A kind of equipment and method for preparing graphene composite material by continuous grinding and extruding

A composite material and graphene technology, applied in the field of material processing, can solve the problems of difficult control of the preparation process, complex screw mechanical structure, thick peeling layers, etc., and achieve high peeling efficiency, short preparation cycle, and thin peeling thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

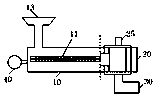

[0048] Such as figure 1 As shown, a kind of equipment for preparing graphene composite material by continuous grinding and extruding in the present invention includes feeding mechanism 10, stripping mechanism 20 communicated with feeding mechanism 10 along the process sequence, and is used to collect graphene composite material The collecting mechanism 30 and the driving mechanism 40 include a motor device, which is connected to the feeding mechanism 10 and the peeling mechanism 20 and is used to drive the feeding mechanism 10 and the peeling mechanism 20 individually or simultaneously.

[0049] A feeding port 13 is provided on the feeding mechanism 10 . The feeding mechanism 10 is composed of a co-rotating screw group 11. During implementation, the co-rotating screw group 11 can be a co-rotating twin-screw group, a co-rotating three-screw group, a co-rotating four-screw group or a co-rotating screw group. One of the screw groups with more than four screws. In this embodiment...

Embodiment 2

[0055] Such as figure 1 As shown, a kind of equipment for preparing graphene composite material by continuous grinding and extruding in the present invention includes feeding mechanism 10, stripping mechanism 20 communicated with feeding mechanism 10 along the process sequence, and is used to collect graphene composite material The collecting mechanism 30 and the driving mechanism 40 include a motor device, which is connected and conducted with the feeding mechanism 10 and the stripping mechanism 20 for driving the feeding mechanism 10 and the stripping mechanism 20 .

[0056] Wherein, the feeding mechanism 10 is composed of co-rotating meshing screw groups 11 , and at least one feeding port 13 is provided on the feeding mechanism 10 . During the implementation process, the screw group 11 that engages in the same direction can be one of twin-screw groups that engage in the same direction, three-screw groups that engage in the same direction, four-screw groups that engage in th...

Embodiment 3

[0062] Such as figure 1 As shown, a kind of equipment for preparing graphene composite material by continuous grinding and extruding in the present invention includes feeding mechanism 10, stripping mechanism 20 communicated with feeding mechanism 10 along the process sequence, and is used to collect graphene composite material The collecting mechanism 30 and the driving mechanism 40 include a motor device, which is connected and conducted with the feeding mechanism 10 and the stripping mechanism 20 for driving the feeding mechanism 10 and the stripping mechanism 20 .

[0063] Wherein, the feeding mechanism 10 is composed of co-rotating meshing screw groups 11 , and at least one feeding port 13 is provided on the feeding mechanism 10 . In the implementation process, the co-engaging screw group 11 can be one of the co-engaging twin-screw group, the co-rotating three-screw group, the co-rotating four-screw group or the co-engaging four-screw or more screw group. In the embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com