Internal mixer for preparing graphene through tensile peeling and method for preparing graphene

A stretching exfoliation and graphene technology, which is applied in the field of material processing, can solve the problems such as the limited exfoliation efficiency of graphene size uniformity, and achieve the effects of easy large-scale industrial production, avoiding damage, and easy storage and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

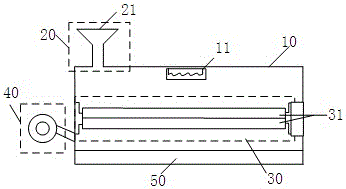

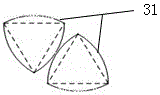

[0043] Such as figure 1 Shown and figure 2 As shown, an internal mixer for preparing graphene by stretching and peeling in the present invention includes a barrel 10, a temperature control device 11 is arranged inside the barrel 10, the temperature control device 11 is installed on the inner wall of the barrel 10, and the temperature control device 11 Including a thermocouple to measure the temperature in real time and feedback to control the material processing temperature to maintain a certain range. The diameter of the barrel 10 is 1000 mm. The feeding mechanism 20 is arranged on the barrel 10 and is composed of at least one feeding port 21; the internal mixing mechanism 30 is connected to the feeding mechanism 20 and includes two cam rotors with a curved side triangle in cross section as the stirring shaft 31. The ratio of the length of the shaft to the length of the side of the curved triangle is 4.5 / 1, and the stirring shaft body is covered with a wear-resistant ceramic...

Embodiment 2

[0050] Such as figure 1 Shown and figure 2 As shown, an internal mixer for preparing graphene by stretching and peeling in the present invention includes a barrel 10, a temperature control device 11 is arranged inside the barrel 10, the temperature control device 11 is installed on the inner wall of the barrel 10, and the temperature control device 11 Including a thermocouple to measure the temperature in real time and feedback to control the material processing temperature to maintain a certain range. The diameter of the barrel 10 is 800 mm. The feeding mechanism 20 is arranged on the barrel 10 and is composed of at least one feeding port 21; the internal mixing mechanism 30 is connected to the feeding mechanism 20 and includes two cam rotors with a curved side triangle in cross section as the stirring shaft 31. The ratio of the length of the shaft to the length of the side of the curved triangle is 4.5 / 1, and the stirring shaft body is covered with a wear-resistant ceramic ...

Embodiment 3

[0057] Such as figure 1 Shown and figure 2 As shown, an internal mixer for preparing graphene by stretching and peeling in the present invention includes a barrel 10, a temperature control device 11 is arranged inside the barrel 10, the temperature control device 11 is installed on the inner wall of the barrel 10, and the temperature control device 11 Including a thermocouple to measure the temperature in real time and feedback to control the material processing temperature to maintain a certain range. The diameter of the barrel 10 is 1100 mm. The feeding mechanism 20 is arranged on the barrel 10 and is composed of at least one feeding port 21; the internal mixing mechanism 30 is connected to the feeding mechanism 20 and includes two cam rotors with a curved side triangle in cross section as the stirring shaft 31. The ratio of the length of the shaft to the length of the side of the curved triangle is 7 / 1, and the stirring shaft body is covered with a wear-resistant ceramic l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com