Method for preparing small-diameter anatase nano-titanium dioxide

A nano-titanium dioxide and anatase-type technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problem of high production cost of the gas phase method, achieve good dispersion, extremely small grain size, and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

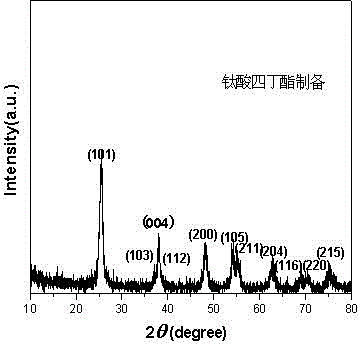

Embodiment 1

[0035] Mix 7mL of tetrabutyl titanate with 30mL of absolute ethanol, the mixing temperature is 18°C, and the stirring time is 5min to obtain a uniformly mixed solution, add 5 mL of n-octanoic acid and 1 mL of distilled water, and stir and mix evenly at room temperature , the mixed solution was transferred to a reaction kettle and heated to 180 °C for 19 h. The final product was filtered, washed several times, and dried to obtain titanium dioxide nanospheres with a size of about 8 nm.

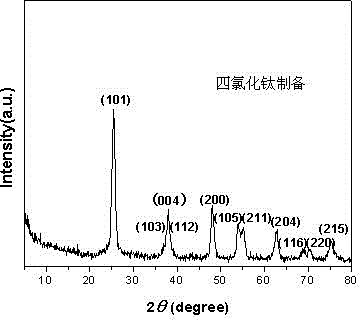

Embodiment 2

[0037] Mix 7mL of titanium tetrachloride with 30mL of absolute ethanol, the mixing temperature is 20°C, and the stirring time is 6min to obtain a uniformly mixed solution, add 5 mL of n-octanoic acid and 1.5 mL of distilled water, and stir at room temperature to mix evenly. The mixed solution was transferred to a reaction kettle and heated to 180 °C for 19 h. The final product was filtered, washed several times, and dried to obtain titanium dioxide nanospheres of about 12 nm.

Embodiment 3

[0039] Mix 15mL of tetrabutyl titanate with 30mL of absolute ethanol, the mixing temperature is 17 ℃, and the stirring time is 4min to obtain a uniformly mixed solution, add 12 mL of n-octanoic acid and 4 mL of distilled water, and stir and mix evenly at room temperature , the mixed solution was transferred to a reaction kettle and heated to 180 °C for 19 h. The final product was filtered, washed several times, and dried to obtain titanium dioxide nanospheres with a size of about 15 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com