Patents

Literature

39results about How to "Quality advantage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nutritive feed for improving pork quality

The invention discloses a nutritive feed for improving pork quality. The formulation of the nutritive feed is mainly composed of a compound feed and a feed pre-mixing agent. According to the nutritive feed, the feed pre-mixing agent is a mixture composed of amino acid, vitamin, catalyzing enzyme, a microelement additive, a mineral substance additive and a carrier, wherein the carrier is bran shell powder, the amino acid comprises lysine; the catalyzing enzyme comprises compound enzyme and phytase; the microelement additive comprises manganese sulfate, copper sulfate, ferrous sulfate and zinc sulfate; the mineral substance additive comprises salt, dicalcium phosphate and calcium carbonate. The massive use of antibiotics and a growth promoter in the existing feed pre-mixing agent is avoided, and the nutritive component of the feed is optimized; the nutritive feed disclosed by the invention satisfies the biological property of the growth of a pig, and can achieve the advantages of the fast growth speed, good meat quality sense, good pork taste and the like, and has excellent market potential and substantial economic benefits.

Owner:王达文

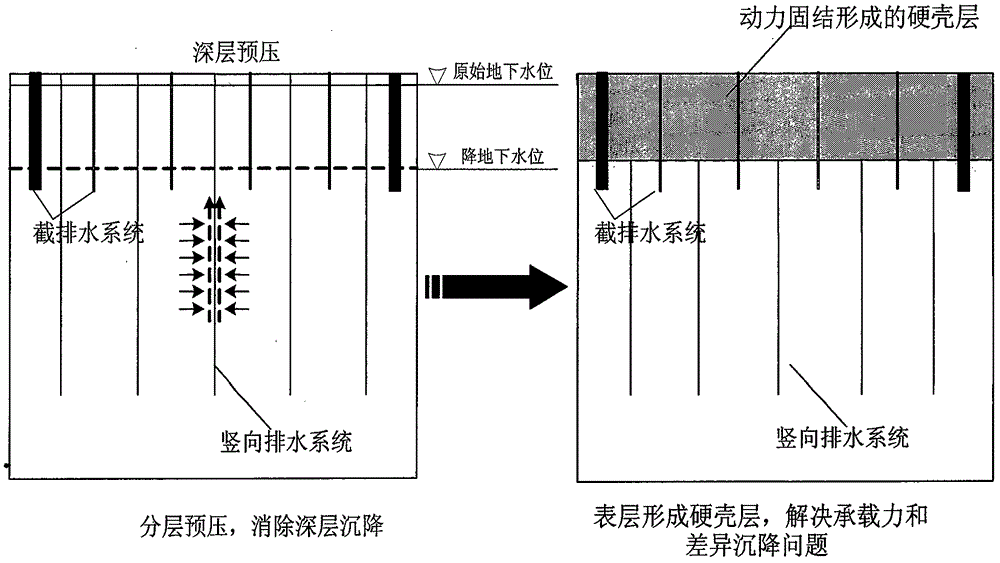

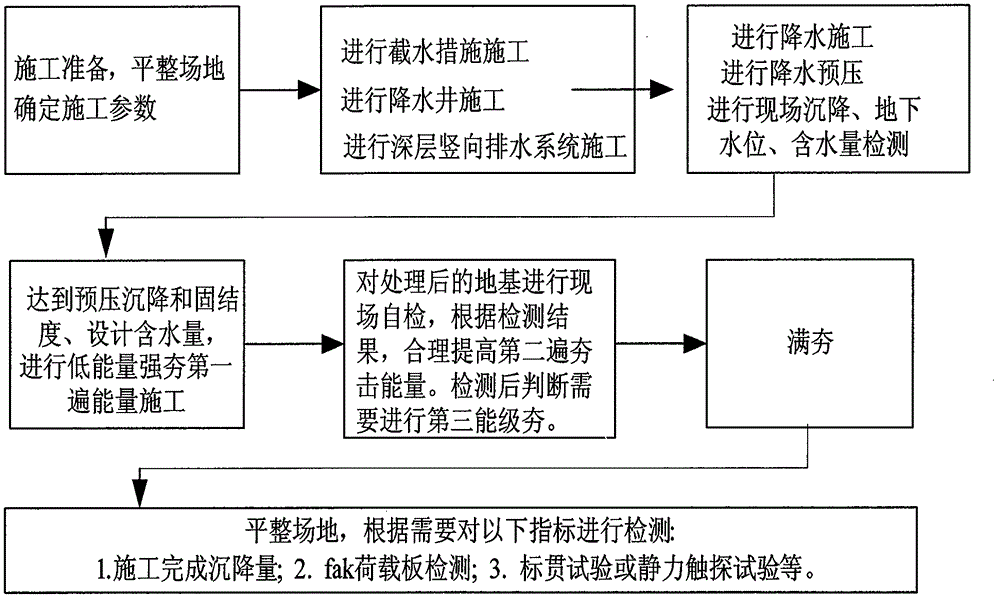

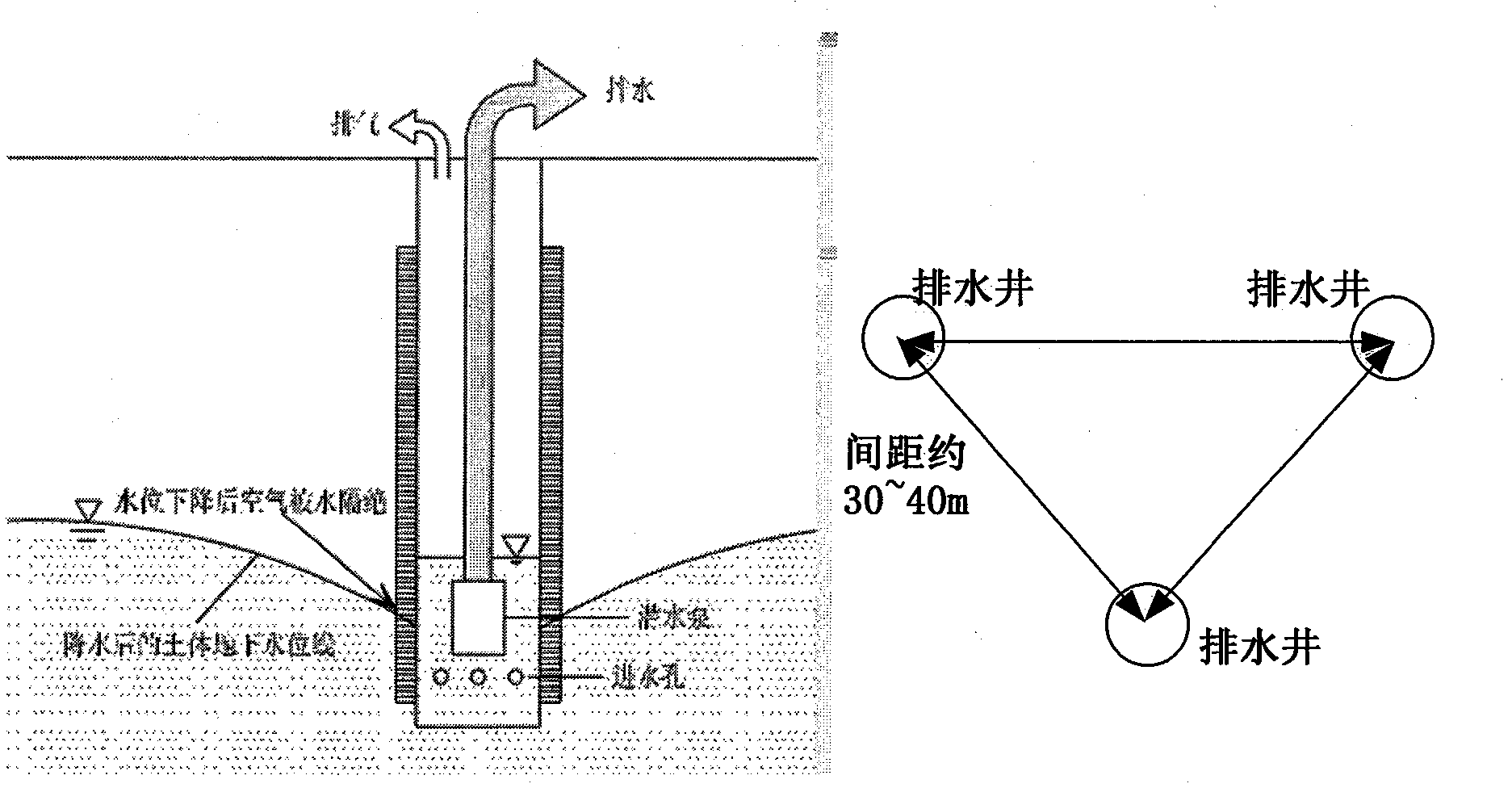

Soft foundation treatment method employing 'cutting drainage deep-layer preloading and dynamic consolidating'

InactiveCN102720180ACost advantageAdvantages of construction periodSoil preservationDynamic compactionMechanical index

The invention relates to a soft foundation treatment method employing 'cutting drainage deep preloading and dynamic consolidating'. Water sealing, strong drainage, deep-layer vertical discharge system, vibrating compacting or dynamic compaction are organically combined to reduce an additional load formed by the ground water level of a deposal field, so as to carry out deep preloading on a soft substratum, finish consolidation of a soft soil layer and remove sedimentation of a soft substratum; compactness and physical and mechanical indexes of a shallow sediment are improved by organic combination of dynamic consolidation and cutting drainage, and the capacity requirements on the field are met. The method comprises the following construction implementation processes of: 1) punching a waterstop curtain and a strong drainage system, reducing the ground water level and the moisture content of a soil body; 2) punching a vertical drainage channel penetrating a silt seam, carrying out the deep-layer preloading and removing the sedimentation; 3) carrying out the dynamic consolidating, so that the compactness and the physical and mechanical indexes of the shallow sediment are improved, and the capacity requirements on the field are met. According to the method, the problems and the defects in the prior art are overcome, and the soft foundation treatment method has the characteristics that the schedule is short, the construction cost is low, the process is simple, the quality is controllable and the difficulty of deep-layer silt engineering can be solved.

Owner:汪文彬

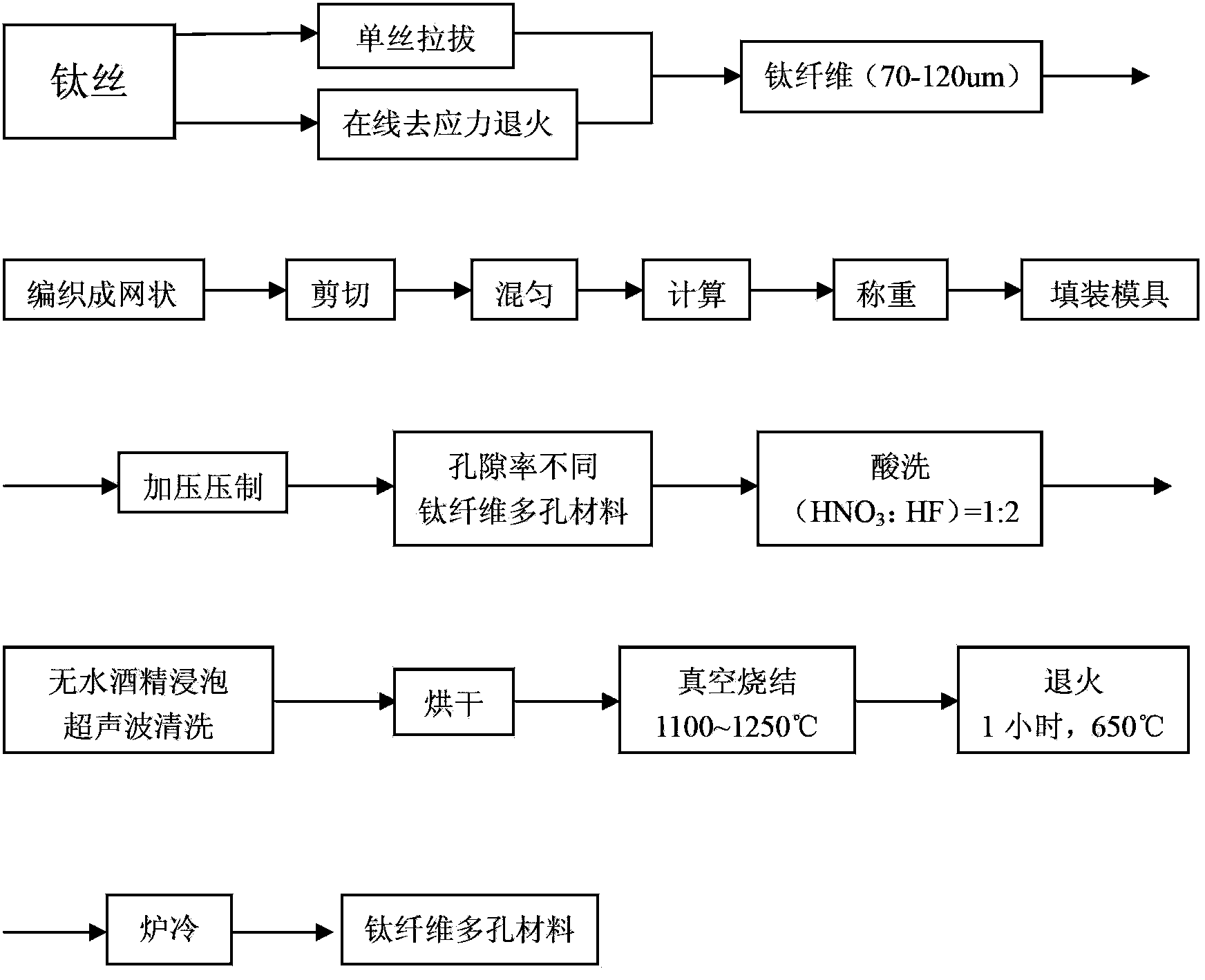

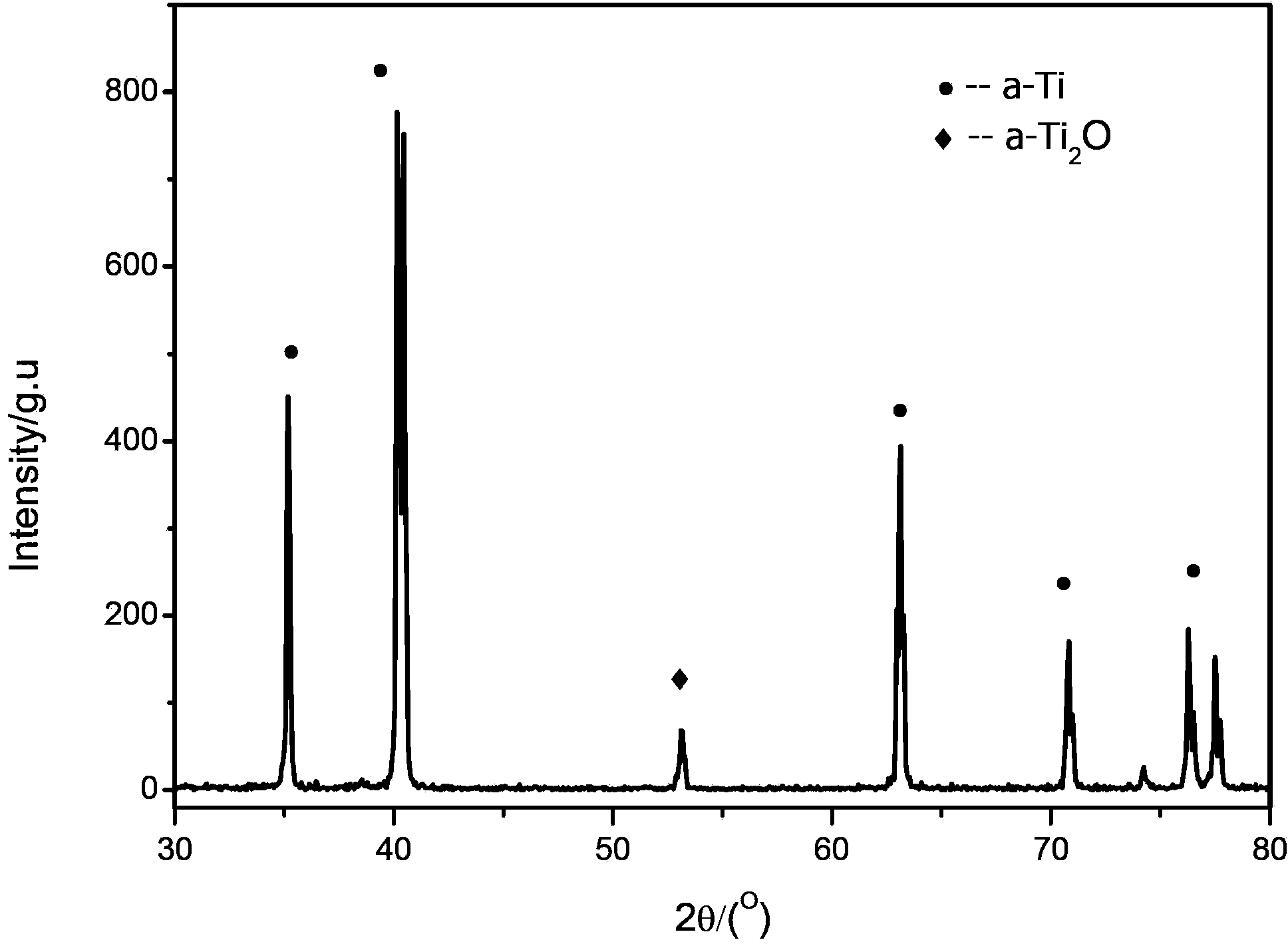

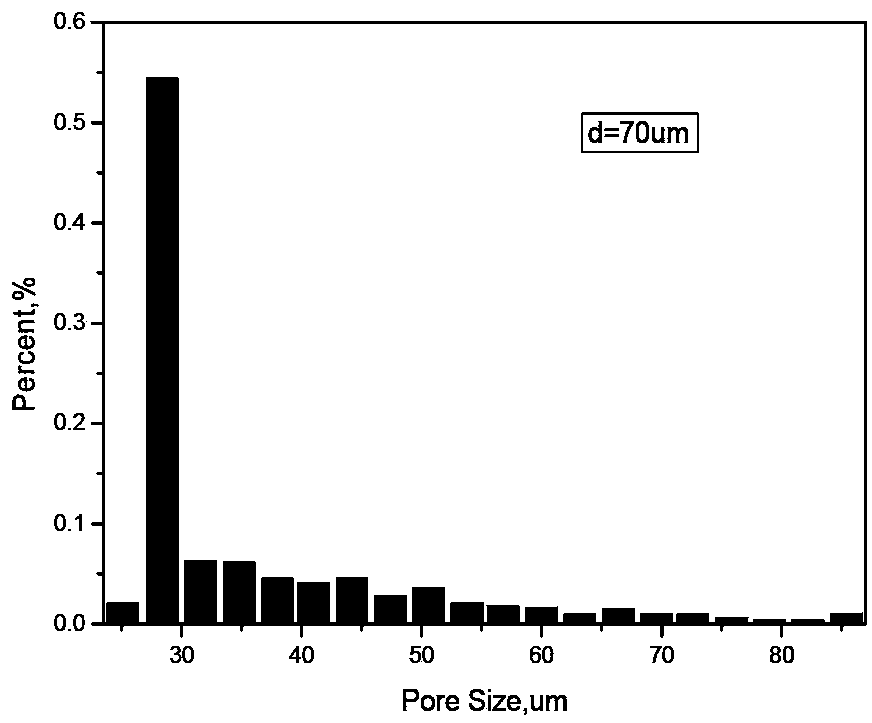

Preparation method of titanium fiber porous material

The invention provides a preparation method of a titanium fiber porous material, which has controllable fiber diameter and porosity. The material is prepared by: drawing a titanium wire into a fibrous state, and then carrying out weaving and compression molding. After the material is prepared, pickling is conducted to remove of the oxide on the surface of the titanium fiber porous material, and then the material is subjected to high temperature sintering by a vacuum sintering furnace. By means of the method provided in the invention, a sintered titanium fiber porous material can be obtained, and all properties of the titanium fiber porous material are greatly improved. Thus, the method provides an important basis for realization of product industrialization.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method based on extensional rheology for stripping graphene and application of graphene

ActiveCN106744879AImprove stripping efficiencyQuality improvementMaterial nanotechnologyGrapheneGraphiteCam

The invention provides a method based on extensional rheology for stripping graphene and application of the graphene. The method comprises the following steps: collectively adding graphite and viscous substances into a designed stretching mechanism, adopting a cam rotor in a cavity to enable the size of the cavity in a drum to be reduced and increased in reciprocating manner when in rotation, compressing and stretching the graphite and the viscous substances in the cavity in a reciprocating manner by virtue of a can and a leaf spring, and stretching, cutting and stripping a graphite mixture under the adhesion effect of an adhesive additive to obtain a graphene precursor, so that the lattice damage of the graphene caused by an excessively large shear force is effectively avoided. According to the scheme disclosed by the invention, the preparation process is simple, the source of raw materials is wide, the pollution is avoided, the cost is low, and the prepared graphene is high in quality, easy to store and transport, and easy for realizing the industrialized mass production.

Owner:东港智科产业园有限公司

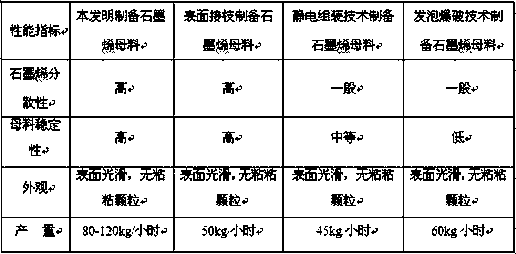

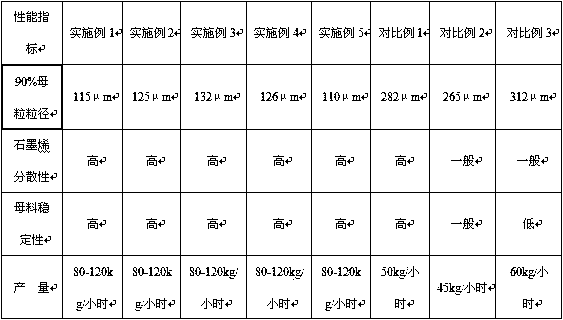

Graphene coating master batch and preparation method

InactiveCN107815170APromote mass productionContinuous and stable preparationCoatingsPigment treatment with macromolecular organic compoundsSurface layerGraphene coating

The invention provides a graphene coating master batch and a preparation method. The preparation method comprises the following steps of respectively preparing a graphene oxide water dispersing liquidand a copper sulfate water solution, mixing with emulsified carrier resin, and dispersing by ultrasonic waves; utilizing graphene oxide to forcibly adsorb copper ions in the mixing solution to generate complexing reaction, reducing the graphene oxide, spraying, and drying, so as to obtain the coating master batch. The graphene coating master batch has the advantages that the forcible adsorption function of the graphene oxide is utilized, and graphene oxide is combined with the uniformly dispersed copper ions in the solution, so that the dispersivity of the graphene in the resin carrier is improved, the carrier resin is covered to the surface layer after spraying and granulating, the compatibility is improved, and the defects of poor dispersing effect of the graphene in the resin carrier of the master batch, long preparation time of master batch, high cost, failure to realize continuous and stable large-scale production and the like are overcome; the graphene master batch can be continuously and stably prepared, and the batched production of the graphene master batch is further promoted.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

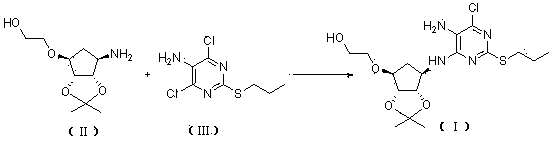

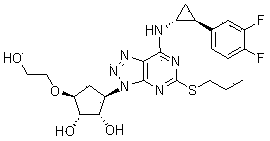

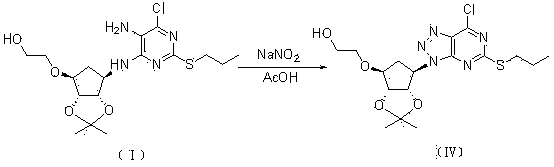

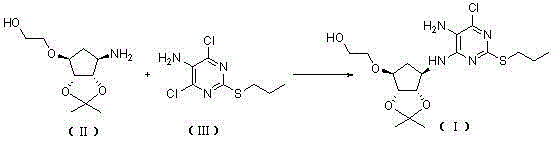

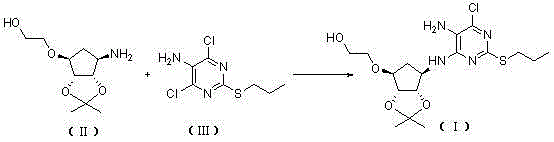

Preparation method for ticagrelor intermediate

ActiveCN103626745AInhibit side effectsAdvantage conversion rateOrganic chemistryState of artTicagrelor

The invention provides a preparation method for ticagrelor intermediate. The preparation method comprises the following steps: using tertiary amine as an acid-binding agent, performing N-aromatic alkylated reaction on a compound (II) or salt of the compound (II) and a compound (III) in an appropriate solvent at the temperature of 90 to 130 DEG C, and generating a compound (I). The preparation method provided by the invention has the following advantages: side reaction of impurity generated in the reaction of the solvent and raw materials can be effectively avoided, the preparation method has obvious superiority on product quality, the raw material conversion rate and productive rate of the product compound (I) are improved, the productive rate is 85.8% to 89.5%, the HPLC purity of the product is 98.8% to 99.5%, the preparation method has obvious superiority on raw material conversion rate, sealed reaction is not needed, equipment is simple, a pressure-resistant reaction kettle is not needed to be used, and compared with the prior art, the preparation method has obvious superiority on equipment use.

Owner:QINGDAO HUANGHAI PHARM CO LTD +1

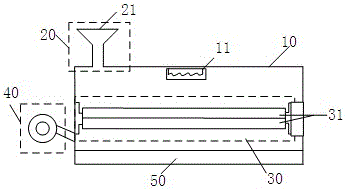

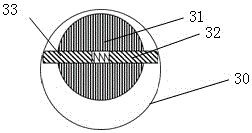

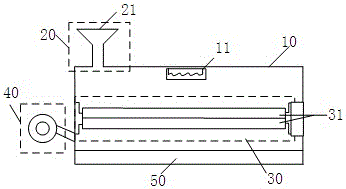

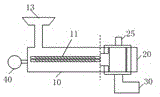

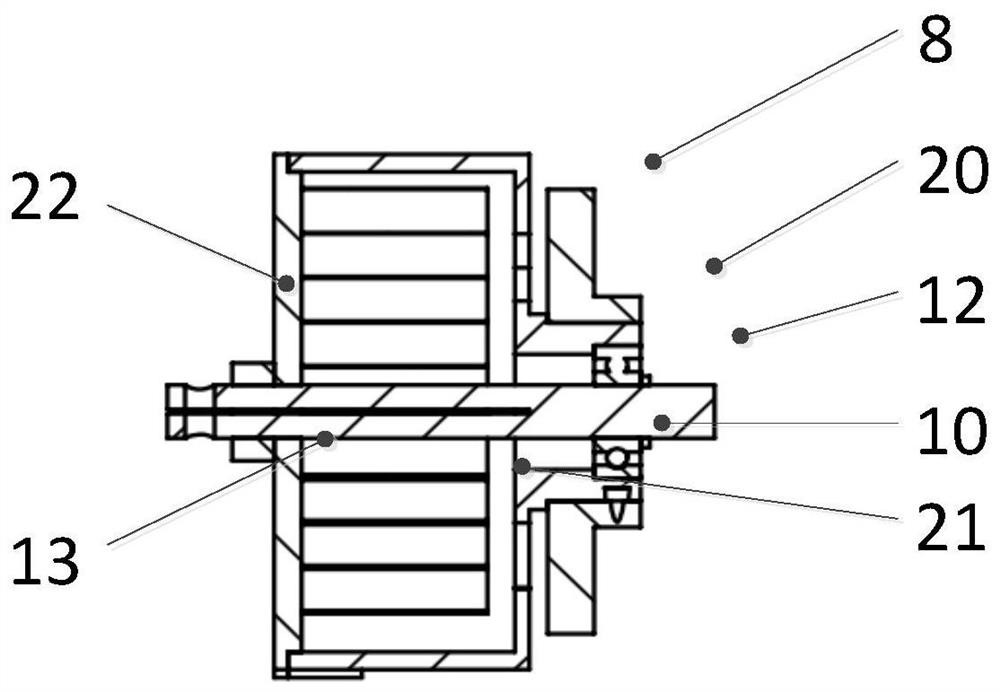

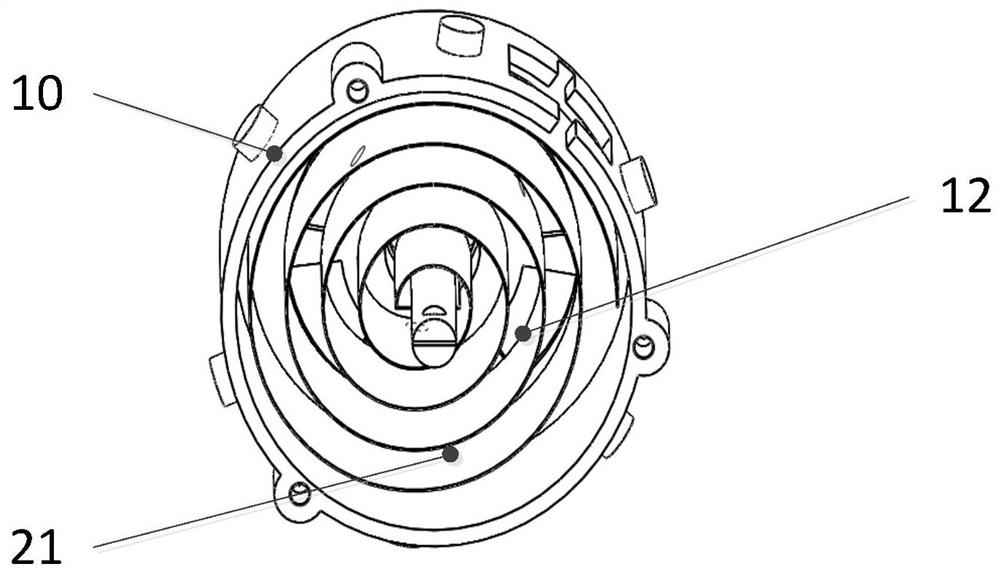

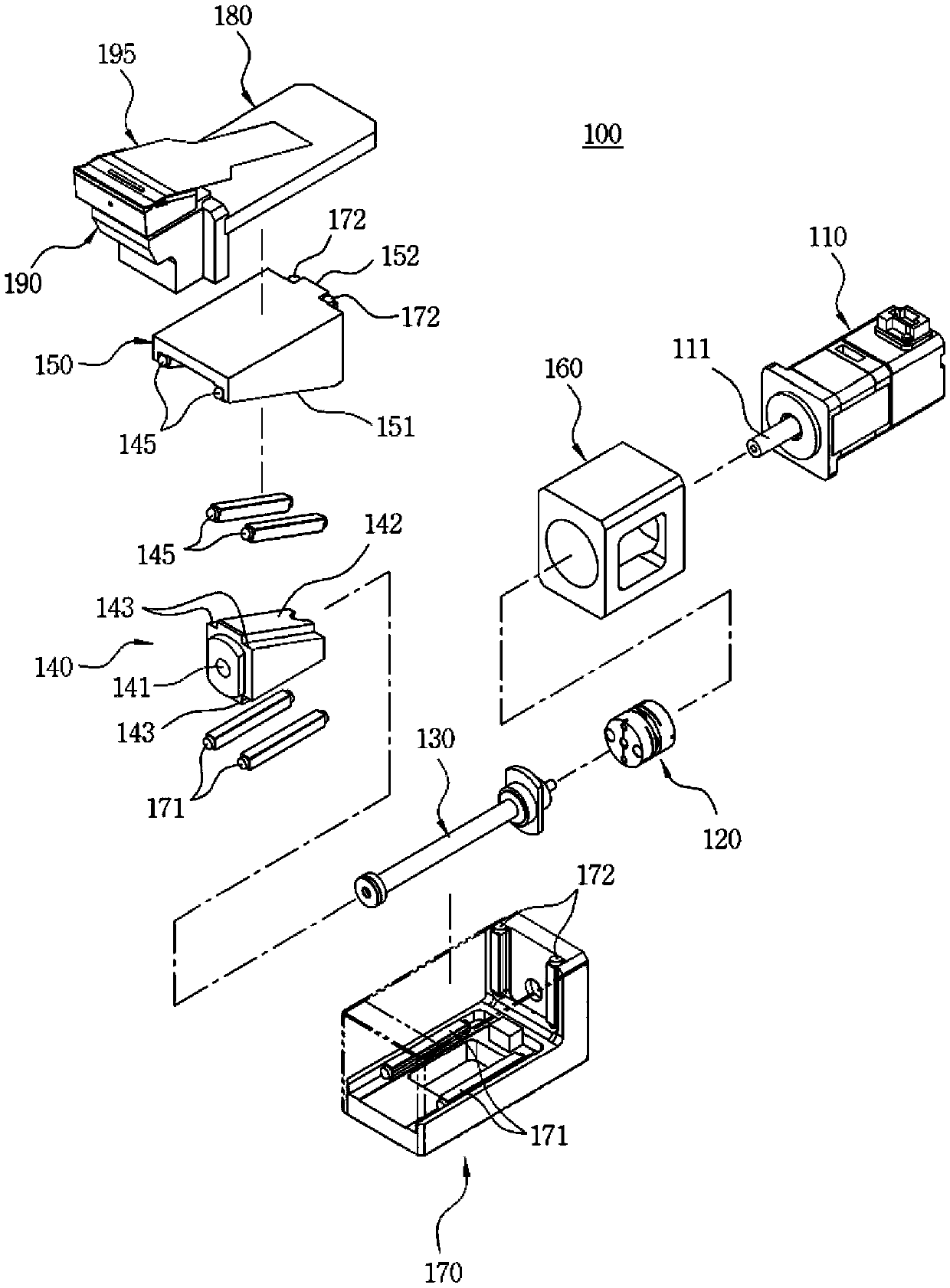

Internal mixer for preparing graphene through tensile peeling and method for preparing graphene

The invention provides an internal mixer for preparing graphene through tensile peeling and a method for preparing graphene. The internal mixer comprises a machine barrel, a feeding mechanism, an internal mixing mechanism, a power transmission mechanism and a collection mechanism, wherein the internal mixing mechanism comprises two cam rotors of which the cross sections are curved triangles as stirring shafts, and the two rotors generate relatively small shear force in a rotation process and generate relatively large compressive force and tensile force, so that a pasty graphite mixture is indirectly stretched, sheared and stripped to form a graphene precursor by a viscous additive under the bonding effect of the viscous additive when continuously passing through the stirring shafts, and thus the lattice damage of over-large shearing force to graphene is effectively avoided. The internal mixer is simple in preparation technology, wide in raw material source, free of pollution and low in cost; prepared graphene is high in quality and easy to store and transport; and large-scale industrial production is easy to implement.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

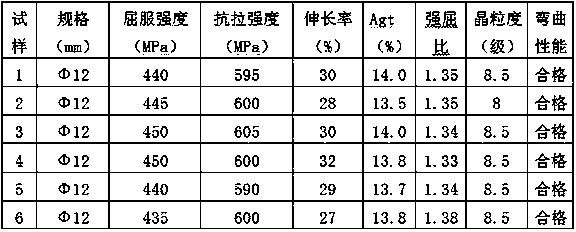

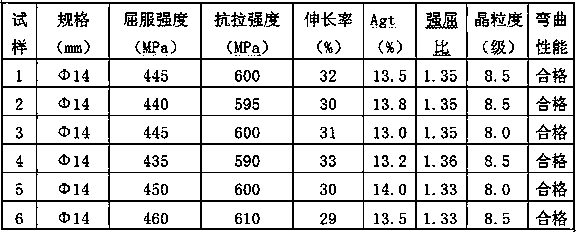

NbV composite microalloyed HRB400E steel bar and production process

InactiveCN109023094AGood cold bending and anti-bending performanceYield platform is obvious and stableRebarChemical composition

The invention discloses an NbV composite microalloyed HRB400E steel bar and a production process. The NbV composite microalloyed HRB400E steel bar comprises the chemical composition of, by mass, 0.19-0.21% of C, 0.32-0.38% of Si, 1.33-1.38% of Mn, less than or equal to 0.041% of P, less than or equal to 0.041% of S, 0.017-0.019% of Nb, 0.010-0.014% of V, 50-70ppm of N, less than or equal to 50ppmof O, and the balance Fe and inevitable impurities. The production process includes the steps of smelting, continuous casting and rolling. The NbV composite microalloyed HRB400E steel bar produced bythe production process has a metallographic structure of F+P+B and the grain size of 8.0-8.5 grades, the yield platform is obvious, the surface of the steel bar is provided with dense Fe3O4 structures, the grain structure is refined, and the welding performance, cold bending performance, fatigue limit performance and oxidation resistance of the steel bar are superior to the performance of steel bars simply using a Nb or V alloy.

Owner:宣化钢铁集团有限责任公司

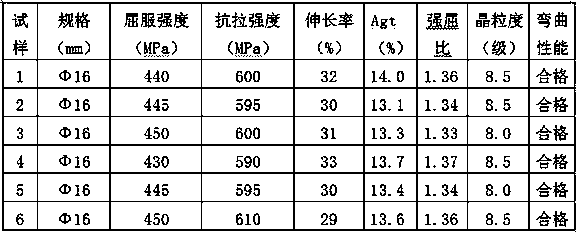

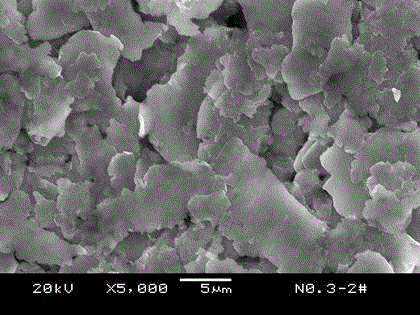

Method for preparing graphene in screw extruder through crystal form inducing

The invention provides a method for preparing graphene in a screw extruder through crystal form inducing. The method comprises the steps that shearing slicing is performed on a carbon source through the screw extruder, a crystal form inducing agent is utilized, the crystal form inducing agent generates a variant along with gradual increasing of the temperature to induce the carbon source to form crystals and enable the crystals to grow along layers, the layer structure of graphite is more obvious, the layer size of the graphite exceeds 1 mm, and finally the graphene is obtained through shearing stripping of the screw extruder. Accordingly, the defect of high-temperature long-time sintering of a catalyst used in the process of graphene preparation through the carbon source is overcome, therefore, the layer structure of the graphite is complete, and then the large-size graphene with the two-dimensional area is obtained. The method has the advantages that the technology is simple, the cheap and rich raw materials are used, a chemical reaction or high synthesizing temperature is effectively prevented from being adopted, and industrial production is achieved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

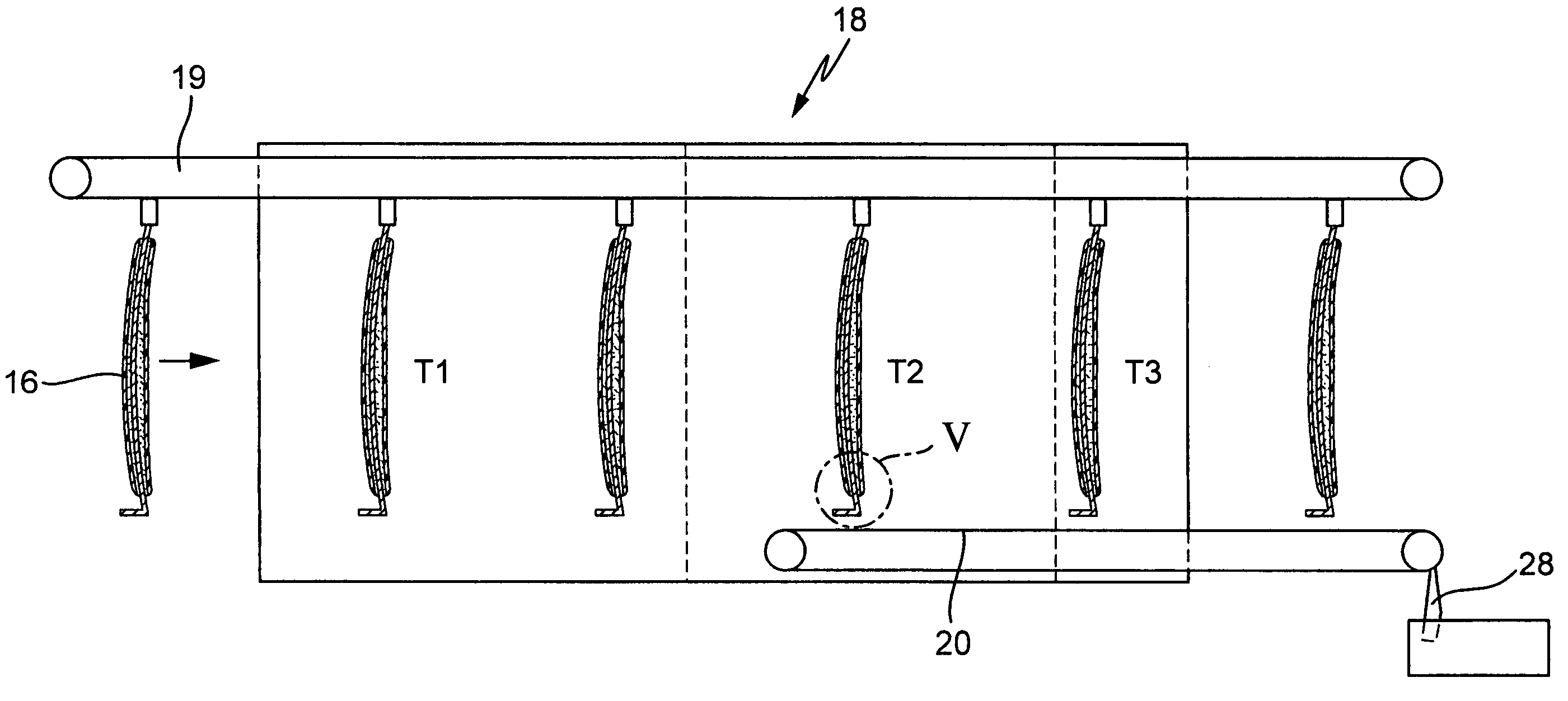

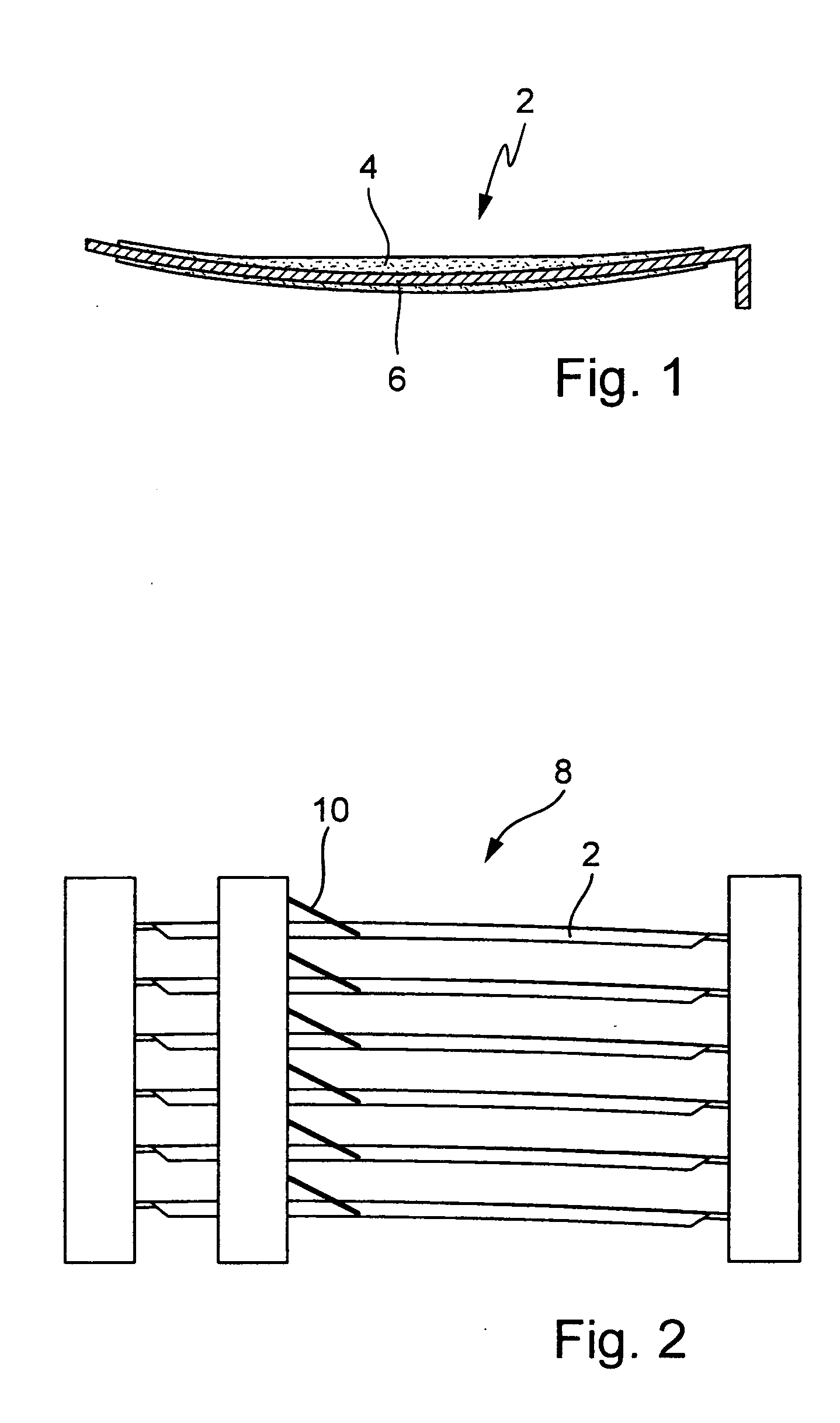

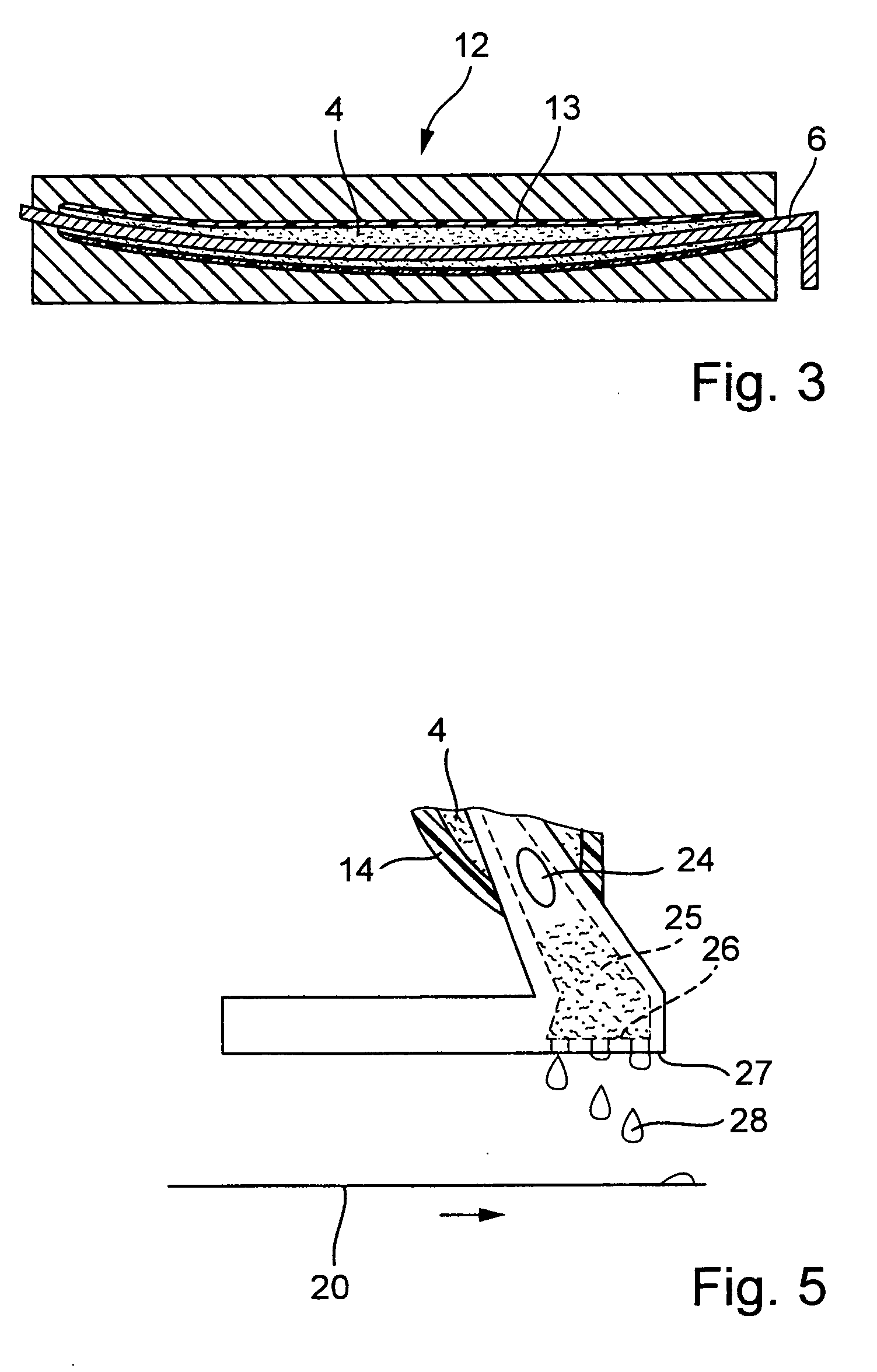

Method for producing a component from fiber composite material

InactiveUS20050023734A1Dimensional stabilityImprove surface qualityLaminationLamination apparatusStable stateOptoelectronics

The invention relates to a method for producing a partly hollow component (36) from a fiber composite material. In this case, a fusible core (4) is applied to a supporting core (6) by injection molding or casting. A reinforcing fiber (10) is then applied to the core (2). In the process, a fiber structure (14) is produced. The fiber structure (14) is impregnated with a resin. The fiber structure (14), together with the core (2), is put into a conveyor oven (18). During a continuous temperature process, first of all the resin is cured in order that the fiber structure (14) reaches a dimensionally stable state, and then the fusible core material is melted out of the core (2). The supporting core (6) is then removed from the component (36).

Owner:DAIMLER AG

Method for preparing graphene powder through crushing and application of graphene powder

ActiveCN107055518ADestroy lattice integrityDecreased lattice integrityGrapheneAdditivesGraphiteCvd graphene

The invention provides a method for preparing graphene powder through crushing and application of the graphene powder. The graphene powder with uniform particle sizes is obtained through gradual reduction of the particle sizes of graphite. The method particularly comprises the steps of carrying out sheet treatment on the graphite by adopting a cone mill, crushing by using a high-speed rod pulverizer to obtain the graphene powder with uniform and large radial dimension; and carrying out further intercalation, crushing and peeling by using the shear force generated by a grader and carrying out grading treatment to obtain the graphene powder. The prepared graphene powder is low in cost, good in disperse machinability, large in sheet diameter and suitable for a lubricating additive. According to the method, continuous, clean and environment-friendly technical effects of graphene production are achieved, and industrialized production of the graphene powder is promoted.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

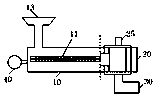

Apparatus and method for preparing graphene composite material through continuous grinding extrusion

The invention provides an apparatus and method for preparing a graphene composite material through continuous grinding extrusion. The method comprises the following steps: adding graphite and a plastic stripping agent to a screw extruder, and carrying out oriented shearing on above raw materials through a feeding mechanism formed by a screw in order to obtain a primary stripping product, conveying the primary stripping product to a stripping mechanism formed by a millstone group, and the primary stripping product undergoes secondary shearing striping through relative rotation of an internal millstone and an external millstone in order to obtain the graphene composite material. The method overcomes the defects of low stripping strength and thick stripping layers of graphene prepared through using screw stripping in the prior art, and the apparatus has the advantages of simple structure, improvement of the shearing strength, realization of continuous production of the graphene composite material, further obtaining of the graphene composite product with thin stripping thickness, avoiding of graphene aggregation, improvement of the quality of graphene, convenience for storage, and promotion of mass production of the graphene product.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Method for preparing graphene nanosheets by utilizing friction stripping of same-direction three-roll grinder

The invention provides a method for preparing graphene nanosheets by utilizing friction stripping of a same-direction three-roll grinder. The method comprises the following steps: preparing a mixed body from graphite and a soluble inorganic salt; adding dried powder into the three-roll grinder, wherein the three rollers of the three-roll grinder rotate in the same direction, grinding points of every two rollers have opposite rotation directions, and friction is transferred through the soluble inorganic salt in the rotation process; stripping the graphite into graphene, cleaning to remove the soluble inorganic salt, thereby obtaining the large graphene nanosheets. According to the method provided by the invention, the technical defects that the yield of the graphene nanosheets prepared by utilizing the three-roll grinder is low and the requirement on production equipment is high are overcome. According to the method provided by the invention, damage of extrusion of the rollers on the graphene size can be effectively avoided, the graphene nanosheets with high uniformity and large radial size can be obtained, the method is simple in preparation process, is green and environmental-friendly and does not need heating, and large-scale industrial production is easily realized.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

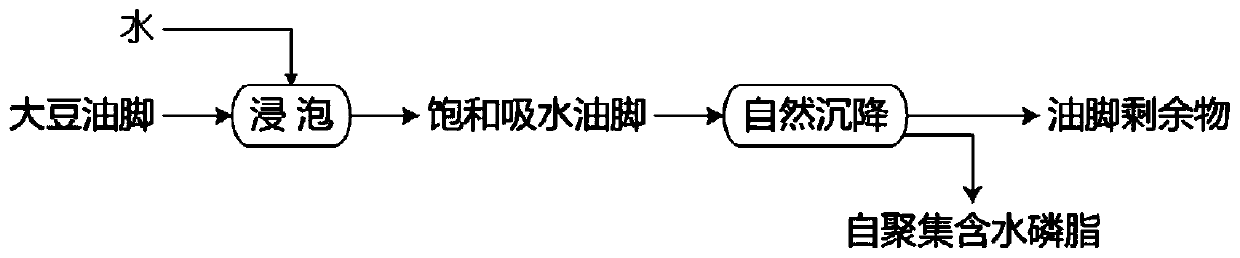

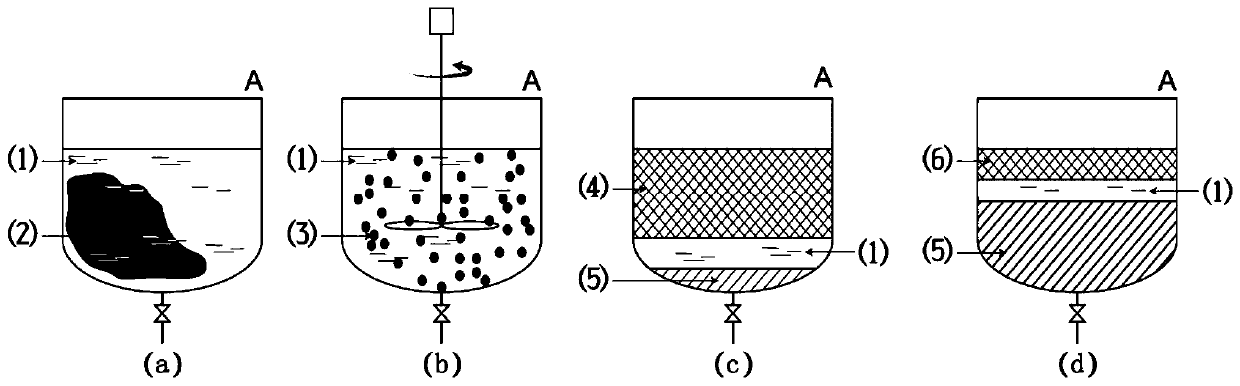

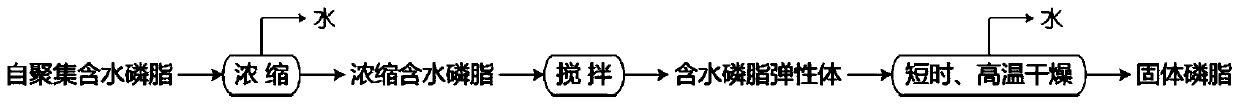

Self-aggregation water-containing phospholipid

PendingCN111548862AEliminate environmental pollutionReduce food safety hazardsFatty oils/acids recovery from wasteGroup 5/15 element organic compoundsSolventEnvironmental chemistry

The invention belongs to the technical field of phospholipid processing, and particularly relates to a self-aggregation water-containing phospholipid. The main components of the self-aggregation water-containing phospholipid are phospholipid, grease and water, the water content is 70-80 g / 100 g, the content of acetone insoluble substances based on dry basis is 92.5-95.5 g / 100 g, and the sensory index is brown semi-transparent fluid. The defects that the content of acetone insoluble substances of the existing water-containing phospholipid is not high and the industry depends on a solvent methodto prepare the powdered phospholipid for a long time are overcome, and the technical problem that industrial production of the hydrated powdered phospholipid cannot be realized is also solved. The self-aggregation water-containing phospholipid is used for preparing hydrated powder phospholipid. The content of acetone insoluble substances is as high as 92.5-95.5 g / 100g, the color is natural yellow, bleaching is avoided, no solvent is used, solvent-method powdered phospholipid can be replaced, environmental pollution and food safety hidden danger caused by solvent-method powdered phospholipid are avoided, and the production cost of hydrated powdered phospholipid is far lower than that of solvent method powdered phospholipid.

Owner:INNER MONGOLIA BOBEYMAN TECH CO LTD

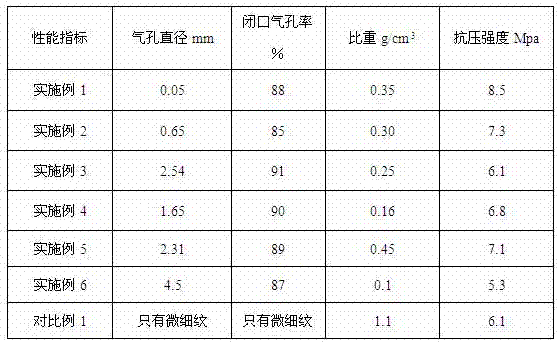

Low-density building foaming glass and preparation method thereof

The invention provides low-density building foaming glass and a preparation method thereof. The method comprises the following steps: mixing micron glass powder with a proper amount of hollow glass microspheres; directly sintering the acquired mixed particles under high temperature; and by taking the hollow glass microspheres as framework materials, splicing the microspheres after melting the micron glass powder due to the easiness in sintering of the microspheres, thereby acquiring the low-density building foaming glass. The preparation method overcomes the technical defects of relative high impurity content and influence of the excessive impurities on the overall performance of the prepared end product of the foaming glass preparation in the prior art; the mixture prepared according to the invention is directly sintered under high temperature; except for the glass raw material, the mixture almost contains no other impurity; the joint parts of the accumulated glass microspheres are formed into glass microspheres with porous structure and uniform size; the generated pores are uniformly distributed, the pore size distribution is narrower and the product is high in strength; and the low-density building foaming glass is suitable for high-strength building materials and decorative materials.

Owner:江门市俊发安全玻璃有限公司

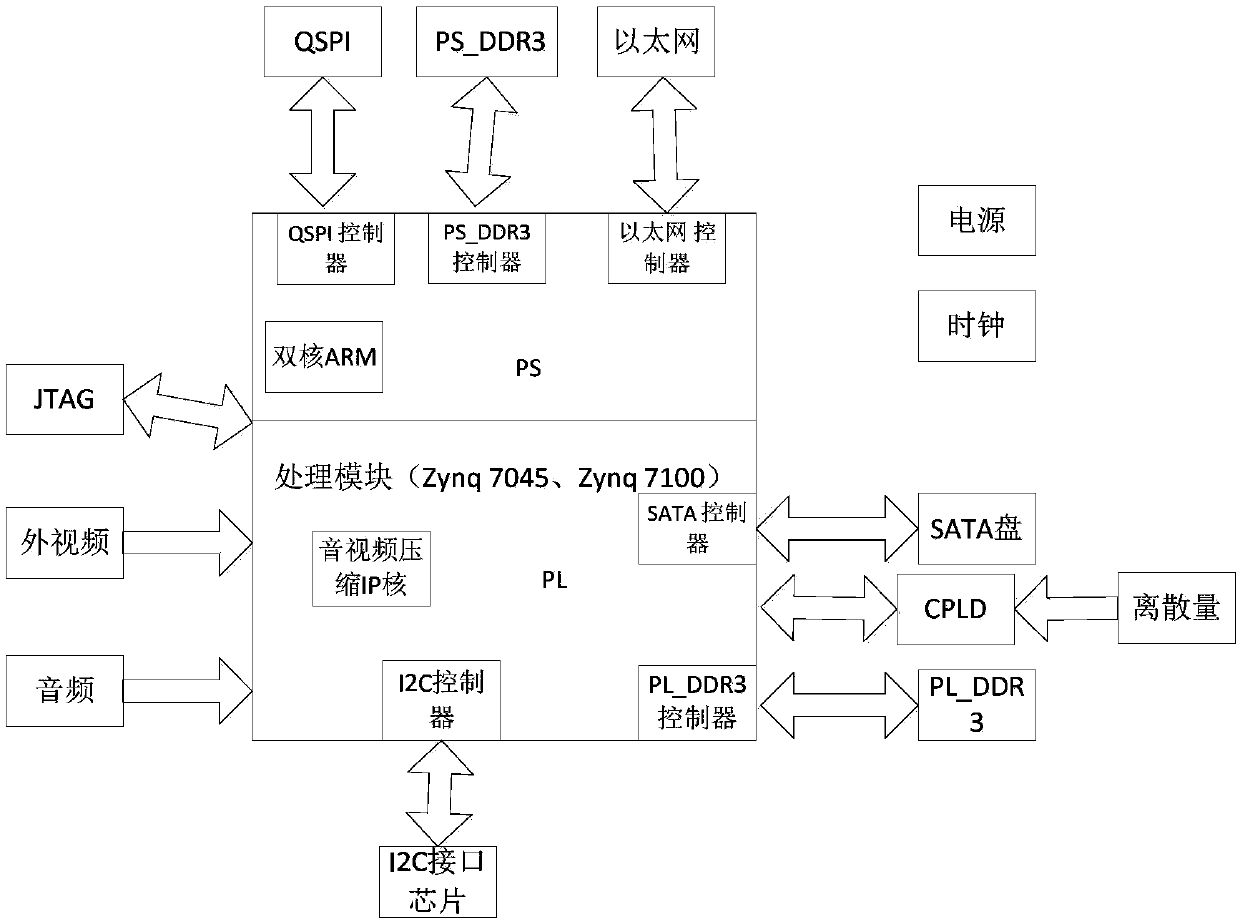

Video compressor and recorder

InactiveCN107948653AHighly integratedQuality advantageDigital video signal modificationVideo recordMiniaturization

The invention discloses a video compressor and recorder. The video compressor and recorder comprises a processing module, a PL_DDR3 memory, a PS_DDR3 memory, and a SATA disk, wherein the processing module adopts a Xilinx Zynq-7045 chip or a Xilinx Zynq-7100 chip, and comprises an audio-video compression IP core and a SATA controller; the audio-video compression IP core is used for saving input audio-video data in the PL_DDR3 memory, reading the audio-video data from the PL_DDR3 memory to perform compression encoding, and transmitting the audio-video data subjected to compression encoding to the SATA controller; and the SATA controller is used for firstly sending the compressed audio-video data to the PS_DDR3 memory to cache, and then writing the cached audio-video data into the SATA disk.An original video recording module and a video compression module are combined on one processing module to realize the video compression and recording functions, thereby satisfying the demands of miniaturization and low power consumption.

Owner:CHINESE AERONAUTICAL RADIO ELECTRONICS RES INST

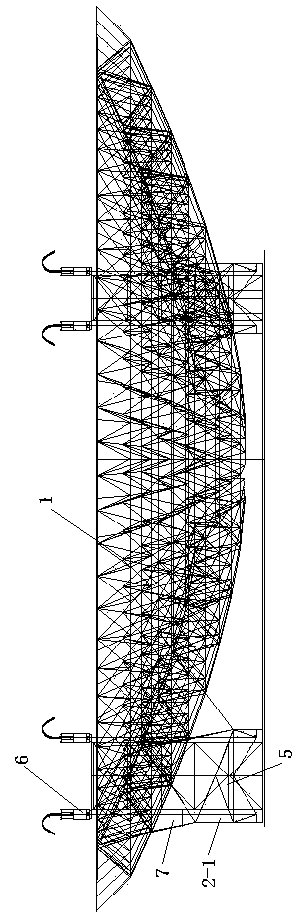

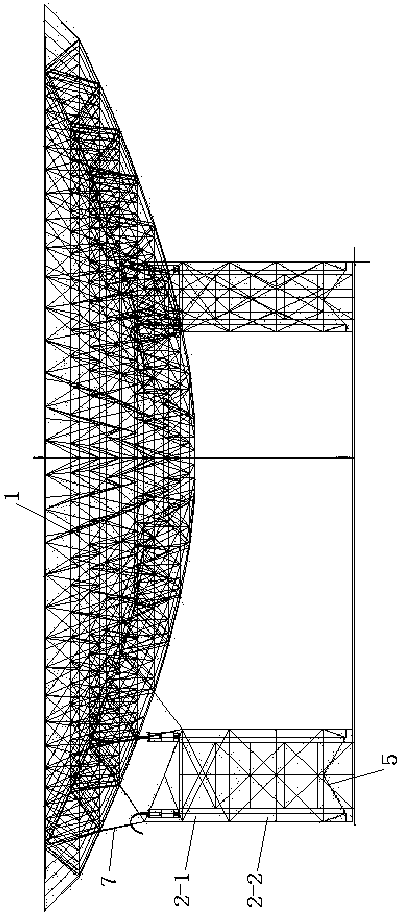

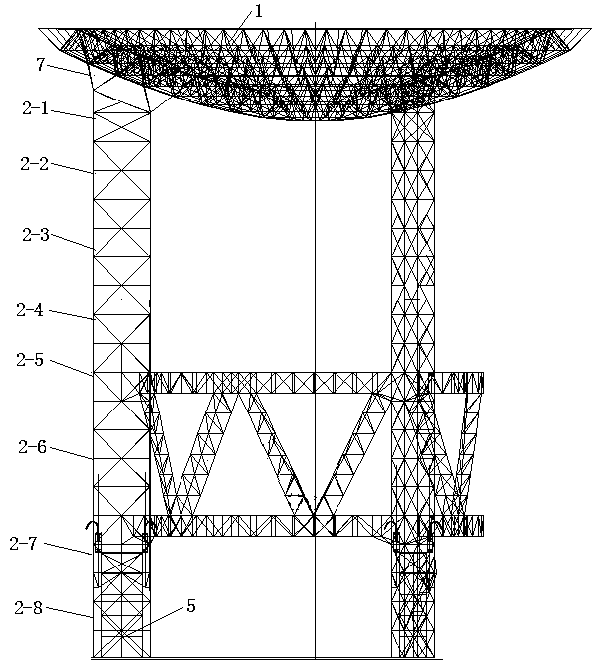

Construction technology of large high-altitude assembled steel member

The invention discloses a construction technology of a large high-altitude assembled steel member and relates to the technical field of construction of large assembled steel members. A temporary fullbracket is erected on the ground, and an upper main structure of the large assembled steel member is assembled; a plurality of sets of temporary lifting towers are mounted and fixed to a reinforced concrete foundation of a vertical steel support through pre-embedded iron parts, and lifters are fixed to all sets of lifting brackets in a distributed mode; and the steel support is built in a sectioned mode. Through sectioned accumulation lifting of the steel support, the upper steel member is lifted, and the large steel member with the extremely large weight is lifted without other heavy liftingdevices. The mounting and construction difficulty is greatly lowered, and the construction technology has great advantages of controlling over the quality, safety, construction period and constructioncost and the like.

Owner:JIANGSU JIANGJIAN GRP CO LTD

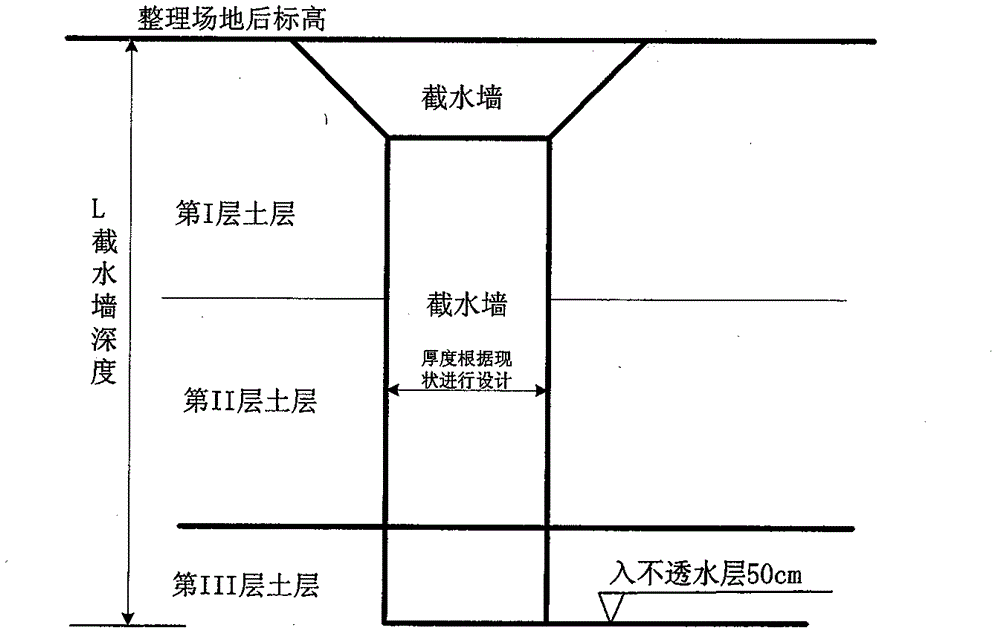

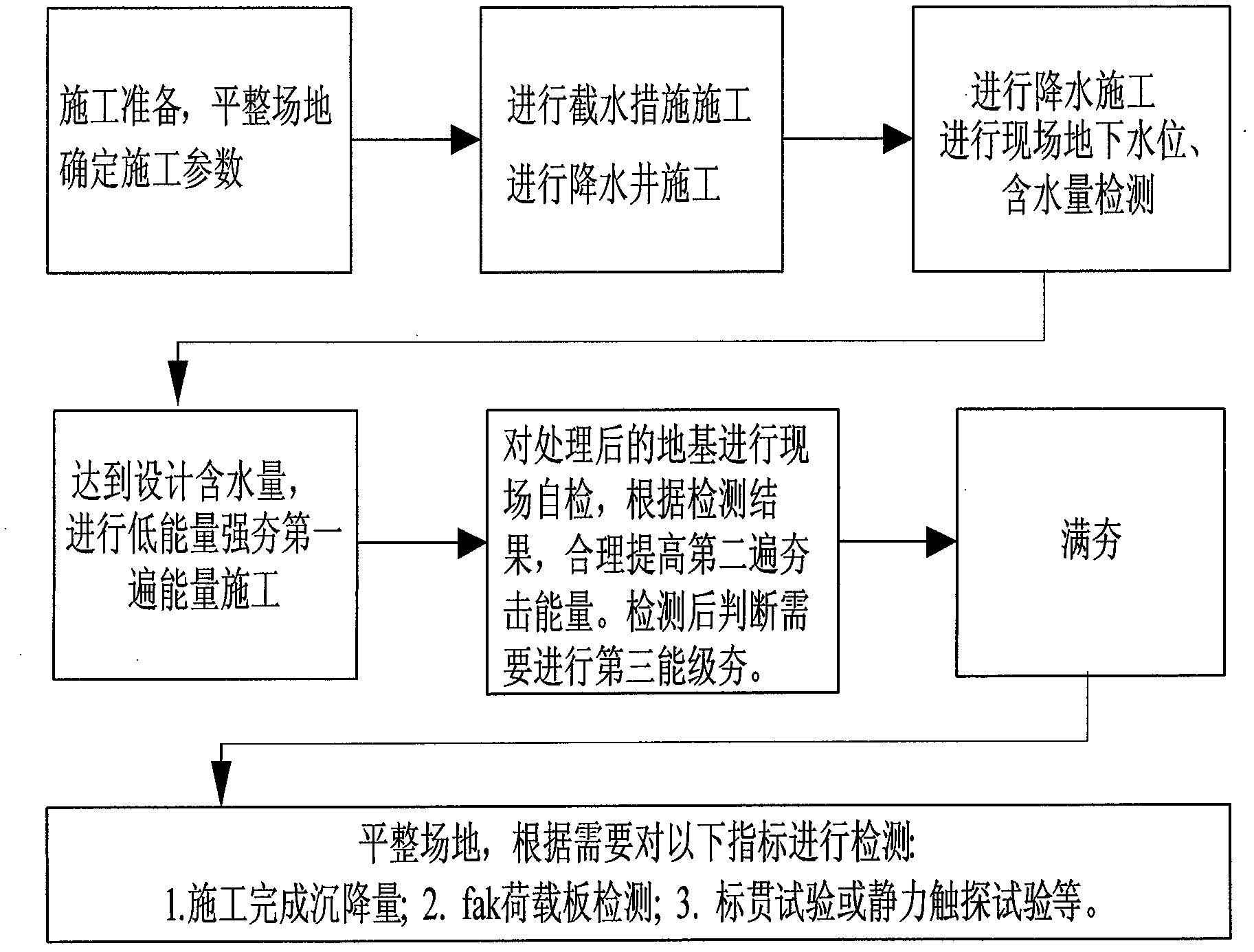

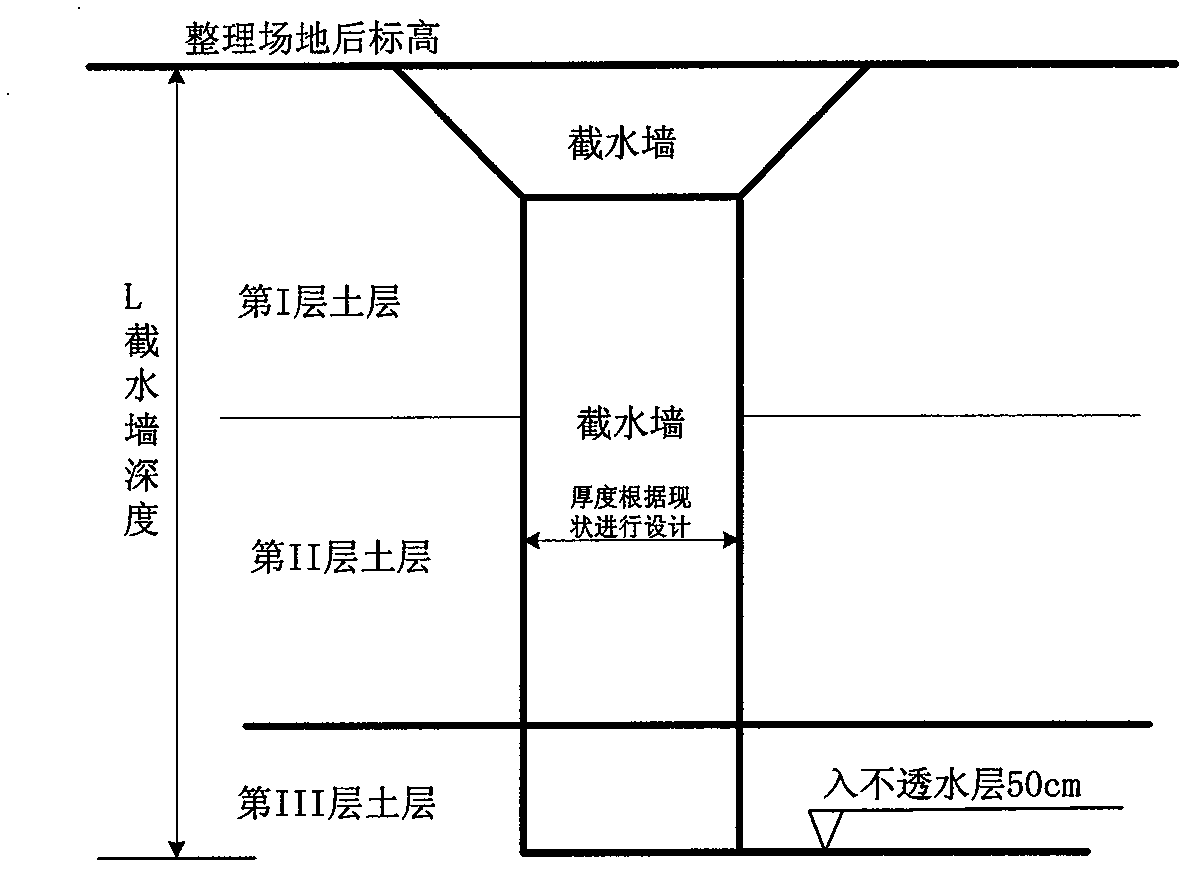

Interception and drainage power consolidation soft foundation treatment method

InactiveCN102691287ASolving difficult problems - groundwater problemsShort construction periodSoil preservationDynamic compactionEngineering

The invention relates to an'interception and drainage power consolidation' soft foundation treatment method which reduces the groundwater level and water content of a soil body of a treatment field and improves the density and physical mechanics index of the soil body by organically combining interception, strong drainage and vibration rolling or dynamic compaction. The interception is realized in a way that an interception curtain is arranged at the periphery of the treatment area, and water is supplied inside and outside a separation area; the strong drainage is realized in a way that a certain number of strong vacuum wells or other strong drainage systems are arranged in the treatment field so that the groundwater level and the water content of the soil body are in the optimal range; and the power consolidation is realized in a way that when the groundwater level and the water content of the soil body are optimal, the soil body is beaten by vibration rolling or dynamic compaction so as to achieve certain density and improve the physical mechanics index of the soil body in the treatment area. According to the invention, the groundwater level is always kept in the control range in the power consolidation construction process, and the water content of the soft soil is kept optimal; and the method provided by the invention has the characteristics of short construction period, low manufacturing cost, simple technology, high quality, no pollution and the like.

Owner:汪文彬

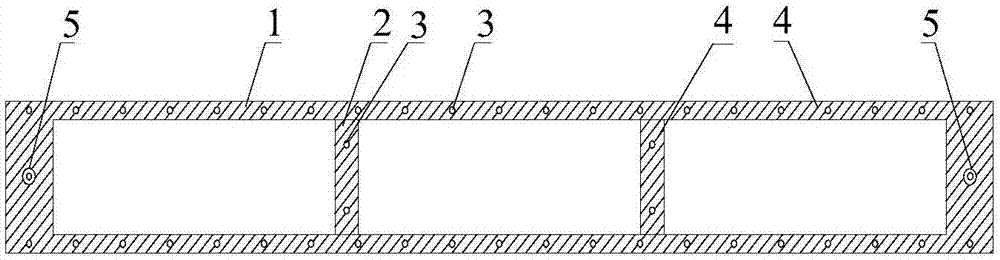

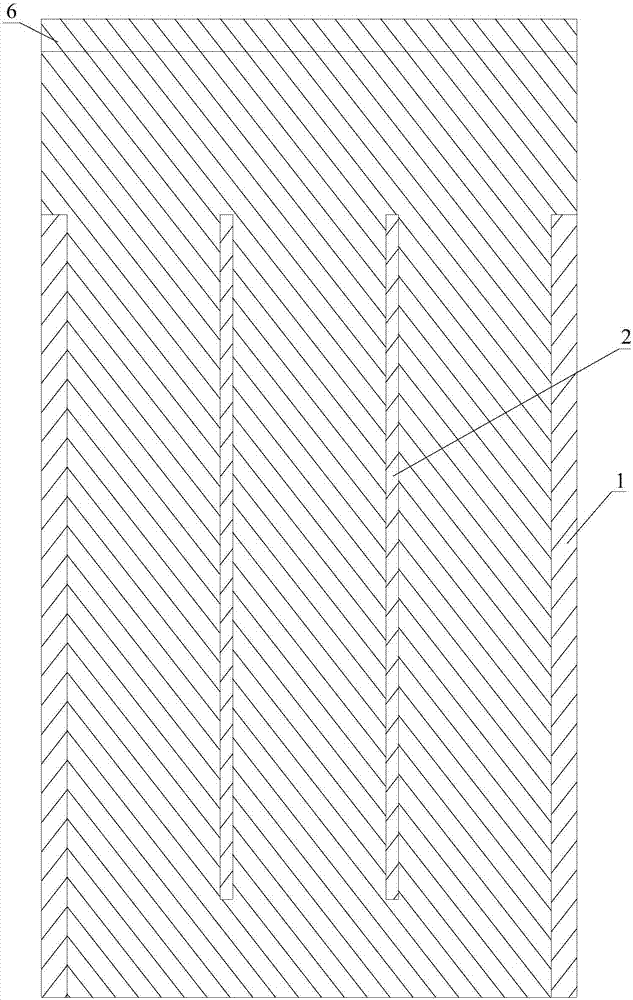

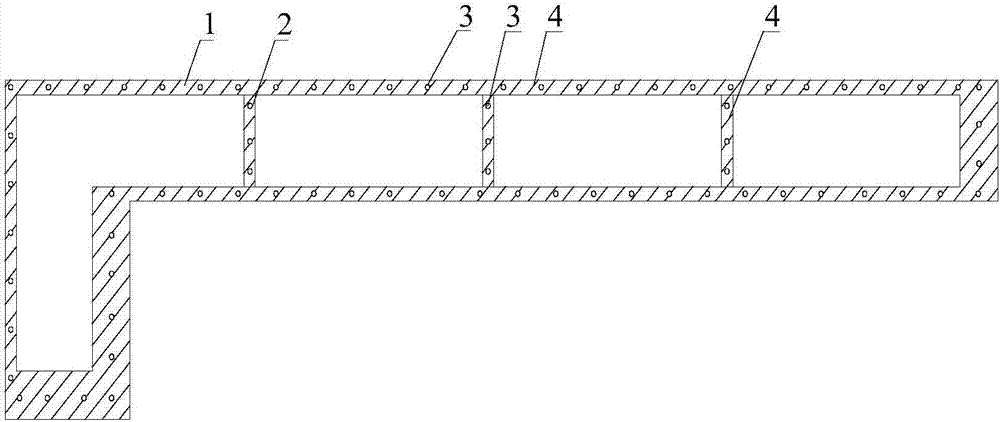

Novel forming whole set wall (column) formworks and production method and on-site construction technique thereof

InactiveCN107268980AQuality advantageEconomic advantageForms/shuttering/falseworksForming/stuttering elementsReinforced concreteEngineering

The invention belongs to the technical field of building construction and relates to walls (columns) in house building main body construction, in particular to novel forming whole set wall (column) formworks and a production method and on-site construction technique thereof. According to the novel forming whole set wall (column) formwork, the wall (column) formworks are various frame formworks of different shapes and sizes, reinforcing pull plates which are larger than or equal to zero blocks and distributed at intervals are arranged in the frame formworks. The frame formworks and the reinforcing pull plates are formed by pouring reinforced net concrete. The bottom ends of the reinforcing pull plates are higher than the bottoms of the frame formworks, and the upper ends of the reinforcing pull plates are flush with or lower than the upper ends of the frame formworks. The wall (column) formworks replace existing wood formworks through reinforced concrete frame formwork structures, and great advantages in the aspects of the quality, environmental friendliness, energy saving, universal applicability, economy, efficiency, safety, reliability and the like are achieved.

Owner:文金龙

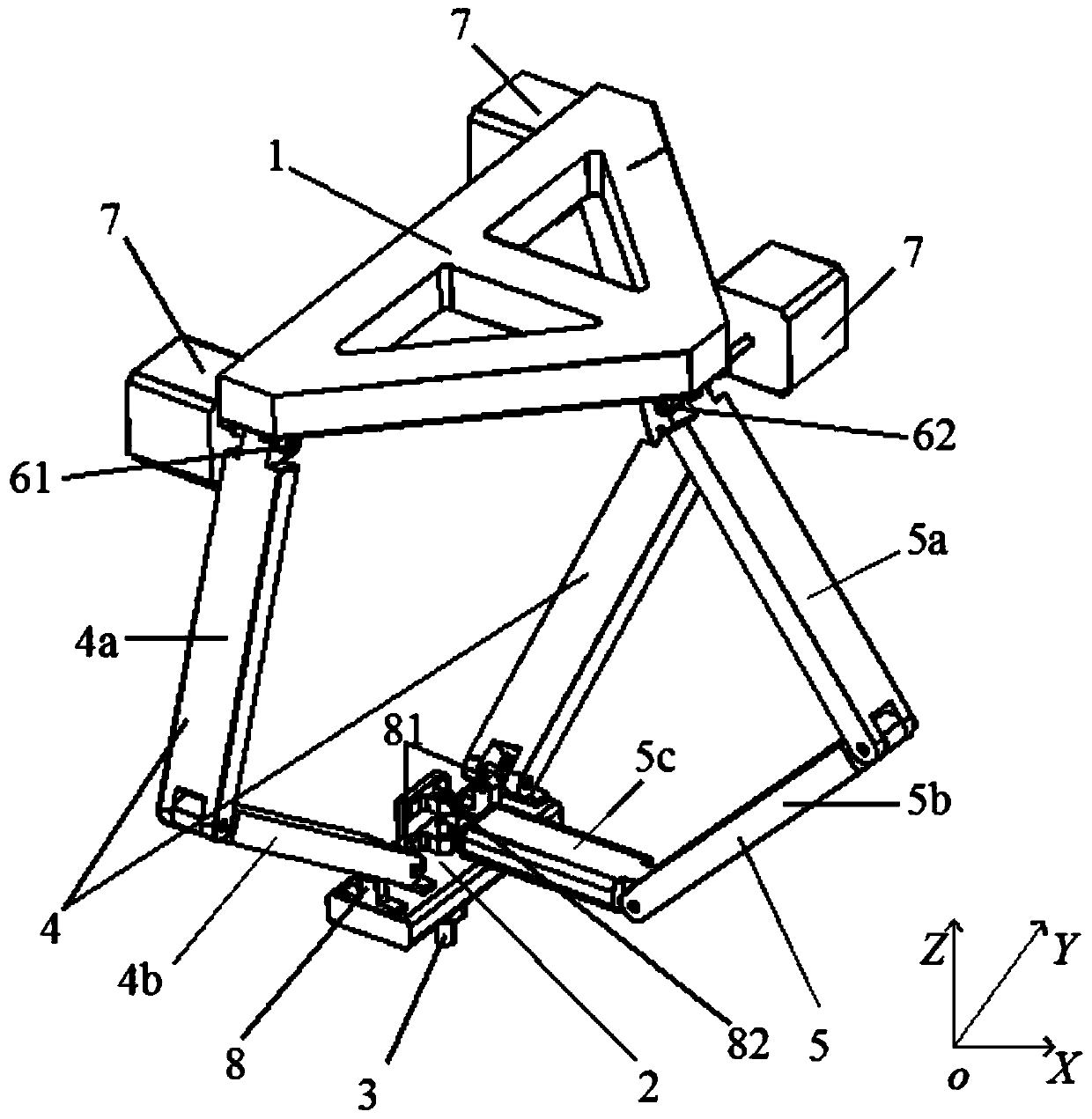

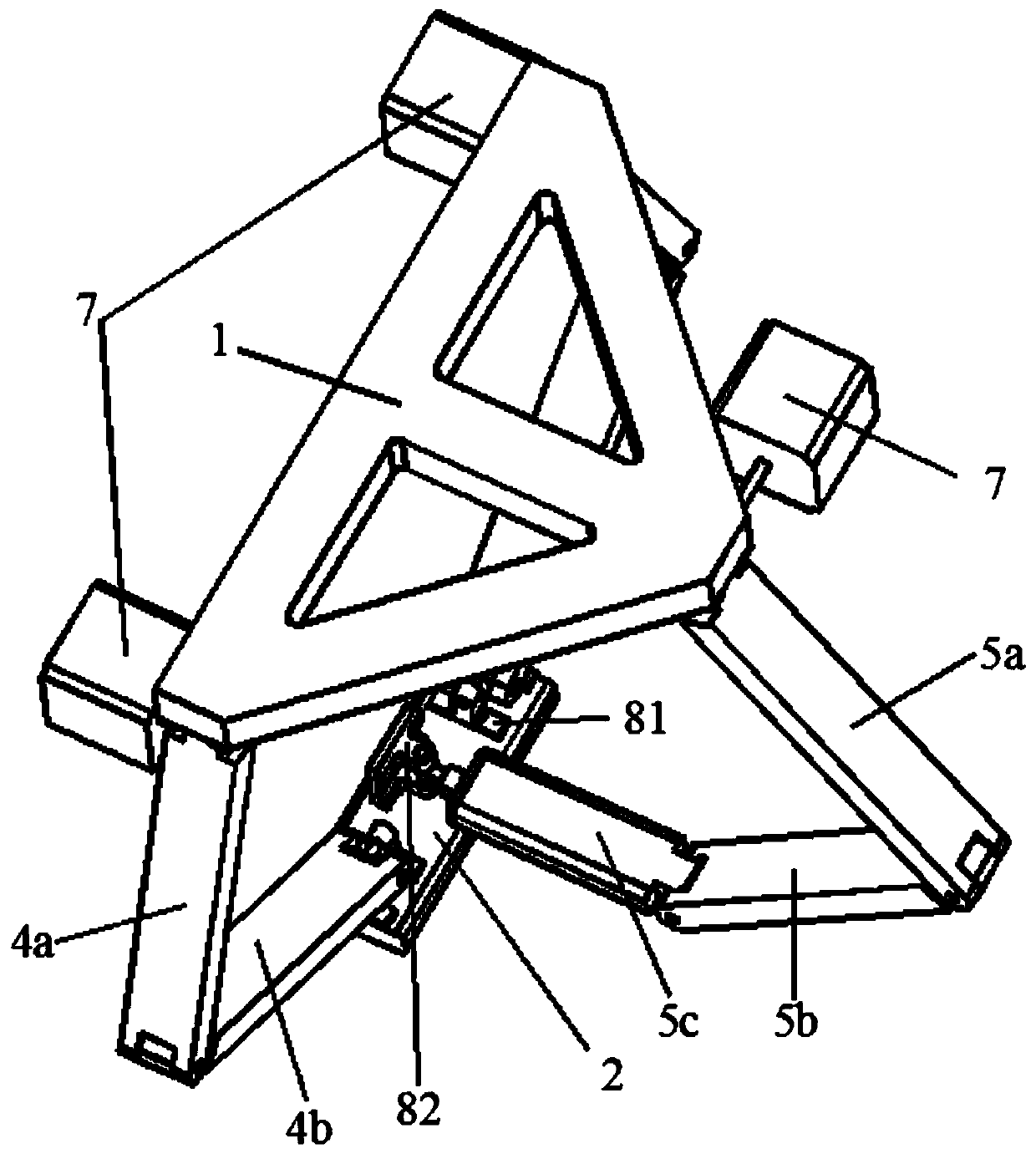

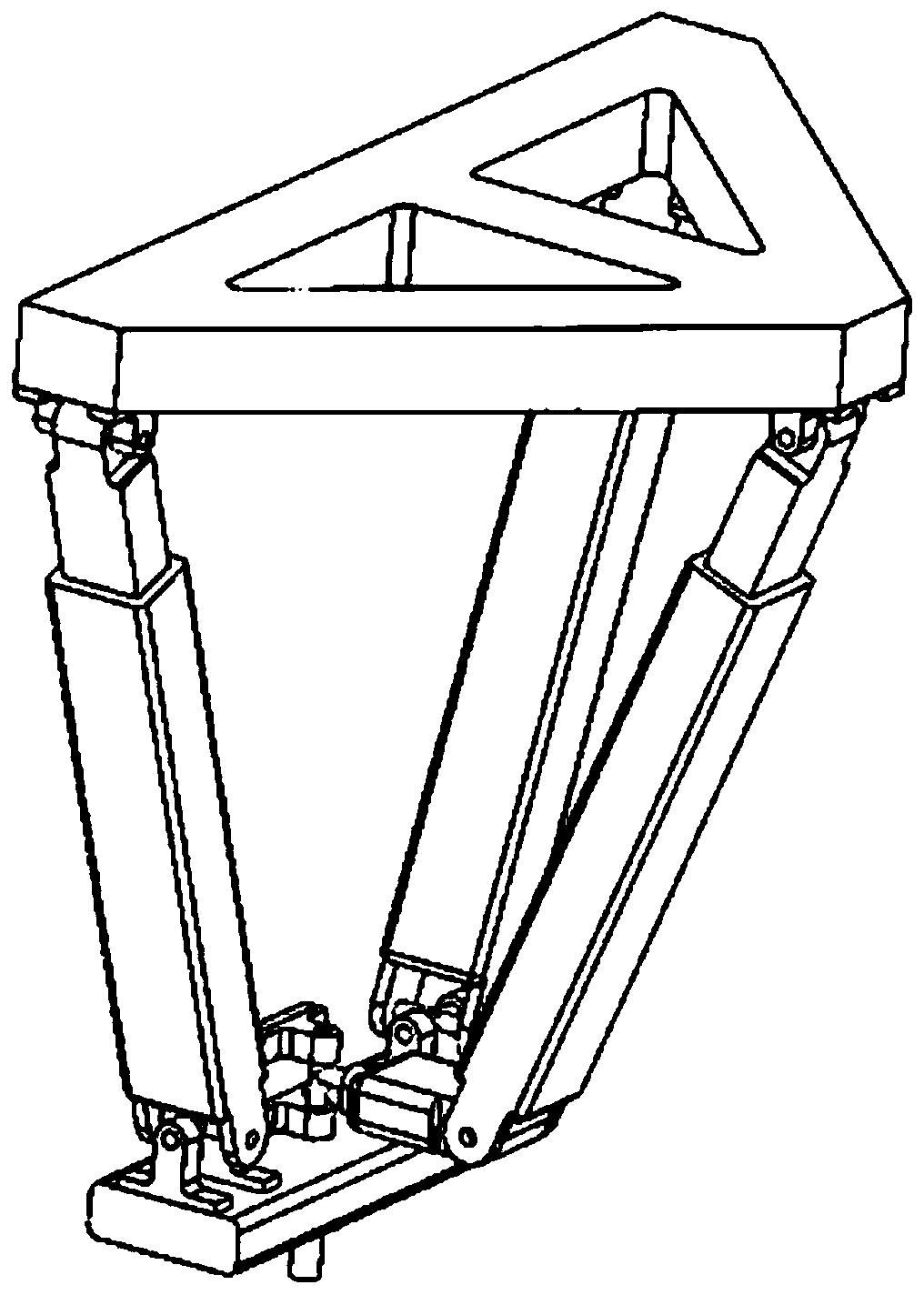

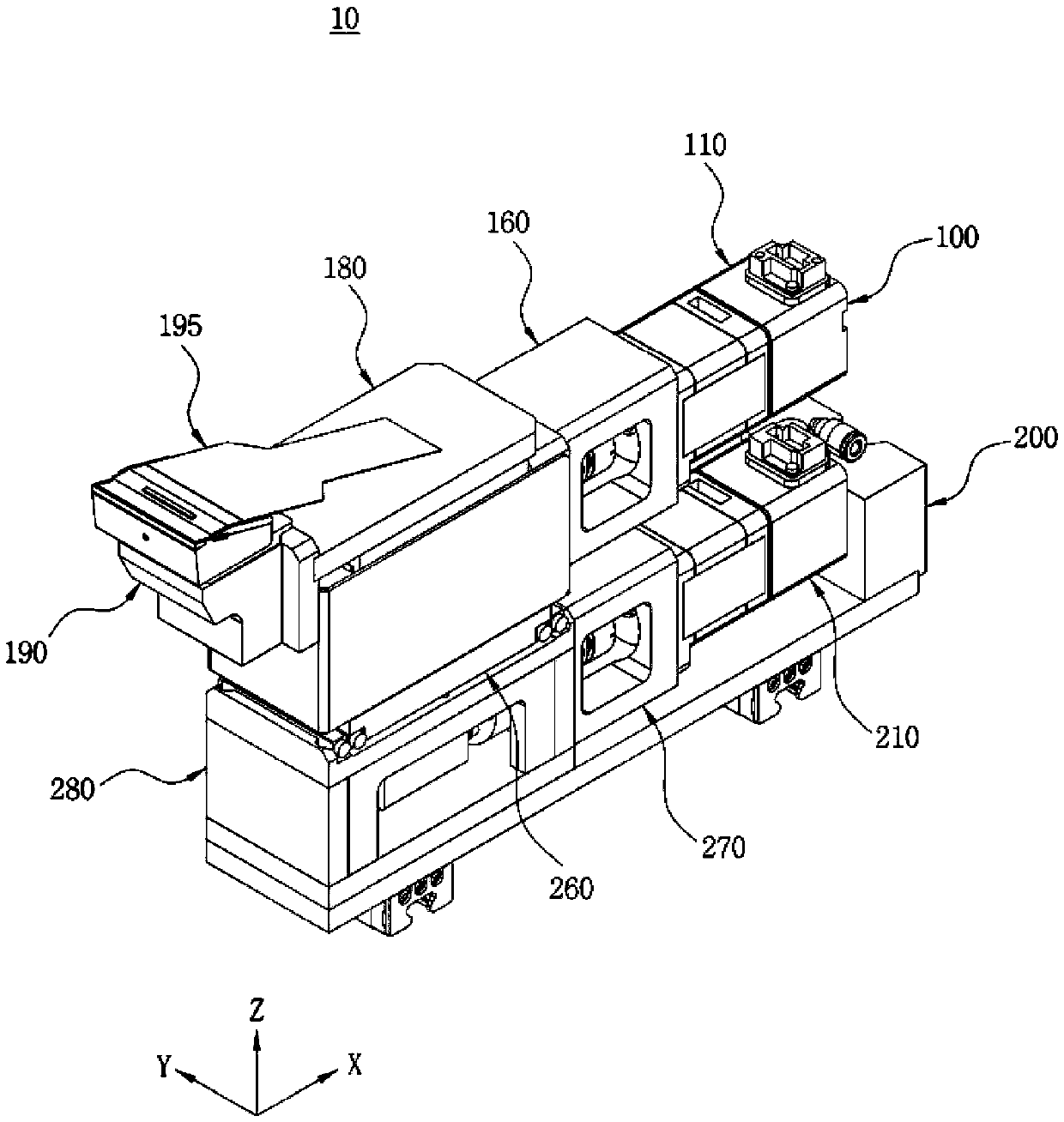

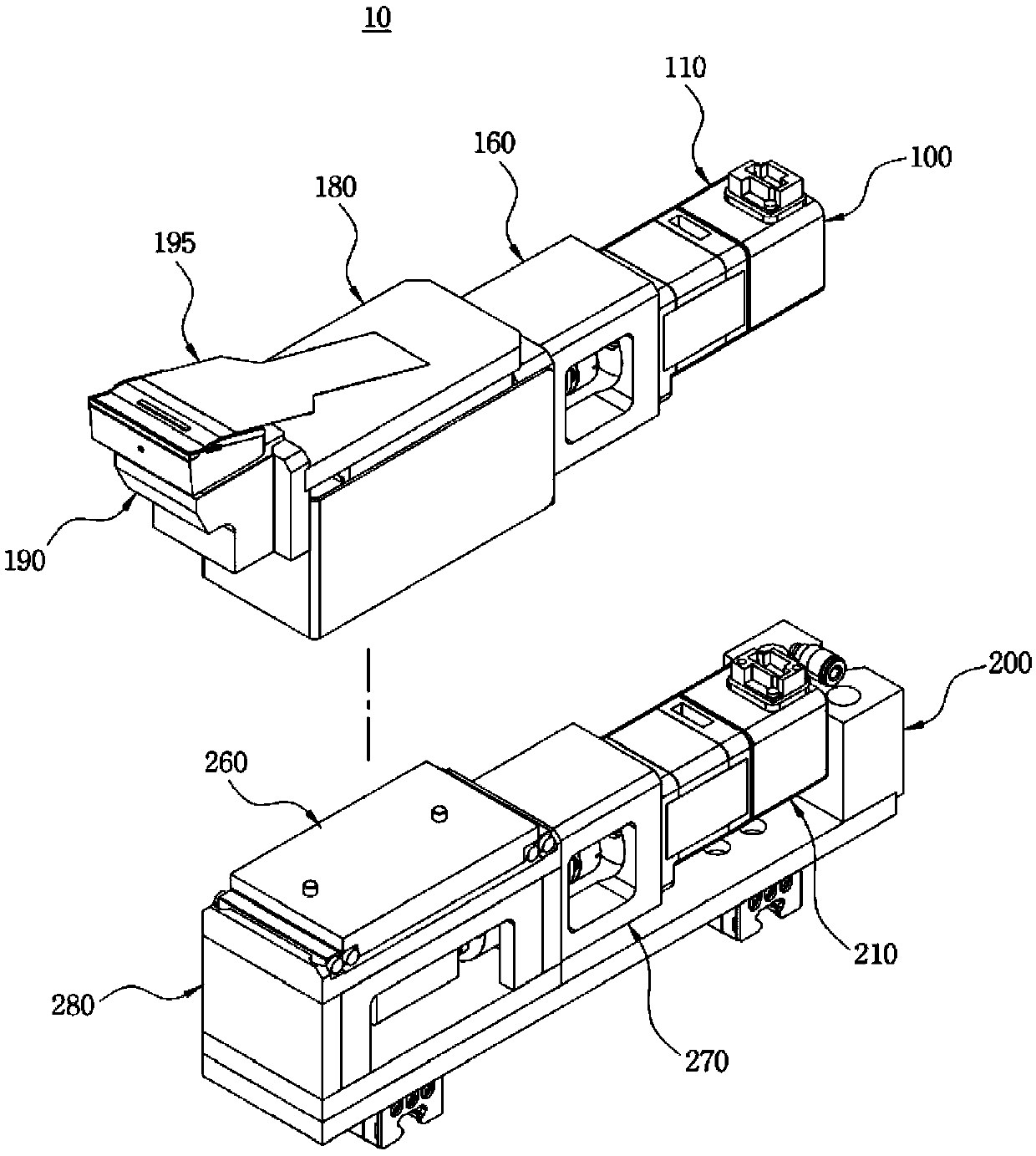

Three-degree-of-freedom parallel mechanism without accompanying movement

ActiveCN110815187AStrong carrying capacityGood kinematic performanceProgramme-controlled manipulatorStructural engineeringMechanical engineering

The invention discloses a three-degree-of-freedom parallel mechanism without accompanying movement. The three-degree-of-freedom parallel mechanism without accompanying movement comprises a static platform and a movable platform, wherein the static platform is fixedly arranged on an external device, and the movable platform is connected with the static platform through a flexible driving chain. Theflexible driving chain comprises two arranged symmetrically three-joint movable assemblies, a four-joint movable assembly and a plurality of rotary driving assemblies, wherein the upper ends of the three joint movable assemblies are rotationally connected with the static platform, and the lower ends of the three joint movable assemblies are movably connected with the movable platform; and the upper end of the four-joint movable assembly is rotationally connected with the static platform, and the lower end of the four-joint movable assembly is movably connected with the movable platform; and the three-joint movable assemblies and the four-joint movable assembly are located on the same straight line with the movable connection of the movable platform. According to the three-degree-of-freedom parallel mechanism without accompanying movement, the movable platform has two rotational degrees of freedom and one translational degree of freedom in space, accompanying movement does not exist, good kinematic performance is achieved, motion decoupling of all degrees of freedom is achieved, and the design of a controller is convenient to achieve.

Owner:TONGJI UNIV

Method for preparing high-purity and high-dispersion nano magnesium oxide material

ActiveCN107253733AGood dispersionWide variety of sourcesMaterial nanotechnologyMagnesiaDispersityHigh pressure

The invention discloses a method for preparing a high-purity and high-dispersion nano magnesium oxide material. The method comprises the following steps: taking magnesium sulfate as a raw material, dispersing the magnesium sulfate with a dispersion emulsifier, magnesium oxide quantum points and ammonia water in a high-pressure homogenizer to form an emulsion, performing high-pressure ejection, and at the same time performing laser sintering at a dispersion state. By adopting the method, the technical defects that a nano material is poor in property and popularization and application of nano magnesium oxide are obstructed as a conventional nano magnesium oxide material is easy to agglomerate and relatively poor in purity are solved, and the technical effect that magnesium oxide quantum points as crystal cores grow rapidly in an isotropic manner to form spherical nano magnesium oxide with high dispersity and high purity is achieved. Furthermore, the scheme disclosed by the invention is simple in preparation process, free of pollution and easy in on-scale industrial production.

Owner:湛江市中诚电热材料有限公司

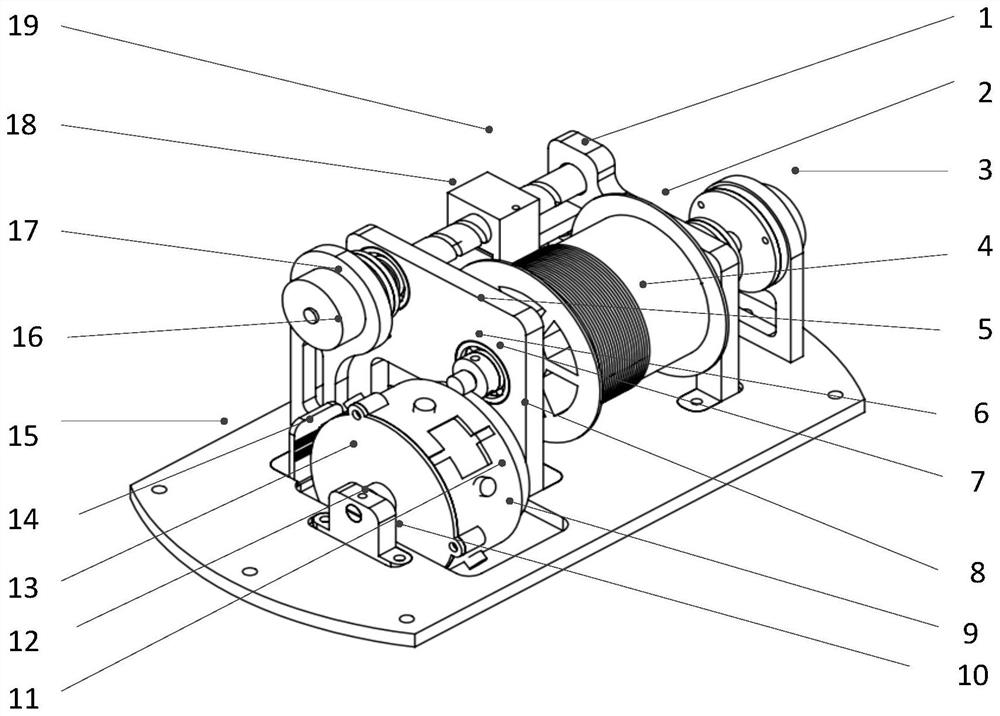

A small tension anti-winding slow-release rope retractable mechanism

Owner:NANJING UNIV OF SCI & TECH

Method of fast preparing graphene through microwave assisted stirring

The invention provides a method of fast preparing graphene through microwave assisted stirring. Graphite powder is adopted as a raw material, graphite powder and a foamer are mixed, graphite is infiltrated by the foamer and then put into a high mixing machine, high speed stirring is utilized to make graphite in a complete suspension state and a high speed motion state, meanwhile, microwave stripping is adopted to aid so that the foamer among graphite layers can fast react to generate support force, and continuous, fast, environment-friendly and clean preparation of a graphene material can be achieved. According to the method of fast preparing graphene through microwave assisted stirring, the technical effect of continuous, clean and environment-friendly production of graphene is achieved, and industrialized production of graphene dry powder is promoted; further, cutting and stripping are completed through one step in the high mixing machine, graphene is scattered evenly, not only is the layer structure of graphene maintained to the greatest extent, but also the graphene material can be prepared continuously and stably, surface integrity and topological symmetry of graphene are not destroyed, and the quality of graphene finished products is ensured further.

Owner:山东聊城莱鑫粉末材料科技有限公司

probe

ActiveCN105445574BTo achieve lifting effectEconomic advantageElectrical measurement instrument detailsElectrical testingEngineering

Owner:DE&T

A kind of equipment and method for preparing graphene composite material by continuous grinding and extruding

The invention provides an apparatus and method for preparing a graphene composite material through continuous grinding extrusion. The method comprises the following steps: adding graphite and a plastic stripping agent to a screw extruder, and carrying out oriented shearing on above raw materials through a feeding mechanism formed by a screw in order to obtain a primary stripping product, conveying the primary stripping product to a stripping mechanism formed by a millstone group, and the primary stripping product undergoes secondary shearing striping through relative rotation of an internal millstone and an external millstone in order to obtain the graphene composite material. The method overcomes the defects of low stripping strength and thick stripping layers of graphene prepared through using screw stripping in the prior art, and the apparatus has the advantages of simple structure, improvement of the shearing strength, realization of continuous production of the graphene composite material, further obtaining of the graphene composite product with thin stripping thickness, avoiding of graphene aggregation, improvement of the quality of graphene, convenience for storage, and promotion of mass production of the graphene product.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

A kind of preparation method of ticagrelor intermediate

The invention provides a preparation method for ticagrelor intermediate. The preparation method comprises the following steps: using tertiary amine as an acid-binding agent, performing N-aromatic alkylated reaction on a compound (II) or salt of the compound (II) and a compound (III) in an appropriate solvent at the temperature of 90 to 130 DEG C, and generating a compound (I). The preparation method provided by the invention has the following advantages: side reaction of impurity generated in the reaction of the solvent and raw materials can be effectively avoided, the preparation method has obvious superiority on product quality, the raw material conversion rate and productive rate of the product compound (I) are improved, the productive rate is 85.8% to 89.5%, the HPLC purity of the product is 98.8% to 99.5%, the preparation method has obvious superiority on raw material conversion rate, sealed reaction is not needed, equipment is simple, a pressure-resistant reaction kettle is not needed to be used, and compared with the prior art, the preparation method has obvious superiority on equipment use.

Owner:QINGDAO HUANGHAI PHARM CO LTD +1

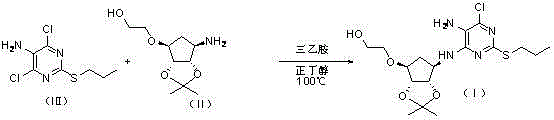

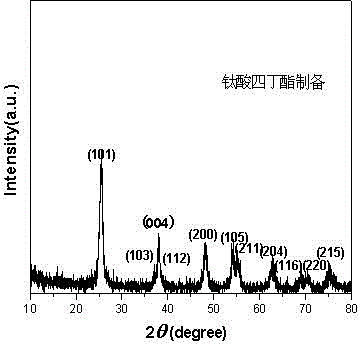

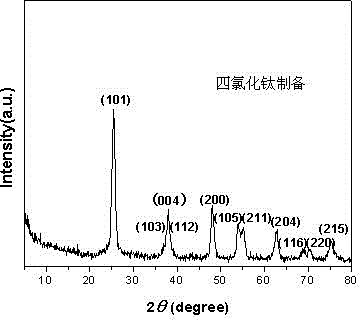

Method for preparing small-diameter anatase nano-titanium dioxide

InactiveCN103553125BGood dispersionSimple processMaterial nanotechnologyTitanium dioxideCarbon numberDispersity

The invention belongs to the field of fine chemical engineering and in particular relates to a simple method for preparing small particle size anatase nano TiO2. The method comprises the following steps: by adopting ethanol as a solvent of tetrabutyl titanate or titanium tetrachloride, adding fatty acids with the carbon number of 6-20 and distilled water, uniformly stirring and mixing, transferring into a reaction kettle, heating, obtaining a mixed solution of white powder; filtering, washing, and obtaining a target product, wherein the mixing temperature of the ethanol and the tetrabutyl titanate or titanium tetrachloride is 13-25 DEG C, the stirring time is 2-7 minutes, a volume ratio of the tetrabutyl titanate or titanium tetrachloride to the ethanol is (7-15):30, and an amount of the distilled water is 14-27 percent of the volume of the added tetrabutyl titanate or titanium tetrachloride. The method is simple in process, safe in operation and fewer in environmental pollutants, the product is extremely small in grain size and stable in quality, the dispersity in oil is high, and the method is suitable for large-scale production.

Owner:BOHAI UNIV

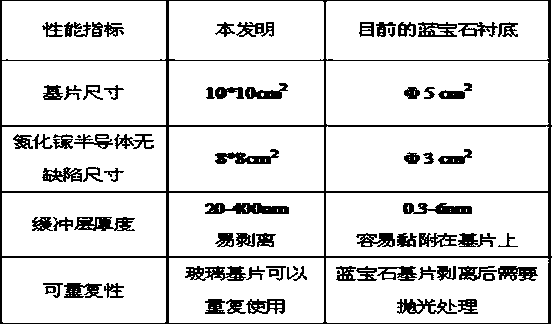

A kind of preparation method of large-scale gallium nitride semiconductor chip for LED

ActiveCN107464867BQuality advantageSubstrate size advantageSemiconductor devicesSemiconductor chipComposite substrate

The invention proposes a fabrication method of a large-size GaN semiconductor sheet for an LED. The fabrication method comprises the steps of fabricating a large-area GaN substrate by taking silicon dioxide aerogel and aluminum oxide as raw materials; mixing the silicon dioxide aerogel and the aluminum oxide to obtain aluminum oxide-silicon dioxide aerogel composite sol, performing coating process, coating the aluminum oxide-silicon dioxide aerogel composite sol on a surface of ordinary glass, forming a composite substrate material by a sintering process, and performing deposition to grow the large-size GaN semiconductor. Due to the scalability, the high-temperature resistance and the strippability of the silicon dioxide aerogel, the obtained GaN is large in size and complete in lattices and has no defect; and moreover, the substrate fabricated according to the method can be repeatedly used, is low in cost and simple in process, and is suitable for industrial production on a large scale.

Owner:启东盛丽光电科技有限公司

A method for rapidly preparing graphene with microwave-assisted stirring

Owner:山东聊城莱鑫粉末材料科技有限公司

A kind of preparation method of high-purity and high-dispersion nano-magnesia material

ActiveCN107253733BGood dispersionWide variety of sourcesMaterial nanotechnologyMagnesiaDispersityHigh pressure

The invention discloses a method for preparing a high-purity and high-dispersion nano magnesium oxide material. The method comprises the following steps: taking magnesium sulfate as a raw material, dispersing the magnesium sulfate with a dispersion emulsifier, magnesium oxide quantum points and ammonia water in a high-pressure homogenizer to form an emulsion, performing high-pressure ejection, and at the same time performing laser sintering at a dispersion state. By adopting the method, the technical defects that a nano material is poor in property and popularization and application of nano magnesium oxide are obstructed as a conventional nano magnesium oxide material is easy to agglomerate and relatively poor in purity are solved, and the technical effect that magnesium oxide quantum points as crystal cores grow rapidly in an isotropic manner to form spherical nano magnesium oxide with high dispersity and high purity is achieved. Furthermore, the scheme disclosed by the invention is simple in preparation process, free of pollution and easy in on-scale industrial production.

Owner:湛江市中诚电热材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com