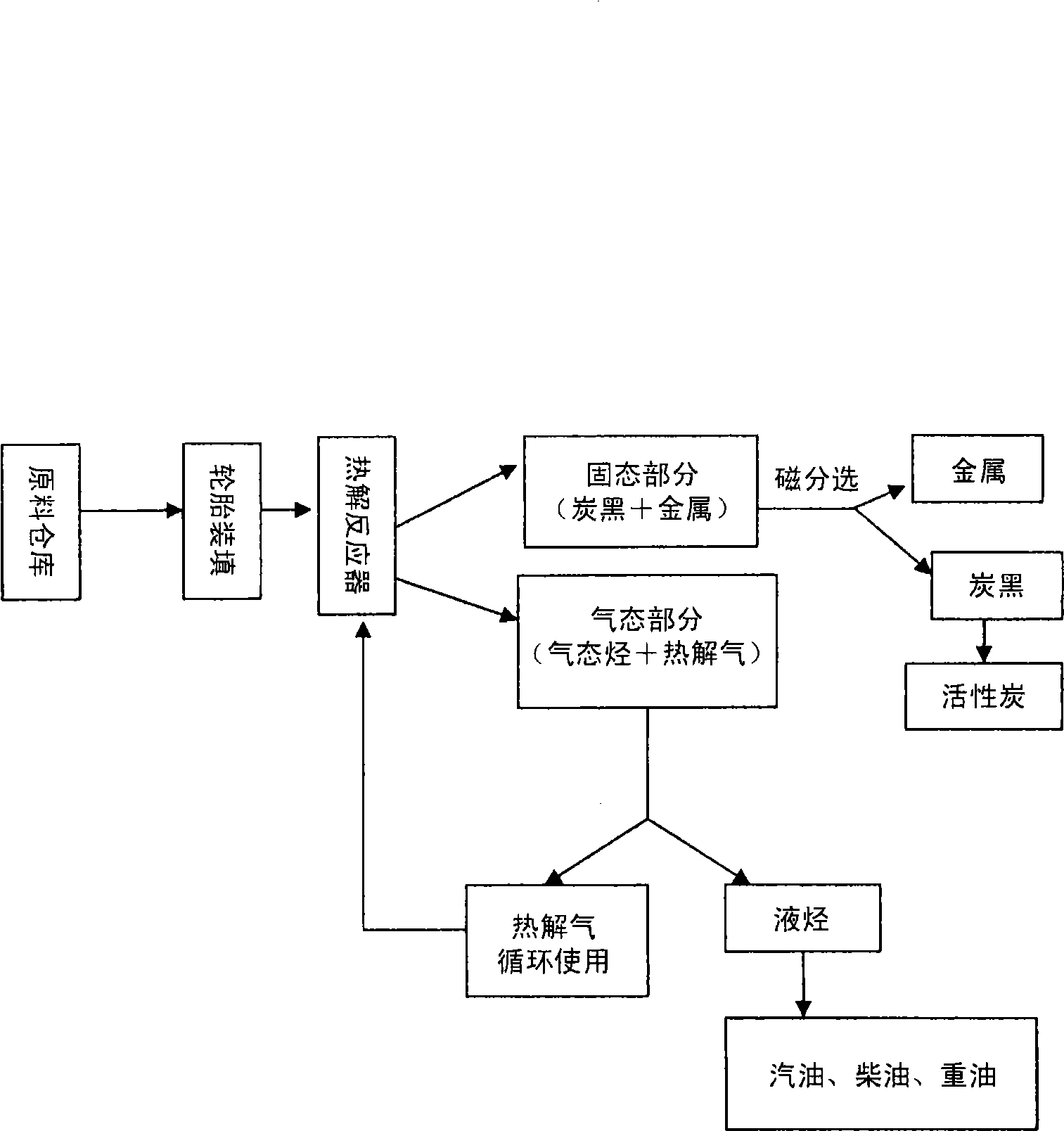

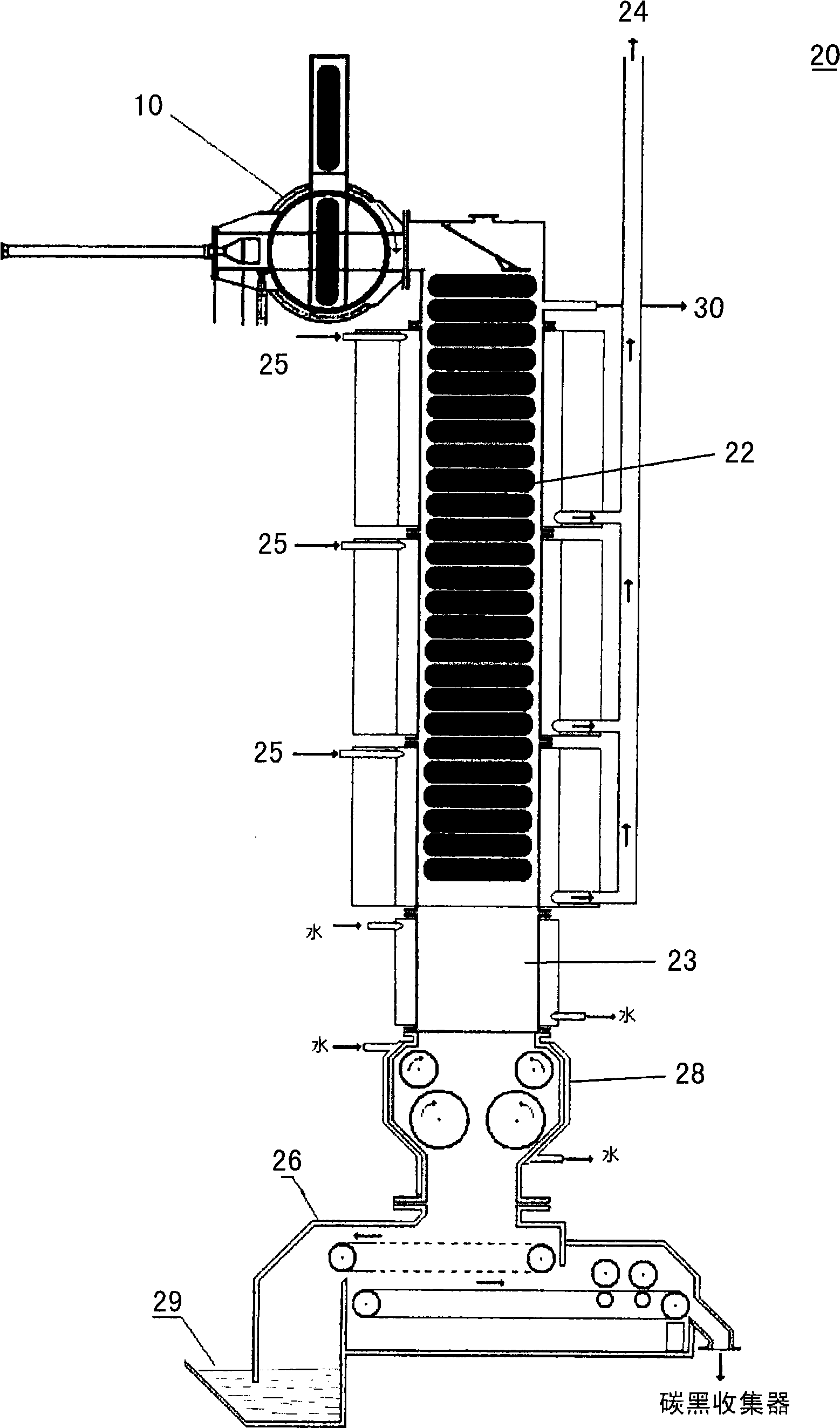

The invention relates to a method for treating waste tires, which comprises the following steps: the thermal decomposition of a waste tire is carried out at the airproof state and under the oxygen-free condition; the thermal decomposition temperature is divided into three sections, wherein the first section is close to a feeding end with the thermal decomposition temperature of 700-800 DEG C; the third section is close to a discharging end with the thermal decomposition temperature of 900-1000 DEG C, and the second section is arranged between the feeding end and the discharging end with the thermal decomposition temperature of 800-900 DEG C; mixed steams generated during the thermal decomposition of the tire are condensed to form liquid hydrocarbon and thermal decomposition gas, and the thermal decomposition gas circularly returns to a reactor and is used as fuel; and the solid products are separated to obtain metals and carbon black.

Owner:BEIJING TIANHAIYUAN TECH +1

Method for pollution-free production of molybdenum oxide

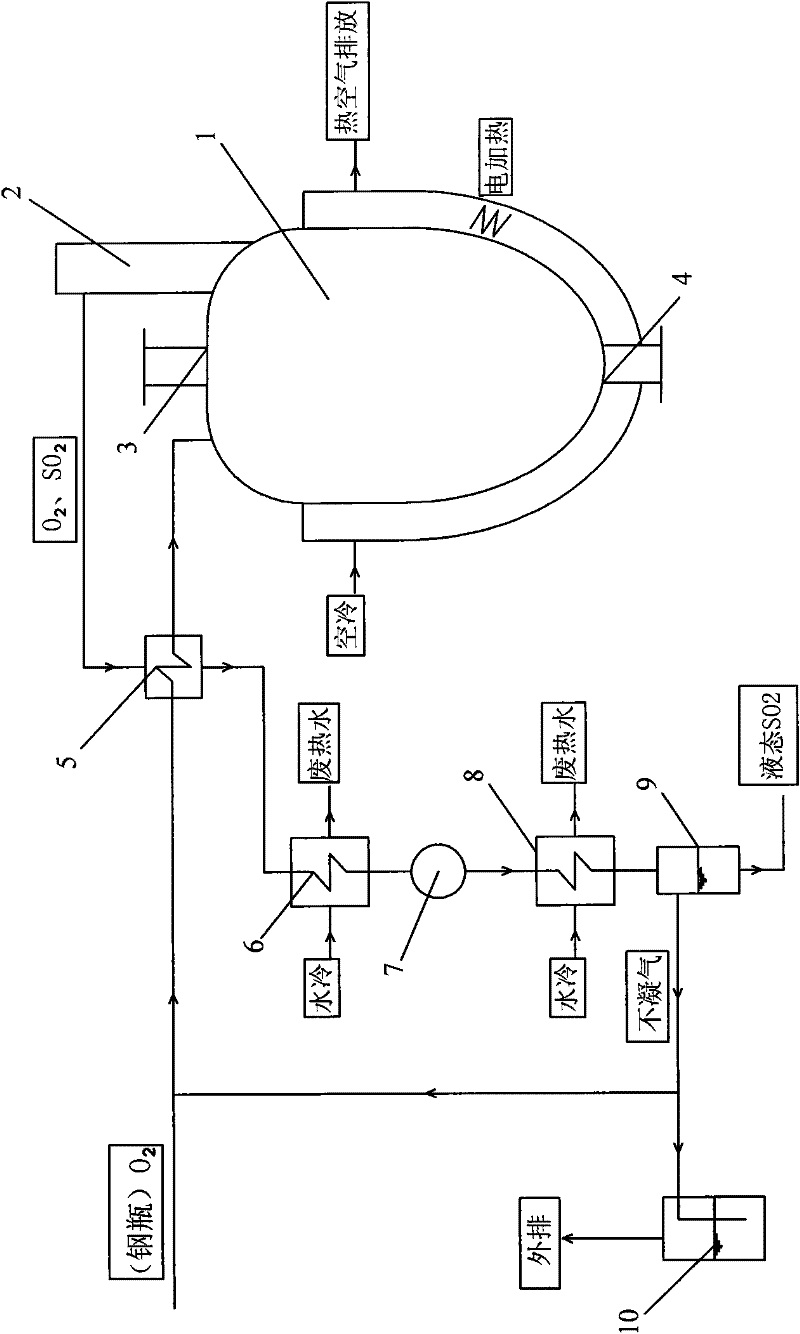

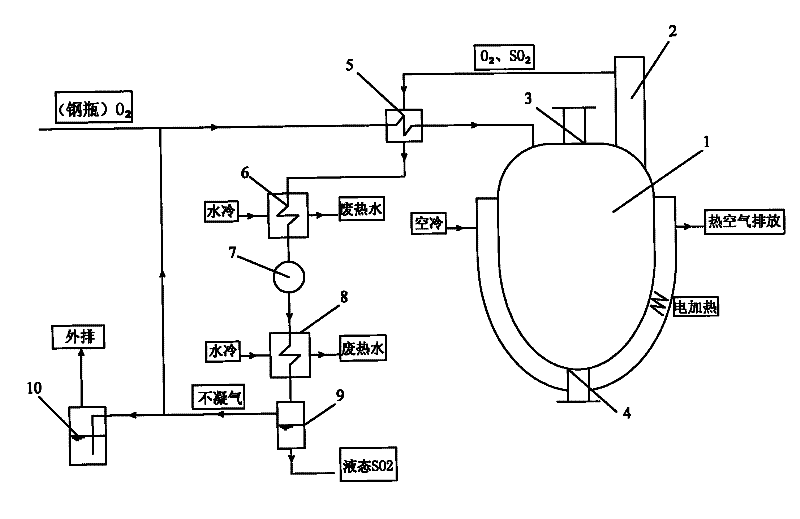

InactiveCN102126757AFast oxidationReduce filter areaMolybdenum oxides/hydroxidesHigh concentrationChemical reaction

The invention provides a method for pollution-free production of molybdenum oxide, which comprises the following steps of: adding molybdenum sulfide into a sealing reactor and introducing oxygen into the reactor, and heating, so that the molybdenum sulfide reacts with the oxygen to generate molybdenum oxide and sulfur dioxide; and filtering generated high-temperature gas by a dust collector, and cooling, compressing and separating to obtain high-concentration liquid sulfur dioxide. In the method, the molybdenum oxide is produced by adopting the closed oxygen-enriched combustion technology, so the production efficiency of the product is improved, and mineral resources are saved; energy consumption is saved by utilizing heat in a chemical reaction; and the SO2 generated in the production process can be recycled to realize the resource utilization of exhaust gas and reduce atmosphere pollution, so the method has a bright application prospect.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

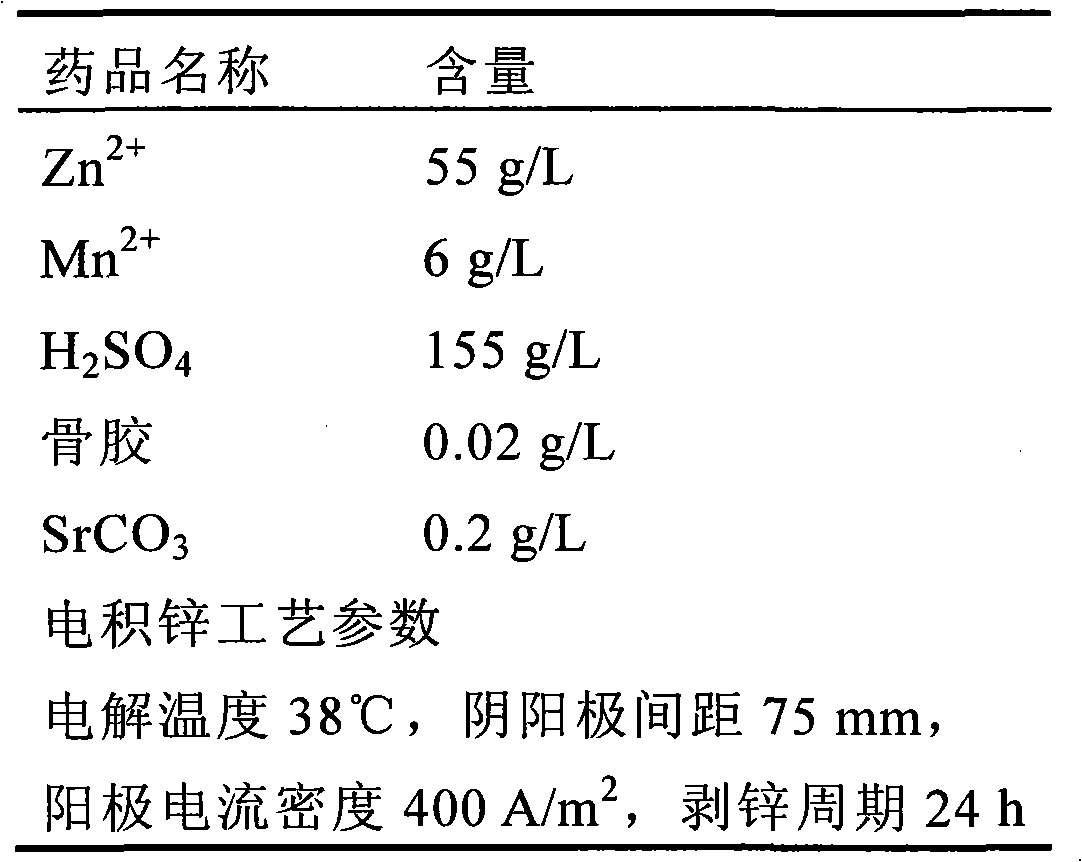

Preprocessing method of lead/lead-alloy inert anode for zinc electrowinning

InactiveCN102465314AReduce cut strengthYield advantagePhotography auxillary processesElectrodesPretreatment methodAlloy

The invention relates to a processing method of an lead / lead-alloy inert anode for zinc electrowinning, wherein a preprocessing solution consists of fluorides, sulfuric acid, MnSO4 and distilled water, and the temperature of the preprocessing temperature is 20-80 DEG C; the anode is an anode to be preprocessed, a cathode is a lead / lead-alloy electrode, a distance between the cathode and the anode is 3-6cm, and the circulation amount of the preprocessing solution is 0.05-0.5V tank / h, wherein V tank refers to volume of a preprocessing tank; and the preprocessing process parameters are as follows: the anode current density is 200-800A / m<2>, and the preprocessing time is 8-24h. According to the invention, the preprocessing solution containing fluorine ions is adopted, preprocessing process parameters are optimized, and the preprocessing process is simple and convenient to operation and is beneficial to industrial application. According to the preprocessing method disclosed by the invention, a period of forming a stable protection layer of the lead / lead-alloy anode for zinc electrowinning is shortened to be within 7 days from 3-6 months.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

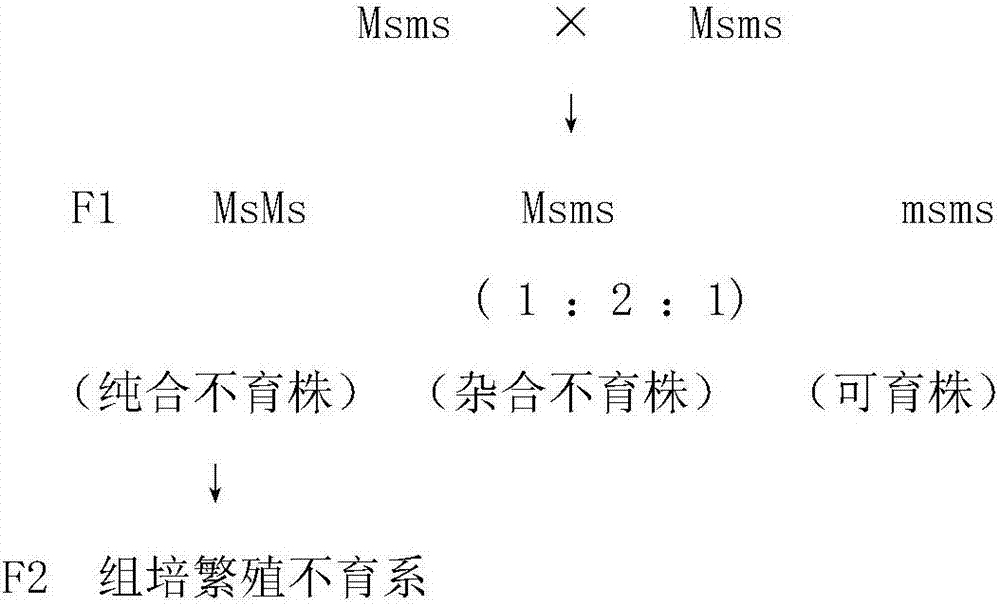

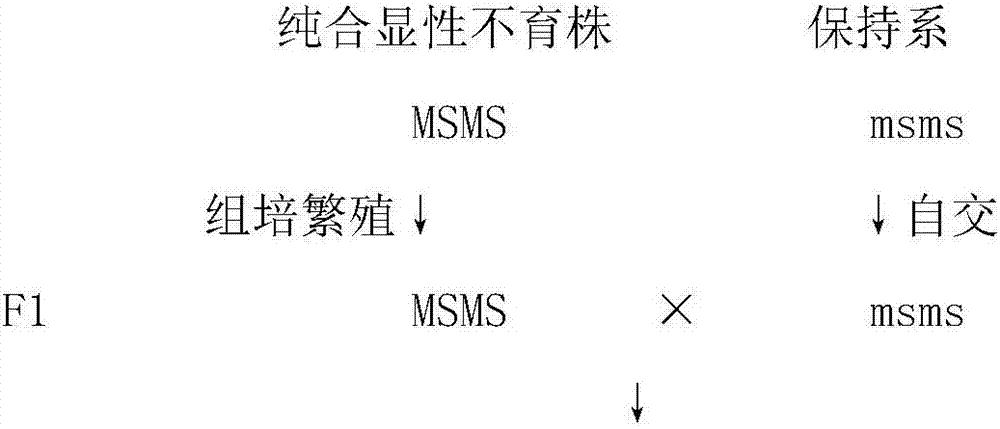

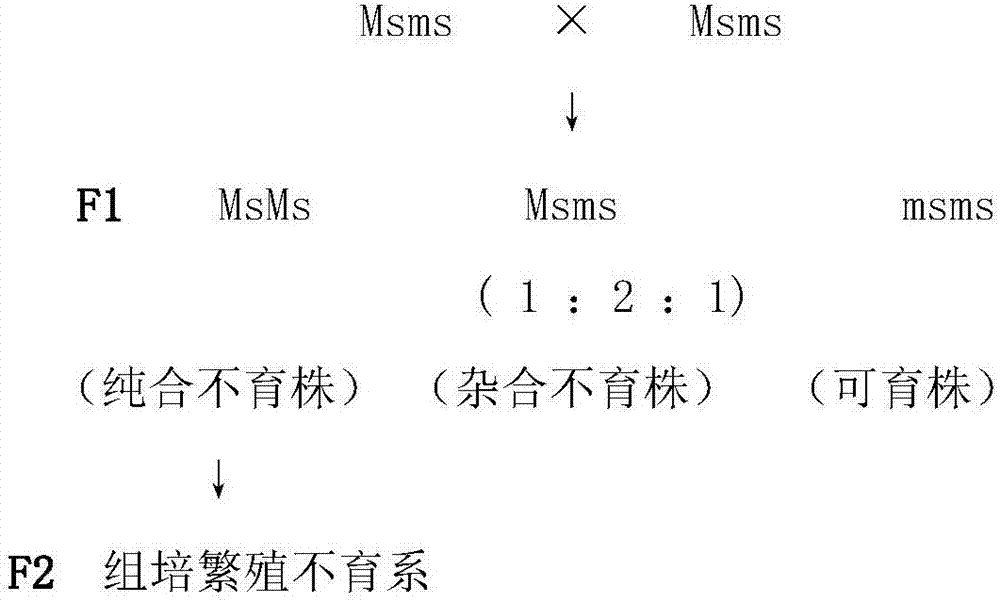

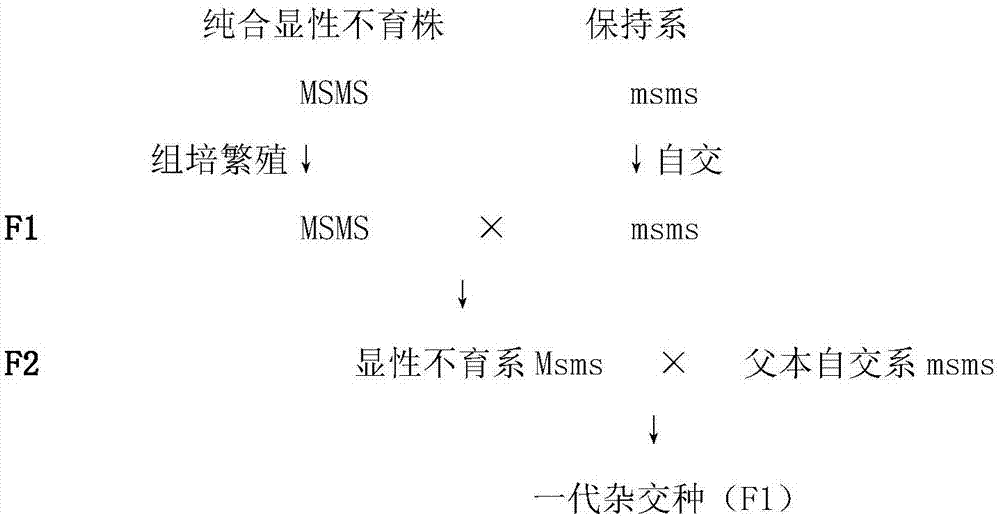

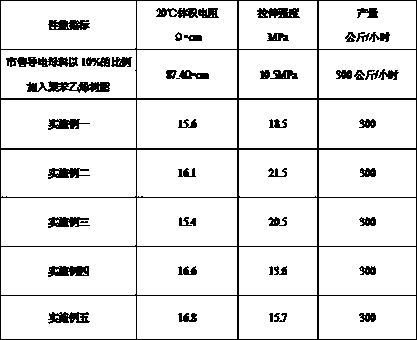

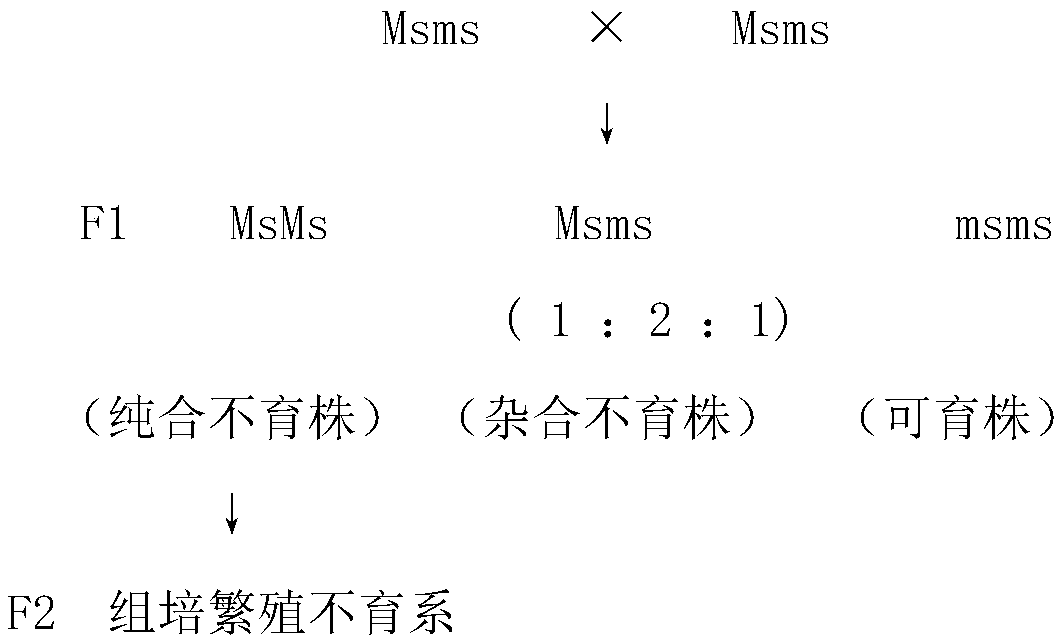

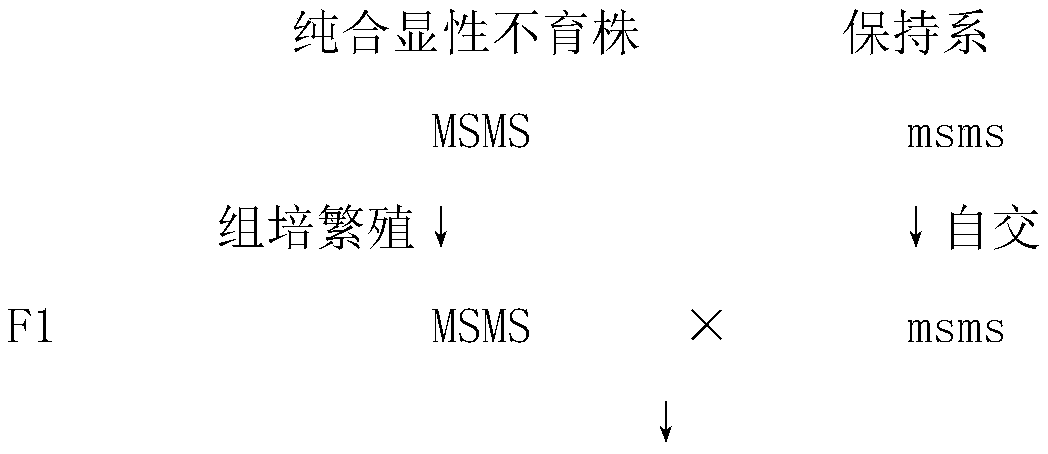

Brassica oleracea seed production technology

ActiveCN106962195AIncrease productionStable productionPlant cultivationCultivating equipmentsDiseasePollination

The invention discloses a brassica oleracea seed production technology, an adopted seed production method comprises the steps that a lateral bud is cut from a knot position and cultured on a culture medium, and subculture is performed in a lab continuously to obtain an original mother plant; seed reproduction of a sterile line is performed; a sun bed is prepared; a seeding tray is prepared; provisonal planting of the mother plant is performed; maintainer line seedling growing is performed; field planting is performed; pollination is performed; ventilation harvesting is performed; in the podding mid-term, maintainer line rows are removed; the row space is increased to facilitate ventilation and light transmitting, 70% of pods are cut when yellowing and dried for threshing after ripening; male parent seed reproduction is performed; the bud selection standard is strictly required, the bud stripping and pollination operation is standardized, and pollination marks are made; coeno-species seed reproduction is performed. According to the seed production technology, the yield can reach 65-75 kg / mu, the germination rate and the germination potential can reach up to 85% or above, the seed yield is high, and a foundation is laid for brassica oleracea stable production; after planting, the species has remarkable advantages over the other species on whether the disease resistance, the cold resistance, the physical shape or the yield, and the brassica oleracea is convenient to popularize, promote and plant.

Owner:ZHANGJIAKOU ACAD OF AGRI SCI

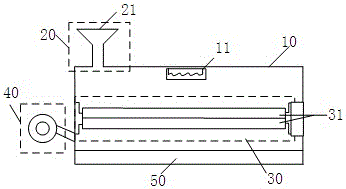

Method based on extensional rheology for stripping graphene and application of graphene

ActiveCN106744879AImprove stripping efficiencyQuality improvementMaterial nanotechnologyGrapheneGraphiteCam

The invention provides a method based on extensional rheology for stripping graphene and application of the graphene. The method comprises the following steps: collectively adding graphite and viscous substances into a designed stretching mechanism, adopting a cam rotor in a cavity to enable the size of the cavity in a drum to be reduced and increased in reciprocating manner when in rotation, compressing and stretching the graphite and the viscous substances in the cavity in a reciprocating manner by virtue of a can and a leaf spring, and stretching, cutting and stripping a graphite mixture under the adhesion effect of an adhesive additive to obtain a graphene precursor, so that the lattice damage of the graphene caused by an excessively large shear force is effectively avoided. According to the scheme disclosed by the invention, the preparation process is simple, the source of raw materials is wide, the pollution is avoided, the cost is low, and the prepared graphene is high in quality, easy to store and transport, and easy for realizing the industrialized mass production.

Owner:东港智科产业园有限公司

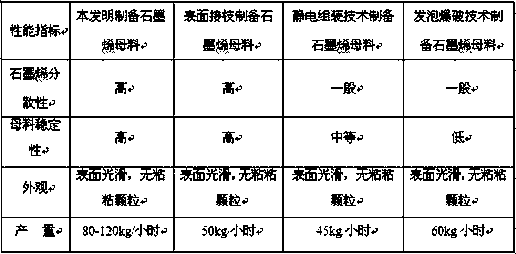

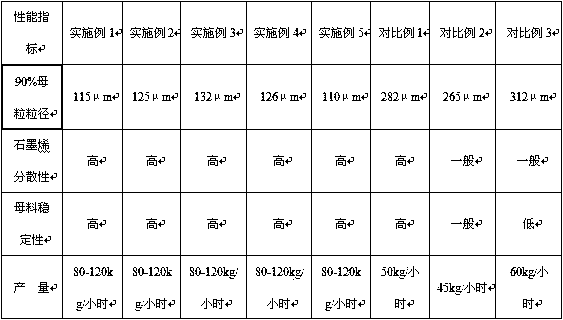

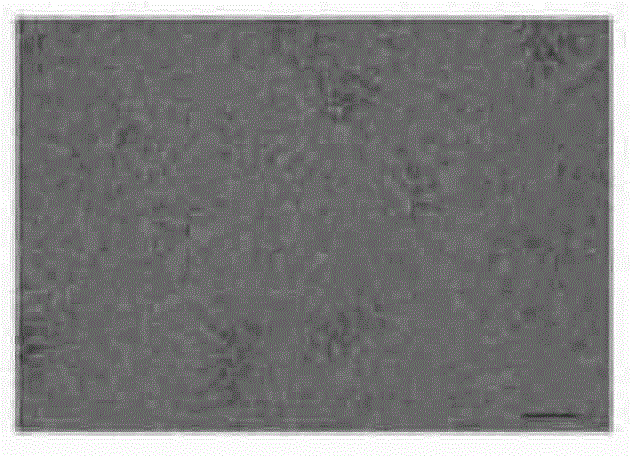

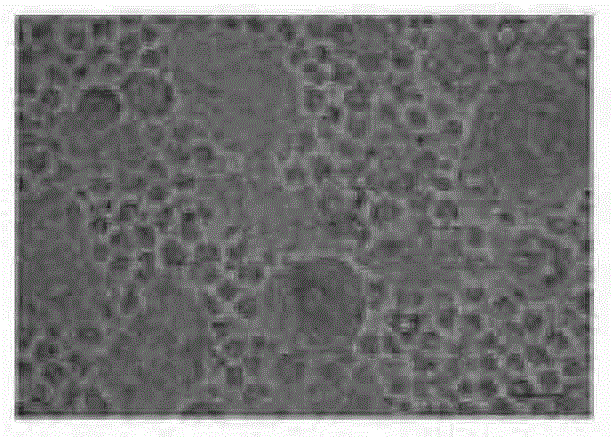

Graphene coating master batch and preparation method

InactiveCN107815170APromote mass productionContinuous and stable preparationCoatingsPigment treatment with macromolecular organic compoundsSurface layerGraphene coating

The invention provides a graphene coating master batch and a preparation method. The preparation method comprises the following steps of respectively preparing a graphene oxide water dispersing liquidand a copper sulfate water solution, mixing with emulsified carrier resin, and dispersing by ultrasonic waves; utilizing graphene oxide to forcibly adsorb copper ions in the mixing solution to generate complexing reaction, reducing the graphene oxide, spraying, and drying, so as to obtain the coating master batch. The graphene coating master batch has the advantages that the forcible adsorption function of the graphene oxide is utilized, and graphene oxide is combined with the uniformly dispersed copper ions in the solution, so that the dispersivity of the graphene in the resin carrier is improved, the carrier resin is covered to the surface layer after spraying and granulating, the compatibility is improved, and the defects of poor dispersing effect of the graphene in the resin carrier of the master batch, long preparation time of master batch, high cost, failure to realize continuous and stable large-scale production and the like are overcome; the graphene master batch can be continuously and stably prepared, and the batched production of the graphene master batch is further promoted.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

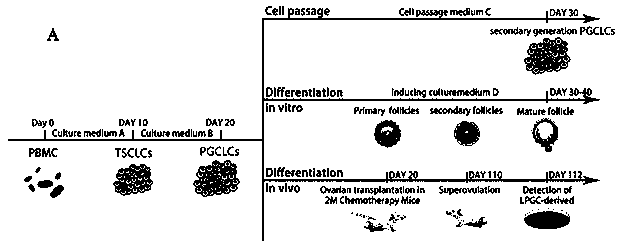

Method for preparing male non-testicular-sourced protein-induced autologous-reproduction stem cells, kit, the stem cells and application

InactiveCN104419658ASimple production technologyYield advantageDead animal preservationMammal material medical ingredientsSomatic cellReproduction

The invention provides a method for preparing male non-testicular-sourced protein-induced autologous-reproduction stem cells. The method comprising following steps: (1) cultivating somatic cells in a cell culture fluid A for 1-3 days, cultivating the somatic cells in a cell culture fluid B for 1-6 days and then cultivating the somatic cells in a cell culture fluid C for 1-6 days; and (2) collecting the male non-testicular-sourced protein-induced autologous-reproduction stem cells. The invention also provides a kit used for preparing the male non-testicular-sourced protein-induced autologous-reproduction stem cells. The method and the kit are advantaged in yield, purity, and producing speed of the production of the protein-induced autologous hematopoietic stem cells.

Owner:深圳百年干细胞技术研究院有限公司

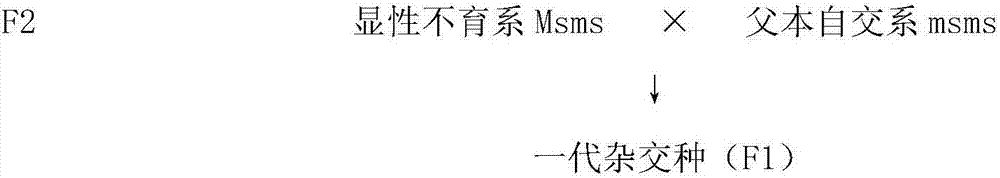

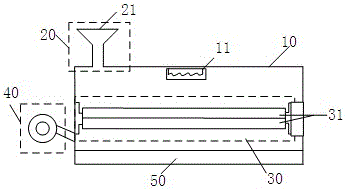

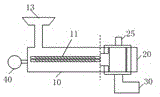

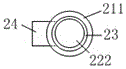

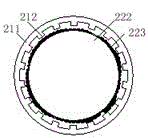

Internal mixer for preparing graphene through tensile peeling and method for preparing graphene

The invention provides an internal mixer for preparing graphene through tensile peeling and a method for preparing graphene. The internal mixer comprises a machine barrel, a feeding mechanism, an internal mixing mechanism, a power transmission mechanism and a collection mechanism, wherein the internal mixing mechanism comprises two cam rotors of which the cross sections are curved triangles as stirring shafts, and the two rotors generate relatively small shear force in a rotation process and generate relatively large compressive force and tensile force, so that a pasty graphite mixture is indirectly stretched, sheared and stripped to form a graphene precursor by a viscous additive under the bonding effect of the viscous additive when continuously passing through the stirring shafts, and thus the lattice damage of over-large shearing force to graphene is effectively avoided. The internal mixer is simple in preparation technology, wide in raw material source, free of pollution and low in cost; prepared graphene is high in quality and easy to store and transport; and large-scale industrial production is easy to implement.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

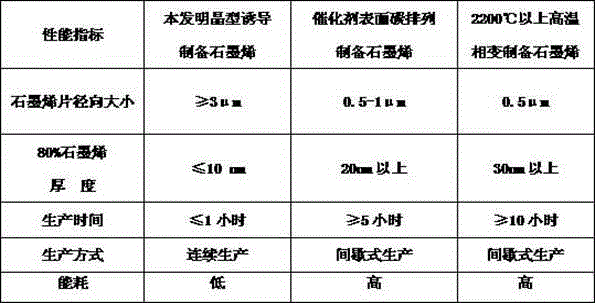

Method for preparing graphene in screw extruder through crystal form inducing

The invention provides a method for preparing graphene in a screw extruder through crystal form inducing. The method comprises the steps that shearing slicing is performed on a carbon source through the screw extruder, a crystal form inducing agent is utilized, the crystal form inducing agent generates a variant along with gradual increasing of the temperature to induce the carbon source to form crystals and enable the crystals to grow along layers, the layer structure of graphite is more obvious, the layer size of the graphite exceeds 1 mm, and finally the graphene is obtained through shearing stripping of the screw extruder. Accordingly, the defect of high-temperature long-time sintering of a catalyst used in the process of graphene preparation through the carbon source is overcome, therefore, the layer structure of the graphite is complete, and then the large-size graphene with the two-dimensional area is obtained. The method has the advantages that the technology is simple, the cheap and rich raw materials are used, a chemical reaction or high synthesizing temperature is effectively prevented from being adopted, and industrial production is achieved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Method for preparing graphene powder through crushing and application of graphene powder

ActiveCN107055518ADestroy lattice integrityDecreased lattice integrityGrapheneAdditivesGraphiteCvd graphene

The invention provides a method for preparing graphene powder through crushing and application of the graphene powder. The graphene powder with uniform particle sizes is obtained through gradual reduction of the particle sizes of graphite. The method particularly comprises the steps of carrying out sheet treatment on the graphite by adopting a cone mill, crushing by using a high-speed rod pulverizer to obtain the graphene powder with uniform and large radial dimension; and carrying out further intercalation, crushing and peeling by using the shear force generated by a grader and carrying out grading treatment to obtain the graphene powder. The prepared graphene powder is low in cost, good in disperse machinability, large in sheet diameter and suitable for a lubricating additive. According to the method, continuous, clean and environment-friendly technical effects of graphene production are achieved, and industrialized production of the graphene powder is promoted.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Apparatus and method for preparing graphene composite material through continuous grinding extrusion

The invention provides an apparatus and method for preparing a graphene composite material through continuous grinding extrusion. The method comprises the following steps: adding graphite and a plastic stripping agent to a screw extruder, and carrying out oriented shearing on above raw materials through a feeding mechanism formed by a screw in order to obtain a primary stripping product, conveying the primary stripping product to a stripping mechanism formed by a millstone group, and the primary stripping product undergoes secondary shearing striping through relative rotation of an internal millstone and an external millstone in order to obtain the graphene composite material. The method overcomes the defects of low stripping strength and thick stripping layers of graphene prepared through using screw stripping in the prior art, and the apparatus has the advantages of simple structure, improvement of the shearing strength, realization of continuous production of the graphene composite material, further obtaining of the graphene composite product with thin stripping thickness, avoiding of graphene aggregation, improvement of the quality of graphene, convenience for storage, and promotion of mass production of the graphene product.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

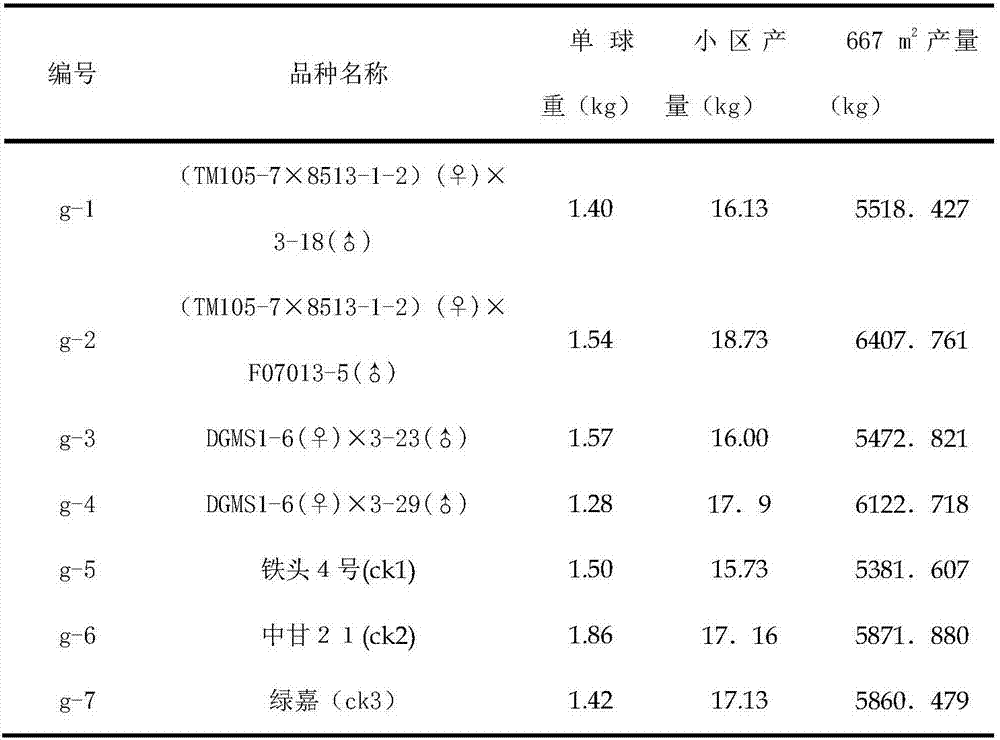

High-yield cultivation method of Brassica oleracea

The invention discloses a high-yield cultivation method of Brassica oleracea, comprising the steps of raising seedlings with trays, to be specific, using 35-50 g of seeds per mu to raise seedlings in April to May; managing after seeding, to be specific, removing mulch in time at the moment of sprouts emerging from soil, topdressing with 0.3% urea when each seedling grows 3 true leaves, and performing field planting when the seedlings are about 30 days old; performing field planting, to be specific, transplanting to a large field for field planting when each seedling grows 6-7 true leaves, preparing the field and applying fertilizer before field planting, and cultivating in plum-blossom high-density mode; managing the field, to be specific, applying 15-20 kg of urea per mu of holes during field planting based on sufficient farmyard manure applied; harvesting. By using the high-yield cultivation method of Brassica oleracea, the yield per mu can be increased to 6400 kg per mu, basis is laid for the stable production of Brassica oleracea, and the produced variety of Brassica oleracea is significantly superior to other varieties in terms of disease resistance, cold resistance, physiological form and yield, and is applicable to planting in various regions and convenient to popularize.

Owner:ZHANGJIAKOU ACAD OF AGRI SCI

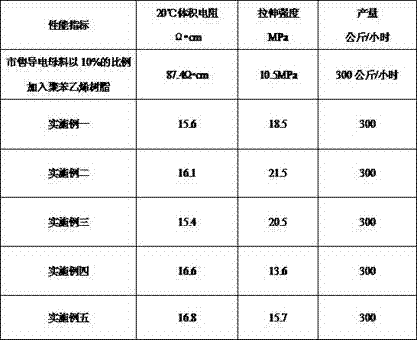

Graphene microchip electric conduction master batch and preparation method thereof

ActiveCN107200947AGood effectUniform and stable dispersionTransportation and packagingMetal-working apparatusGraphiteCvd graphene

The invention provides a graphene microchip electric conduction master batch and a preparation method thereof. The graphene microchip electric conduction master batch is characterized in that graphite powder is mixed with metallic tin, tin is melted in a high-temperature condition, graphite is peeled into graphene microchip glass bead quenching clad layer through stirring, smashing and shearing, so that graphene is stably and uniformly dispersed into the metallic tin and clad in glass beads, furthermore, tin-stabilized graphene particles are formed through grinding, and the tin-stabilized graphene particles are dispersed into a high polymer material to prepare and obtain the graphene microchip electric conduction master batch through a screw extruder. The graphene microchip electric conduction master batch has good dispersibility, and is applicable to electric conduction of various electric conduction plastics, electronic plastics and photovoltaic plastics.

Owner:东营睿港投资服务有限责任公司

Preparation method, kit and application of hematogenous female autologous germline stem cells

PendingCN111484971AProduction speed advantageYield advantageEpidermal cells/skin cellsCulture processMolecular biologyStem cell

The invention relates to a preparation method, a kit and application of hematogenous female autologous germline stem cells, in particular to a technology and a method for producing hematogenous femaleautologous germline stem cells through non-transgenosis by using female autologous blood cells as raw material cells. The preparation method of the hematogenous female autologous germline stem cellscomprises the following steps of: culturing female autologous blood cells in a cell culture solution O1 for 3 days; continuously culturing in a cell culture solution O2 for 6-9 days; continuously culturing in a cell culture solution O3 for 6-9 days; and collecting the hematogenous female autologous germline stem cells. The invention further provides a kit for preparing the hematogenous female autologous germline stem cells. The method and the kit disclosed by the invention have remarkable advantages in the aspects of sampling, production speed, yield and purity of the hematogenous female autologous germline stem cells.

Owner:林柳吟

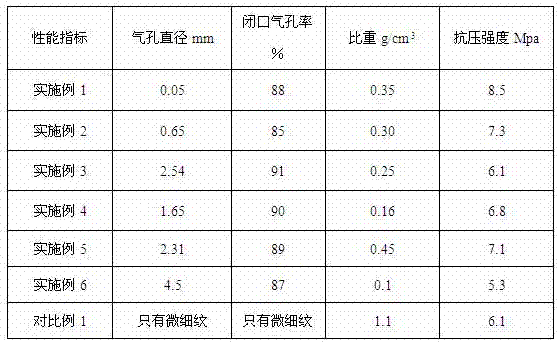

Low-density building foaming glass and preparation method thereof

The invention provides low-density building foaming glass and a preparation method thereof. The method comprises the following steps: mixing micron glass powder with a proper amount of hollow glass microspheres; directly sintering the acquired mixed particles under high temperature; and by taking the hollow glass microspheres as framework materials, splicing the microspheres after melting the micron glass powder due to the easiness in sintering of the microspheres, thereby acquiring the low-density building foaming glass. The preparation method overcomes the technical defects of relative high impurity content and influence of the excessive impurities on the overall performance of the prepared end product of the foaming glass preparation in the prior art; the mixture prepared according to the invention is directly sintered under high temperature; except for the glass raw material, the mixture almost contains no other impurity; the joint parts of the accumulated glass microspheres are formed into glass microspheres with porous structure and uniform size; the generated pores are uniformly distributed, the pore size distribution is narrower and the product is high in strength; and the low-density building foaming glass is suitable for high-strength building materials and decorative materials.

Owner:江门市俊发安全玻璃有限公司

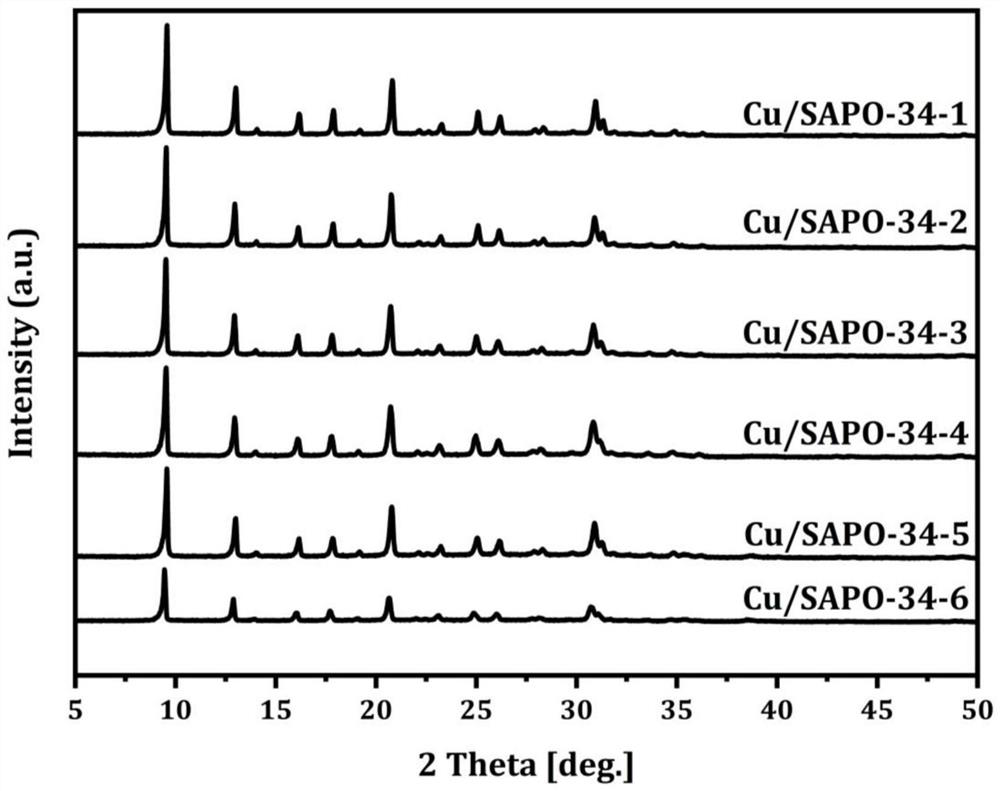

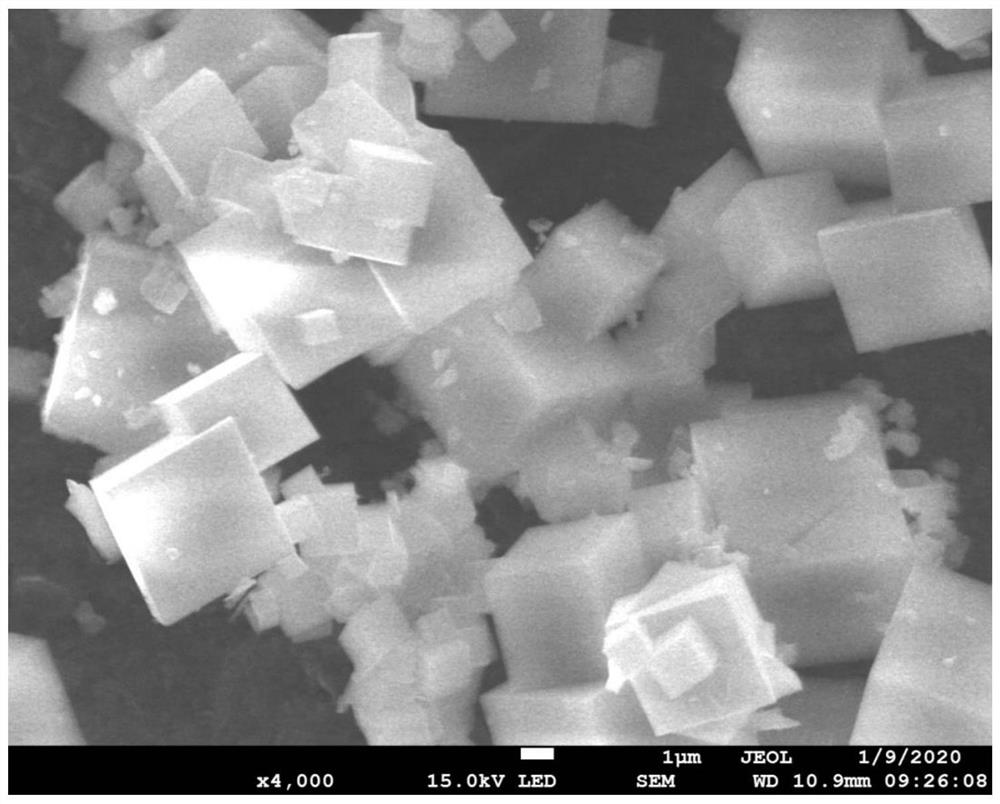

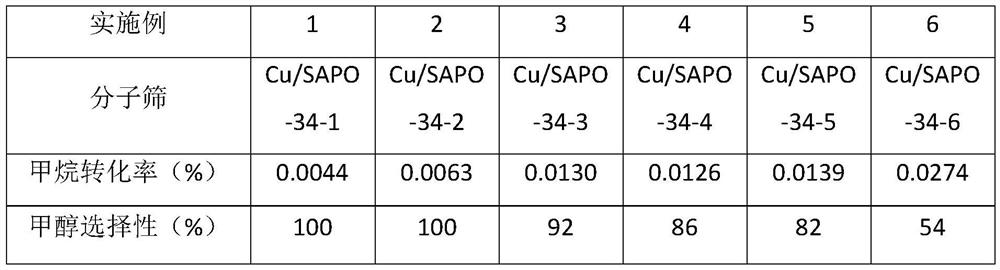

Preparation method and application of copper modified molecular sieve catalyst

PendingCN112973784ABeneficial oxidation reactionPromote oxidation reactionPreparation by oxidation reactionsMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a preparation method of a copper modified molecular sieve catalyst applied to preparation of methanol by selective oxidation of methane, which comprises the following step of placing a certain amount of molecular sieve catalyst sample in a quartz tube of a fixed bed reactor, introducing inert gas, and pretreating at 500 DEG C, cooling to a reaction temperature, introducing a reaction gas mixture of methane, water vapor and oxygen in a certain proportion into the fixed bed reactor, reacting at 200-400 DEG C, introducing a product into a gas chromatograph for analysis and detection, preferably, enabling the selectivity of methanol to be 93%, and the yield to be 184 mol / kgcat / h. The copper modified molecular sieve catalyst provided by the invention is Cu / SAPO-34 which is synthesized in situ by utilizing a one-step method and controls the gradient change of the content of loaded metal copper. The molecular sieve catalyst obtained by the invention has the characteristics of simple synthesis process, good hydrothermal stability and excellent catalytic performance. When the catalyst is applied to methanol preparation through methane oxidation, continuous production of methanol can be realized, the reaction process is simple, the process is green and economical, the methanol yield is high, and the industrial application value is high.

Owner:NANKAI UNIV

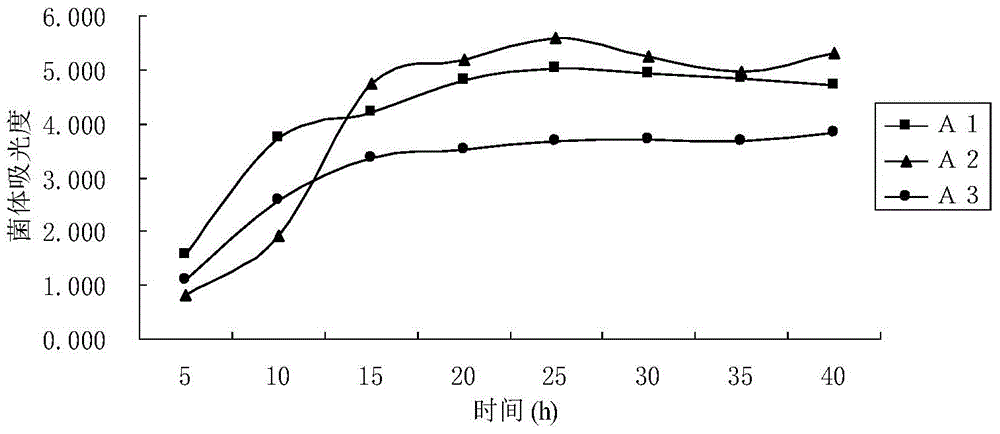

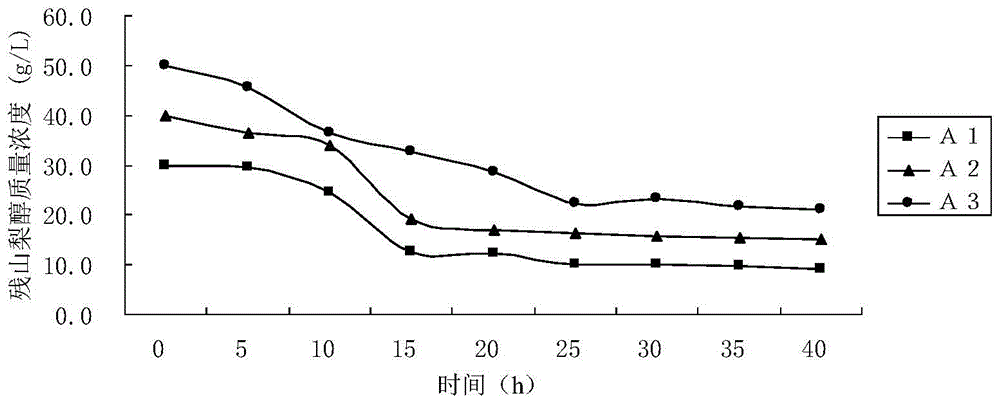

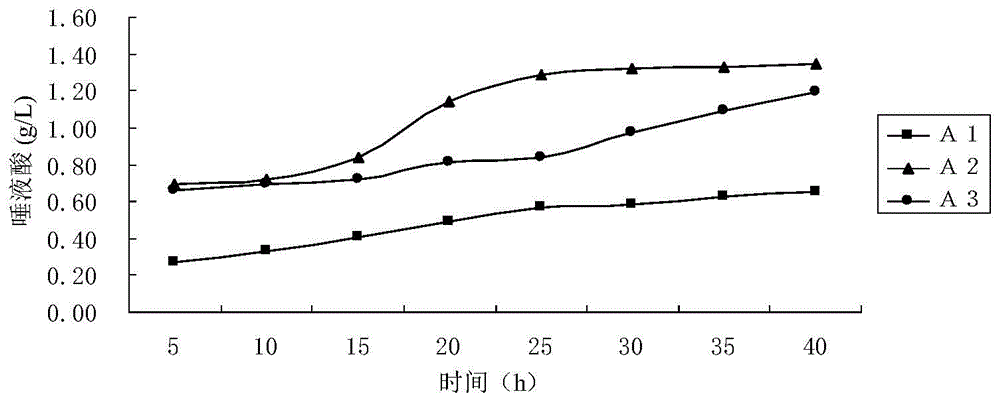

A method for producing sialic acid through fermentation

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

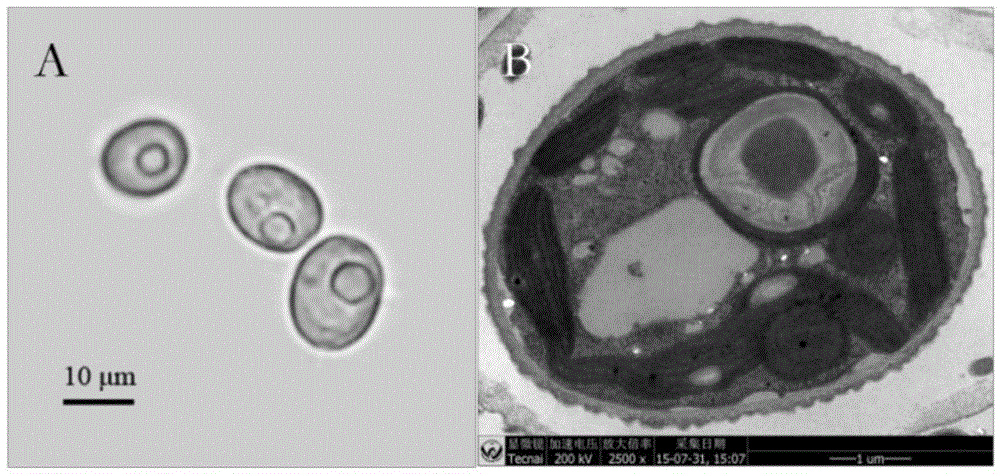

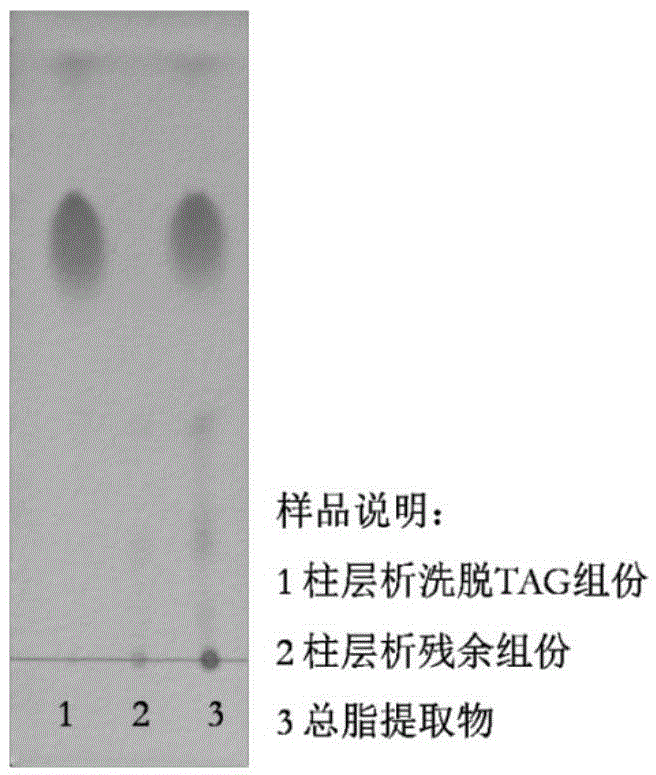

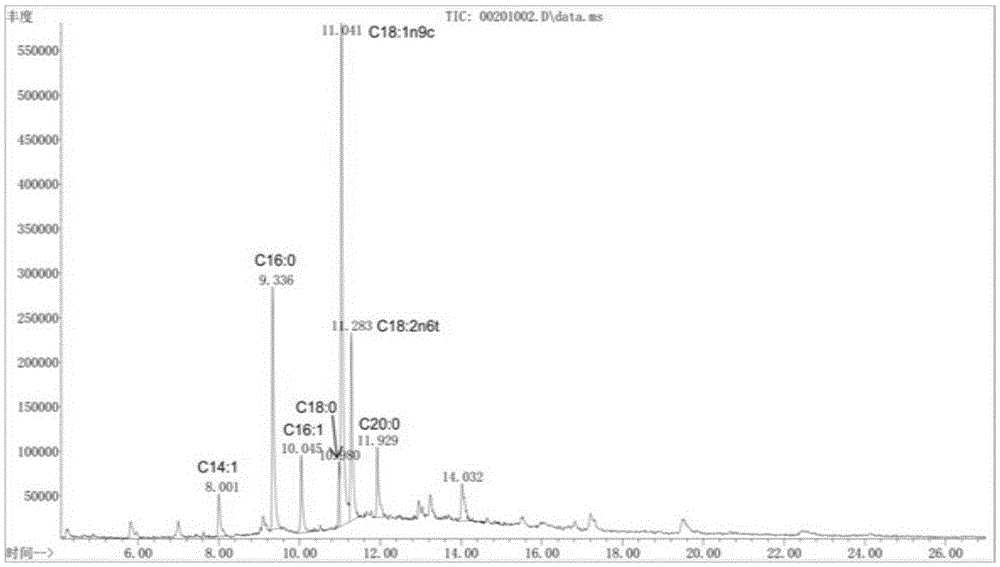

Graesiella sp. WBG-1 as well as isolation and screening method and application thereof

ActiveCN105543099AWide adaptability to the environmentTolerates high pH environmentsUnicellular algaeBiofuelsBiodiesel feedstockProtozoa

The invention discloses Graesiella sp. WBG-1 as well as an isolation and screening method and an application thereof. The algal strain grows fast, is high in adaptability to pH change, and has the characteristics of large cells, proneness to sedimentation, resistance to protozoa swallow and the like, which are suitable for cultivation in large scale. The Graesiella sp. WBG-1 accumulates a large amount of grease in cells under the low-nitrogen cultivation condition, so that the Graesiella sp. WBG-1 can be used as raw materials of microalgae biodiesel; a large amount of protein is accumulated in the cells of the Graesiella sp. WBG-1 under the high-nitrogen cultivation condition, the Graesiella sp. WBG-1 can be applied to production of microalgae protein accordingly; besides, the Graesiella sp. WBG-1 can fix exogenous carbon dioxide efficiently under the higher pH condition, thereby being capable of being applied to biological fixation of flue gas carbon dioxide.

Owner:WUHAN BOTANICAL GARDEN CHINESE ACAD OF SCI +1

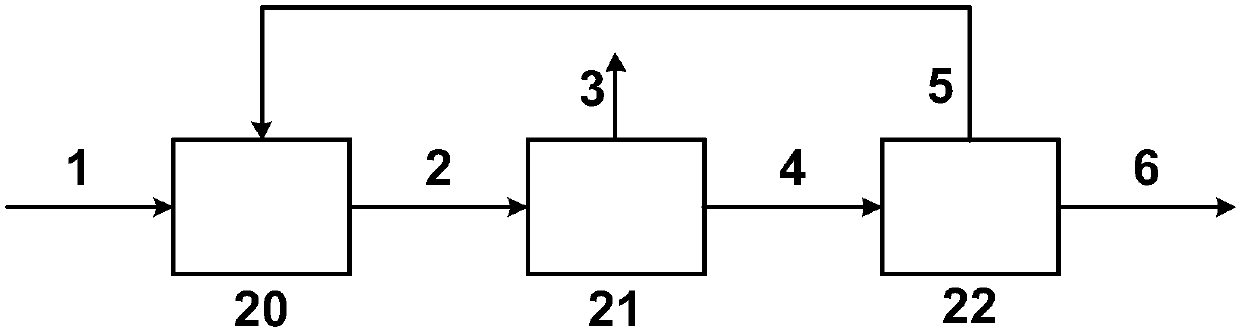

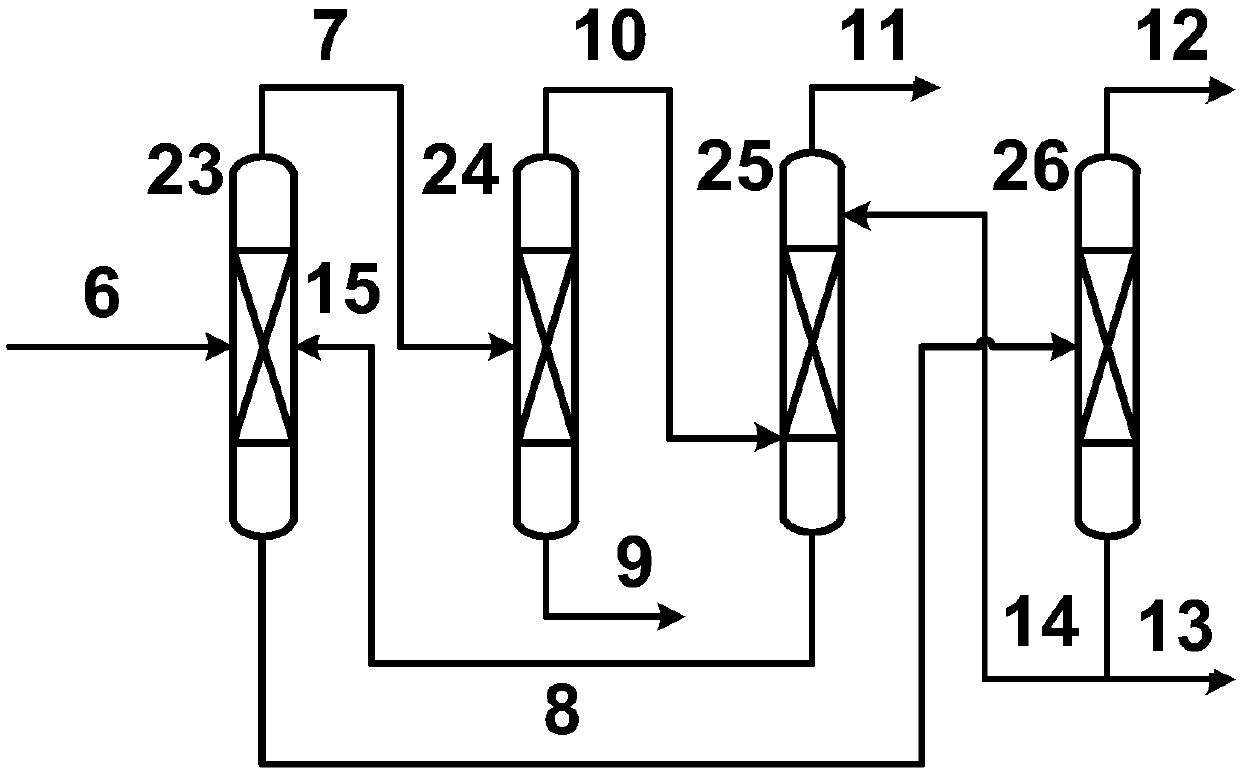

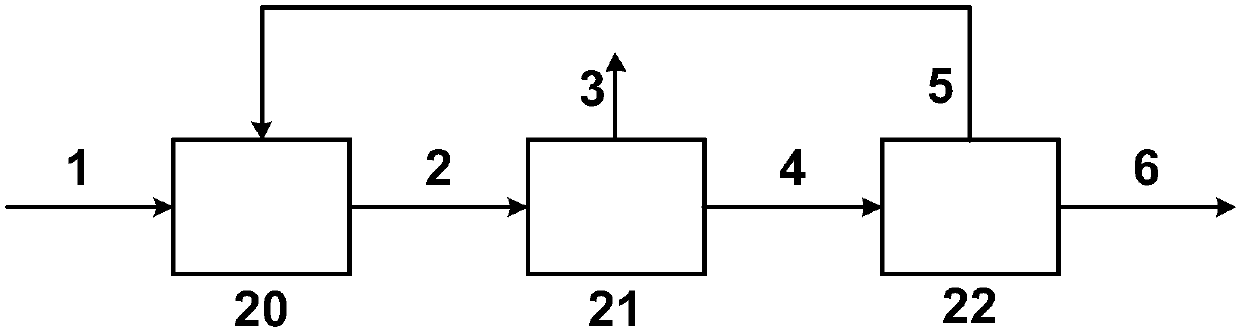

Method of preparing olefins from synthetic gas

ActiveCN109704899AAbsorption reachedYield advantageHydrocarbon from carbon oxidesEthylene productionDehydrogenationReaction zone

The invention relates to a method of preparing olefins from synthetic gas and mainly solves the problems that production of olefins in the coal chemical industry technology in the prior art is long inroute, relates to a large number of technologies, is large in investment and manpower and material cost, and is high in olefin production cost. The method includes: the synthetic gas flow is reactedin a reaction zone to obtain a product flow; the product flow is separated in a decarbonization zone to obtain a material flow XI, mainly containing CO2, and a decarbonized flow; the decarbonized flowis separated in a dehydrogenation zone to obtain a circulating flow mainly containing CO and H2 and a blend hydrocarbon flow, wherein at least a part of the circulating flow returns to the reaction zone. The technical scheme can solve the problems well and can be used in production of light olefin products. The method is short in process, is low in investment and is low in production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Precise fermentation culture medium for edible fungus liquid strains and application

PendingCN108849240AReduce volatilityChanging Technological BiasesCultivating equipmentsMushroom cultivationBiotechnologySodium diacetate

The invention relates to a precise fermentation culture medium for edible fungus liquid strains and application. The medium comprises a carbon source with monotonous components, a nitrogen source withmonotonous components, glycerin, KH2PO4, K2HPO4, MgSO4.7H2O, FeSO4, gibberellin, sodium diacetate, VB1, VB2 and GPE. The inventor of the medium discovers for the first time that the precise culture medium can be obtained by blending all kinds of compounds clear in component, and is suitable for growth of edible fungus mycelia, which overcomes the technical prejudice, that edible fungi need to becultured through a culture medium prepared from natural components, of technicians in the field. Since the components of the culture medium are controllable, mycelium growth speed is uniform after theliquid strains of different batches obtained through culturing are inoculated in solid compost, and production management is easily standard and programmable; the new conception is provided for reducing fluctuations in industrialized production of the edible fungi.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

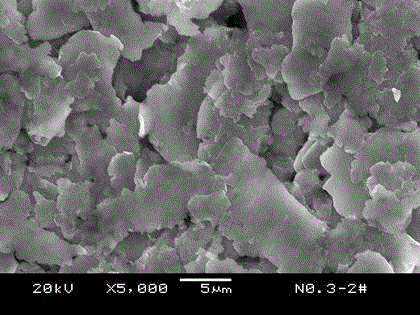

Method for preparing high-purity and high-dispersion nano magnesium oxide material

ActiveCN107253733AGood dispersionWide variety of sourcesMaterial nanotechnologyMagnesiaDispersityHigh pressure

The invention discloses a method for preparing a high-purity and high-dispersion nano magnesium oxide material. The method comprises the following steps: taking magnesium sulfate as a raw material, dispersing the magnesium sulfate with a dispersion emulsifier, magnesium oxide quantum points and ammonia water in a high-pressure homogenizer to form an emulsion, performing high-pressure ejection, and at the same time performing laser sintering at a dispersion state. By adopting the method, the technical defects that a nano material is poor in property and popularization and application of nano magnesium oxide are obstructed as a conventional nano magnesium oxide material is easy to agglomerate and relatively poor in purity are solved, and the technical effect that magnesium oxide quantum points as crystal cores grow rapidly in an isotropic manner to form spherical nano magnesium oxide with high dispersity and high purity is achieved. Furthermore, the scheme disclosed by the invention is simple in preparation process, free of pollution and easy in on-scale industrial production.

Owner:湛江市中诚电热材料有限公司

A kind of graphene microchip conductive masterbatch and preparation method thereof

ActiveCN107200947BPerformance advantageYield advantageTransportation and packagingMetal-working apparatusMasterbatchMolecular materials

The invention proposes a graphene microchip conductive masterbatch and a preparation method thereof, which is characterized in that graphite powder is mixed with metal tin, the tin is melted under high temperature conditions, the graphite is peeled into graphene microchips by stirring, crushing and shearing, and then mixed with glass The microbeads are quenched and coated, so that graphene is stably and uniformly dispersed in metal tin and coated on glass microspheres. Further, graphene particles stabilized by tin are formed by grinding, dispersed in polymer materials and prepared by a screw extruder. The graphene microchip conductive masterbatch has good dispersibility, and is suitable for the conduction of various conductive plastics, electronic plastics, and photovoltaic plastics.

Owner:东营睿港投资服务有限责任公司

Method of fast preparing graphene through microwave assisted stirring

The invention provides a method of fast preparing graphene through microwave assisted stirring. Graphite powder is adopted as a raw material, graphite powder and a foamer are mixed, graphite is infiltrated by the foamer and then put into a high mixing machine, high speed stirring is utilized to make graphite in a complete suspension state and a high speed motion state, meanwhile, microwave stripping is adopted to aid so that the foamer among graphite layers can fast react to generate support force, and continuous, fast, environment-friendly and clean preparation of a graphene material can be achieved. According to the method of fast preparing graphene through microwave assisted stirring, the technical effect of continuous, clean and environment-friendly production of graphene is achieved, and industrialized production of graphene dry powder is promoted; further, cutting and stripping are completed through one step in the high mixing machine, graphene is scattered evenly, not only is the layer structure of graphene maintained to the greatest extent, but also the graphene material can be prepared continuously and stably, surface integrity and topological symmetry of graphene are not destroyed, and the quality of graphene finished products is ensured further.

Owner:山东聊城莱鑫粉末材料科技有限公司

A kind of cabbage seed production method

ActiveCN106962195BIncrease productionDisease resistance advantageLeaf crop cultivationCultivating equipmentsPollinationSeedling

The invention discloses a seed production technology of cabbage, which adopts the following seed production method: cutting the lateral buds from the nodes, culturing them on the culture medium, and continuously subculturing in the laboratory to obtain the original mother plant; breeding the sterile line: Preparation of sunbeds; preparation of seedling trays; artificial planting of mother plants; maintainer seedlings; planting; pollination; ventilated harvest: remove the row of maintainer plants in the middle of pod formation, increase the row spacing to facilitate ventilation and light transmission, and cut when 70% of the pods turn yellow Make it post-ripening, threshing after drying; male parent breeding: strict bud selection standards, standardized bud peeling and pollination operations, and well-marked pollination; hybrid breeding. The invention provides seed production technology, the yield reaches 65-75kg / mu, the bud rate and bud vigor are as high as more than 85%, and the seed yield is high, laying the foundation for realizing the stable production of cabbage; after planting, whether it is disease resistance, cold resistance Compared with other varieties, it has obvious advantages in terms of physiological shape and output, and is convenient for popularization and planting.

Owner:ZHANGJIAKOU ACAD OF AGRI SCI

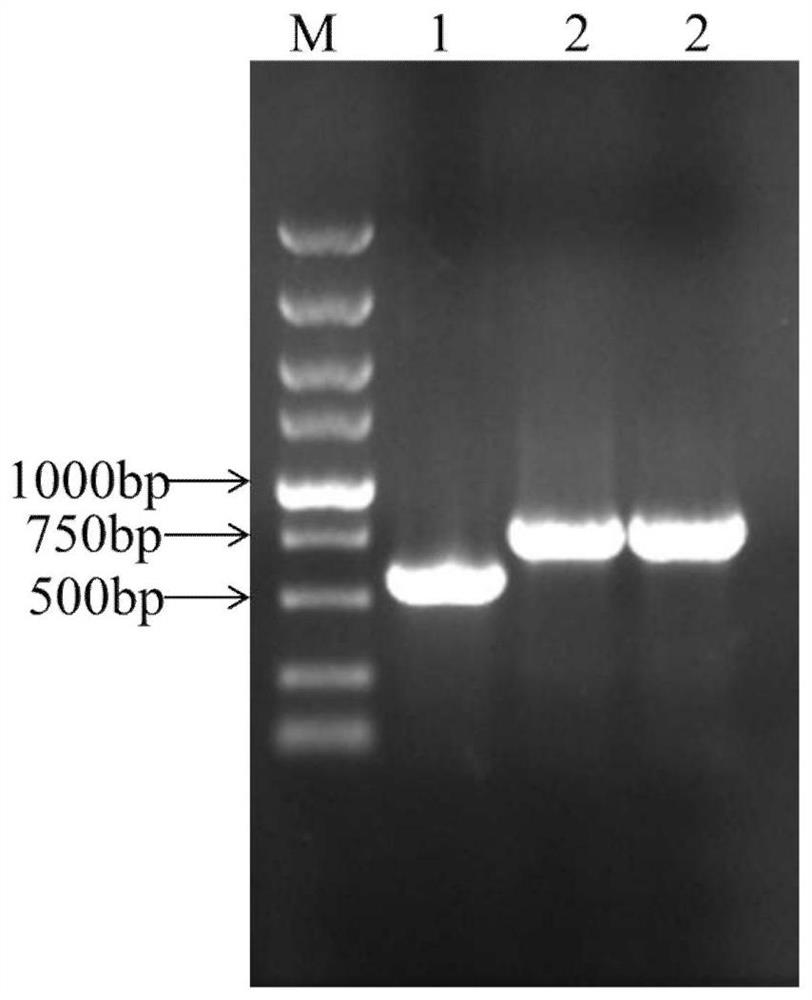

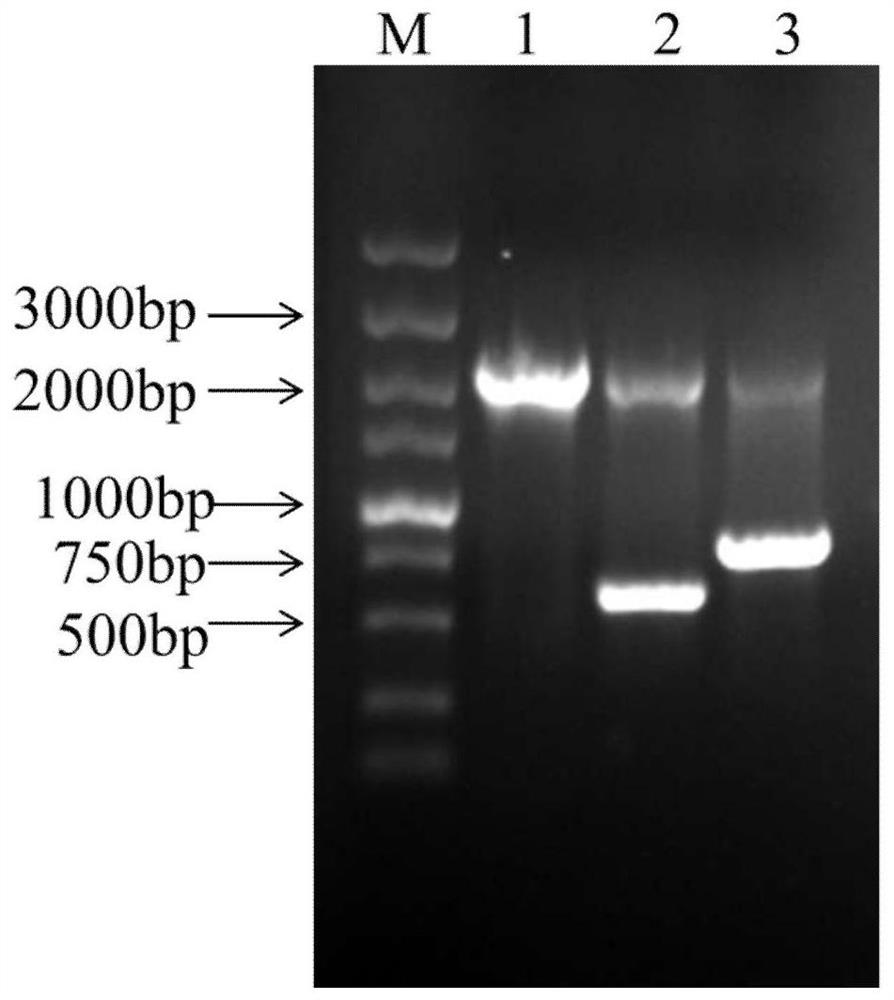

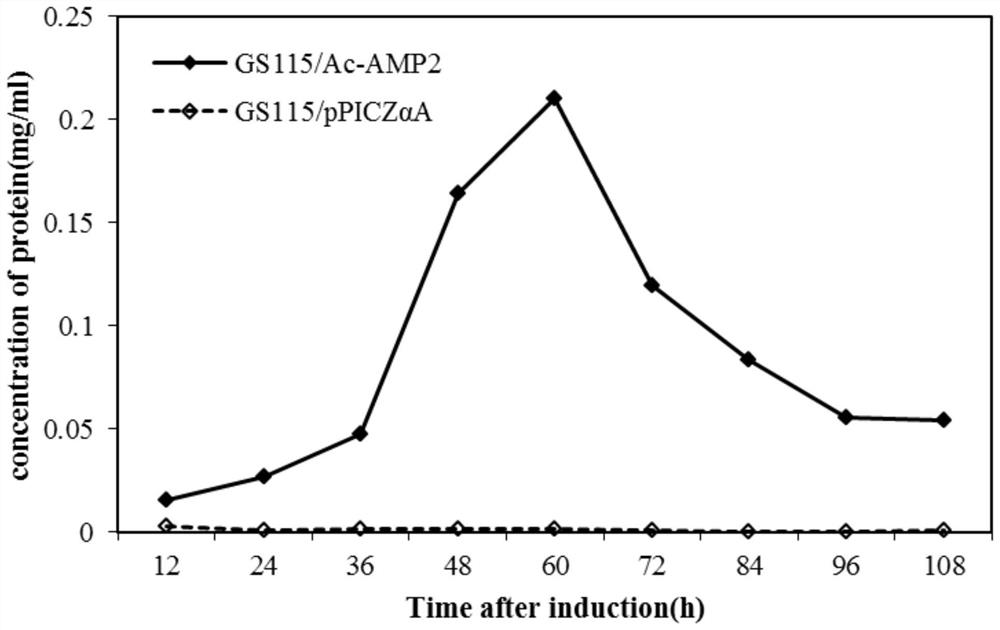

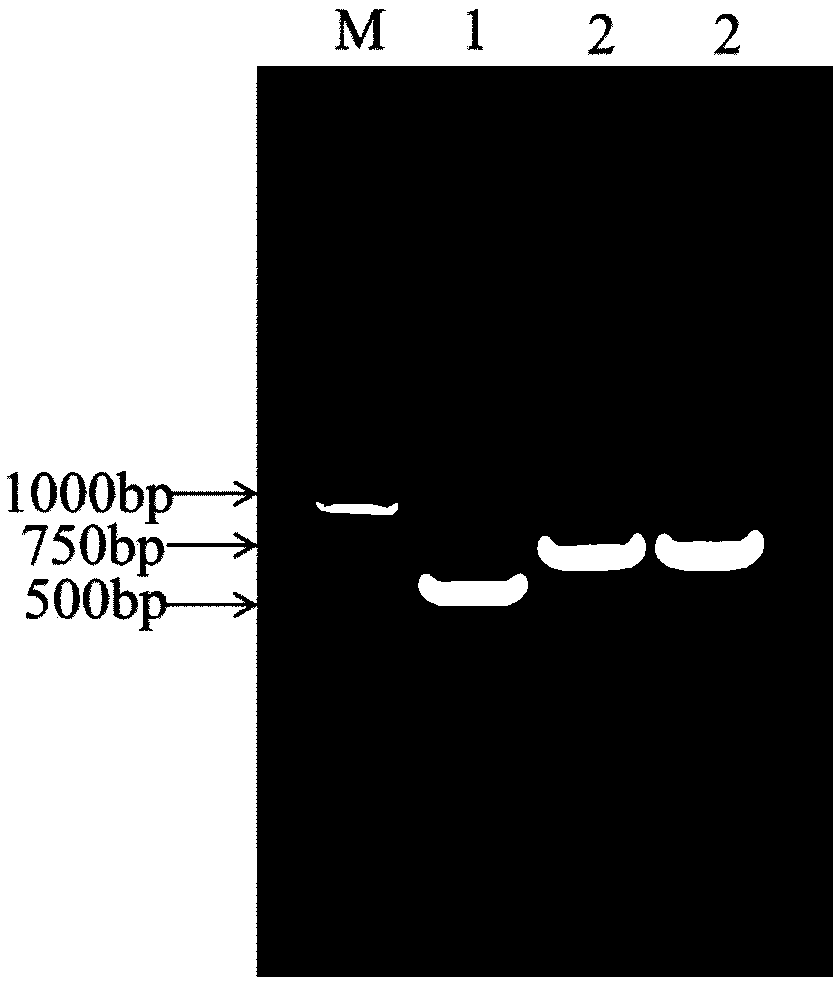

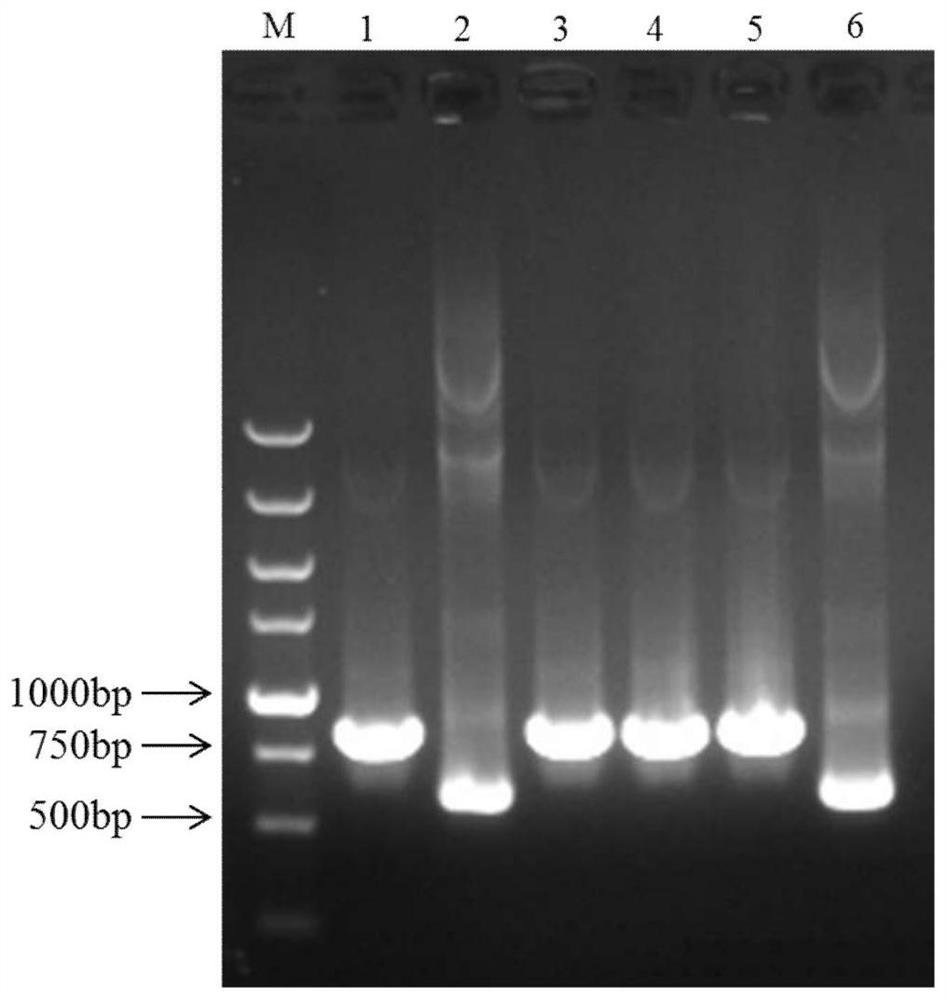

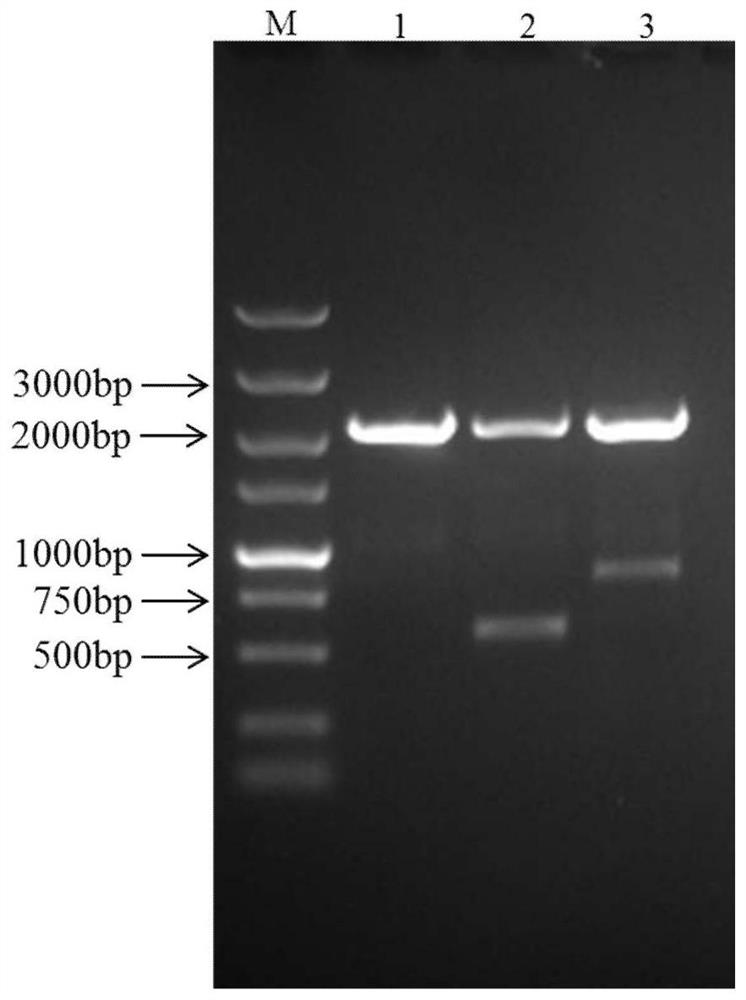

Preparation gs115/ac-amp2 for inhibiting postharvest blue mold in pear fruit

InactiveCN108018222BReduce rotExtended shelf lifeFungiFruit and vegetables preservationAntimikrobielle peptideEnzyme digestion

The invention discloses a preparation GS115 / Ac-AMP2 for inhibiting pear-fruit postharvest penicilliosis. The preparation is recombinant yeast GS115 / Ac-AMP2 obtained after Ac-AMP2 antimicrobial peptideis introduced. A construction method for the recombinant yeast GS115 / Ac-AMP2 includes the following steps that optimized Ac-AMP2 genes are constructed onto pPICZalphaA vectors through Xho I and Not Idouble enzyme digestion and T4 ligase, the formed pPICZalphaA / Ac-AMP2 recombinant expression vectors are subjected to linear enzyme digestion, and then are electrically transformed into GS115 competent cells, a single colony PCR is selected in a Zeocin-contained resistant plate, sequencing verification is carried out, and a recombinant pichia yeast GS115 / Ac-AMP2 strain is obtained. The preparation GS115 / Ac-AMP2 can be used for refreshment for inhibiting fruit postharvest diseases.

Owner:ZHEJIANG UNIV

A kind of equipment and method for preparing graphene composite material by continuous grinding and extruding

The invention provides an apparatus and method for preparing a graphene composite material through continuous grinding extrusion. The method comprises the following steps: adding graphite and a plastic stripping agent to a screw extruder, and carrying out oriented shearing on above raw materials through a feeding mechanism formed by a screw in order to obtain a primary stripping product, conveying the primary stripping product to a stripping mechanism formed by a millstone group, and the primary stripping product undergoes secondary shearing striping through relative rotation of an internal millstone and an external millstone in order to obtain the graphene composite material. The method overcomes the defects of low stripping strength and thick stripping layers of graphene prepared through using screw stripping in the prior art, and the apparatus has the advantages of simple structure, improvement of the shearing strength, realization of continuous production of the graphene composite material, further obtaining of the graphene composite product with thin stripping thickness, avoiding of graphene aggregation, improvement of the quality of graphene, convenience for storage, and promotion of mass production of the graphene product.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

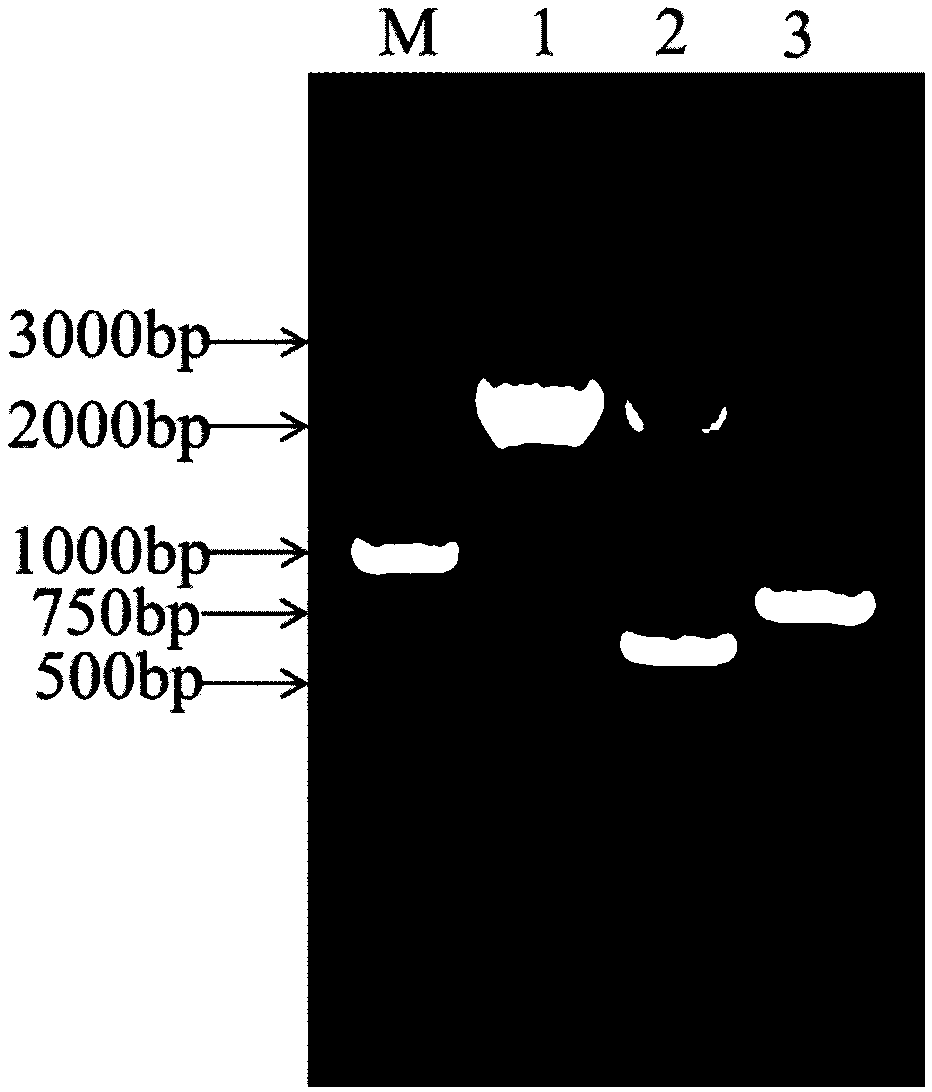

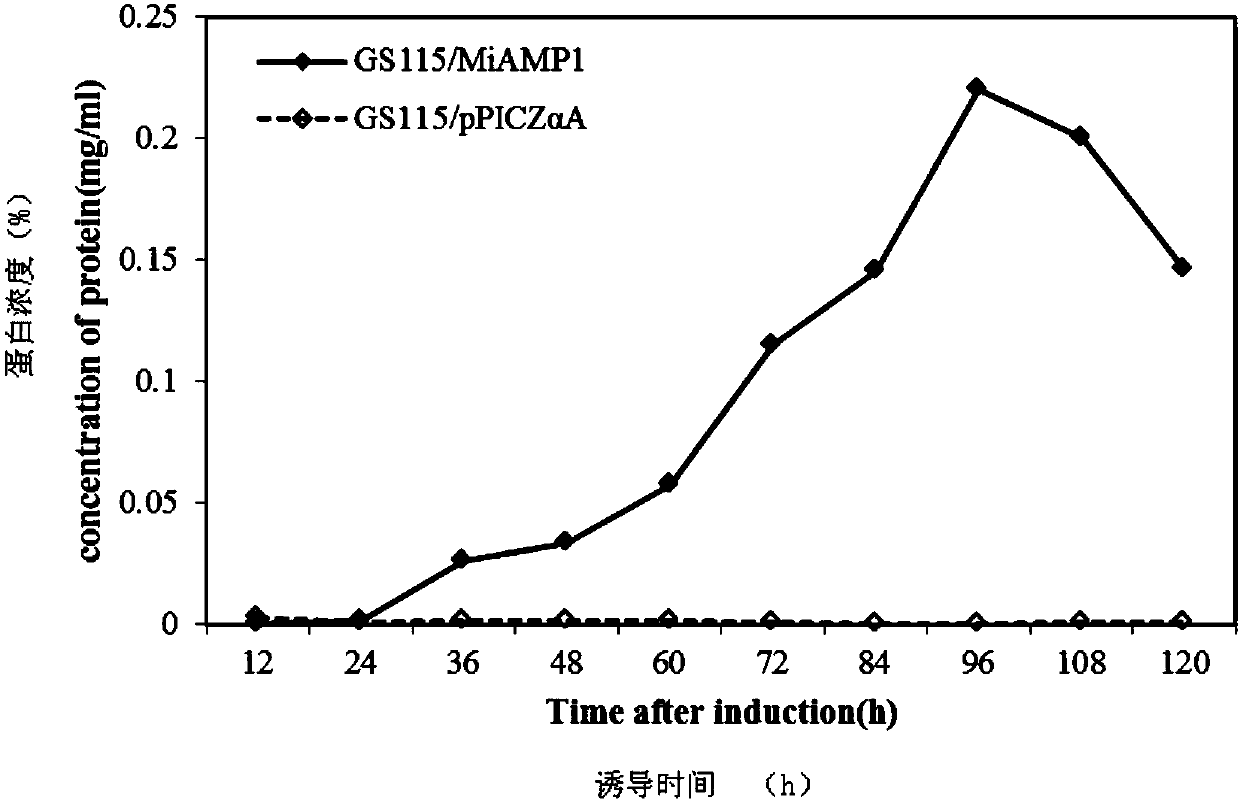

Preparation GS115/MiAMP1 for inhibiting pear-fruit postharvest penicilliosis

The invention discloses a preparation GS115 / MiAMP1 for inhibiting pear-fruit postharvest penicilliosis. The preparation is recombinant yeast GS115 / MiAMP1 obtained after MiAMP1 antimicrobial peptide isintroduced. A construction method for the recombinant yeast GS115 / MiAMP1 includes the following steps that optimized MiAMP1 genes are constructed onto pPICZalphaA vectors through Xho I and Not I double enzyme digestion and T4 ligase, the formed pPICZalphaA / MiAMP1 recombinant expression vectors are subjected to linear enzyme digestion, and then are electrically transformed into GS115 competent cells, a single colony PCR is selected in a Zeocin-contained resistant plate, sequencing verification is carried out, and a recombinant pichia yeast GS115 / MiAMP1 strain is obtained. The preparation GS115 / MiAMP1 can be used for refreshment for inhibiting fruit postharvest diseases.

Owner:ZHEJIANG UNIV

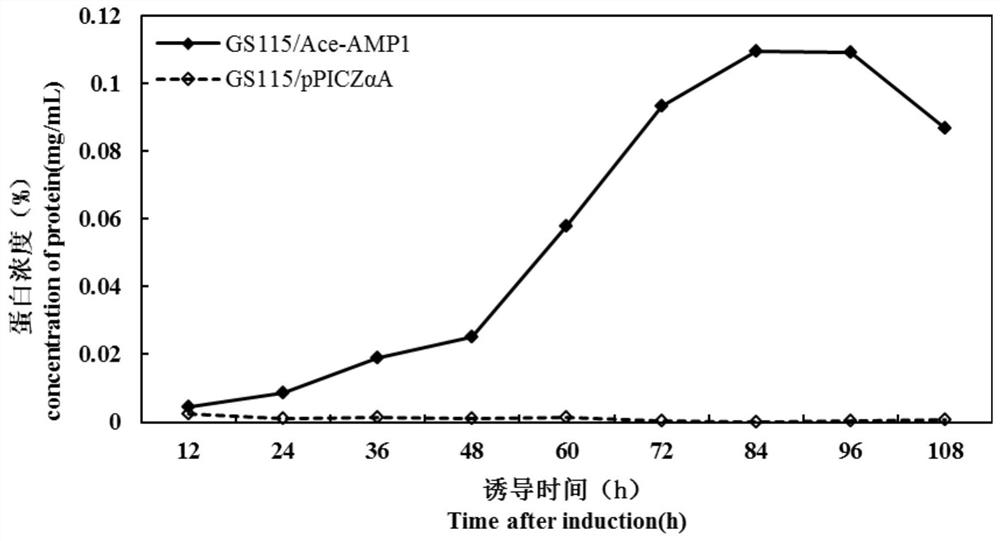

Preparation gs115/ace-amp1 for inhibiting postharvest blue mold in pear fruit

InactiveCN108018221BReduce rotExtended shelf lifeFungiFruit and vegetables preservationAntimikrobielle peptideEnzyme digestion

The invention discloses a preparation GS115 / Ace-AMP1 for inhibiting pear-fruit postharvest penicilliosis. The preparation is recombinant pichia yeast GS115 / Ace-AMP1 obtained after Ace-AMP1 antimicrobial peptide is introduced. A construction method for the recombinant pichia yeast GS115 / Ace-AMP1 includes the following steps that optimized Ace-AMP1 genes are constructed onto pPICZalphaA vectors through Xho I and Not I double enzyme digestion and T4 ligase, the pPICZalphaA / Ace-AMP1 recombinant expression vectors are subjected to linear enzyme digestion, and then are electrically transformed intoGS115 competent cells, a single colony PCR is selected in a Zeocin-contained resistant plate, sequencing verification is carried out, and a recombinant pichia yeast GS115 / Ace-AMP2 strain is obtained.The preparation GS115 / Ace-AMP1 can be used for refreshment for inhibiting fruit postharvest diseases.

Owner:ZHEJIANG UNIV

A method for rapidly preparing graphene with microwave-assisted stirring

Owner:山东聊城莱鑫粉末材料科技有限公司

A kind of preparation method of high-purity and high-dispersion nano-magnesia material

ActiveCN107253733BGood dispersionWide variety of sourcesMaterial nanotechnologyMagnesiaDispersityHigh pressure

The invention discloses a method for preparing a high-purity and high-dispersion nano magnesium oxide material. The method comprises the following steps: taking magnesium sulfate as a raw material, dispersing the magnesium sulfate with a dispersion emulsifier, magnesium oxide quantum points and ammonia water in a high-pressure homogenizer to form an emulsion, performing high-pressure ejection, and at the same time performing laser sintering at a dispersion state. By adopting the method, the technical defects that a nano material is poor in property and popularization and application of nano magnesium oxide are obstructed as a conventional nano magnesium oxide material is easy to agglomerate and relatively poor in purity are solved, and the technical effect that magnesium oxide quantum points as crystal cores grow rapidly in an isotropic manner to form spherical nano magnesium oxide with high dispersity and high purity is achieved. Furthermore, the scheme disclosed by the invention is simple in preparation process, free of pollution and easy in on-scale industrial production.

Owner:湛江市中诚电热材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com